Patents

Literature

36results about How to "Regulation density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

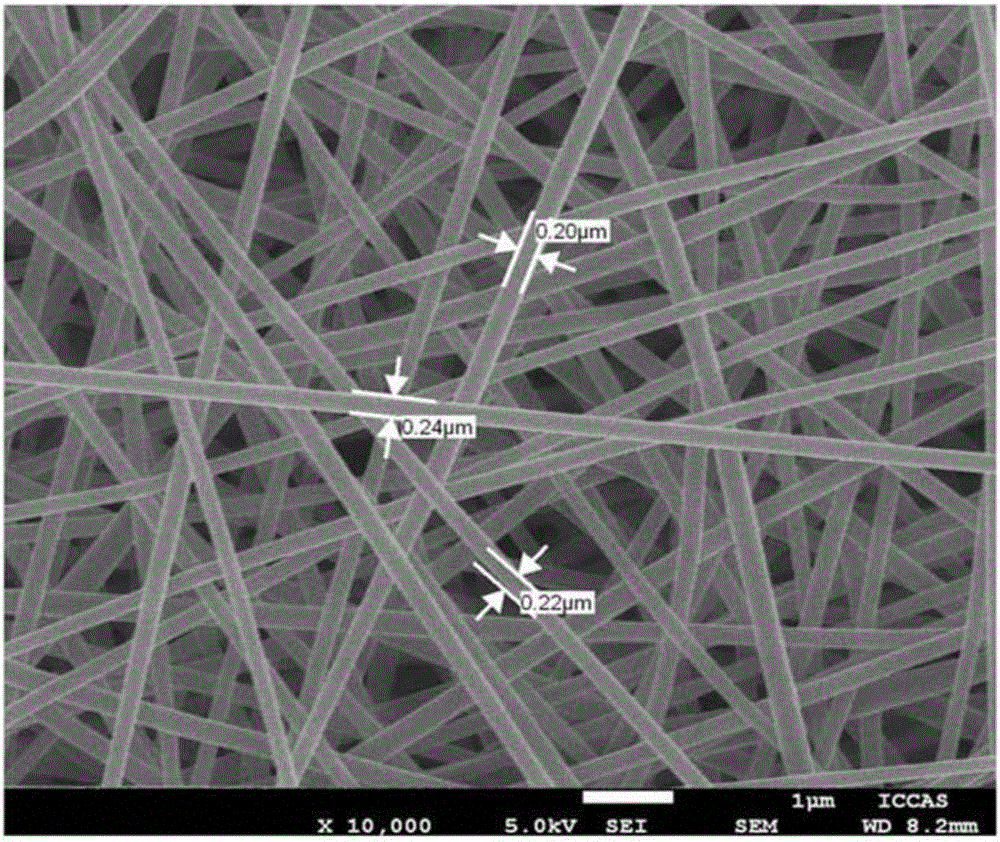

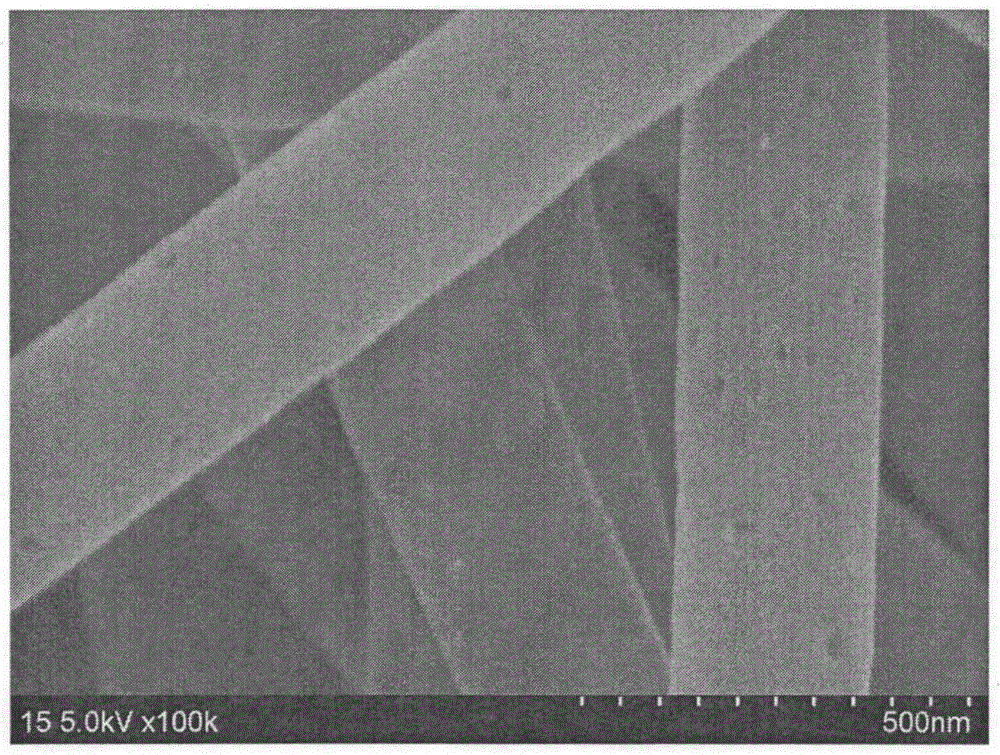

Preparation methods of porous carbon nanofiber felt and porous carbon nanofiber electrode

InactiveCN104342852ALow costRegulation densityHeating/cooling textile fabricsNon-woven fabricsAir atmospherePorous carbon

The invention provides preparation methods of porous carbon nanofiber felt and a porous carbon nanofiber electrode. The preparation method of the porous carbon nanofiber felt is characterized by comprising the following steps of 1, dissolving a high molecular polymer and a pore former in an organic solvent to form a polymer solution, 2, spinning the polymer solution into nanofiber felt by an electrostatic spinning technology, and 3, allowing the nanofiber felt in Step 2 to complete a preoxidation process in an air atmosphere and then performing high-temperature carbonization on the nanofiber felt under inert gas shielding to form the porous carbon nanofiber felt. The preparation method of the porous carbon nanofiber electrode comprises the following steps of preparing the porous carbon nanofiber felt in accordance with the method, and then directly attaching the porous carbon nanofiber felt on a current collector to form the electrode. According to the methods, cheap and recycling dimethyl sulfone is selected as the pore former, so that the cost is effectively lowered.

Owner:DONGHUA UNIV

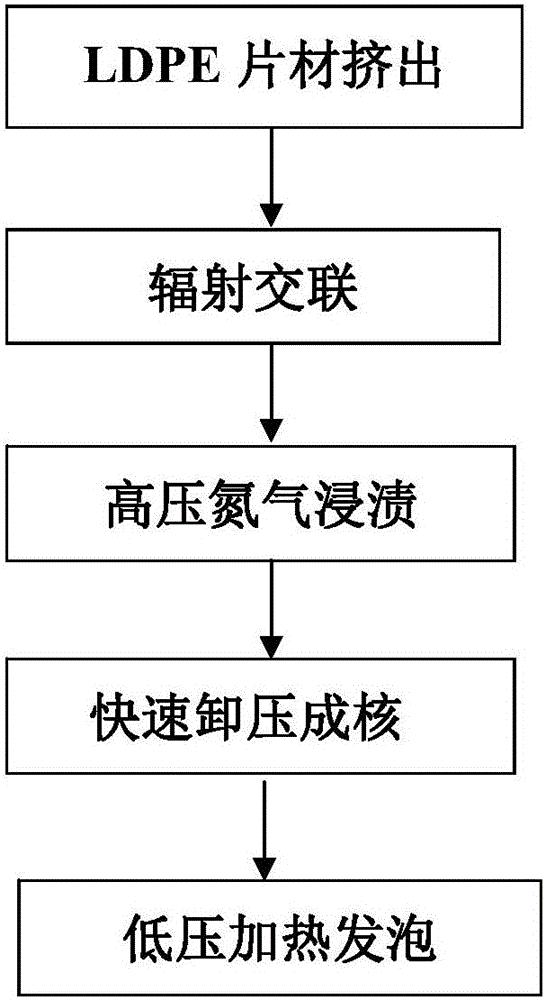

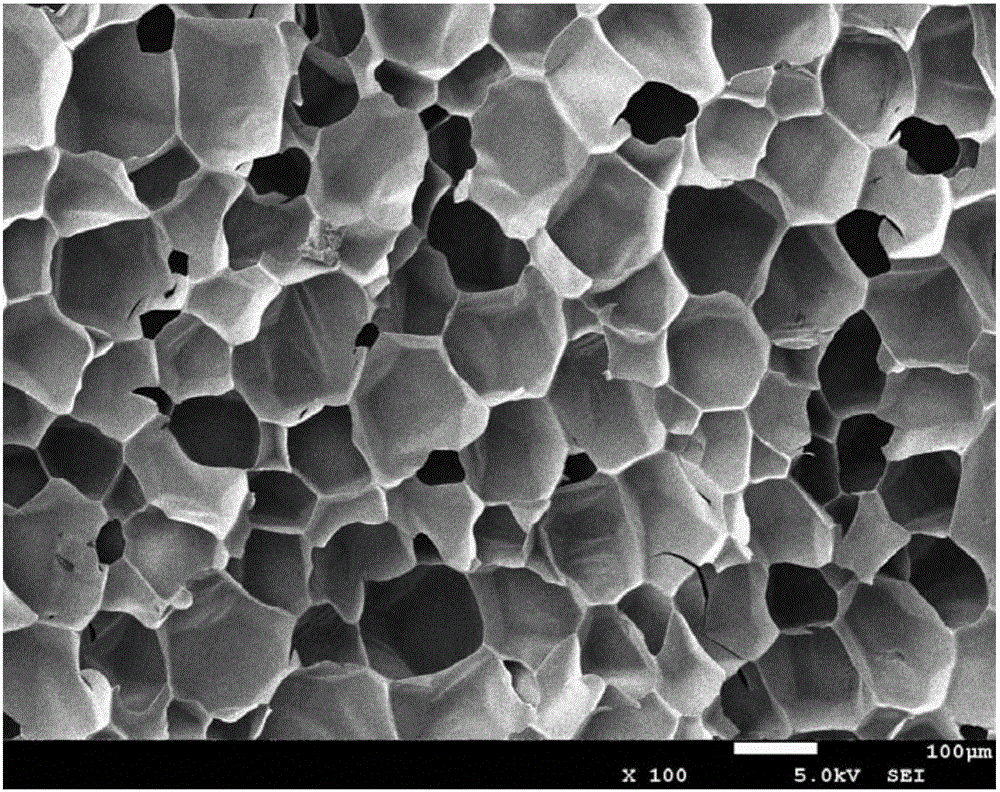

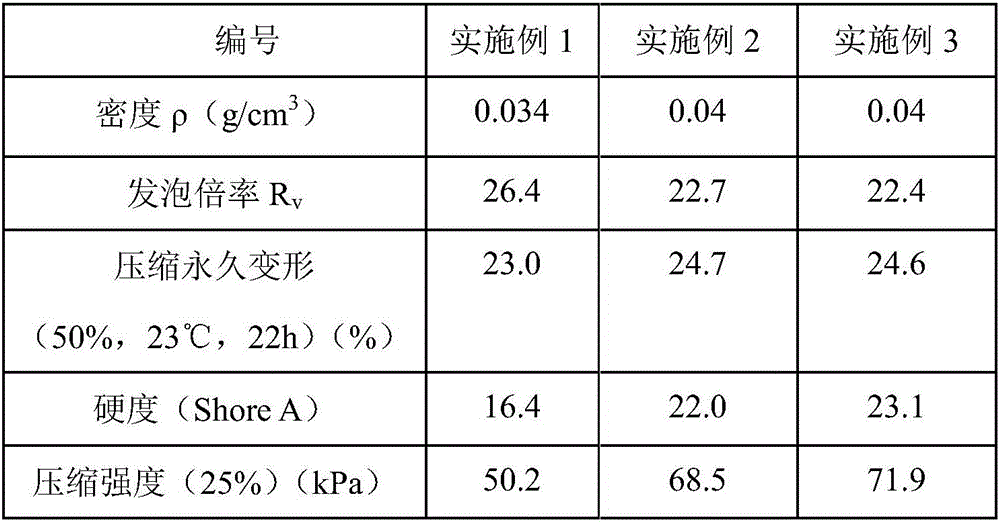

Supercritical fluid foaming polyolefin material and preparing method thereof

ActiveCN106146874AEasy to control the nucleation densityEasy to adjust the degree of expansionPolyolefinPolymer science

The invention provides a supercritical fluid foaming polyolefin material and a preparing method thereof. The supercritical fluid foaming polyolefin material is prepared through the following steps that a polyolefin sheet is prepared, and the melting point of the polyolefin sheet is Tm; radiation crosslinking is carried out on the polyolefin sheet; the crosslinked polyolefin sheet is put into a pressure container for high-pressure nitrogen impregnation, and the impregnation temperature T1 is equal to Tm+(30-120) DEG C; low-temperature heating foaming is carried out, and the foaming temperature T3 is equal to Tm+(20-50) DEG C, and is smaller than T1. By the adoption of the technical scheme, the requirement for material crystallinity is avoided, the time of reaching a dissolution saturation state of gas is greatly shortened, efficiency is improved, and the foaming material which is fine and uniform in bubble, low in density, high in mechanical strength and regular in shape can be obtained.

Owner:湖州长园特发科技有限公司

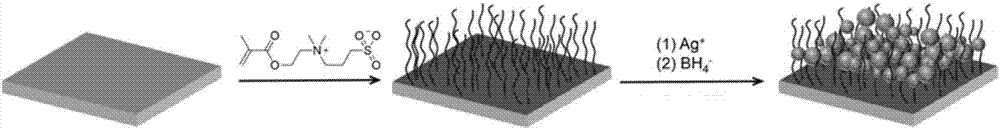

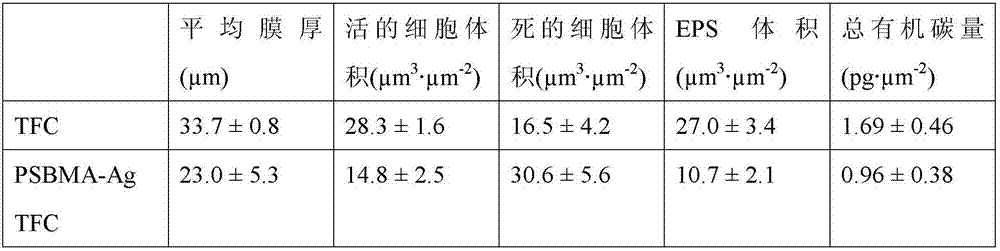

Method for modifying polyamide composite thin film

InactiveCN106916330AEfficient killingInhibition of adhesionLiquid/solution decomposition chemical coatingComposite filmPolyamide

The invention relates to a method for modifying a polyamide composite thin film, relates to a method for improving pollution resistance of a forward osmosis polyamide composite film through post-treatment modification, and is used for solving the problems that because a conventional polyamide TFC film easily gets biological pollution, the film effluent flux is decreased, the film cleaning frequency is increased, the energy consumption is increased, the film life cycle is shortened, then the process treatment efficiency is reduced and the operation cost is increased. The method comprises the steps: one, coupling dopamine and an initiator; two, introducing the initiator to the surface of a film; three, grafting a zwitterionic polymer on the surface of the film; four, adsorbing silver ions; and five, producing nano silver in situ. The obtained modified TFC film has anti-adhesion and bacteriostasis effects, and can effectively control the biological pollution of the film. The atom transfer radical polymerization reaction is adopted for grafting of the zwitterionic polymer, large controllability is achieved, the graft length and density of the organic polymer can be controlled by adjusting and controlling parameters, and the properties of pollution resistance and mass transfer of the film are further optimized.

