Double-cavity valveless piezoelectric pump of tee joint structure

A valveless piezoelectric pump and piezoelectric vibrator technology, which is applied to pumps with flexible working elements, components of pumping devices for elastic fluids, pumps, etc., can solve the problem of increasing the difficulty of making flow channels and the energy efficiency of micropumps. High energy consumption, limited net flow, etc., to avoid boundary layer separation and wall-attached flow phenomenon, strong anti-electromagnetic interference ability, and reduce energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

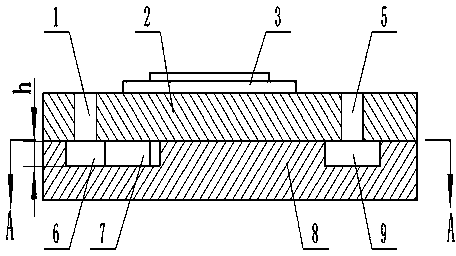

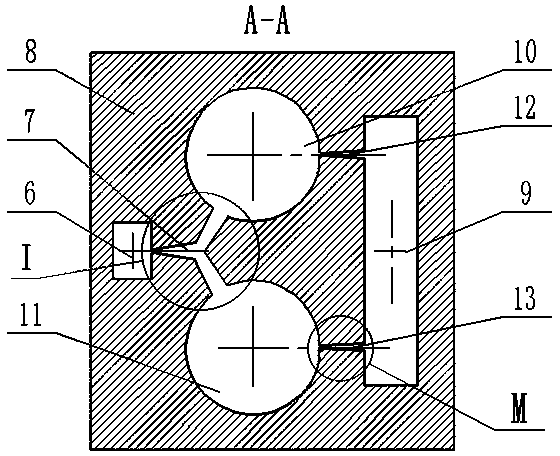

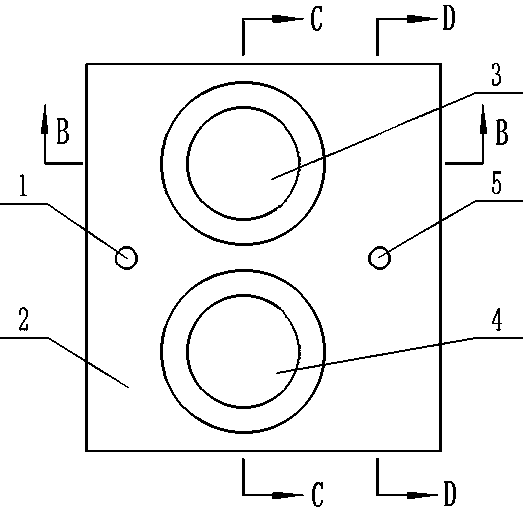

[0022] refer to Figure 1~Figure 8 , the present invention includes a pump body 8, a pump cover 2 and piezoelectric vibrators 3, 4, the material of the pump body 8 is a silicon chip, the material of the pump cover 2 is glass, and the pump body 8 and the pump cover 2 are combined in an anodic bonding process. Together, the two piezoelectric vibrators 3 and 4 are respectively fixed and bonded on the top of the pump cover 2 with an adhesive.

[0023] On the pump cover 2, the pump inlet 1, the pump outlet 5 and the upper half of the pump chambers 10, 11 are processed by laser processing technology, and the two piezoelectric vibrators 3, 4 are respectively located directly above the two pump chambers 10, 11. On the pump body 8, the inlet buffer chamber 6, the outlet buffer chamber 9, the inlet flow pipe 7, the outlet flow pipes 12, 13 and the lower half of the pump chamber 10, 11 are processed by dry etching process, and the inlet buffer chamber 6 and The centerlines of the outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com