Rotary flash drying apparatus and drying method

A technology of rotary flash evaporation and drying equipment, which is applied in the direction of separation method, drying solid material, drying gas arrangement, etc. It can solve the problems that are not suitable for the catalyst synthesis production process, etc., and achieve large adjustment room, eliminate filter bag bonding, and high drying strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

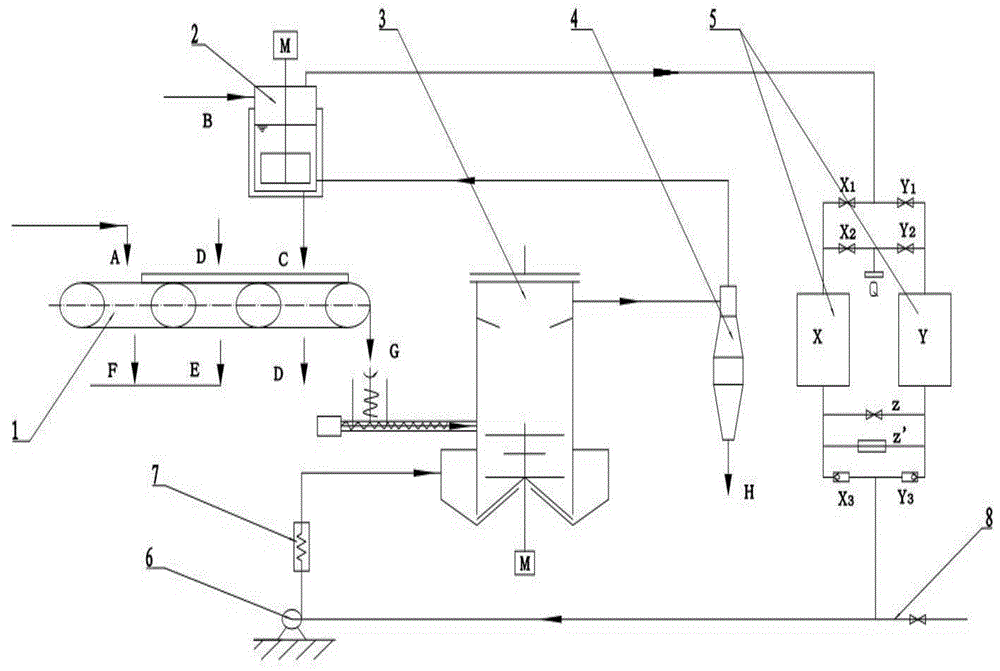

[0045] Such as figure 1 , a spin flash drying equipment, comprising a belt filter 1, a washing water heating tank 2, a spin flash drying device 3, a cyclone separator 4, a gas drying device 5, a fan 6, and an air heater 7;

[0046] The belt filter 1 is a three-stage filter, the outlet of the filter cake is connected to the feed port of the rotary flash drying device 3, and the outlet on the top of the rotary flash drying device 3 is connected to the inlet pipe of the cyclone separator 4. The gas outlet of the cyclone separator 4 is connected to the air inlet of the washing water heating tank 2, the gas outlet of the washing water heating tank 2 is connected to the air inlet of the gas drying device 5, and the washing water outlet of the washing water heating tank 2 is connected to the washing water pipe The gas outlet of the gas drying device 5 is connected to the air inlet of the fan 6, and the gas outlet pipeline of the fan 6 is connected to the cyclone separator 4, and an a...

Embodiment 2

[0050] The equipment of Example 1 was used. Alumina (pseudoboehmite) rotary flash drying method comprises the following steps:

[0051] Step 1: Filter the pseudo-boehmite slurry A prepared by the gelation method with the first section I of the belt filter 1 to separate the waste water F, and then in the second section II of the belt filter 1, the belt filter 1 The third section III is washed twice, and the third section III of the belt filter 1 uses heated washing water, and the obtained secondary washing liquid E is returned to the second section II of the belt filter 1 for washing, and filtering The washing solution D is discharged once to achieve the purpose of recycling. And waste water F, primary washing liquid D are used as filter washing waste water discharge device, and pseudo-boehmite slurry A forms filter cake G at the end of belt filter 1;

[0052] Step 2: Send the filter cake G containing 55 wt% (weight percent) of free water into the drying chamber of the spin f...

Embodiment 3

[0059] The equipment of Example 1 was used. Alumina (pseudoboehmite) rotary flash drying method is:

[0060] Step 1: Filter the pseudo-boehmite slurry A prepared by the gelation method with the first section I of the belt filter 1 to separate the waste water F, and then in the second section II of the belt filter 1, the belt filter 1 The third section III is washed twice, and the third section III of the belt filter 1 uses heated washing water, and the obtained secondary washing liquid E is returned to the second section II of the belt filter 1 for washing, and filtering The washing solution D is discharged once to achieve the purpose of recycling. And waste water F, primary washing liquid D are used as filter washing waste water discharge device, and pseudo-boehmite slurry A forms filter cake G at the end of belt filter 1;

[0061] Step 2: Send the filter cake G containing 60 wt% (weight percent) of free water into the drying chamber of the spin flash dryer 3 with a feeder....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com