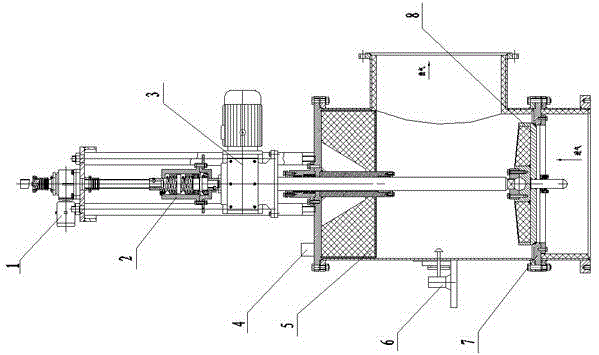

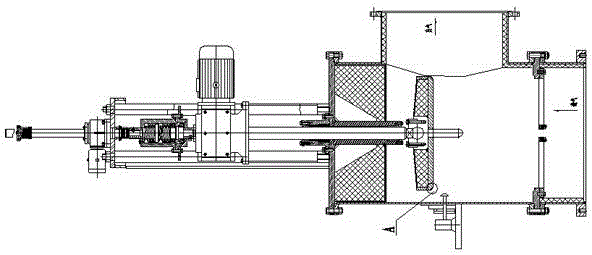

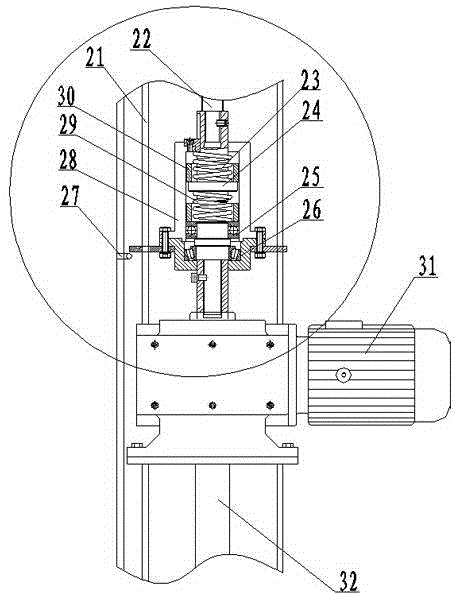

Self-grinding gas pipeline seal seat valve for high temperature and dust environments

A gas pipeline, self-grinding technology, applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of purchase cost, use cost increase, contact surface and valve disc are not tightly matched, not resistant to high temperature, etc., to reduce heat Dissipation, avoid rigid hard wear, and achieve the effect of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] name Sealing cycles (number of times) Outlet air flow after sealing (with / without) Plate valve 3-5 Have This device 10000-11000 none

[0035] It can be seen from the above table that for the same high-temperature dust environment, under the same caliber and air flow, the sealing cycle of this device is increased by more than 2000 times compared with the common high-temperature dust valve body, and there is no air leakage after sealing, while the common Due to the presence of dust, the plate valve is not tightly sealed and leaks.

[0036] name Sealing cycles (opening and closing times) Cleaning mechanism not used 10-20 Cyclone airflow 20-30 The cleaning mechanism of this device 10000-11000

[0037] As can be seen from the table above, the adoption of different cleaning mechanisms in the present invention and the absence of cleaning mechanisms will seriously affect the sealing cycles of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com