A kind of anti-falling device of screw nut type building scaffolding

A screw nut and scaffolding technology, applied in the direction of scaffolding, building, building structure supported by house structure, can solve the problems of complex construction operation, easy to pinch the boom, complex structure, etc., to avoid locking, long-term lubrication and other problems. Anti-rust performance, effect of preventing decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

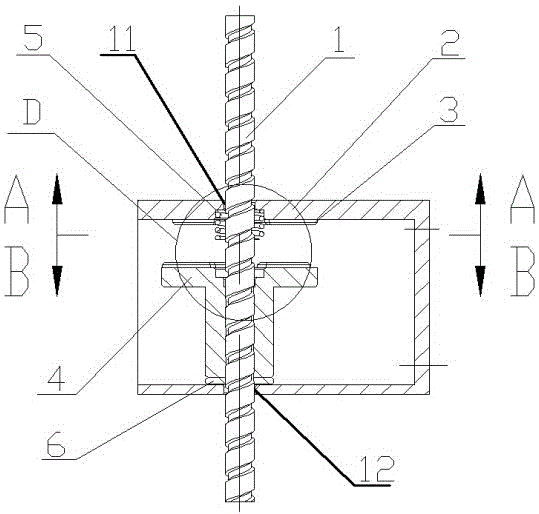

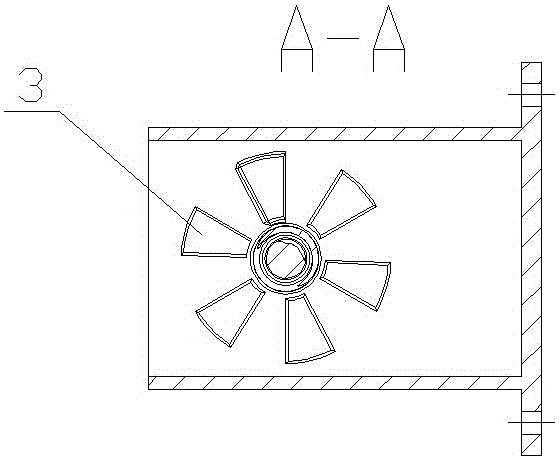

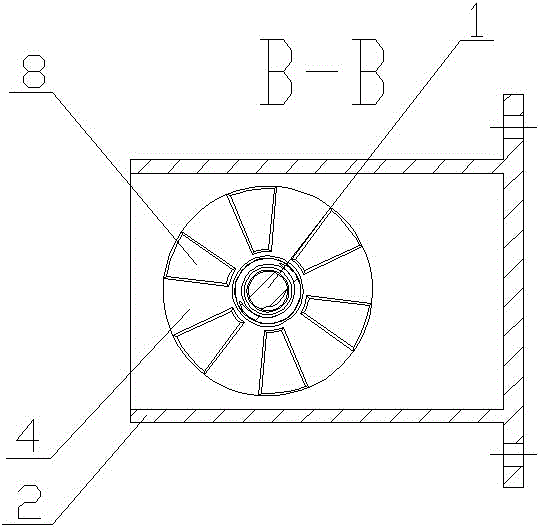

[0022] Such as figure 1 In the present invention, during the lifting and lowering process of the scaffold, the upper end of the screw rod 1 is fixed. During the lifting and lowering process of the scaffold, it penetrates through the round hole 11 of the upper plate of the anti-fall frame of the scaffold and the round hole 12 of the lower plate, and nuts 4 and 4 are arranged on the lower plate. A toothed groove is set on the upper end surface of the nut 4, a spring 5 is set on the upper part of the nut 4, and a corresponding toothed boss 3 is set on the inner surface of the upper plate of the anti-fall frame 2 that is compatible with the nut 4, so that it can cooperate and lock each other to prevent the The anti-falling frame is lowered; thread the screw 1 through it so that it is sequentially connected to the round hole 12 of the lower plate of the anti-falling frame 2, the nut 4, the spring 5 and the round hole 11 of the upper plate of the anti-falling frame 2; The flexible g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com