Master-batch drying device

A technology of drying device and color masterbatch, which is applied in the field of drying devices for drying and dispersing process of color masterbatch in small batches, can solve the problems of uneven heating and drying of upper and lower color masterbatches, uneven temperature at upper and lower sides, unstable moisture content, etc. Eliminate sticking phenomenon and ensure the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

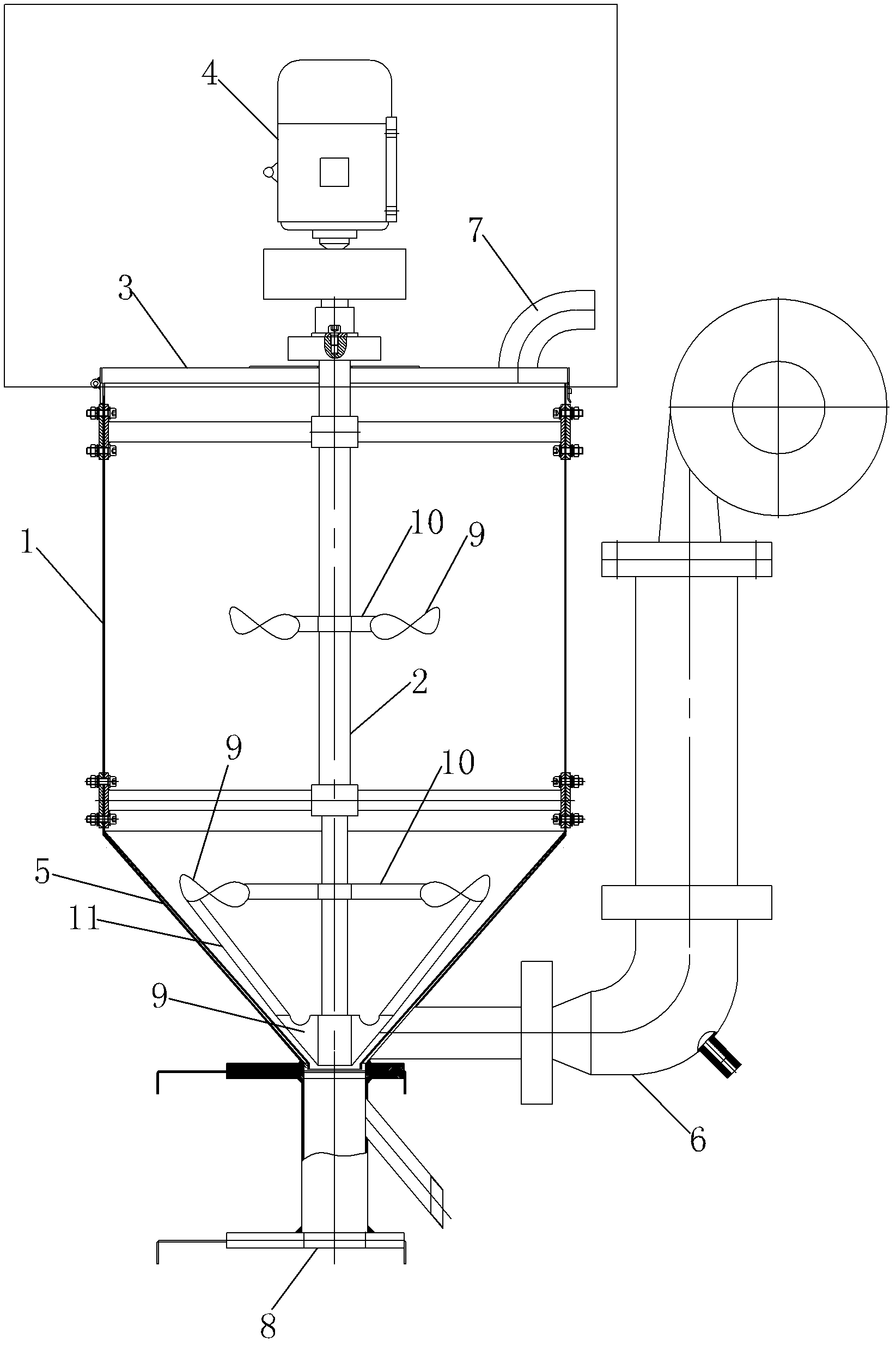

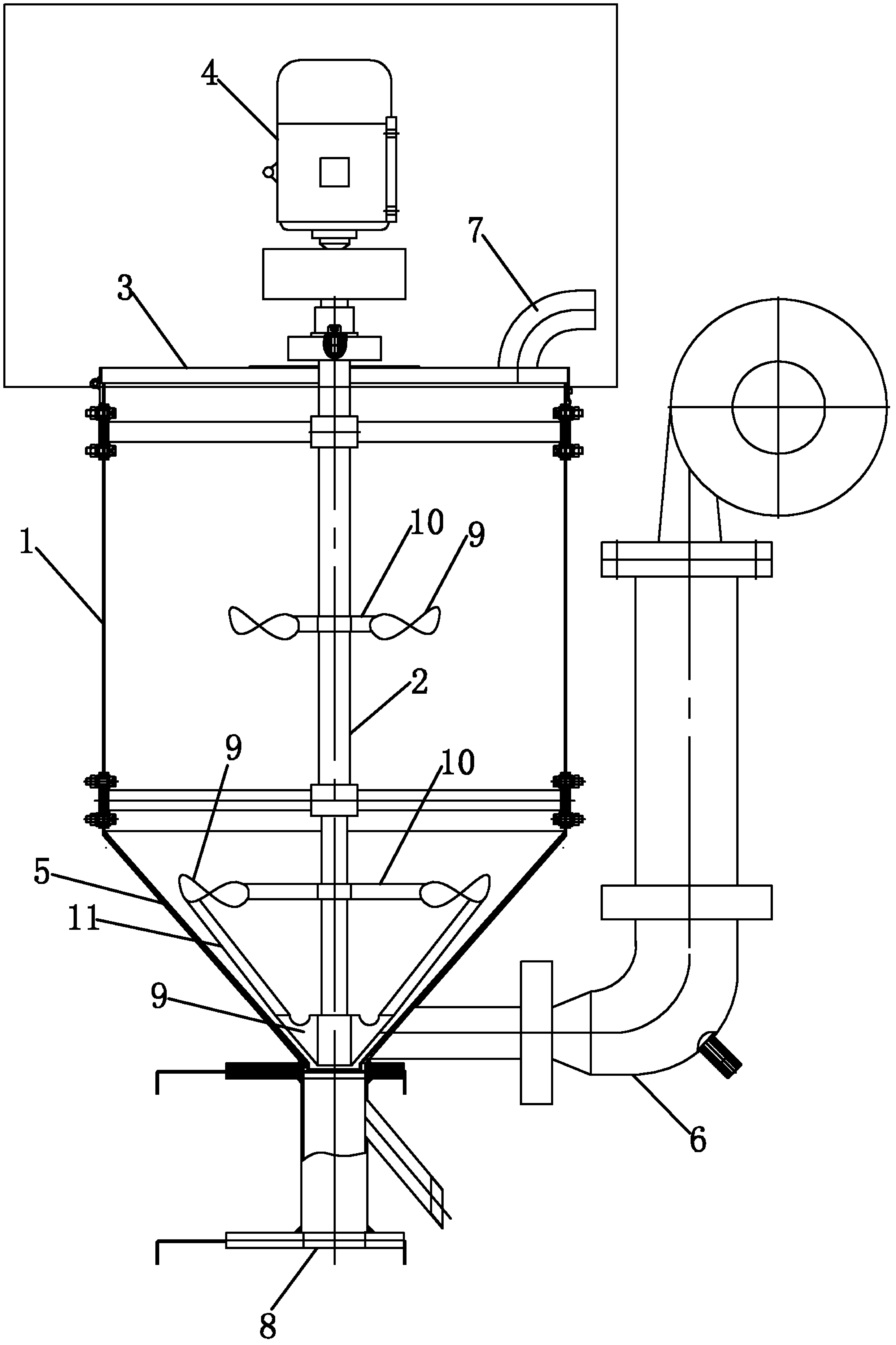

[0014] Embodiment: a kind of masterbatch drying device, such as figure 1 As shown, the drying barrel 1 is included, and the stirring paddle 2 is vertically arranged in the drying barrel 1. The top of the drying barrel 1 is provided with a barrel cover 3, and a motor 4 is fixedly arranged on the barrel cover 3. The motor 4 is connected to the stirring paddle through a reducer. 2. The lower part of the drying barrel 1 is connected with a conical filter 5, the side wall of the lower part of the conical filter 5 is connected to the air duct 6, and a heating pipe is installed in the air duct 6, and an exhaust port 7 is provided on the barrel cover 3, and the conical filter The inner diameter of the net 5 gradually decreases from top to bottom, and a screening net 8 is installed at the outlet of the conical filter 5 bottom, and the stirring paddle 2 extends into the conical filter 5, and there are many Layer stirring blade 9.

[0015] A layer of stirring blades 9 is arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com