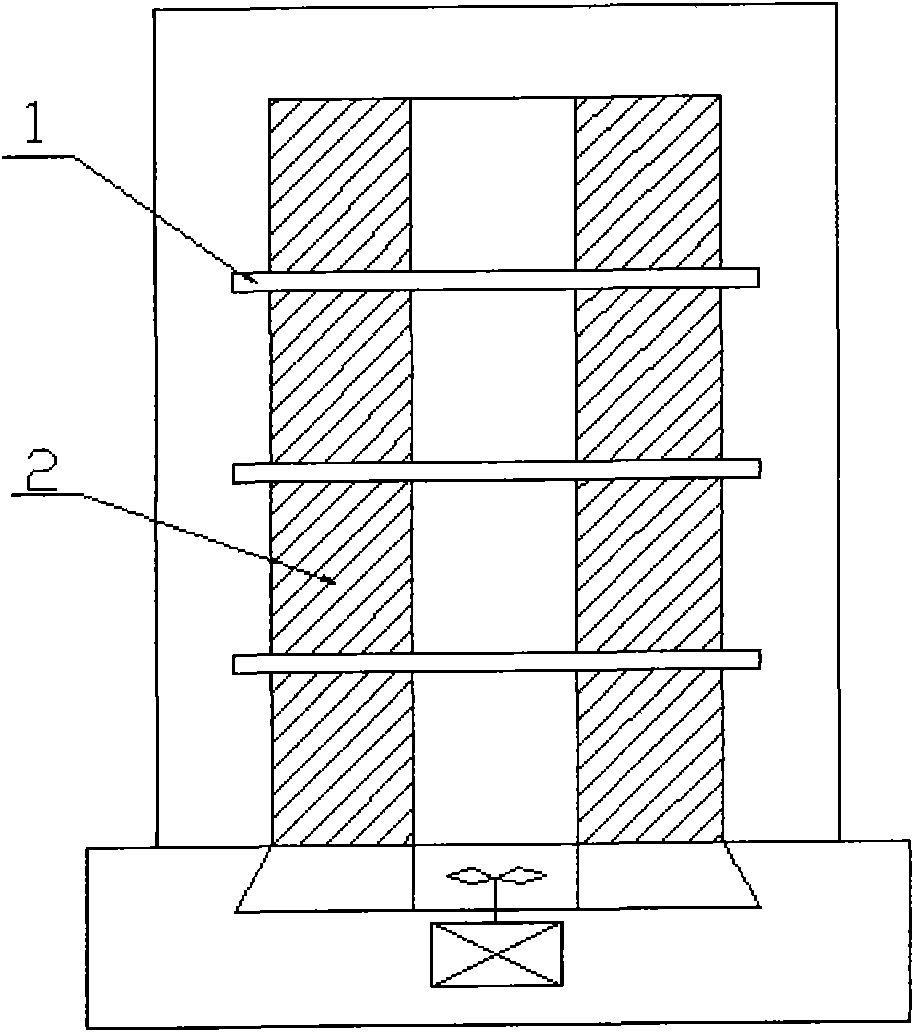

Direct strong convection board used for hood-type annealing furnace and automatically suitable for cold-rolling strip steel bandwidth and working method thereof

A bell-type annealing furnace and cold-rolled strip technology, applied in furnaces, heat treatment furnaces, manufacturing tools, etc., can solve problems such as inability to improve production efficiency, no improvement in bonding, and single function, so as to reduce ineffective dissipation, temperature Increased consistency, enhanced thermal cycling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

