Energy-saving and environment-friendly coal-fired hot-blast heating stove and heating method and application thereof

A heating stove and coal-burning technology, which is applied to the coal-fired hot air heating stove and its heating field, can solve the problems of high cost and low heating thermal efficiency, and achieve the effects of improving efficiency, enhancing burnout degree and reducing combustion volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

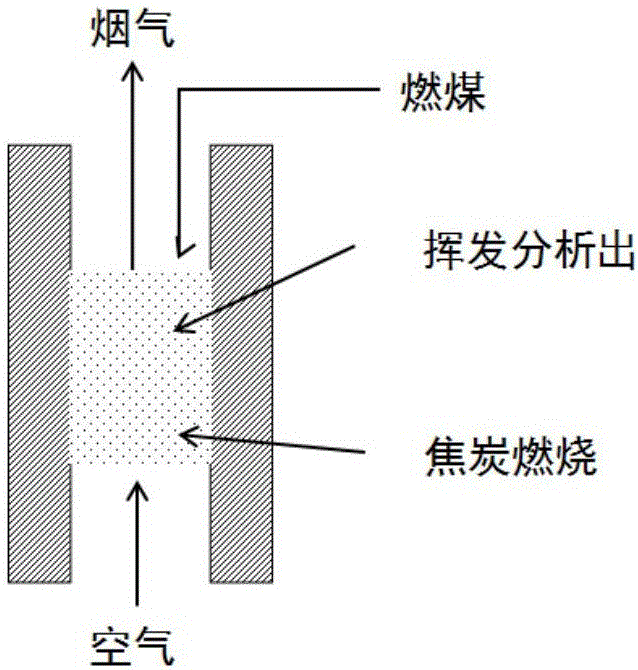

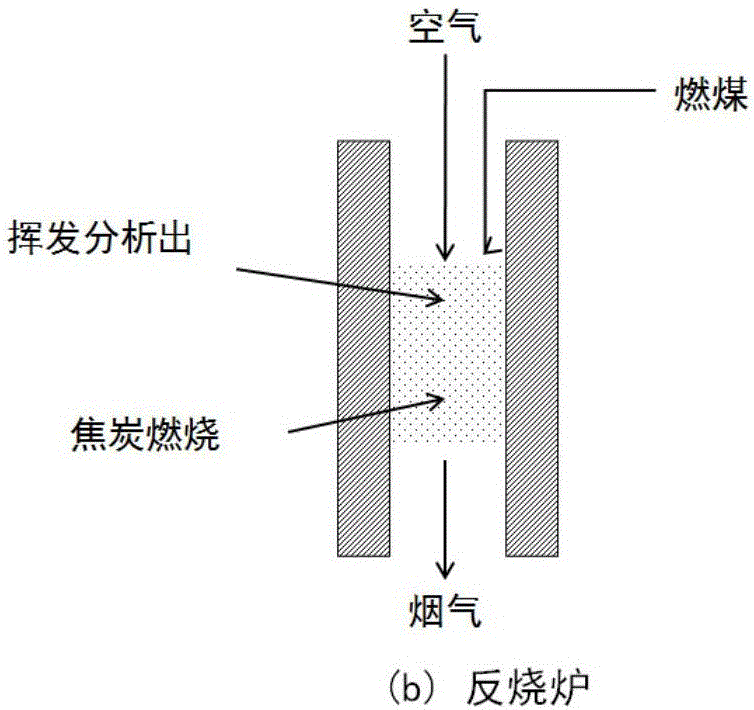

Problems solved by technology

Method used

Image

Examples

Embodiment 1

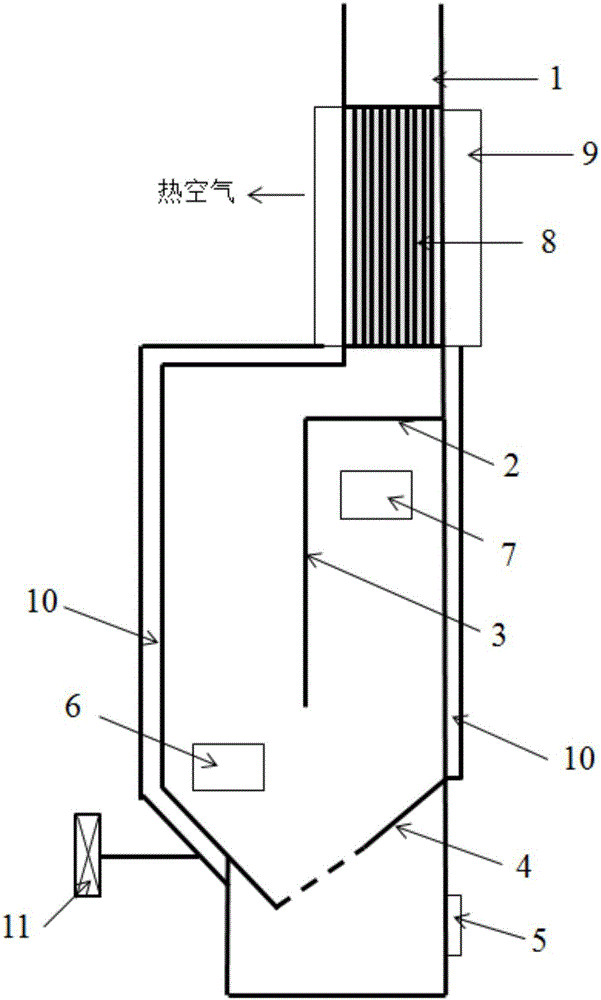

[0055] This embodiment provides a coal-fired hot air heating furnace and a heating method thereof, such as figure 2 As shown, the furnace top side of the coal-fired hot air heating furnace is provided with a chimney 1, the bottom of the chimney 1 inside the furnace body is provided with a first transverse partition 2, and one side of the first transverse partition 2 is connected to the furnace body. The furnace walls on one side of the chimney 1 are connected, and the other side of the first horizontal partition 2 is perpendicular to the first horizontal partition 2. The first vertical partition 3 is arranged, and the first vertical partition 3 divides the interior of the furnace body into two Connected chambers, the chamber located on one side of the chimney 1 is a pyrolysis gasification area, and the chamber on the other side is a flue gas burnout area; a grate 4 is arranged obliquely below the pyrolysis gasification area, and the A primary tuyere 5 is set under the furnace ...

Embodiment 2

