Preparation method of optical hard coating film

A hard coating film and optical technology, applied in the direction of coating, polyester coating, epoxy resin coating, etc., can solve the problems of hard coating film damage, hard coating film deformation, tearing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

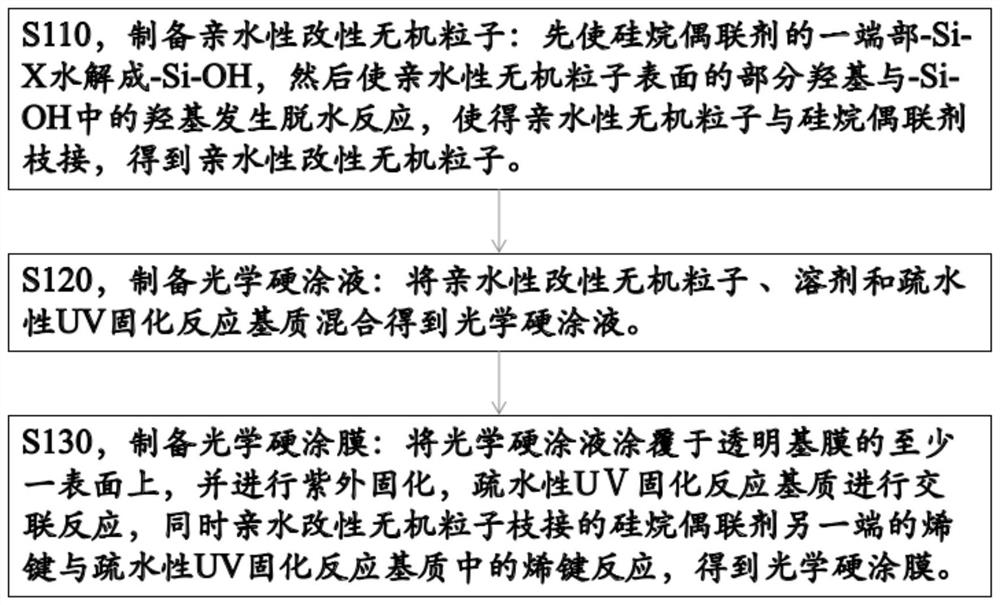

Method used

Image

Examples

preparation example Construction

[0026] In the preparation of optical hard coatings, in order to make the anti-adhesion effect between the hard coatings better, inorganic particles are usually added to the hard coating. After the addition of inorganic particles, the surface of the hard coating can have a certain roughness. Degree, so that it has a certain anti-adhesion performance. At the same time, the inorganic particles on the surface of the hard coating can enhance the scratch resistance of the hard coating; however, if the amount of inorganic particles added is too large, the hard coating will be more brittle, making it easy to crack. Therefore, since the toughness and scratch resistance of the hard coating film need to be balanced, in the prior art, the addition amount of inorganic particles is usually adjusted so that the effects of the two can be balanced.

[0027] In the present application, the inorganic particles are more likely to gather on the surface of the hard coat, which can improve the scrat...

Embodiment 1

[0064] This embodiment provides an optical hard coating film, comprising a transparent base film laminated sequentially from bottom to top and an optical hard coating layer coated on both sides of the transparent base film, wherein the optical hard coating liquid used to form the optical hard coating Components are in parts by weight as shown in Table 1:

[0065] The composition list of the optical hard coating liquid that table 1 embodiment 1 provides

[0066]

[0067] The preparation method of optical hard coating film, comprises the steps:

[0068] (1) Preparation of modified silicon powder: put Evonik hydrophilic silicon powder Aerosil 130 into a blast dryer, dry at 200°C for 12 hours, then put 20 parts by weight of silicon powder into a flask, add volume 100ml of ethanol / water mixed solution with a ratio of 1:1, ultrasonically disperse for 30 minutes to obtain a dispersion, then add oxalic acid to the dispersion, adjust the pH value of the dispersion between 4.0 and 4...

Embodiment 2

[0073] Example 2 is basically the same as Example 1, the difference being that the added amount of the modified dispersion liquid is 3.5 parts by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com