Dry-type phase-change thermal storage floor heating terminal device

A phase change heat storage and terminal device technology, which is applied in hot water central heating systems, heating methods, electric heating systems, etc., can solve the problems of low utilization rate of phase change materials, ineffective heating rate, and downward heat leakage from the floor, etc. Achieve the effect of saving space, reducing building bulk density, and increasing thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

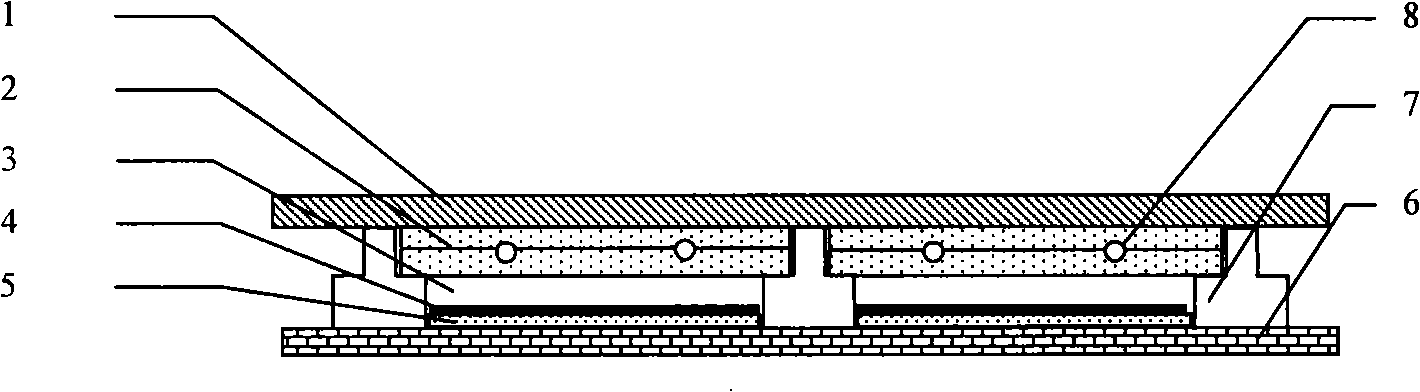

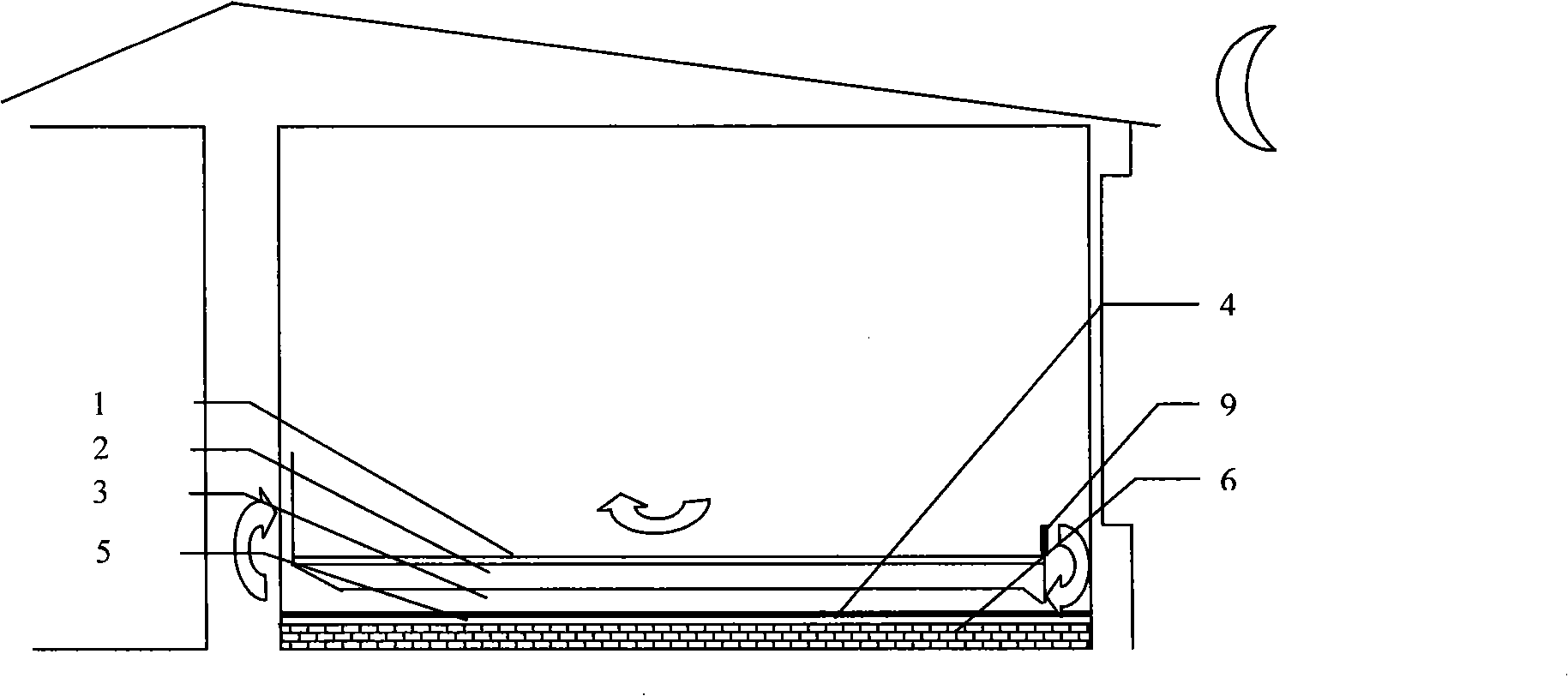

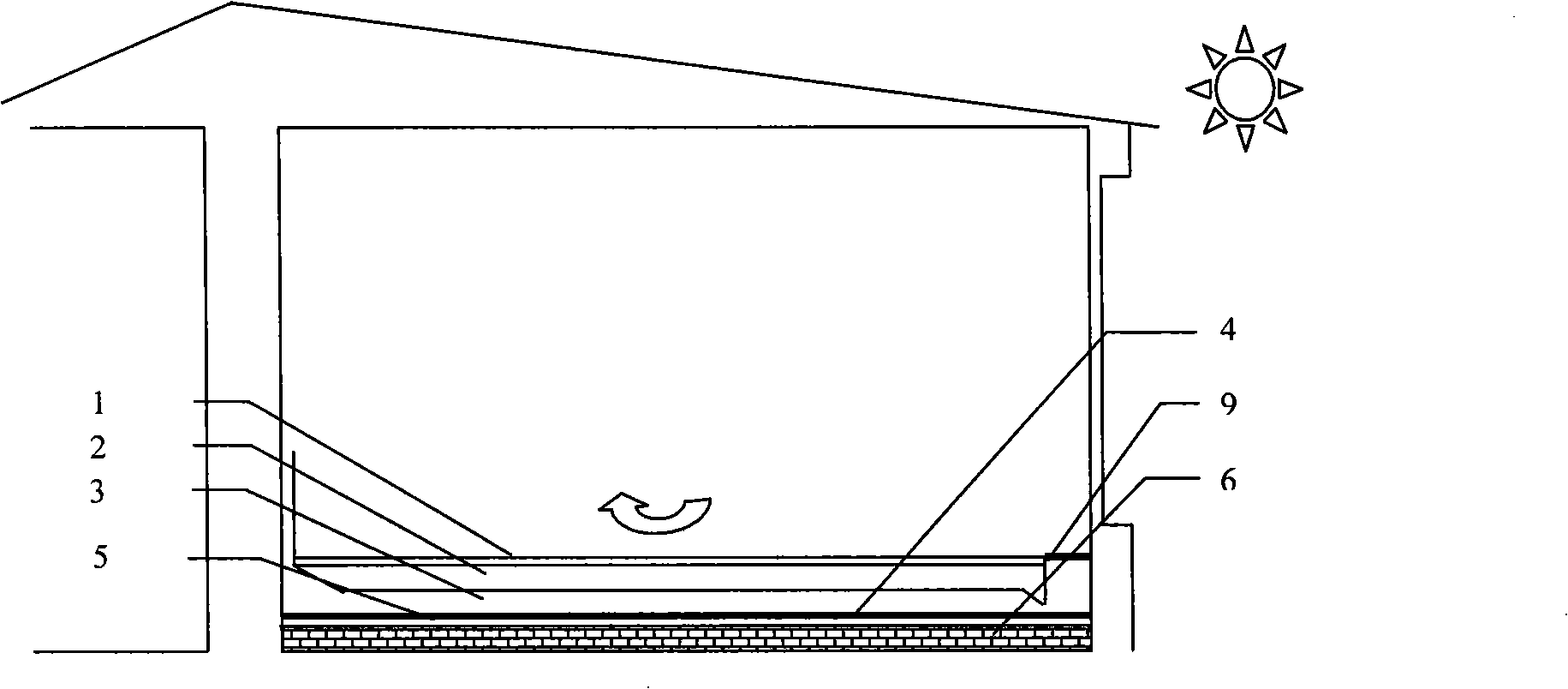

[0020] A dry-type phase change heat storage floor heating terminal device of the present invention, such as figure 1 Shown, below in conjunction with accompanying drawing, describe in detail as follows:

[0021] The floor decoration layer 1 is supported by the keel 7, and the bottom of the floor decoration layer 1 is a phase-change material layer 2, an air channel 3, a radiation-proof film 4, an insulation layer 5 and a floor base layer 6 in order from top to bottom. In the phase change material layer 2 between a group of adjacent keels 7, at least one water supply pipe 8 or an electric heating film is buried. The phase-change material layer between adjacent keels can be in close contact with the floor decoration layer or an air layer can be reserved. The phase change material should completely cover the outer wall of the water supply pipe 8, or the upper and lower surfaces of the electric heating film. The phase change material is divided into upper and lower layers. If it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com