Owner:HARBIN INST OF TECH

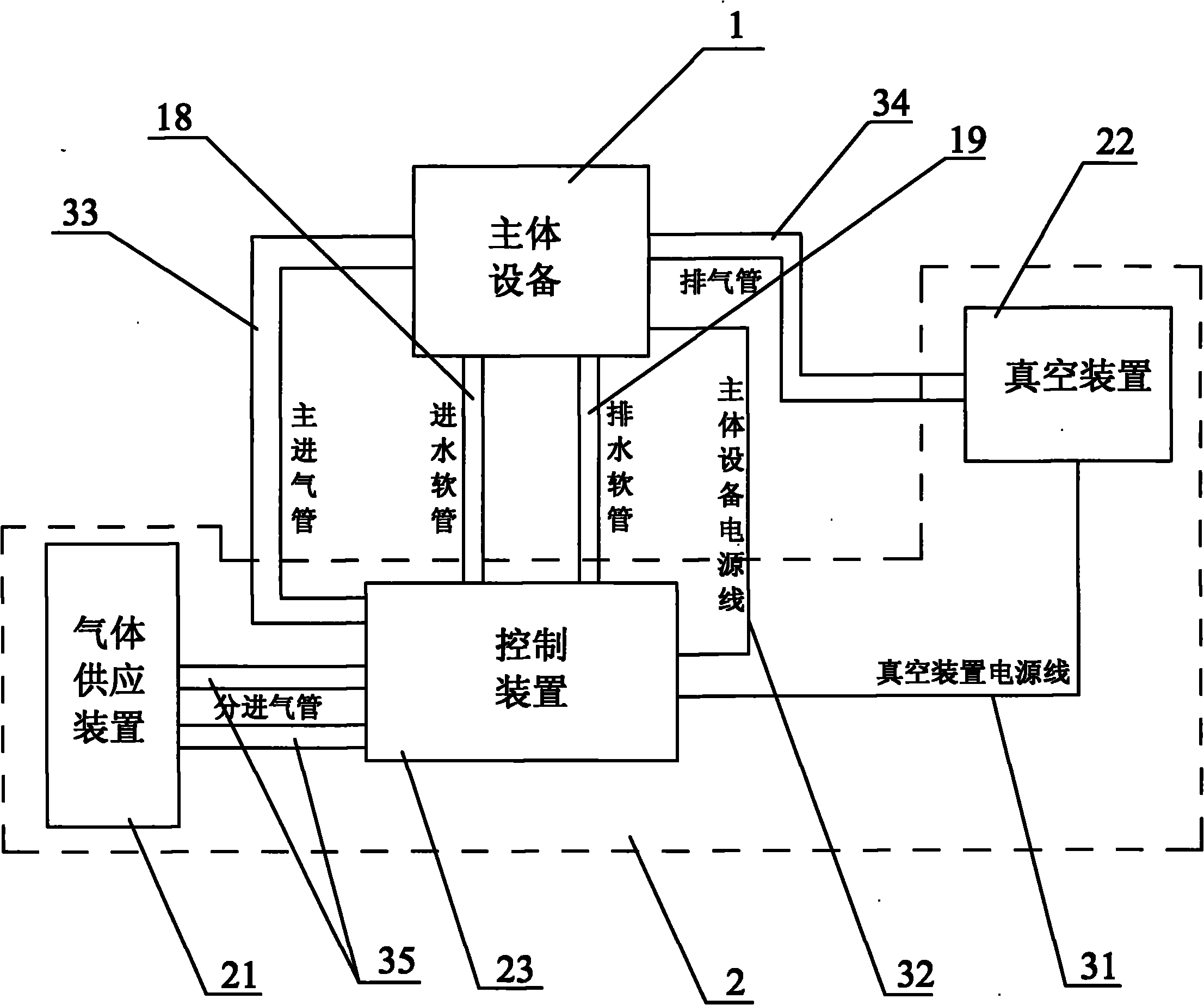

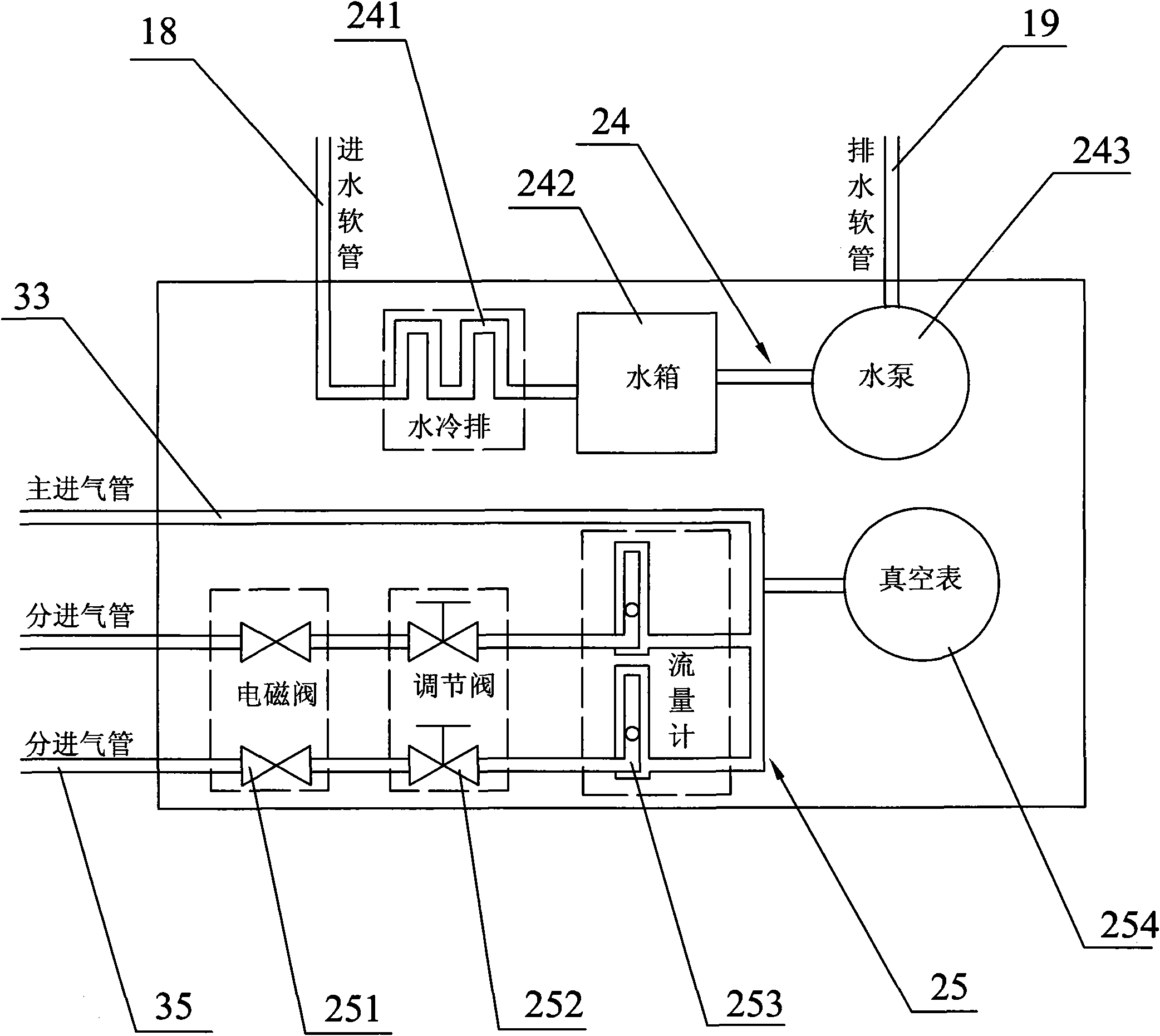

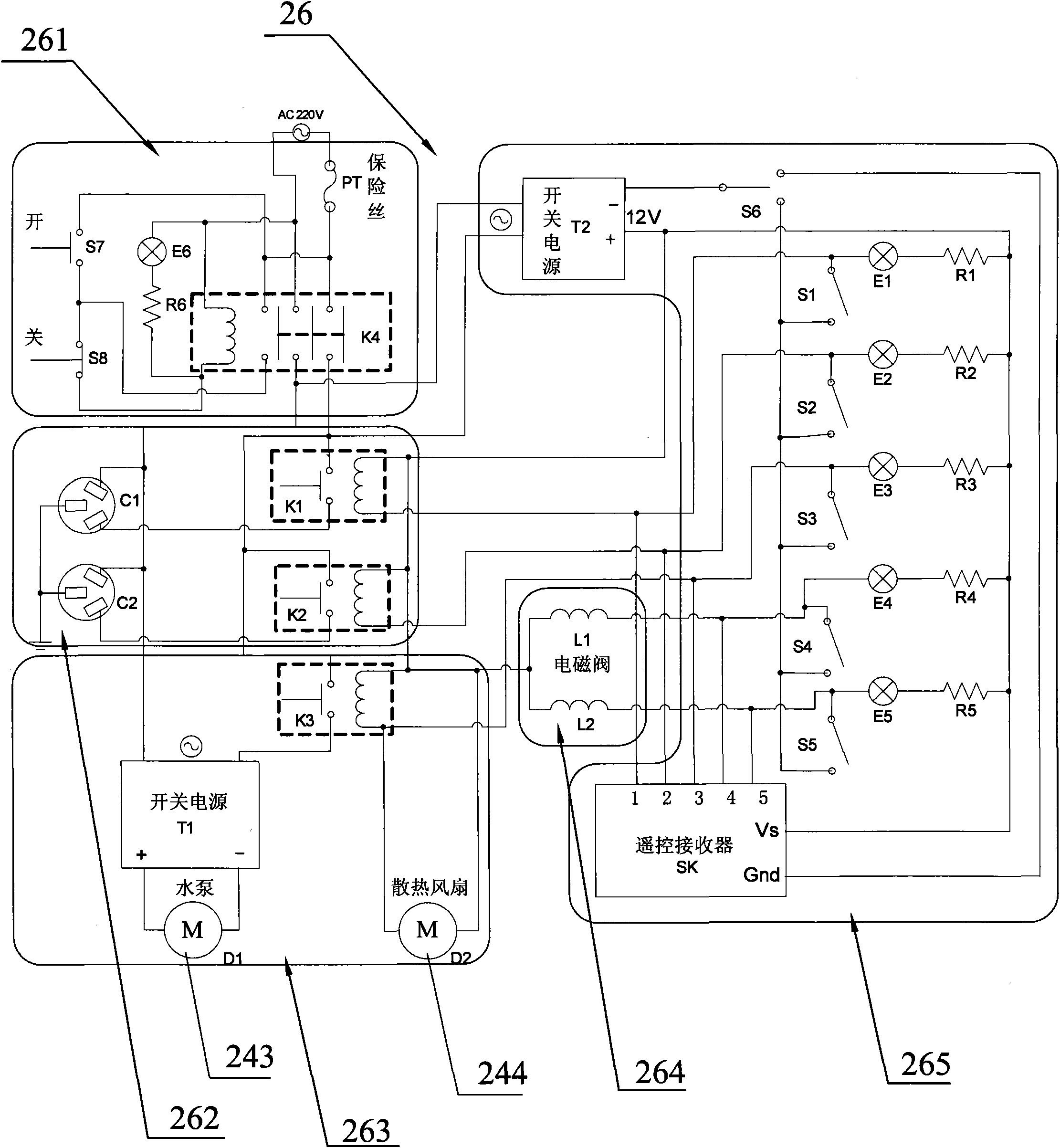

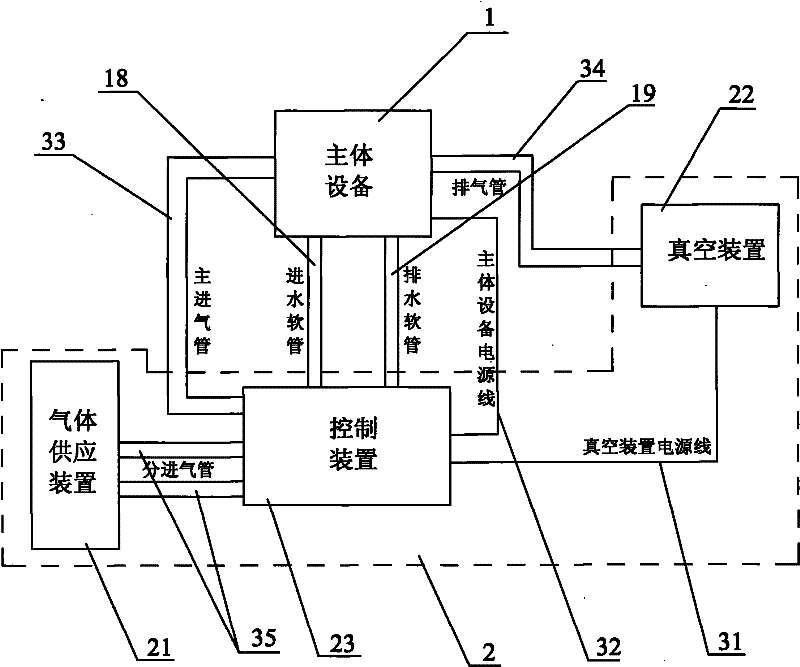

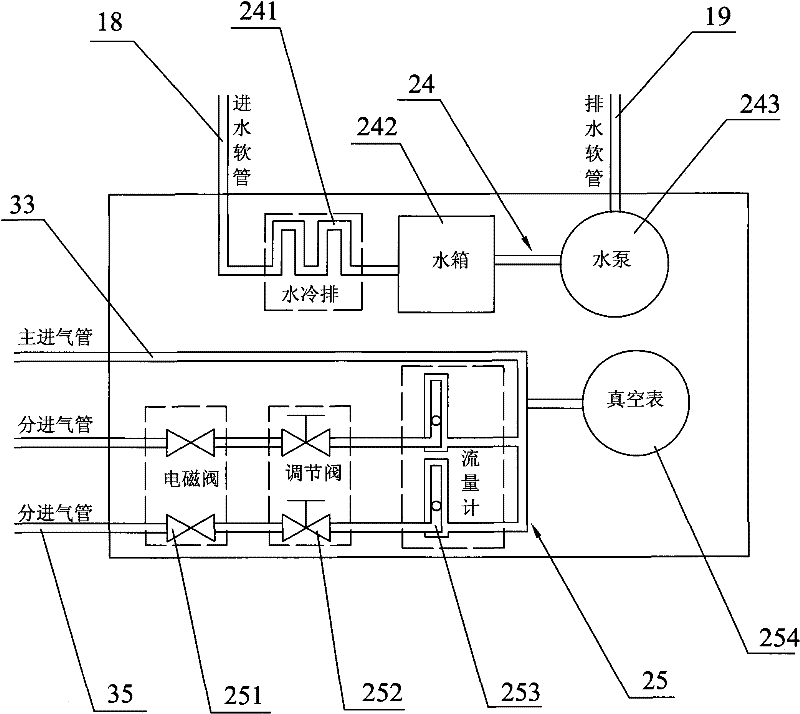

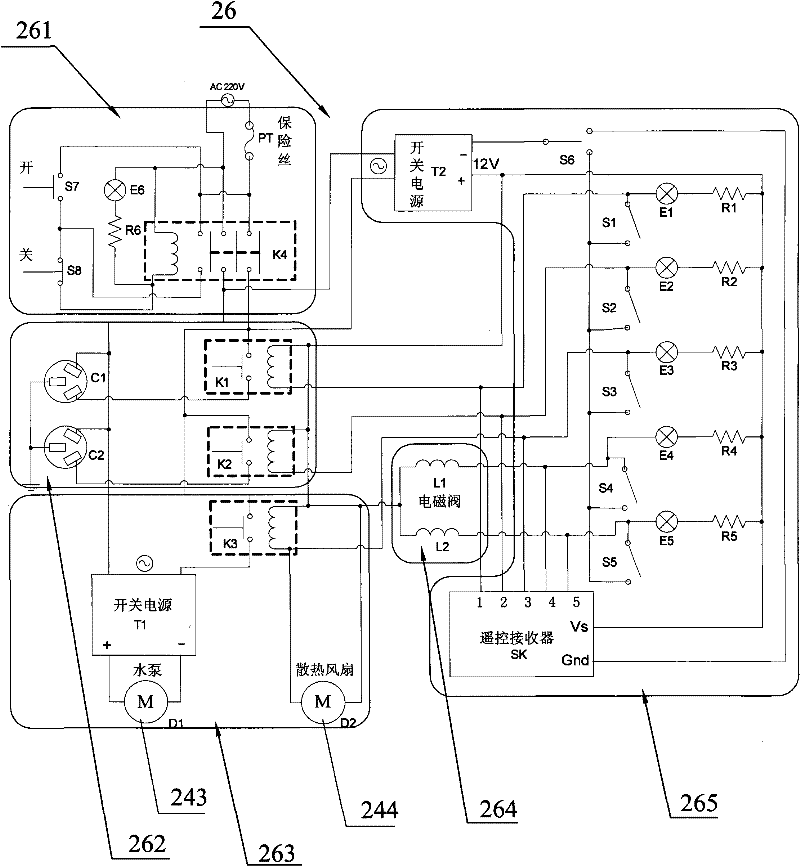

Plasma body cleaning device

InactiveCN101837357AImprove securityRegulation densityCleaning processes and apparatusMaterial typeSurface modification