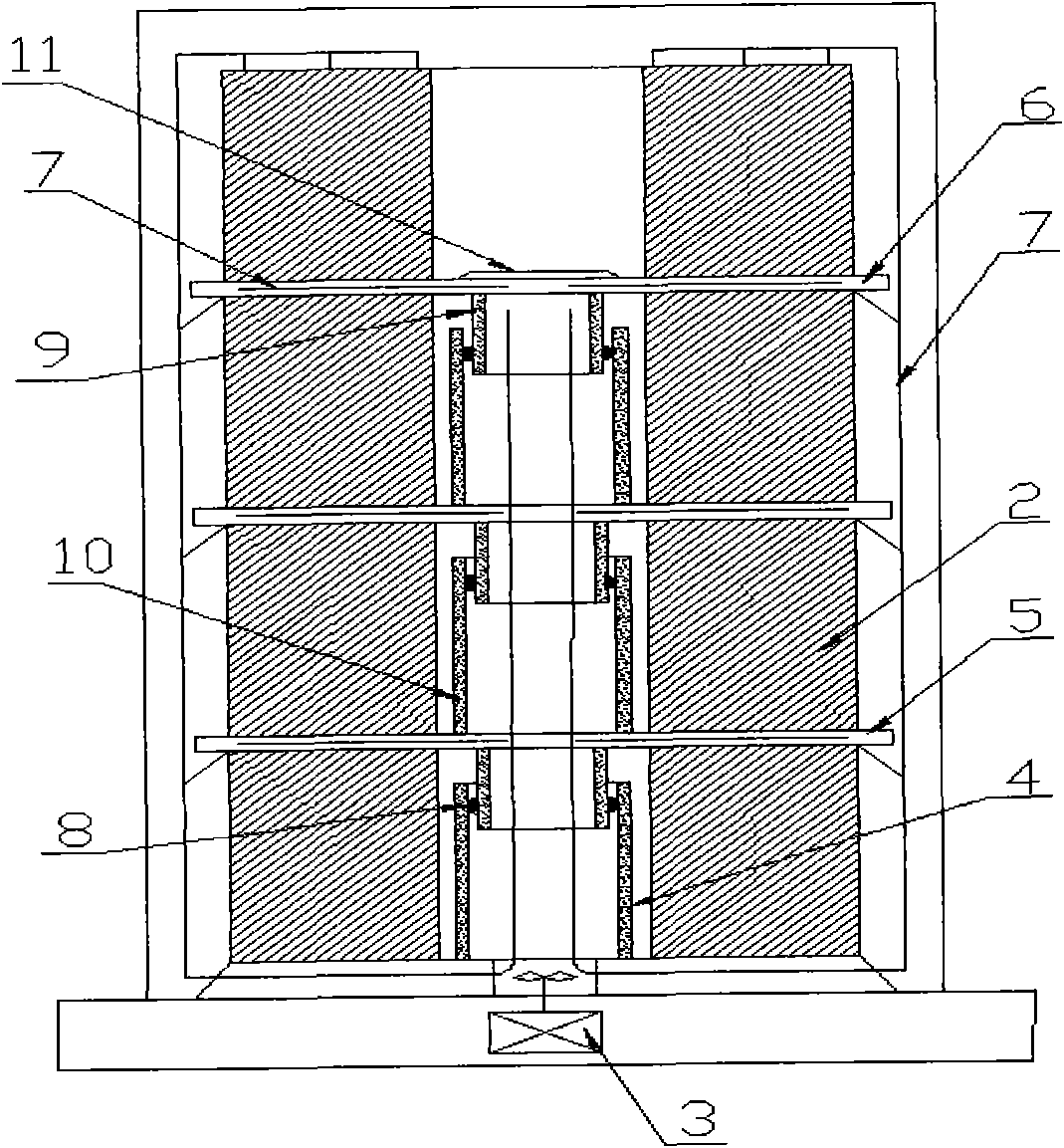

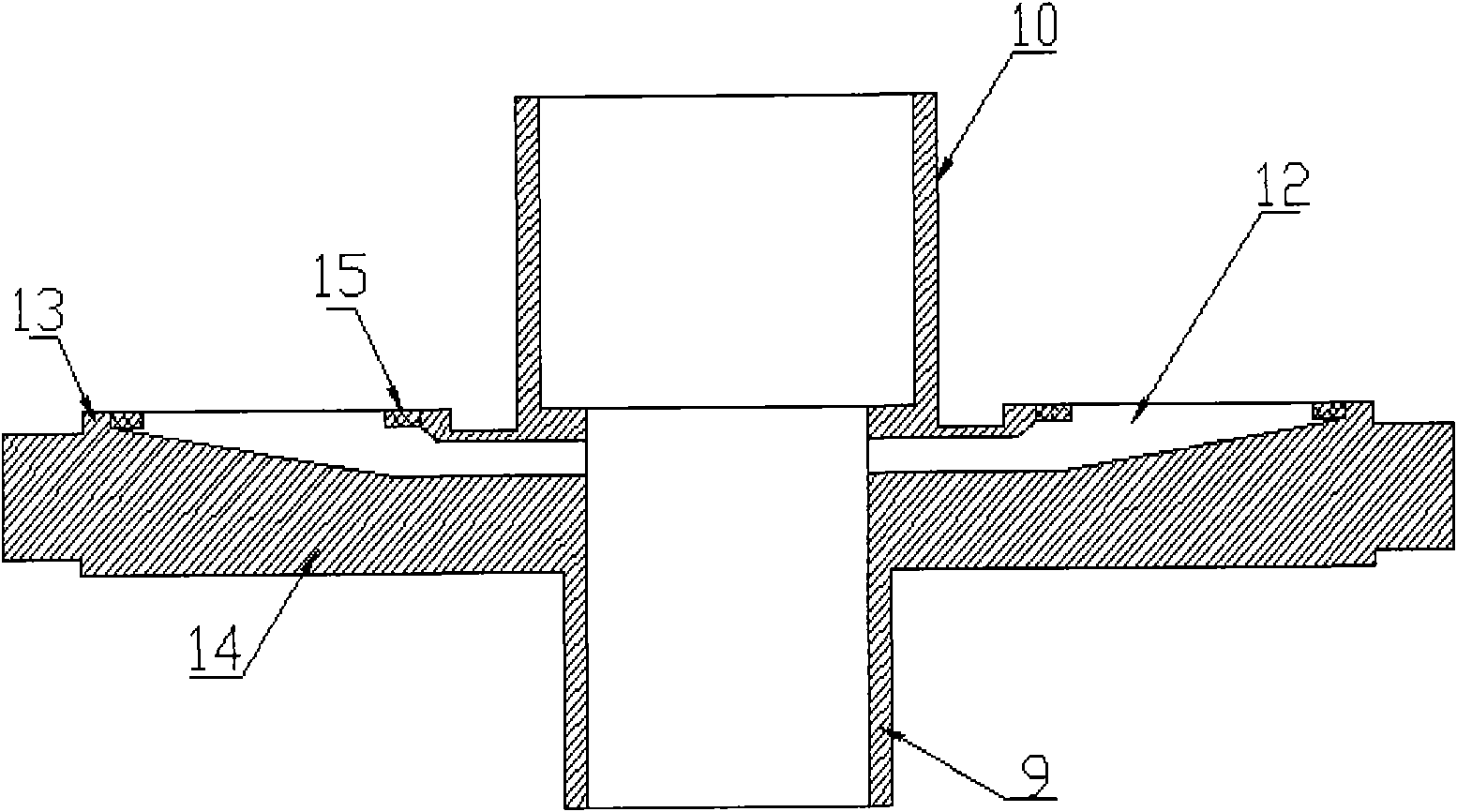

[0047] Such as figure 2 As shown, the four rings of the independent guide pipe are covered with the air outlet of the blower reserved on the hearth, and the length of the upper guide pipe is 100mm smaller than the minimum width of the cold-rolled steel strip that the production line can produce; Stack on the hearth; then place the deflector 5 with the upper and lower deflectors on the first steel coil, and there are 30 radial lines centered on the center of the deflector in the upper half layer of the deflector. Shaped air guide channel (12), the outer diameter of its lower guide tube 9 is 5mm less than the inner diameter of the independent guide tube 4, and the height is 100mm smaller, and the upper guide tube 10 is the same as the inside and outside diameter of the independent guide tube 4, The lengths are the same; the lower draft tube 9 is inserted into the independent draft tube 4 and sealed by a high-temperature-resistant sealing ring 8, wherein the high-temperature-res...

Embodiment 2

[0050] Such as figure 2 As shown, 4 rings of the independent guide pipe are placed on the air outlet of the blower reserved on the hearth, and the length of the upper guide pipe is 50mm smaller than the minimum width of the cold-rolled steel strip that the production line can produce; Stack on the hearth; then place the deflector 5 with the upper and lower deflectors on the first steel coil, and there are 36 radial lines centered on the center of the deflector in the upper half layer of the deflector. Shaped air guide channel (12), the outer diameter of its lower guide tube 9 is 2mm smaller than the inner diameter of the independent guide tube 4, and the height is 50mm smaller, and the upper guide tube 10 is the same as the inside and outside diameter of the independent guide tube 4, The lengths are the same; the lower draft tube 9 is inserted into the independent draft tube 4 and sealed by a high-temperature-resistant sealing ring 8, wherein the high-temperature-resistant se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com