Critical flow venturi nozzle with throat rotating wheel and with adjustable throat area

A Venturi nozzle, critical flow technology, applied in the direction of volume/mass flow generated by mechanical effects, fluid flow detection by measuring differential pressure, etc. Accurate flow control and the effect of reducing pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

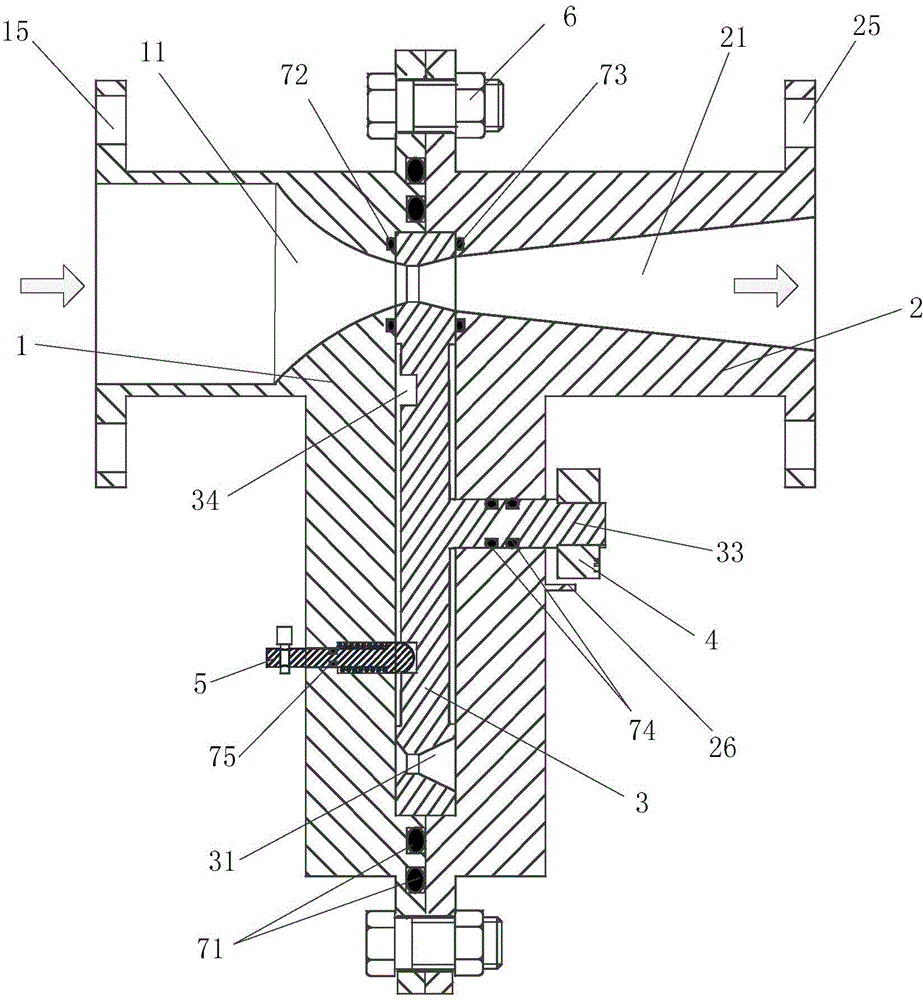

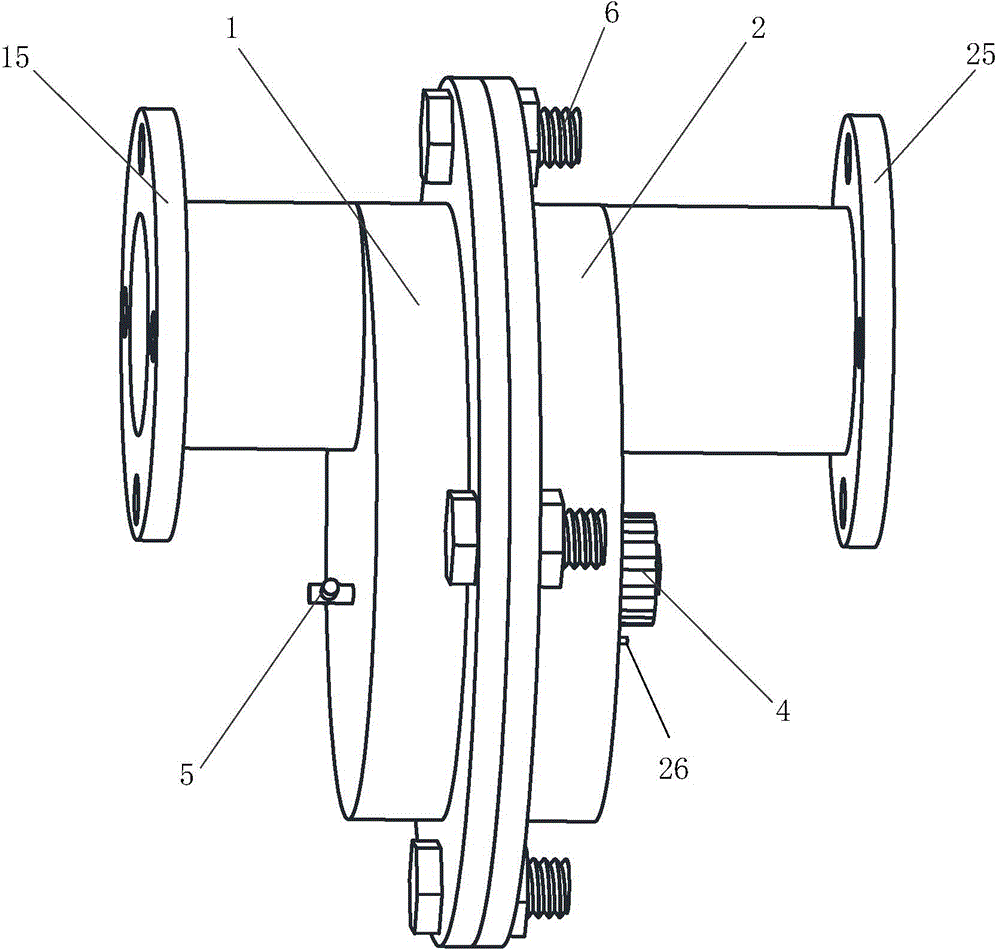

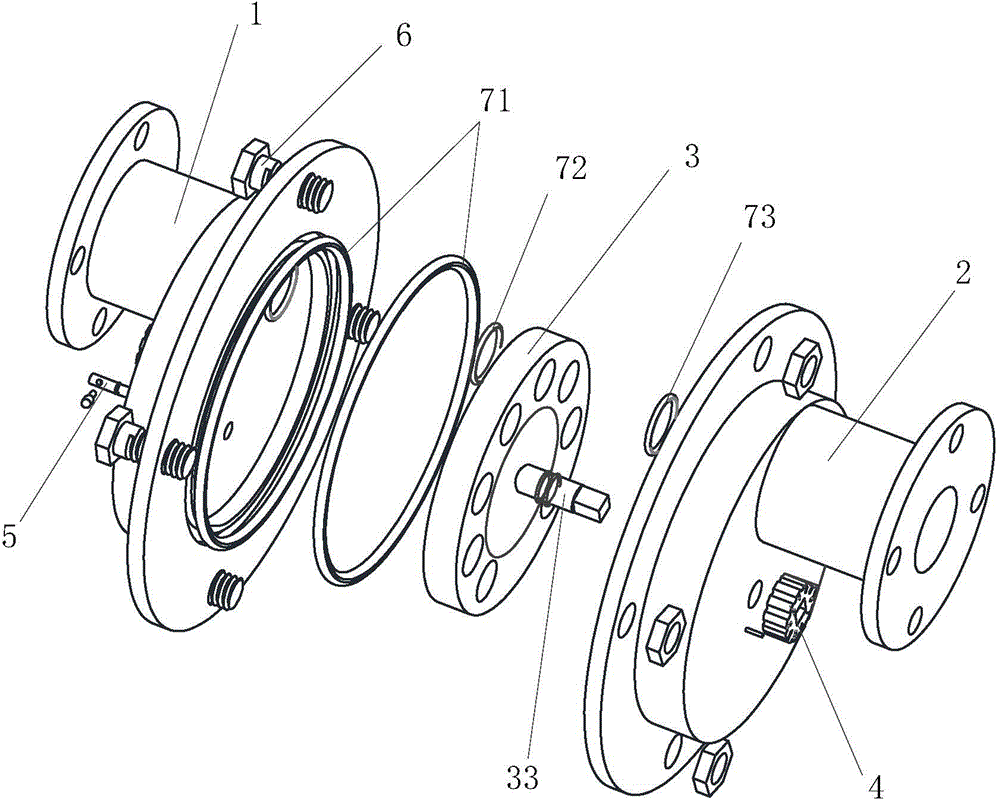

[0031] Such as figure 1 , figure 2 , image 3 As shown, a critical flow Venturi nozzle with an adjustable throat area with a throat runner, including an upstream converging section 1, a downstream diverging section 2, and a plurality of throat holes with different diameters wrapped between the two Throat runner 3 of 31. The converging channel 11 on the upstream contracting section 1, the diverging channel 21 on the downstream diverging section 2 and the throat hole 31 on the throat wheel 3 constitute a critical flow Venturi nozzle. By adjusting the hand wheel 4 and cooperating with the indicator needle 26 and the spring positioning pin 5, the throat wheel 3 can be turned to select different throat holes 31 to cooperate with the contracting flow channel 11 and the diverging flow channel 21 to obtain different throat openings. Orif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com