Owner:浙江尧瑶科技有限公司

Honeycomb-shaped carbon nano tube porous microsphere, and preparation method and application thereof

ActiveCN110237787AUniform sizeReduce sizeOther chemical processesMicroballoon preparationNanoparticleCarbon nanotube

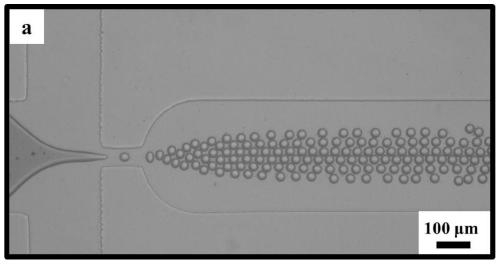

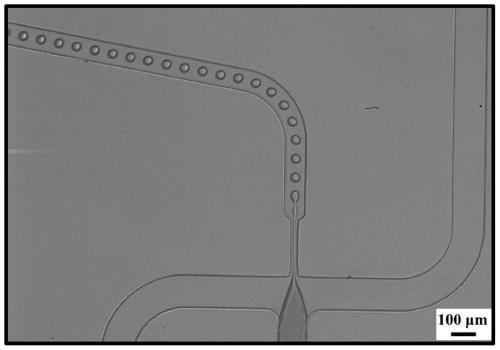

The invention discloses a honeycomb-shaped carbon nano tube porous microsphere, and a preparation method and application thereof. The honeycomb-shaped carbon nano tube porous microsphere is a three-dimensional porous structure formed by carbon nano tubes, has a diameter in a range of 5-200 microns, and contains a large amount of micropores with diameters in a range of of 20-1000 nm. A droplet micro-fluidic technology is adopted, and a porous microsphere structure is constructed by using micro droplets as soft templates and using SiO2 nano particle as hard templates. The honeycomb-shaped carbon nanotube porous microspheres prepared by the method are uniform in size, and the size, shape and density of ''honeycombs'' are controllable. Meanwhile, the preparation method disclosed by the invention is simple, and preparation is flexible and convenient. The flow speed is controlled through an injection pump, so that the advantages of accurate operation control, easy industrial batch production and the like are achieved.

Owner:SOUTH CHINA NORMAL UNIVERSITY

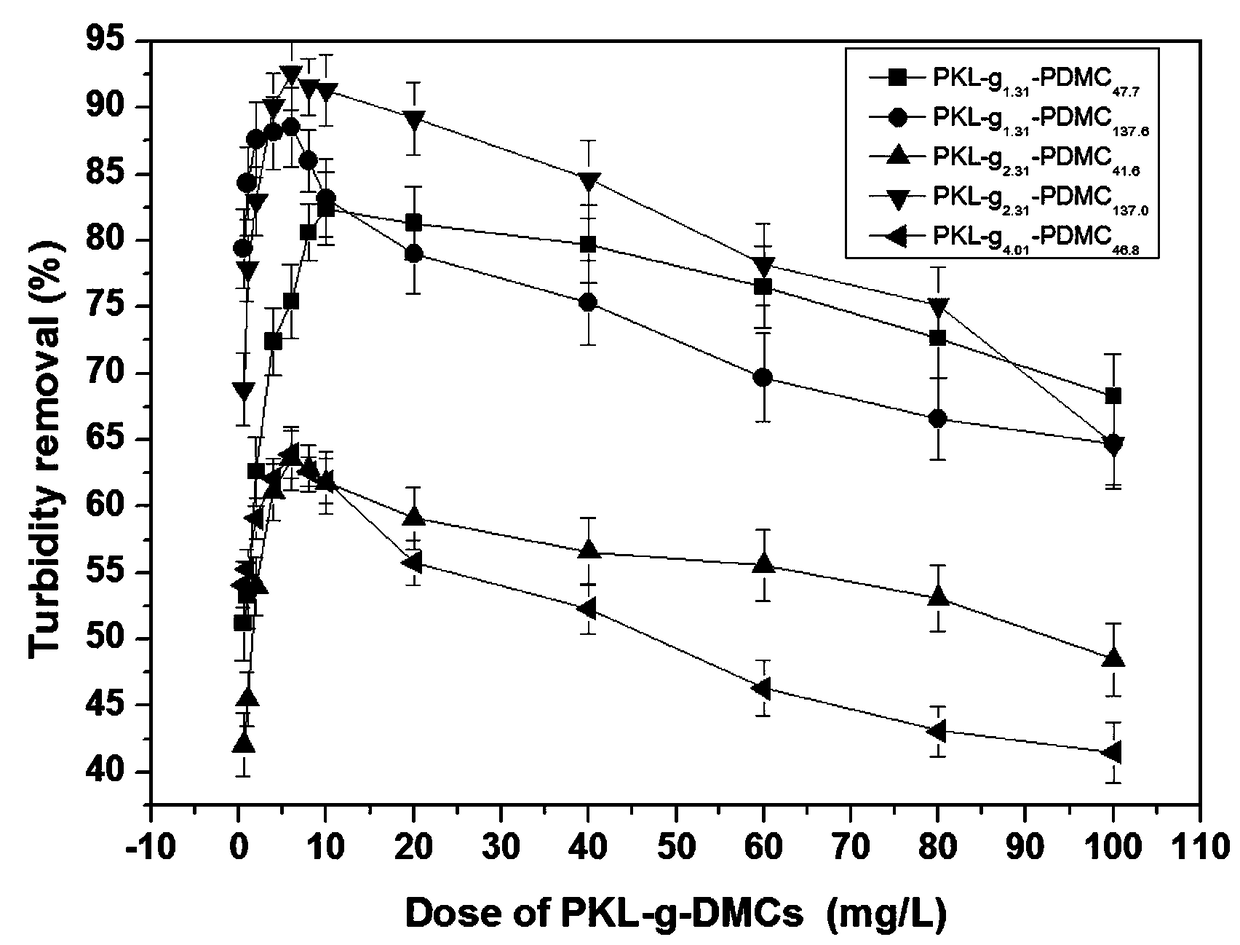

Method for preparing nano silicon-base porous luminescent material by normal pressure plasma gas phase deposition

InactiveCN101122015AChange sizeChange the time to pass through the discharge zoneChemical vapor deposition coatingLuminescent compositionsPlasma generatorWavelength

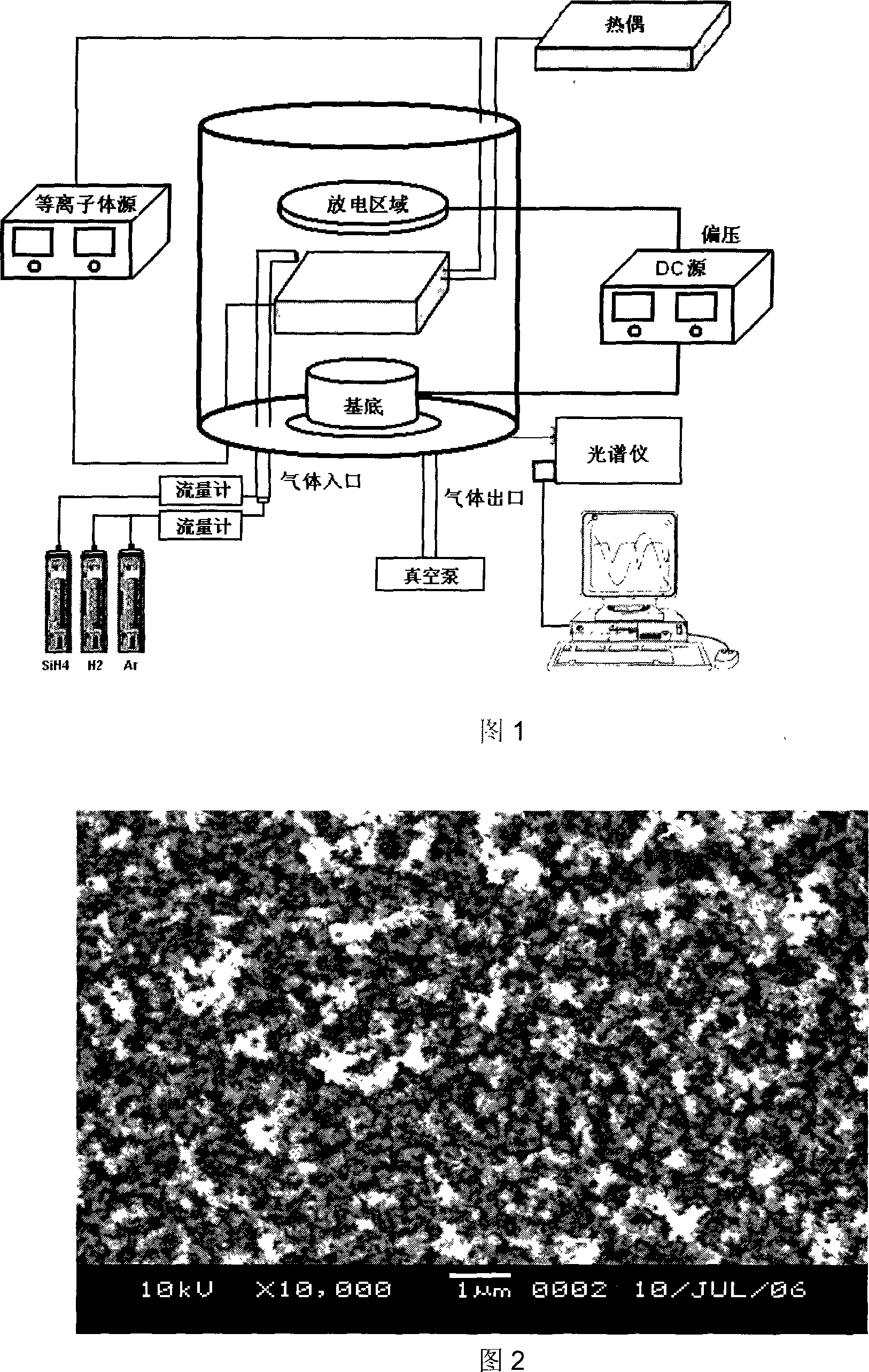

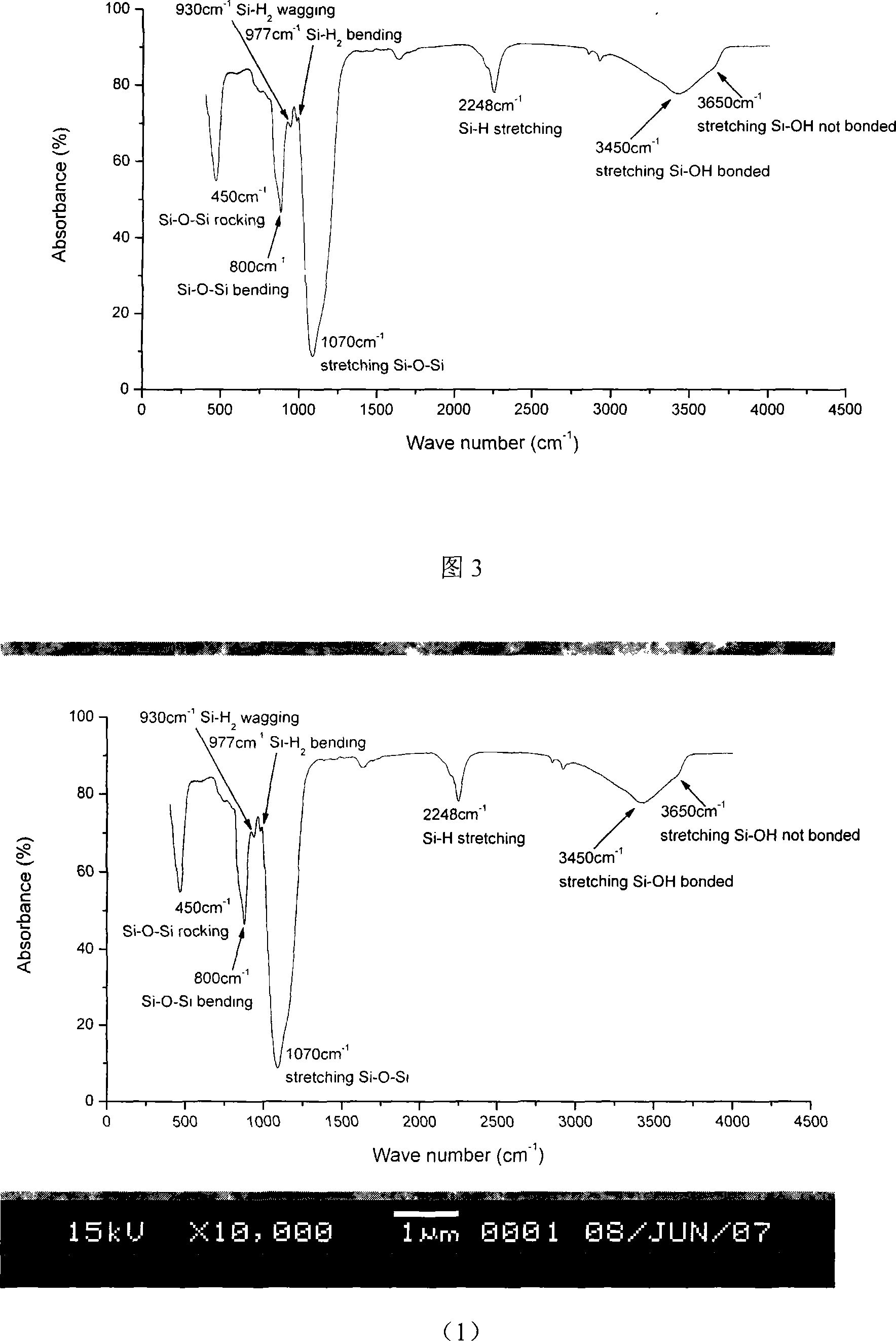

The invention relates to a method of preparing nano Si-based multi-hole luminescent material by atmospheric pressure plasma vapor deposition, which includes the following procedures: (1) a deposition substrate is arranged below a three-dimensional comb-shaped electrode, and a mechanical pump removes the air in a reaction chamber. (2) the mixed gas is fed through an umbrella washer of a gas inlet, to adjust the flow speed of the mixed gas and control the pressure in a deposition chamber to be near atmospheric pressure. (3)after the pressure in the reaction chamber becomes stable, the pulse bias is added to a basal, to adjust the frequency and power of a plasma generator. (4) after the discharge reaction, the substrate is taken out, and the nano Si-based multi-hole luminescent film is obtained. The method can be used in equipments which has dry environment, simple fitting, convenience in operation, and is near to atmospheric pressure, to change the plasma discharge parameters and pulse bias, and adjust the proportion and flow, etc of monomers and carrier gases, which can obtain high quality nano Si-based multi-hole luminescent films with different grain size, hole structures, components and film thicknesses, and provides adjustable luminescence radiation wave length and improved luminescence efficiency.

