Assembly method of expanded graphite reinforced heat conduction ceramic-based shaped high-temperature phase change heat storage element and heat storage element formed by assembly method

An assembly method and technology of expanded graphite, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of easy corrosion, low thermal conductivity, etc., and achieve the effect of high heat exchange efficiency and high heat storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

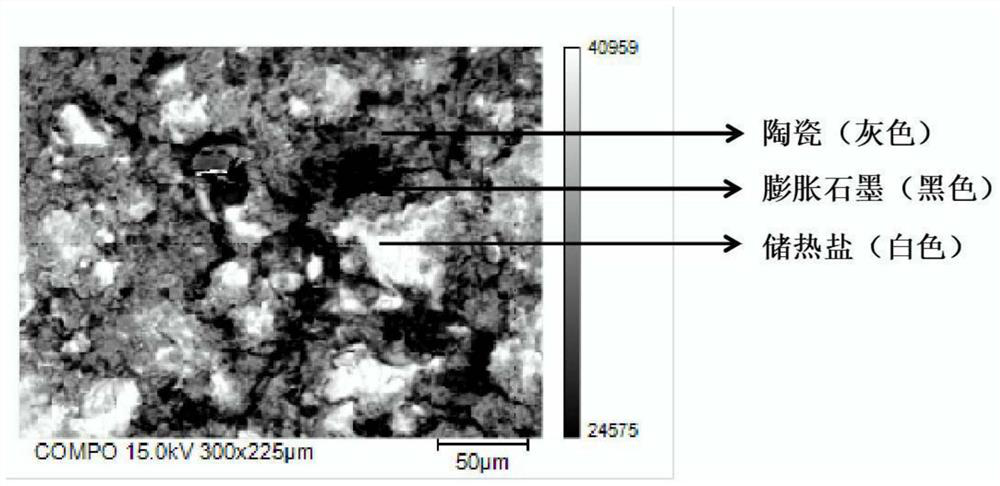

Image

Examples

Embodiment 1

[0019] NaCl, KCl, MgCl 2 Mix by ball milling at a eutectic ratio of 5:3:2, dry, heat to 560°C in a reaction kettle protected by 2 atmospheres and argon, and equilibrate for 4 hours until the salt is completely melted to form a uniform eutectic salt.

[0020] The natural flake graphite is expanded, and then subjected to high-temperature graphitization treatment to remove impurities to obtain expanded graphite.

[0021] Alumina powder and 6% methylcellulose were evenly mixed to form a skeleton material.

[0022] The skeleton material and the eutectic salt are uniformly mixed according to a mass ratio of 3:2 to form a composite phase change material, and 10wt% of expanded graphite is added to the composite phase change material as a heat conducting agent.

[0023] A uniaxial static pressure process is used to press and form under the condition of a pressure of 12-14 MPa to obtain a columnar green body.

[0024] The heat storage element was obtained by sintering at 520°C, and it...

Embodiment 2

[0026] NaCl, KCl, MgCl 2 Mix by ball milling at a eutectic ratio of 5:3:2, dry, heat to 560°C in a reaction kettle protected by 2 atmospheres and argon, and equilibrate for 4 hours until the salt is completely melted to form a uniform eutectic salt.

[0027] The natural flake graphite is expanded, and then subjected to high-temperature graphitization treatment to remove impurities to obtain expanded graphite.

[0028] Alumina powder and 6% methylcellulose were evenly mixed to form a skeleton material.

[0029] The skeleton material and the eutectic salt are uniformly mixed according to a mass ratio of 3:2 to form a composite phase change material, and 15wt% of expanded graphite is added to the composite phase change material as a heat conducting agent.

[0030] A uniaxial static pressure process is used to press and form under the condition of a pressure of 12-14 MPa to obtain a columnar green body.

[0031] Sintering at 520°C to obtain a heat storage element.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com