Method for blowing furnace washing agent by using air inlet of blast furnace

A technology of tuyere injection and furnace cleaning agent, which is applied in the field of iron and steel smelting, and can solve problems such as difficulty in active furnace hearth, graphite accumulation and limited effect, and reduction of slag viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

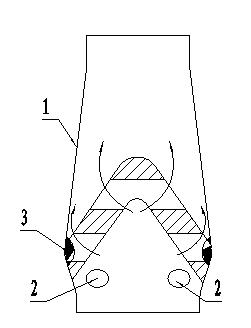

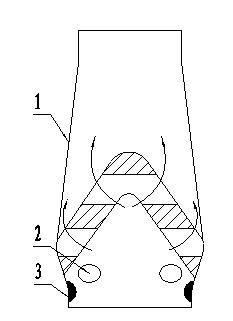

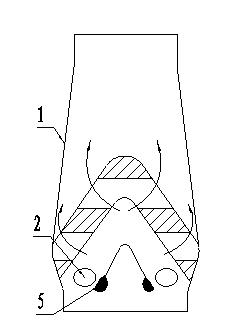

Image

Examples

Embodiment 1

[0023] Example 1: Blast furnace ironmaking process From the perspective of the static pressure distribution of the blast furnace, the resistance loss in the lower part of the blast furnace increased, the pressure difference across the furnace increased, the air permeability of the material column decreased, the air volume decreased by 7% compared with the normal level, and the temperature of the lower cooling wall surface was lower. The temperature of the cooling wall does not change much, and it can be judged that slag iron accumulation has formed in the furnace hearth. The injection of fluorite powder is used for treatment. The injection rate of fluorite powder is 5.0kg / tFe. The basicity of the binary slag determined by the ore, flux, coke and injection coal powder loaded on the furnace top is controlled at 1.02. The injection is until the air volume is restored. until normal. The process of spraying fluorite powder increases the wind temperature by 20 oC.

Embodiment 2

[0024] Example 2: During the blast furnace ironmaking process, from the perspective of the static pressure distribution of the blast furnace, the resistance loss of the lower part of the blast furnace increased, the pressure difference of the whole furnace increased, the air permeability of the material column decreased, the air volume decreased by 8% compared with the normal level, and the temperature of the lower cooling wall surface Little change, it can be judged that slag iron accumulation is formed in the hearth. The injection of fluorite powder is used for treatment, and the injection rate of fluorite powder is 6.0kg / tFe. The basicity of the binary slag determined by the ore, flux, coke and injection coal powder loaded on the furnace top is controlled at 1.06, and the injection is until the air volume is restored. until normal. The process of spraying fluorite powder increases the wind temperature by 24 oC.

Embodiment 3

[0025] Example 3: Blast furnace ironmaking process, from the static pressure distribution of the blast furnace, the resistance loss of the lower part of the blast furnace increased, the pressure difference of the whole furnace increased, the air permeability of the material column decreased, the air volume decreased by 9% compared with the normal level, and the temperature of the lower cooling wall surface Little change, it can be judged that slag iron accumulation has formed in the hearth. The injection of fluorite powder is used for treatment. The injection rate of fluorite powder is 10kg / tFe. The basicity of the binary slag determined by the ore, flux, coke and injection coal powder loaded on the furnace top is controlled at 1.12. so far. The process of spraying fluorite powder increases the comprehensive coke ratio by 8 Kg / tFe while increasing the oxygen content of the blast by 10‰.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com