Owner:DONGHUA UNIV

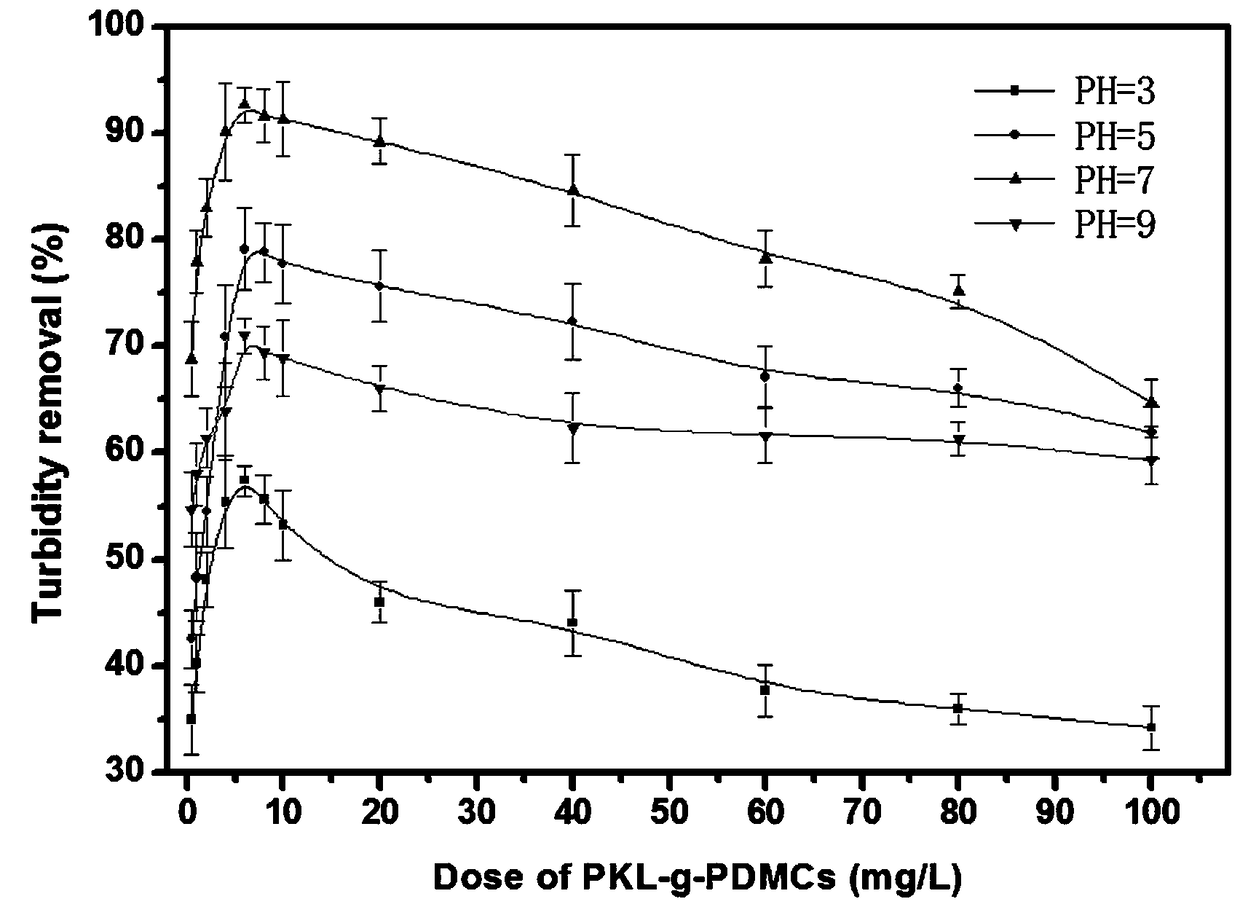

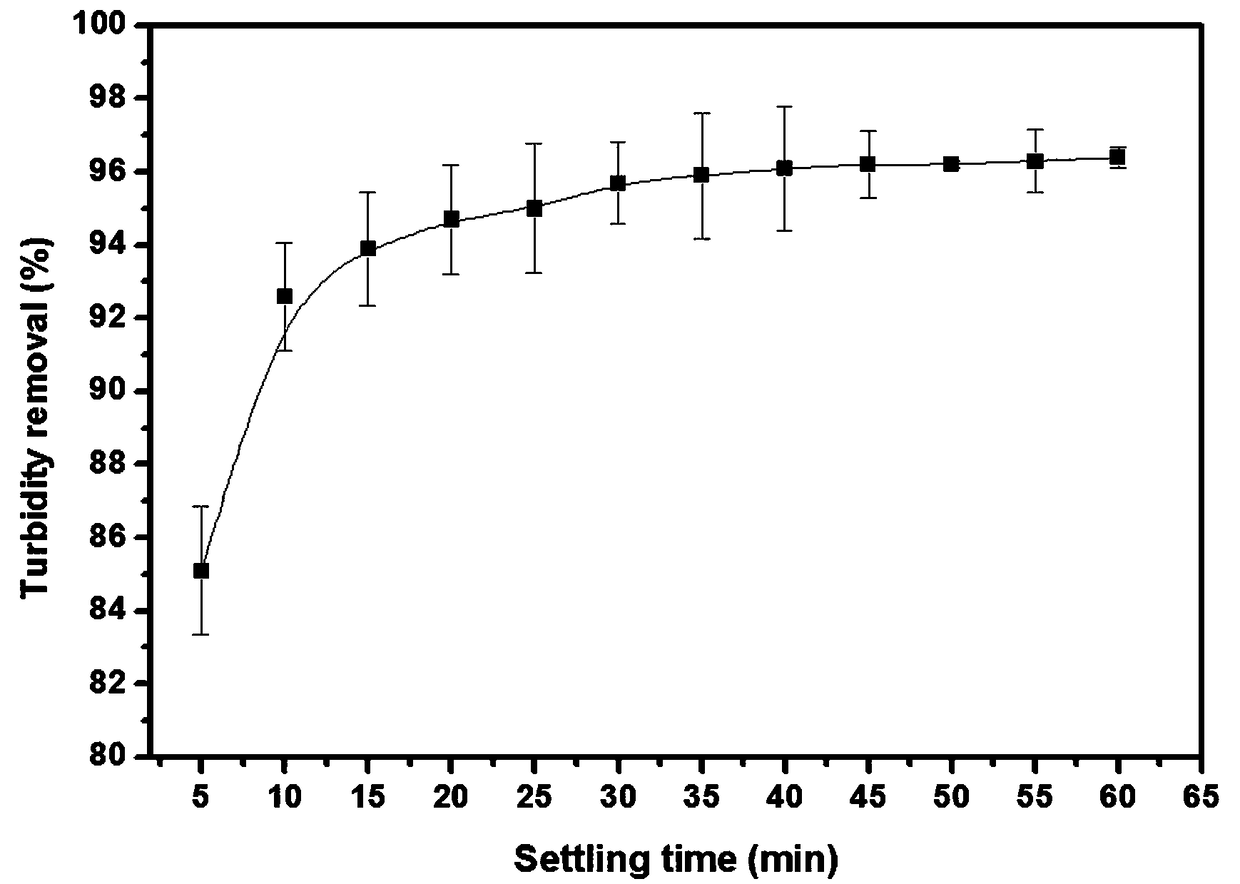

Lignin-based polyquatemary salt cation water treatment agent and preparation method thereof

ActiveCN108751370AImprove settlement performanceImprove conversion rateWater/sewage treatment by flocculation/precipitation2-bromopropionic acidPotassium

The invention relates to the technical field of a sewage treatment material, in particular to a lignin-based polyquatemary salt cation water treatment agent and a preparation method thereof. The method is characterized in that potassium ethyl xanthogenate and 2-bromopropionic acid are used as raw materials for preparing 2-(ethoxythiomethyl) thiodipropionic acid; then, the 2-(ethoxythiomethyl) thiodipropionic acid and alkali lignin or lignin derivatives are synthetized into a lignin-based RAFT chain transfer agent through esterification reaction; finally, under the effects of a radical initiator and the lignin-based RAFT chain transfer agent, methacryloyloxyethyl trimethyl ammonium chloride is polymerized to obtain a star-shaped multi-arm lignin-based polyquatemary salt cation water treatment agent through free radical active polymerization. The method has the characteristics that the conversion rate is high; the molecular weight is great; the molecular weight distribution is narrow; the reaction conditions are mild; the target product structure can be designed, regulated and controlled according to the flocculating performance; the flocculating efficiency is high. The prepared water treatment agent can be widely applied to the removal of suspension solid particles difficult to settle in domestic sewage and industrial sewage.

Owner:GUANGXI UNIV FOR NATITIES

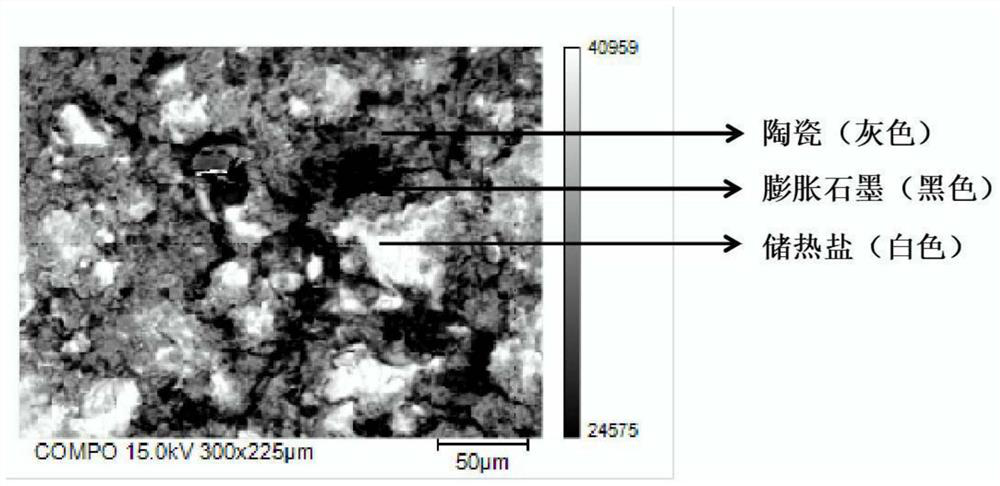

Assembly method of expanded graphite reinforced heat conduction ceramic-based shaped high-temperature phase change heat storage element and heat storage element formed by assembly method

ActiveCN111793474AHigh thermal conductivityImprove heat transfer efficiencyHeat-exchange elementsCompression moldingHeat conducting

The invention relates to an assembly method of an expanded graphite reinforced heat conduction ceramic-based shaped high-temperature phase change heat storage element. The assembly method comprises the following steps: providing an eutectic salt phase change material; providing an expanded graphite heat conducting agent; providing a ceramic powder framework material and a sintering aid; mixing theeutectic salt phase-change material, an expanded graphite heat-conducting agent, a ceramic powder framework material and a sintering aid, putting the mixture into a mold, and performing compression molding at 12-14MPa to obtain a green body; and carrying out heat treatment on the blank to obtain the heat storage element. The invention also relates to a heat storage element formed by the assemblymethod. The heat storage element comprises an eutectic salt phase change material, an expanded graphite heat conduction agent and a ceramic powder framework material. The heat conducting agent expanded graphite material adopted by the high-temperature phase change heat storage element provided by the invention is more resistant to high temperature and corrosion than metal, can be better compatibleand has good thermal cycle performance, and an effective component of the high-temperature phase change material with high heat conductivity and corrosion resistance is provided.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

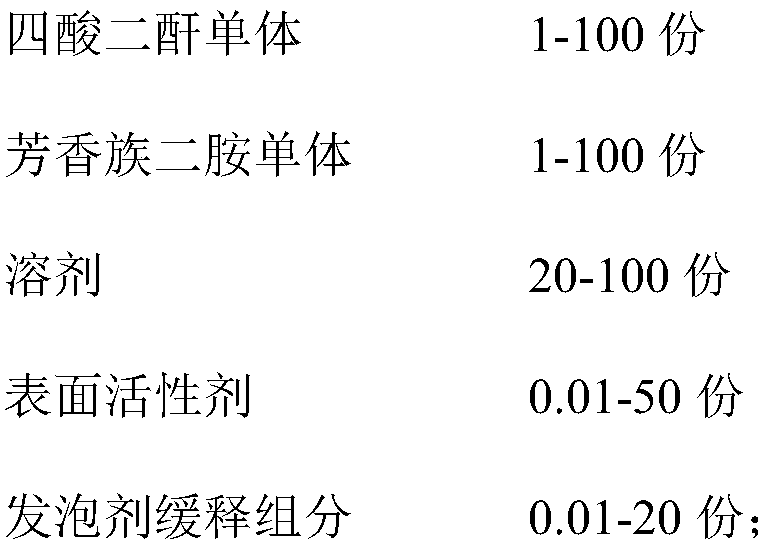

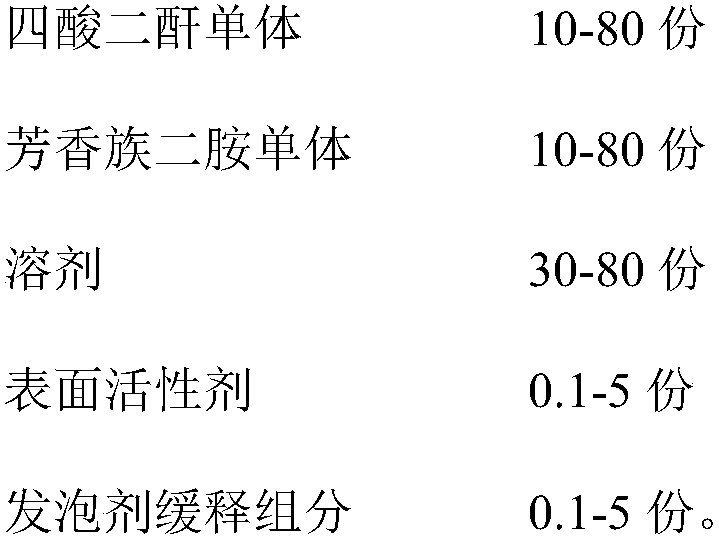

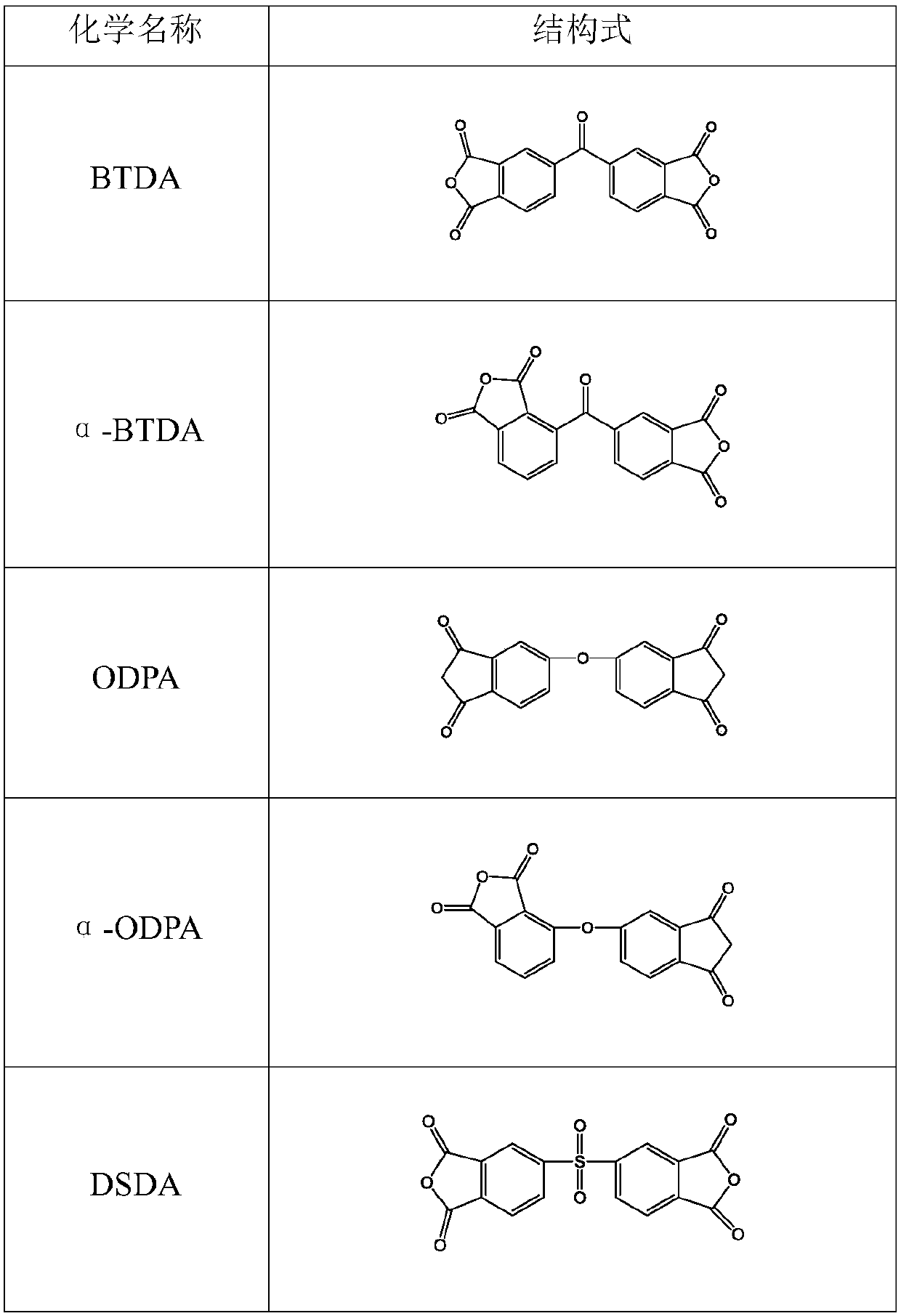

Flexible polyimide foam and preparation method and applications thereof

ActiveCN109593199AProtection against excessive volatilizationUniform pore sizeFoaming agentMicrometer

The present invention relates to flexible polyimide foam and a preparation method and applications thereof. The flexible polyimide foam is obtained by foaming a block / plate-shaped polyimide foam precursor containing slow-release components of a foaming agent; and the flexible polyimide foam has the average density of 14.7-47.7 kg / m<3> and the pore size of 130-530 micrometers. The flexible polyimide foam disclosed by the invention has the beneficial effects that by adopting a foaming form of a polyimide (PI) precursor block / plate, the problem of large density deviation in the thickness direction, of a polyimide precursor powder foaming method, can be effectively solved and the product yield of the foam made from the prepolymerized powder is improved; by adopting the PI precursor containingthe slow-release components and by regulating and controlling the type and the using amount of the slow-release components of the foaming agent, the density of the PI flexible foam can be adjusted andcontrolled, so that the foaming process window is wider and the pore size of the foam is more uniform; and meanwhile, by adopting the polyimide precursor plate, the water absorption rate can be effectively reduced and the storage time of the material is prolonged in the preservation process, so that the quality stability of the final foam product is improved.

