Method for eliminating schreyerite blast furnace smelting hearth center accumulation

A blast furnace smelting and vanadium-titanium ore technology, applied in the field of iron making, can solve the problems of increasing the usage of fluorite and manganese ore, the furnace condition is not effectively improved, and the waste of resources and costs, so as to improve the oxygen potential of the slag and promote the recovery of the furnace condition. , eliminate the effect of center accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

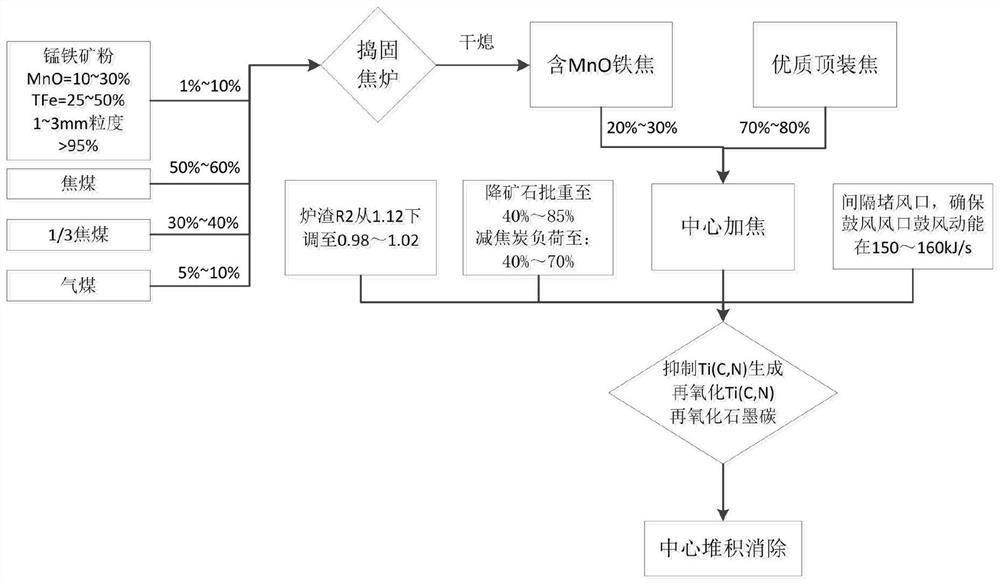

Method used

Image

Examples

preparation example Construction

[0020] The preparation method of the above-mentioned MnO-containing iron coke is to uniformly mix its raw material components according to the proportion, obtain coal cake after tamping through the tamping coke production process, and then push it into a coke oven to complete the coking process, and the coking time is 25-28h, obtaining Iron coke containing MnO, after the iron coke is released from the furnace, it is quenched by a dry quenching coke oven for blast furnace use. Because iron coke has the characteristics of low cooling and heating strength and high reactivity, it is only used in the process of furnace cleaning when it is judged that central accumulation has occurred in the blast furnace. Since in the coking process, the coking center temperature is lower than 1100 ℃, in the coking process, the iron-containing oxides in the manganese ore will undergo a direct reduction reaction with the carbon of the coal, which will increase the heat consumption. In order to make t...

Embodiment 1

[0028] A blast furnace with high-titanium vanadium titanomagnetite as the main production raw material will be scheduled for repair work on April 12, 2020 with a 580-min wind break. When the air volume returns to 80% of the normal smelting state, overhang occurs, and then the air reduction treatment is carried out. A large amount of charge without sufficient heat exchange enters the hearth, causing the furnace temperature to drop rapidly, and the airflow inside the blast furnace is further disordered. In the following week, the blast furnace A has poor wind capacity, the air volume can only recover to 70%-80%, and the blast kinetic energy is reduced from 160kJ / s to 130-140kJ / s. The continuous low air volume and low blast kinetic energy lead to accumulation in the center of the blast furnace, which is directly manifested as the continuous decrease of the temperature of the center of the furnace bottom from 580°C to 460°C. At the same time, the temperature of the secondary outer ...

Embodiment 2

[0032] B blast furnace with high-titanium vanadium titanomagnetite as the main production raw material, on July 4, 2020, because the compressive strength of the pellets entering the furnace was greatly reduced, the relationship between blast furnace air volume and air pressure was tense, and the wind capacity became poor. The air volume was reduced and the air volume was shrinking day by day. The kinetic energy of the blast was gradually reduced from 170kJ / s to 145kJ / s, and the central temperature of the bottom of the blast furnace was gradually reduced from 560 °C to 510 °C, and there was obvious central accumulation in the center of the blast furnace.

[0033] First, the batch weight and coke load of B blast furnace were reduced to 35t / batch and 3.56t / t respectively, 2% manganese-containing iron nugget was added, and the slag basicity was reduced to 1.02. The blast kinetic energy was increased to 155kJ / s, and after 10 days of smelting, the furnace condition was still not impr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com