Fractured rock mass roadway combined active and passive support method

A combined support, active and passive technology, used in tunnels, earth-moving drilling, tunnel lining and other directions, can solve the problems of restricting the improvement of mining enterprise efficiency, high labor intensity, long construction period, etc., and achieve good support effect and construction period. The effect of short time and engineering materials saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

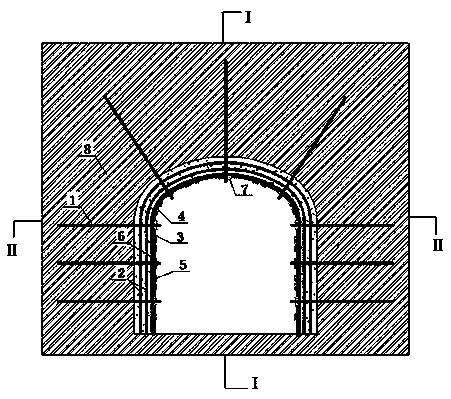

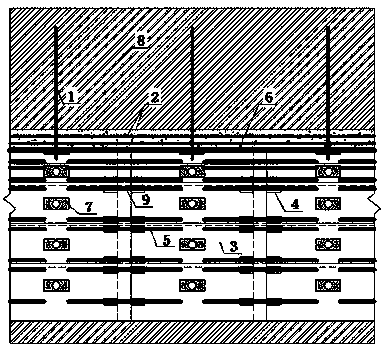

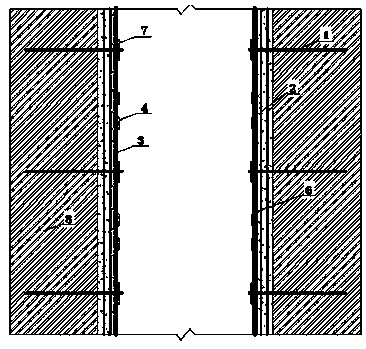

[0027] The active and passive combined support method for broken rock mass roadway is further described below in conjunction with the accompanying drawings and embodiments:

[0028] (1) On-site observation of the development of ore-rock joints and fissures, to determine the thickness of concrete, and to arrange and mark the positions of the bolt holes;

[0029] (2) According to the calculation results, drill the surrounding bolt holes, and use resin bolts to fix them in the bolt holes through anchoring agents. The depth of the bolts entering the ore rock is 2-3m, and the bolts are exposed at a distance of 0.5-1m from the surface of the roadway. ;

[0030] Further, the length of the exposed roadway surface length of the bolt in the present invention usually depends on the design thickness of the roadway construction concrete, and can also be based on the diameter of the roadway constructed, the crushing degree and crushing strength of the rock mass to be maintained; at the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com