Owner:INST OF CHEM CHINESE ACAD OF SCI

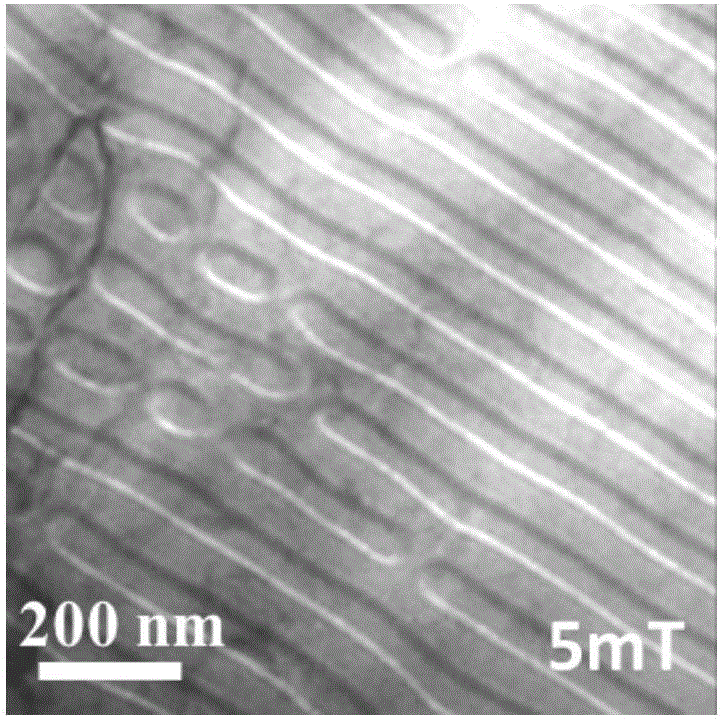

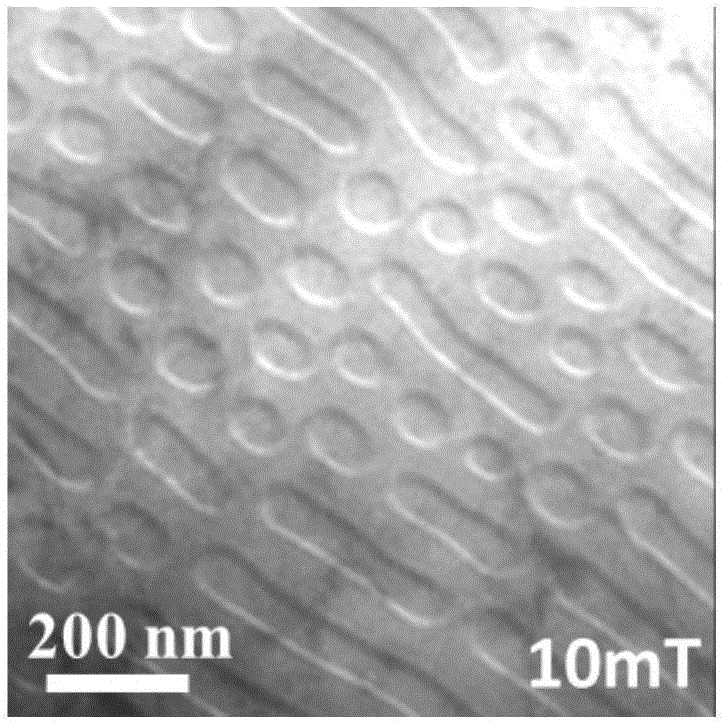

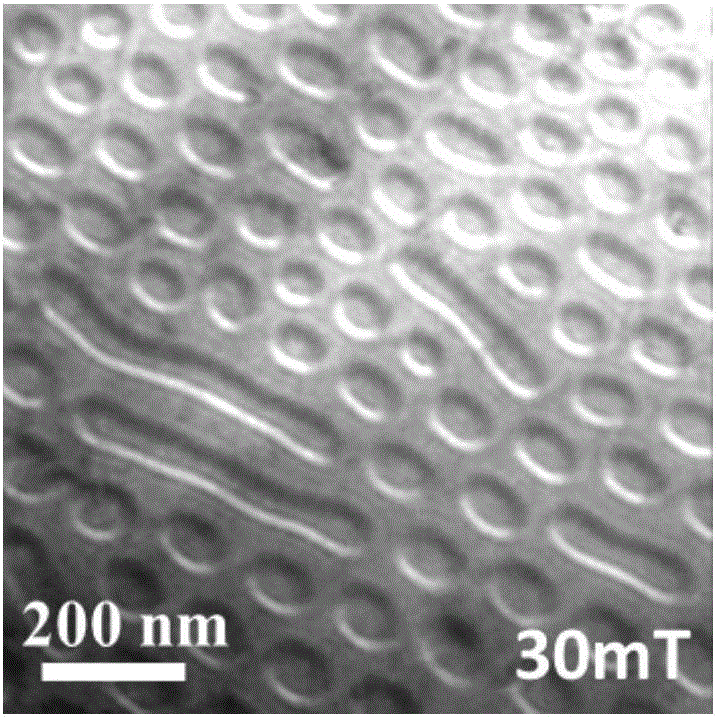

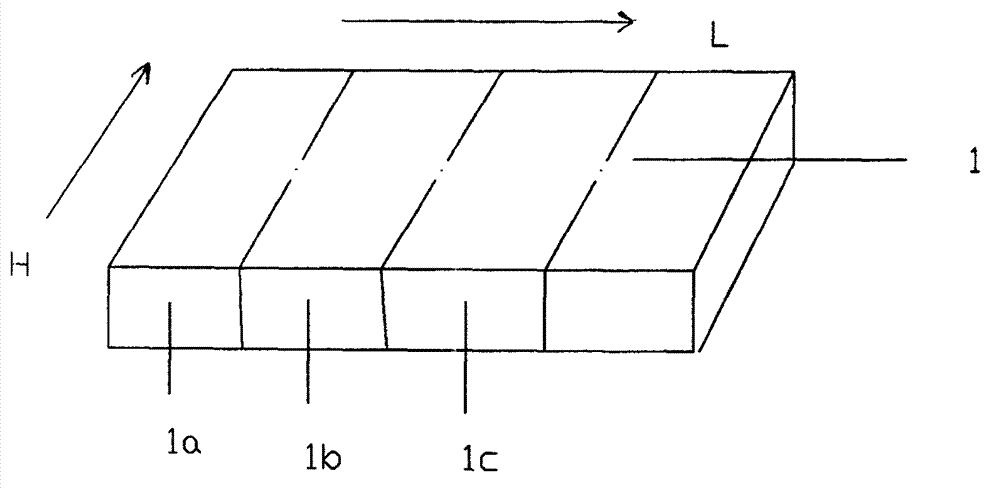

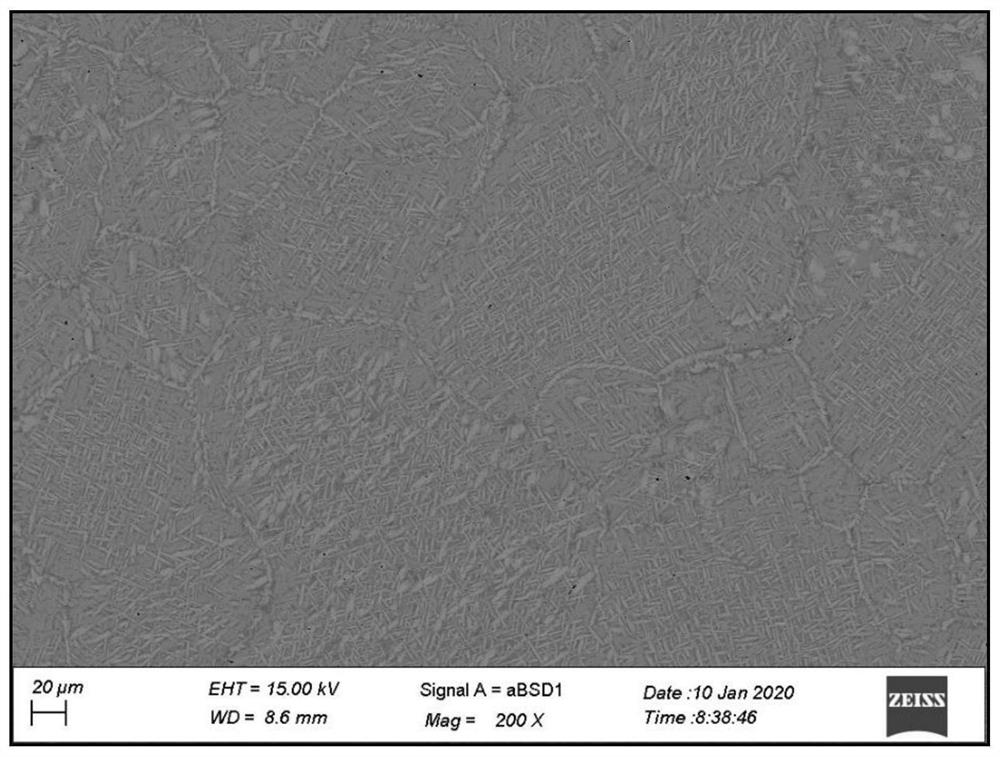

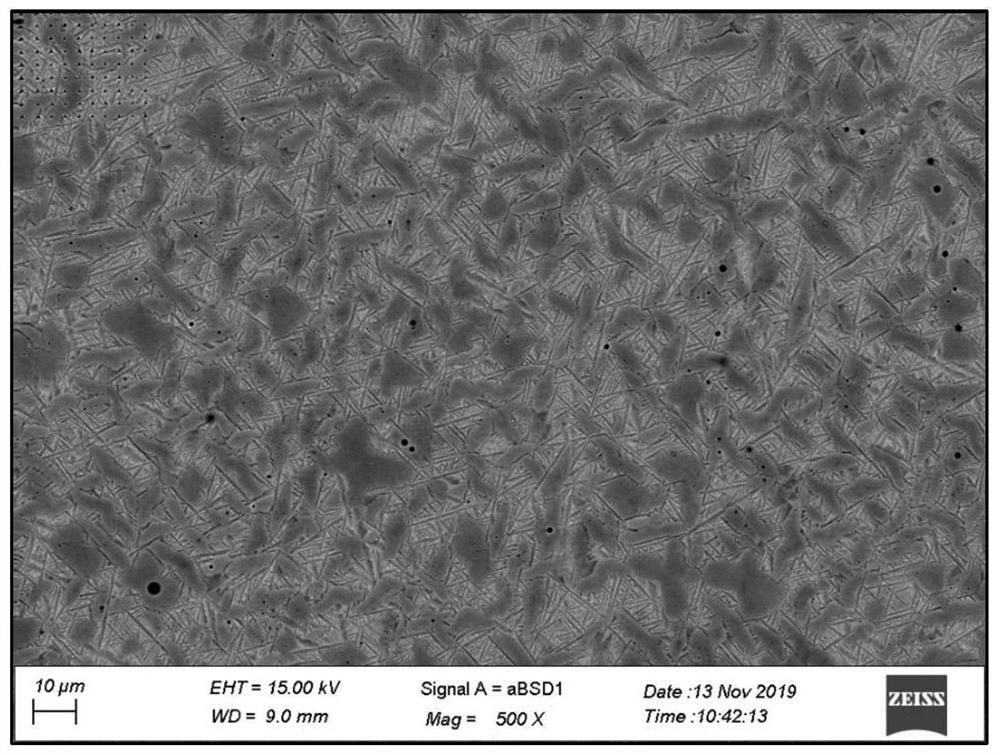

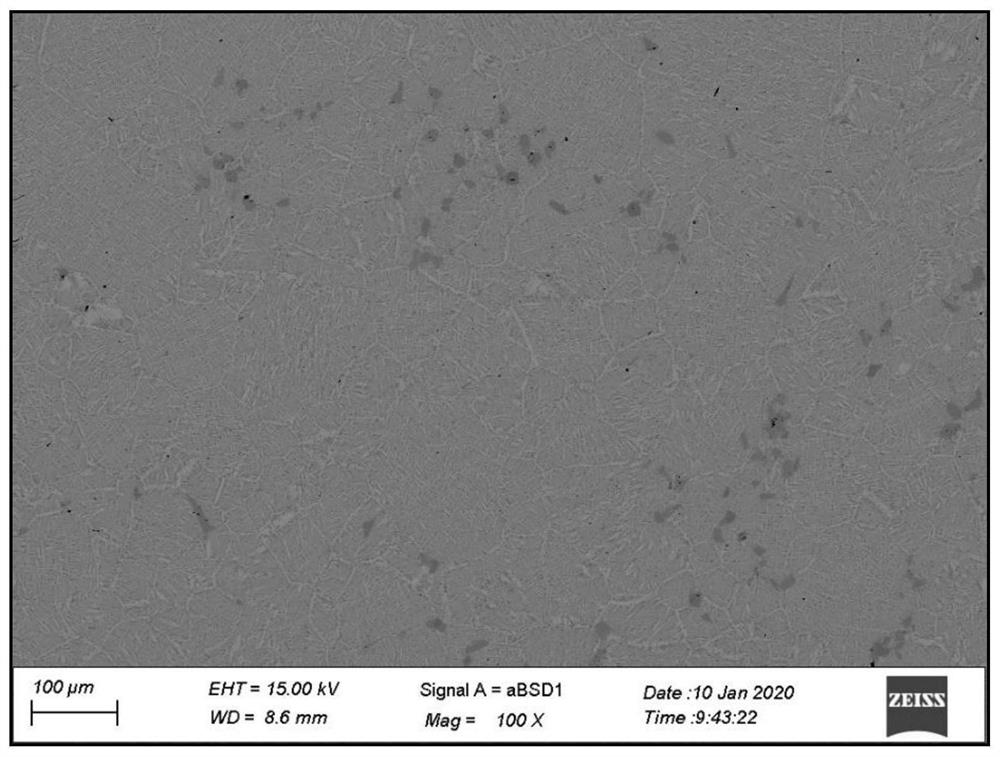

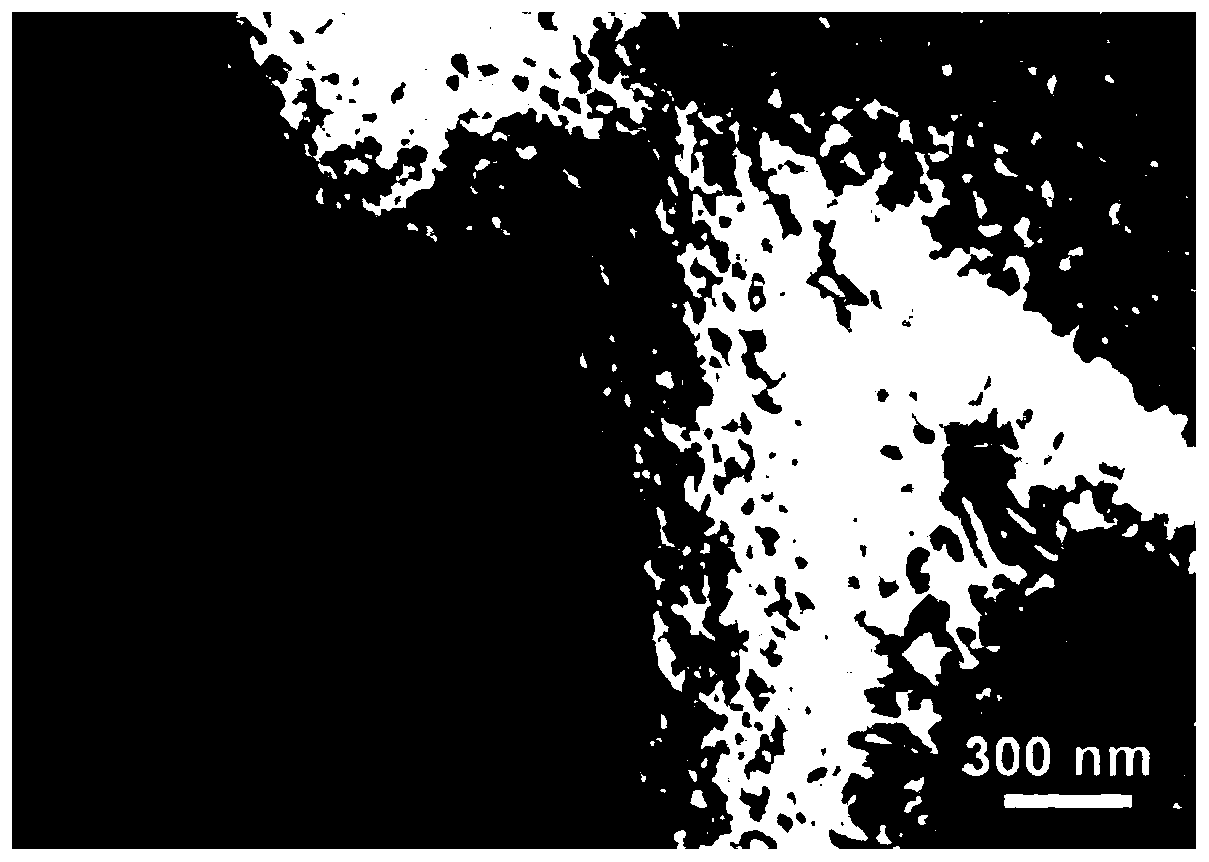

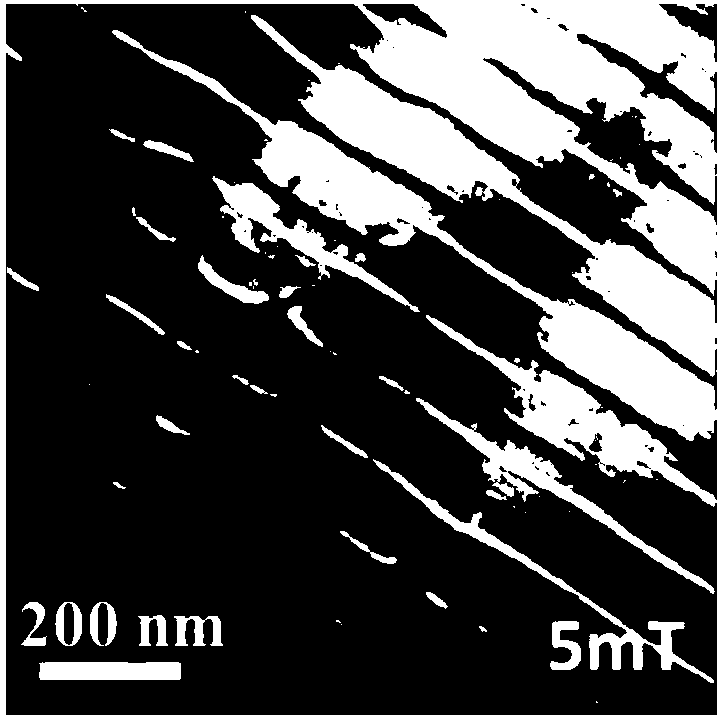

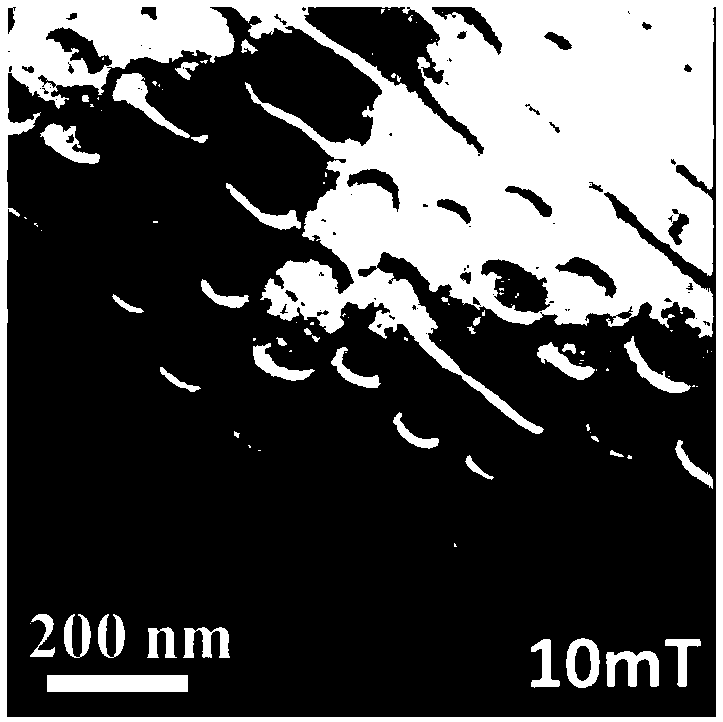

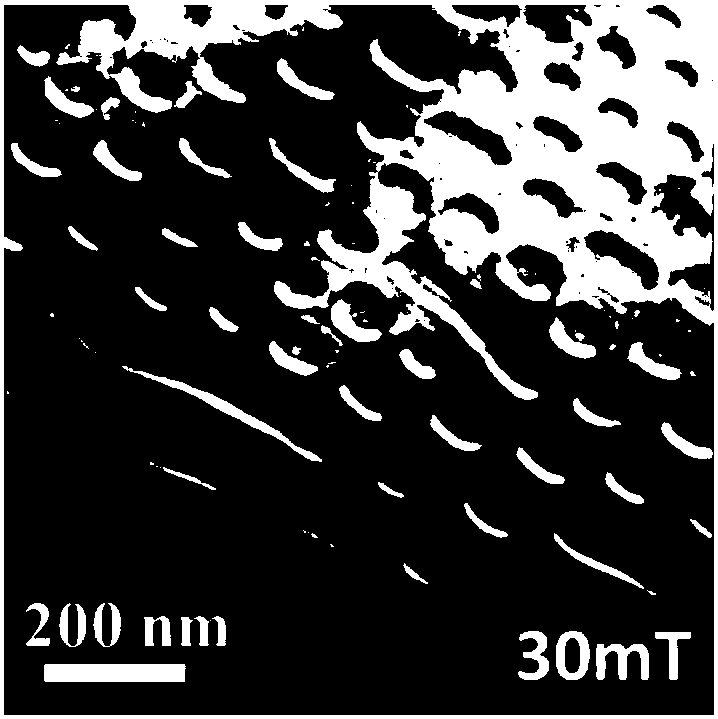

Regulation and control method for Skyrmion in hexagonal MnNiGa

ActiveCN106653262ARegulation densityProcess stabilityInorganic material magnetismLow dimensional magnetism materialsHigh densityRoom temperature

The invention provides a regulation and control method for a Skyrmion in a hexagonal MnNiGa. The regulation and control method comprises the following steps of 1) applying a magnetic field to the hexagonal MnNiGa, wherein the magnetic field is not strong enough to convert a strip-shaped magnetic domain in the hexagonal MnNiGa into the Skyrmion; and the direction of the magnetic field is not parallel to a family of crystal plane [001] in the hexagonal MnNiGa; and 2) applying a current to or / and heating the hexagonal MnNiGa to enable the strip-shaped magnetic domain to disappear. By virtue of the regulation and control method, a high-density Skyrmion array is formed in the hexagonal MnNiGa material system; and in addition, the high-density Skyrmion can exist in both of a null field and a wide-temperature-range room temperature.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Fiber cotton cushion and preparation process thereof

The invention discloses a fiber cotton cushion and preparation process thereof and particularly relates to preparation process for preparing a fiber cotton cushion and the fiber cotton cushion manufactured according to the preparation process, wherein main raw materials are formed by blending heat treatment of low melting point fibers and other fibers. A cellucotton block manufactured according to hot melt cotton preparation process is slit into a plurality of cellucotton sub-blocks, the cellucotton sub-blocks are placed and attached side by side, or cellucotton blocks or a cellucotton block are or is laid on the upper face and the lower face or one of the faces after the process of attaching, then attaching forming is carried out through a heat bonding device, and the fiber cotton cushion is manufactured. According to the fiber cotton cushion and the preparation process thereof, the synthetic cellucotton block manufactured by heat bonding forming and slitting is slit and recombined, the fiber cotton cushion can be adjusted and controlled according to needs, in addition, density, fiber upright degree and surface evenness can be adjusted and controlled according to needs, then hot melting forming process is carried out, and quality of the fiber cotton cushion can be greatly improved.

Owner:广东美梦思床具有限公司

Preparation method of multi-stage pore-size distribution material

ActiveCN105734718AControl pore size distributionRegulation densityPhysical treatmentMonocomponent polyesters artificial filamentMaterials preparationFiber

The invention belongs to the field of material preparation, and particularly relates to a preparation method of a multi-stage pore-size distribution material. The preparation method comprises the following steps: firstly, preparing functional fibers, wherein chemical groups are arranged on the surfaces of the functional fibers; then, homogenizing the functional fibers to obtain homogenized functional fibers; performing crosslinking treatment on the homogenized functional fibers to obtain the multi-stage pore-size distribution material. The multi-stage pore-size distribution material prepared in the invention has multi-stage pore-size distribution, good adsorption properties, good flexibility and processibility, simple processes, high universality and low equipment requirements, can be subjected to industrial production, and has broad application prospects in many fields.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of high-strength Zr-Ti-based alloy