[0065] This embodiment provides a coal-fired hot air heating furnace and a heating method thereof, such as Figure 4 As shown, the furnace top side of the coal-fired hot air heating furnace is provided with a chimney 1, the bottom of the chimney 1 inside the furnace body is provided with a first transverse partition 2, and one side of the first transverse partition 2 is connected to the furnace body. The furnace walls on one side of the chimney 1 are connected, and the other side of the first horizontal partition 2 is perpendicular to the first horizontal partition 2. The first vertical partition 3 is arranged, and the first vertical partition 3 divides the interior of the furnace body into two Connected chambers, the chamber located on one side of the chimney 1 is a pyrolysis gasification area, and the chamber on the other side is a flue gas burnout area; a grate 4 is arranged obliquely below the pyrolysis gasification area, and the A primary tuyere 5 is set under the furnace...

Embodiment 3

[0077] This embodiment provides a coal-fired hot-air heating furnace and its heating method. The structure of the coal-fired hot-air heating furnace refers to the structure of the coal-fired hot-air heating furnace in Example 2. The difference lies in: the number of the tertiary air outlets 13 for 2 pcs.

[0078] The heating method refers to the method in Example 2, the difference is that the coal used is clean briquette prepared from bituminous coal containing a soot-fixing agent, a sulfur-fixing agent and a denitrification agent.

[0079] In this embodiment, the combustion temperature of the semi-coke combustion zone described in step (b) is 900°C; the volumetric heat load of the semi-coke combustion zone is 330kW / m 3 , the area heat load is 2.5kW / m 2 The temperature of the flue gas burnout in the flue gas burnout zone in step (c) is 800° C.; the thermal efficiency of the cooking hot air heating stove is about 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com