The invention provides a preparation method of a high-strength Zr-Ti-based alloy, and belongs to the technical field of powder metallurgy. The preparation method provided by the invention comprises the following steps of mixing Zr powder and Ti powder to obtain mixed powder; conducting cold isostatic pressing on the mixed powder to obtain a formed blank; and sintering the formed blank to obtain the Zr-Ti-based alloy. According to the method, the porosity between the mixed powder is reduced through cold isostatic pressing, and the density of the formed blank is improved; and by controlling the sintering temperature, the sintering time and the sintering environment in different sintering stages and applying pressure in the third sintering stage, the compactness and the structure uniformity of the Zr-Ti-based alloy are further improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

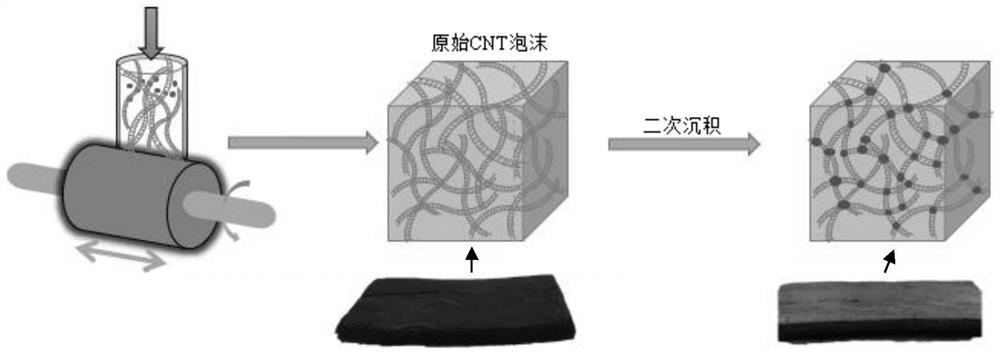

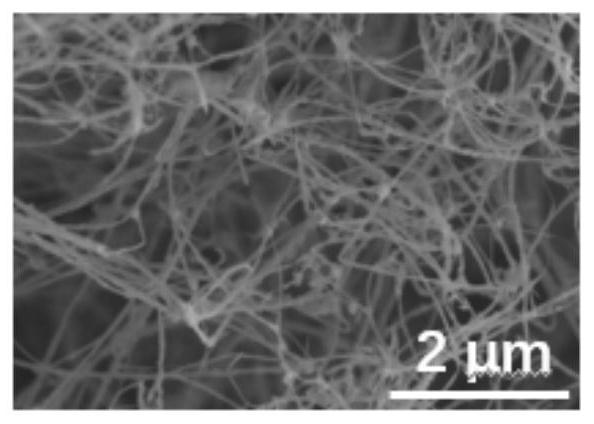

Carbon nanotube foam material with electromagnetic shielding performance, and preparation method and application thereof

ActiveCN112210766AImprove shielding effectControllable densityMagnetic/electric field screeningChemical vapor deposition coatingCarbon nanotubeNetwork structure

The invention discloses a carbon nanotube foam material with electromagnetic shielding performance, and a preparation method and application thereof. The preparation method of the carbon nanotube foammaterial with the electromagnetic shielding performance comprises the following steps: placing carbon nanotube foam into a reaction chamber of chemical vapor deposition equipment; and heating the reaction chamber to 1000-1100 DEG C, and then at least introducing a carbon source and a reducing gas into the reaction chamber, so as to carry out secondary deposition of amorphous carbon on the carbonnanotube foam, thereby obtaining the carbon nanotube foam material with the electromagnetic shielding performance, wherein the carbon nanotube foam material comprises a porous structure composed of a3D network structure with self-supporting capability. According to the invention, the prepared carbon nanotube foam material with the electromagnetic shielding performance has excellent shielding effectiveness, controllable density and thickness, small mass, good flexibility and excellent shielding effectiveness stability; and the preparation process is simple, and batch production can be expanded.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

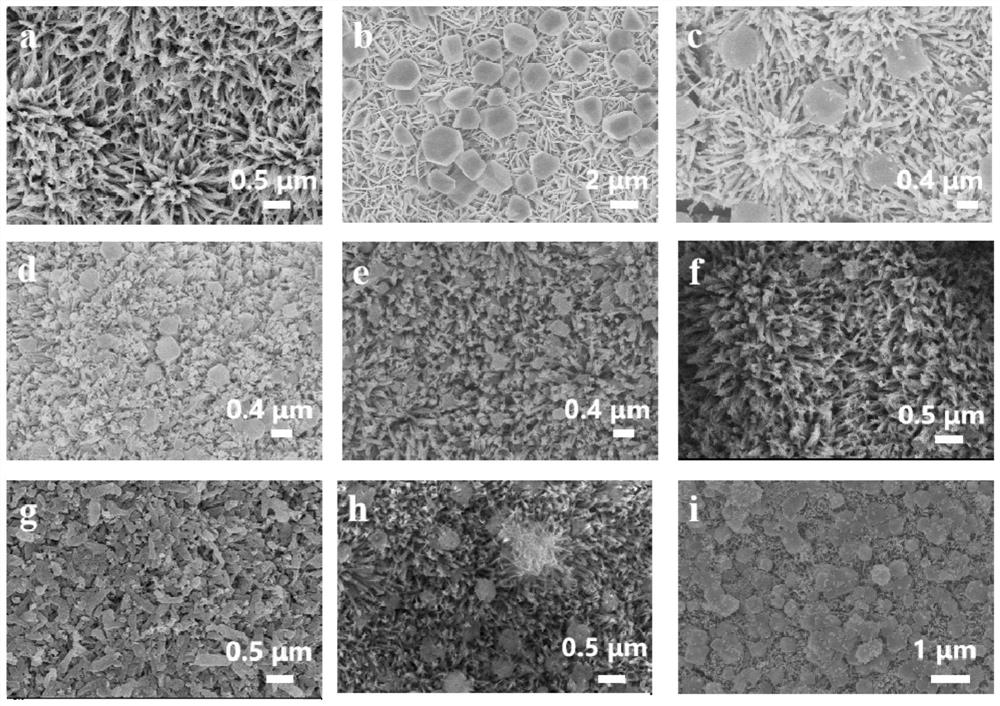

Silk fibroin/silver phosphate nano-wire composite pore channel scaffold, construction method and applications thereof

ActiveCN110201689ARegulatory TopographyRegulation densityPhysical/chemical process catalystsWater/sewage treatment using germicide/oligodynamic-processPhosphoric acidSilver phosphate

The invention discloses a silk fibroin / silver phosphate nano-wire composite pore channel scaffold, a construction method and applications thereof. The preparation method comprises: mixing a silk fibroin solution with a mass percentage concentration of 3-4% and a silver nitrate solution with a mass percentage concentration of 0.5-4% to obtain a mixed solution; freezing the mixed solution, and carrying out low-temperature drying to obtain a silk fibroin oriented pore channel scaffold; adding PAA with a mass volume ratio of 0.15-0.25 mg / ml to a phosphoric acid solution to prepare a reaction solution, placing the silk fibroin oriented pore channel scaffold in the reaction solution, and carrying out a reaction for 0.1-4 h to obtain a reaction product; and freezing the reaction product, and drying at a low temperature to obtain the silk fibroin / silver phosphate nano-wire composite pore channel scaffold. According to the present invention, the silk fibroin / silver phosphate nano-wire compositepore channel scaffold can be used as the carrier of silver phosphate nanometer materials, and during the preparation, the preparation parameters can be adjusted according to the progress of the reaction so as to adjust the morphology and the density of the in-situ growing silver phosphate nanometer crystal.

Owner:HEFEI UNIV OF TECH

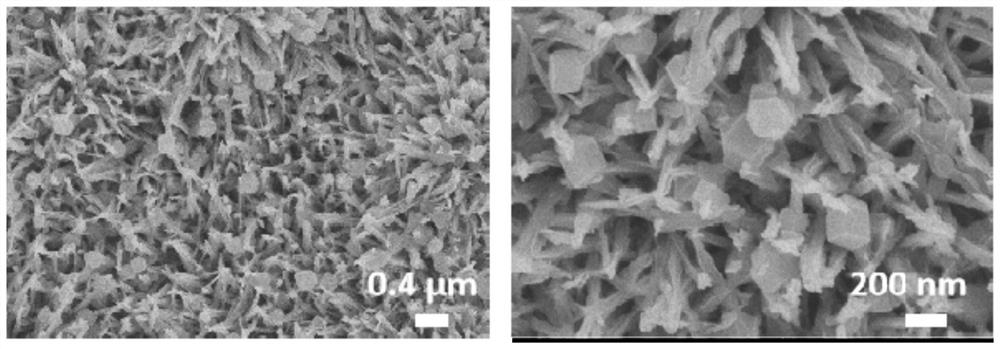

Method for in-situ construction of metal organic framework nanoparticles on surface of titanate

ActiveCN113737178AImprove surface hydrophilicity and hydrophobicityImprove surface roughnessMaterial nanotechnologyNanomedicineFiberMetal-organic framework

The invention belongs to the field of surface modification of biological implant materials, and particularly relates to a method for in-situ construction of metal organic framework nanoparticles on the surface of titanate. The method comprises the following steps that titanium alloy is subjected to alkali heat treatment, and a titanate structure with a special shape is formed on the surface of the titanium alloy; and on the basis, Zn<2+> ions are adsorbed in titanate by utilizing the interlayer cation loading capacity of the titanate, a 2-methylimidazole ligand is dropwise added on the surface of the titanate, a growth environment of the metal organic framework nanoparticles is provided, and the metal organic framework nanoparticles controllably grow on titanate fibers in situ by regulating and controlling the concentration of a solvent and the ligand. The metal organic framework nanoparticles prepared by the method tightly wrap the titanate fibers, the original nanofiber structure of the titanate is reserved, the nanostructure morphology of the titanate can be enriched, the large specific surface area of the metal organic framework nanoparticles and the titanate structure can be used as a loading platform of two different systems, and the intelligent medicine carrying function is realized.

Owner:CHANGZHOU UNIV

A kind of preparation method of porous carbon nanofiber felt and porous carbon nanofiber electrode

InactiveCN104342852BLow costRegulation densityHeating/cooling textile fabricsNon-woven fabricsAir atmosphereOrganic solvent

The invention provides preparation methods of porous carbon nanofiber felt and a porous carbon nanofiber electrode. The preparation method of the porous carbon nanofiber felt is characterized by comprising the following steps of 1, dissolving a high molecular polymer and a pore former in an organic solvent to form a polymer solution, 2, spinning the polymer solution into nanofiber felt by an electrostatic spinning technology, and 3, allowing the nanofiber felt in Step 2 to complete a preoxidation process in an air atmosphere and then performing high-temperature carbonization on the nanofiber felt under inert gas shielding to form the porous carbon nanofiber felt. The preparation method of the porous carbon nanofiber electrode comprises the following steps of preparing the porous carbon nanofiber felt in accordance with the method, and then directly attaching the porous carbon nanofiber felt on a current collector to form the electrode. According to the methods, cheap and recycling dimethyl sulfone is selected as the pore former, so that the cost is effectively lowered.

Owner:DONGHUA UNIV

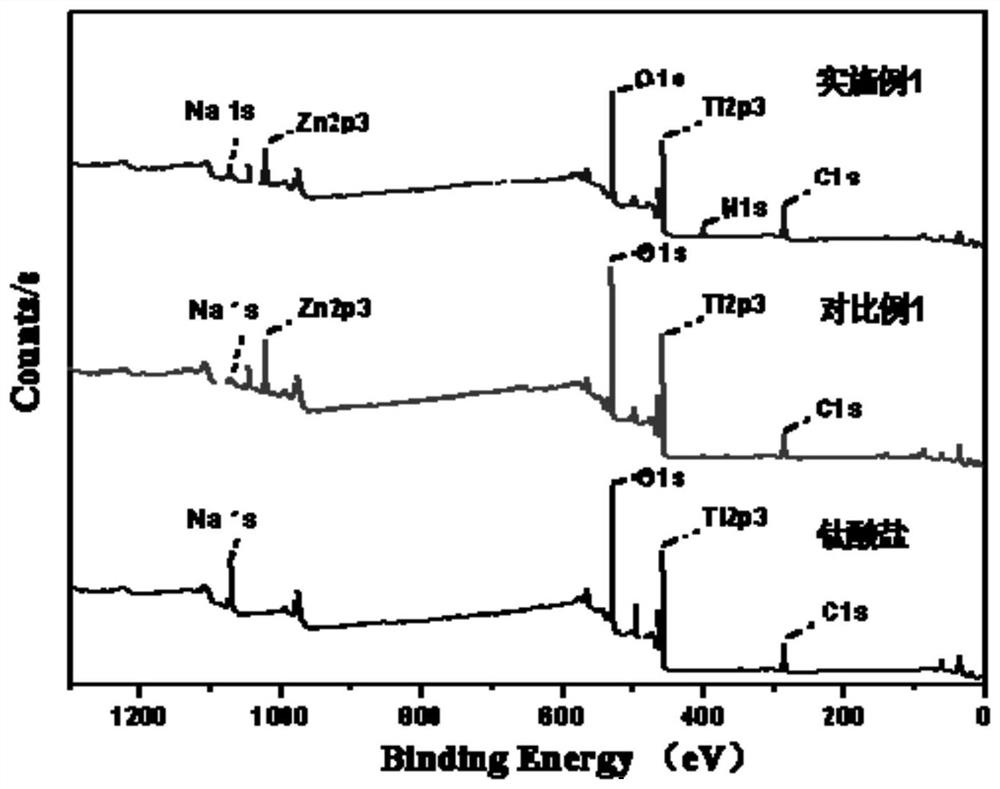

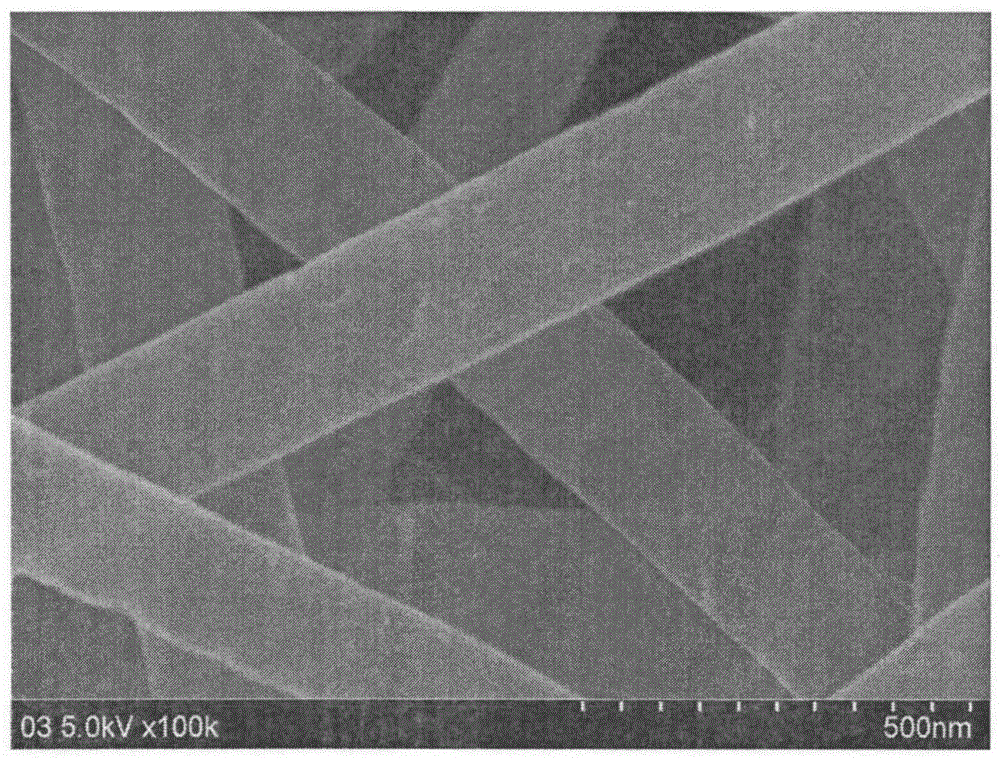

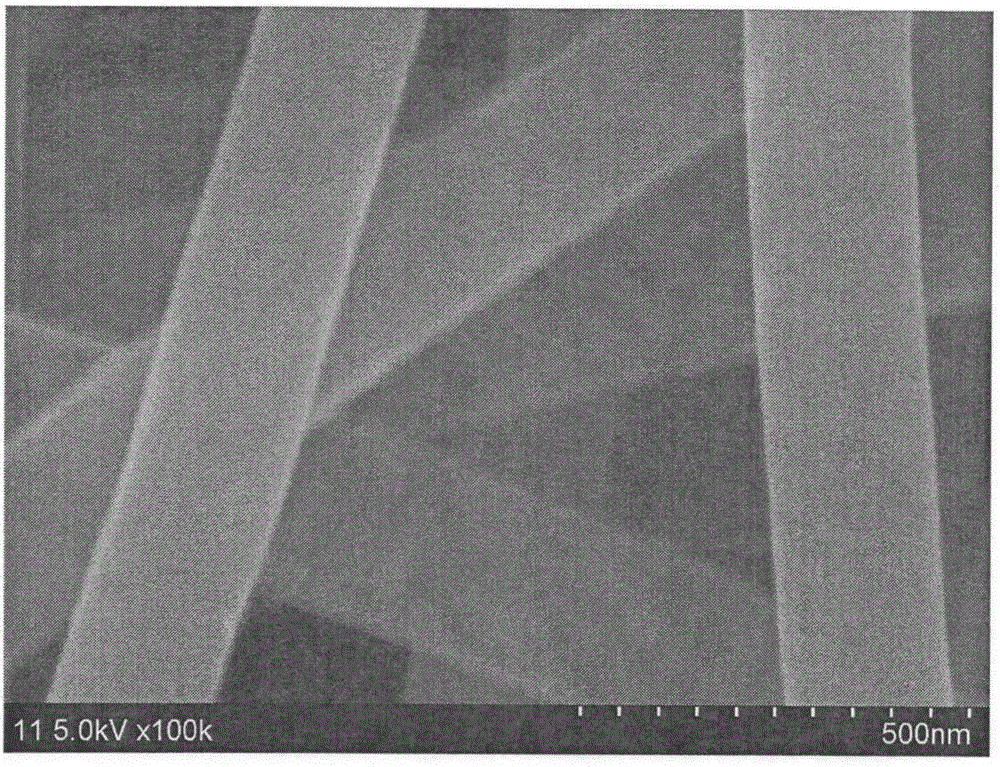

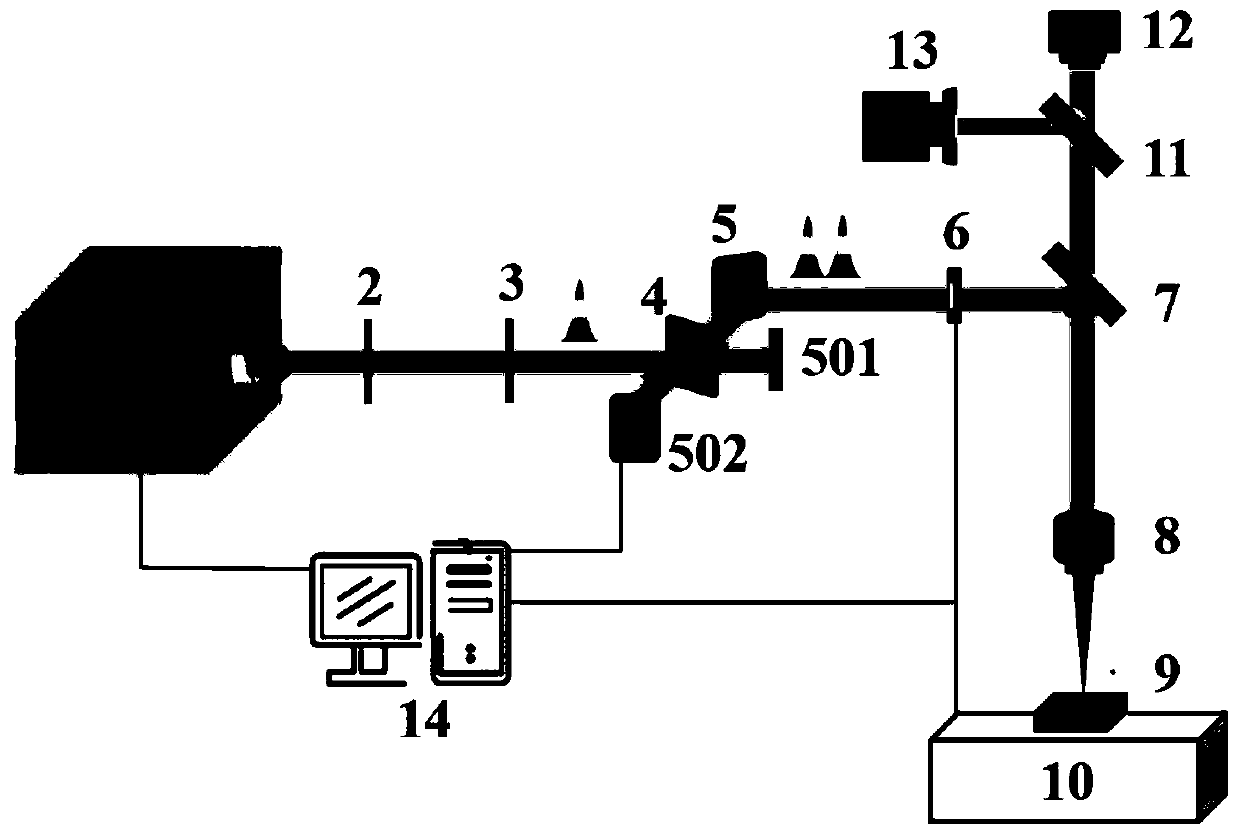

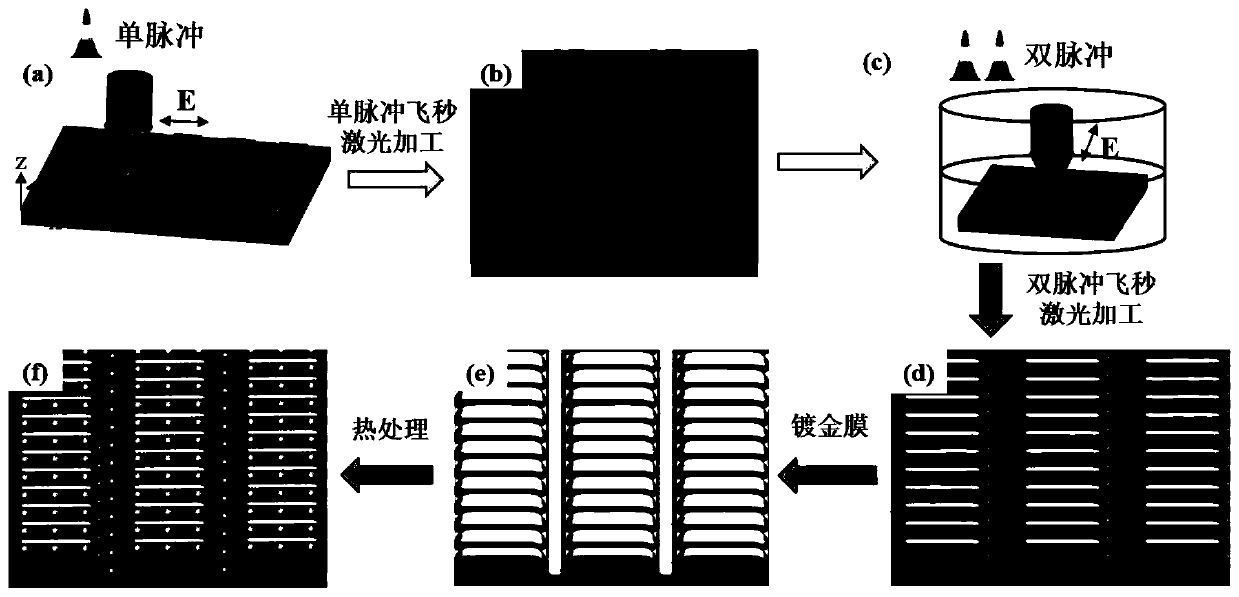

A Surface-Enhanced Raman Substrate Fabrication Method Based on Electron Dynamic Control

ActiveCN107132210BAvoid thermal effectsImprove uniformityMaterial nanotechnologyRaman scatteringAqueous solutionChemical stability

The invention relates to an electronic dynamic regulation-based method for manufacturing a surface-enhanced raman substrate (SERS), and belongs to the technical field of raman spectrum molecular detection. The method comprises the following steps: (1) preparing a large-area consistent periodical wavy structure on a silicon substrate in the air by utilizing single pulse femtosecond laser; (2) performing secondary processing by utilizing 90-degree polarized dual-pulse femtosecond laser in an aqueous solution to prepare a nano-bar array structure; (3) plating a metal film having a nano-thickness on the nano-bar array substrate by utilizing an electron evaporating method; and (4) heating the metal film-plated nano-bar array substrate in a muffle furnace. A great number of uniform metal nano-particles cover the nano-bar array substrate after the heat treatment. Compared with the prior art, the method for manufacturing the SERS active substrate has the advantages of good sensitivity, good chemical stability, good space uniformity and relatively low manufacture cost.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Lightweight low-loss silicon carbide series refractory material and preparation method thereof

InactiveCN107382364AHigh porosityImprove thermal shock resistanceCeramicwarePorositySilicon membrane

The invention relates to a lightweight low-loss silicon carbide series refractory material and a preparation method thereof. Silicon carbide powder and a pore-forming agent are taken as raw materials for forming a green body; the green body generates a silicon carbide sintered body at high temperature; the surface of the silicon carbide sintered body is coated with a layer of dense silicon membrane. By using the pore-forming agent, relatively-high porosity of the silicon carbide series refractory material is ensured, thermal shock resistance of the material is improved, the weight of the material is reduced, and the cost of the raw materials is reduced. Due to the adoption of the silicon membrane layer, the contact between an internal material of the silicon carbide series refractory material and the outside can be effectively isolated, and further the oxidation resistance of the silicon carbide series refractory material is remarkably improved; whether the material is dense or not has no influence on stability and service life of the material. A used coating method is a conventional mature coating technology, stable, simple to control, convenient in control of the coating thickness, coating density or coating material and facilitates industrial production and application.

Owner:长兴泓矿炉料有限公司

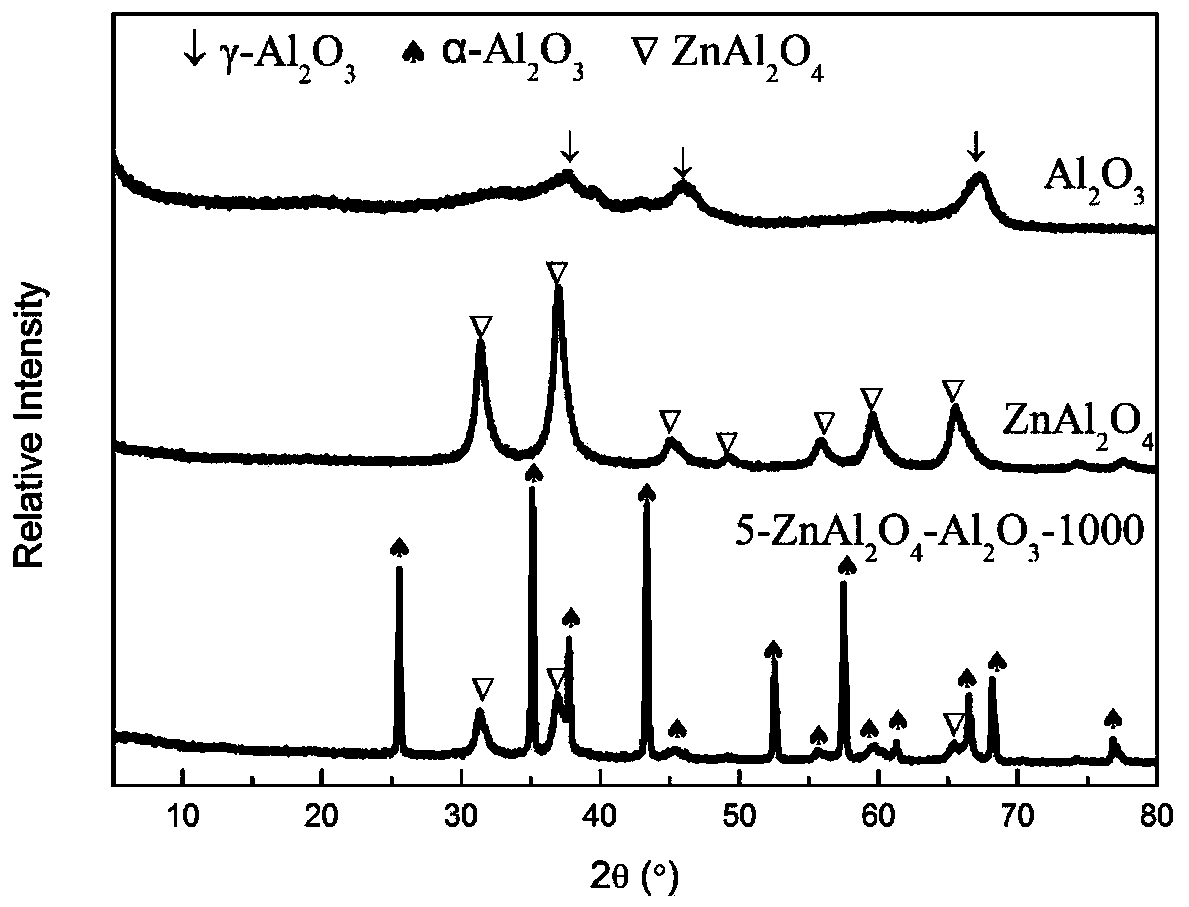

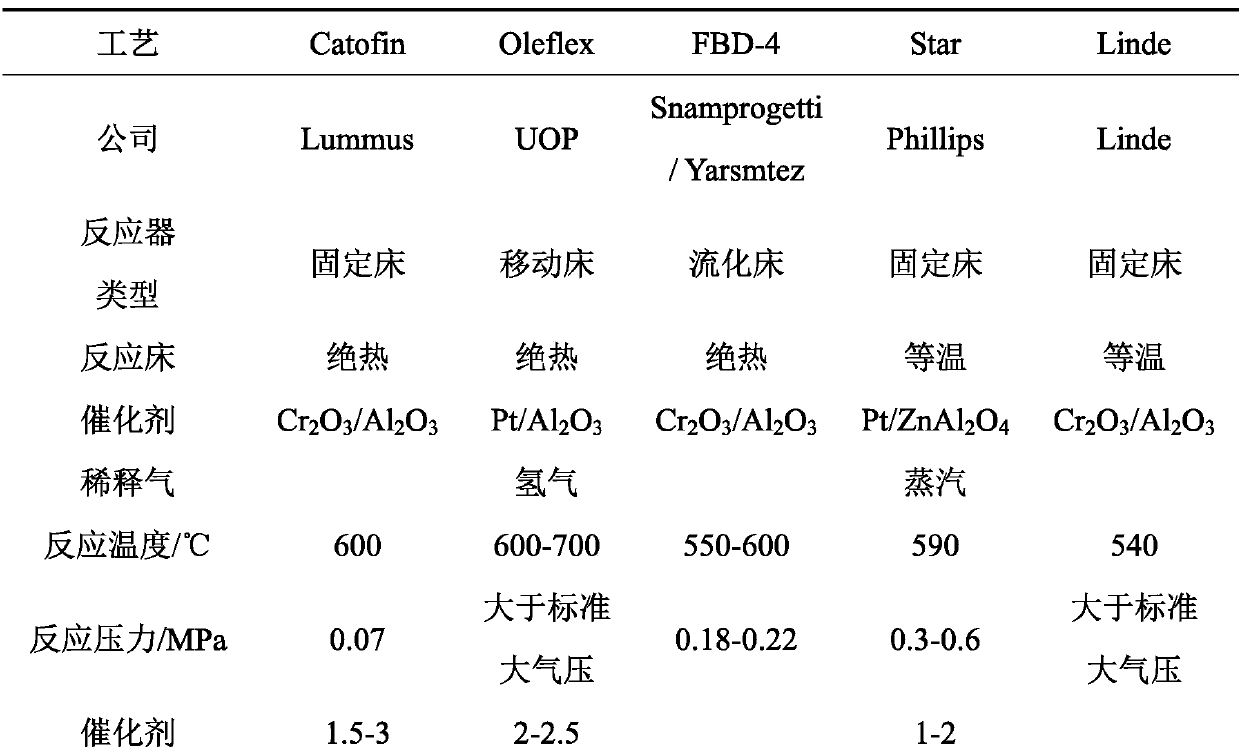

Isobutane dehydrogenation catalyst and preparation method and application thereof

ActiveCN111437813AHigh selectivityImprove stabilityHeterogenous catalyst chemical elementsCatalystsPtru catalystPhysical chemistry

The invention discloses an isobutane dehydrogenation catalyst and a preparation method and application thereof. According to the catalyst, alpha-Al2O3 spheres which are subjected to zinc oxide surfacemodification and heat treatment to form a thin-layer zinc aluminate spinel structure are used as a carrier; a first active layer and a second active layer which are different from each other are sequentially arranged on the surface of the carrier from inside to outside, the first active layer is a platinum oxide layer or a tin oxide layer, and the second active layer is a platinum oxide layer ora tin oxide layer. The isobutane dehydrogenation catalyst has high selectivity, stability and activity, good high-temperature stability, strong carbon deposition resistance and low relative deactivation rate, the active components are distributed on the carrier in an eggshell structure, the utilization rate of the active components is increased and the catalyst has a good industrial application prospect.

Owner:XIAMEN UNIV

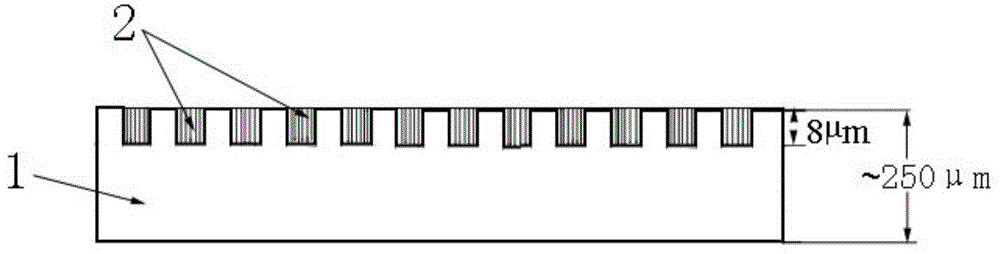

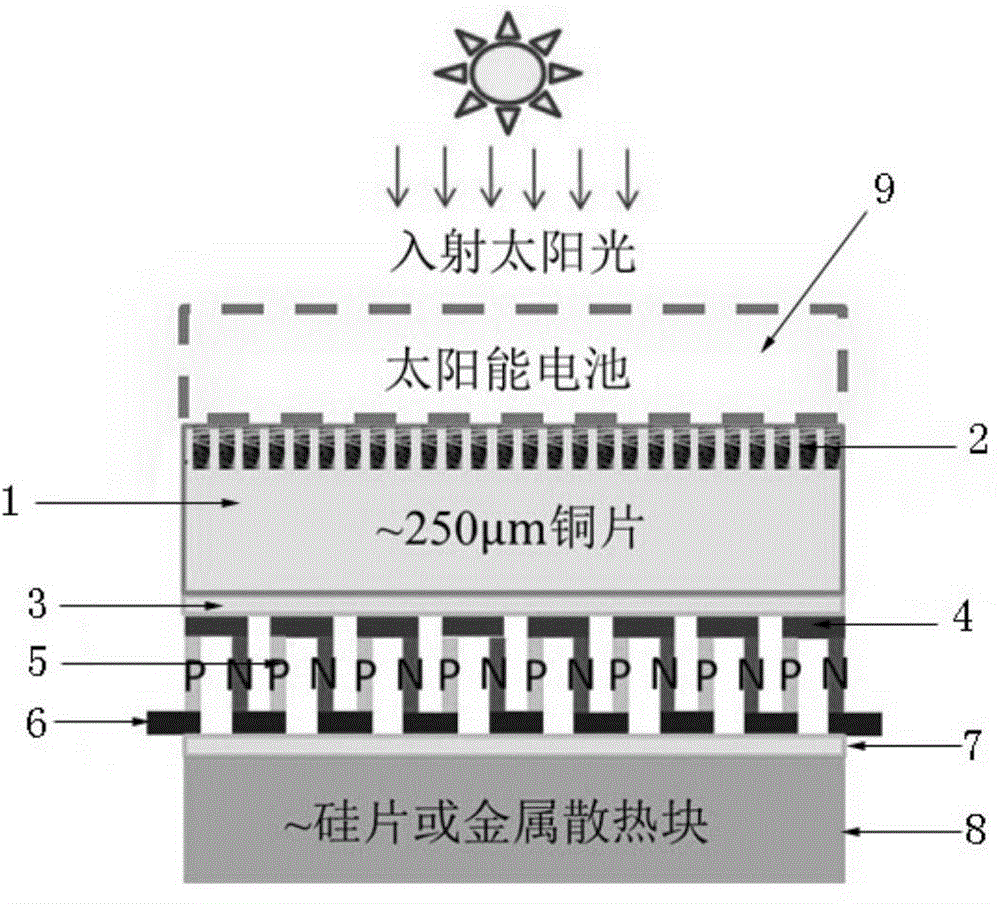

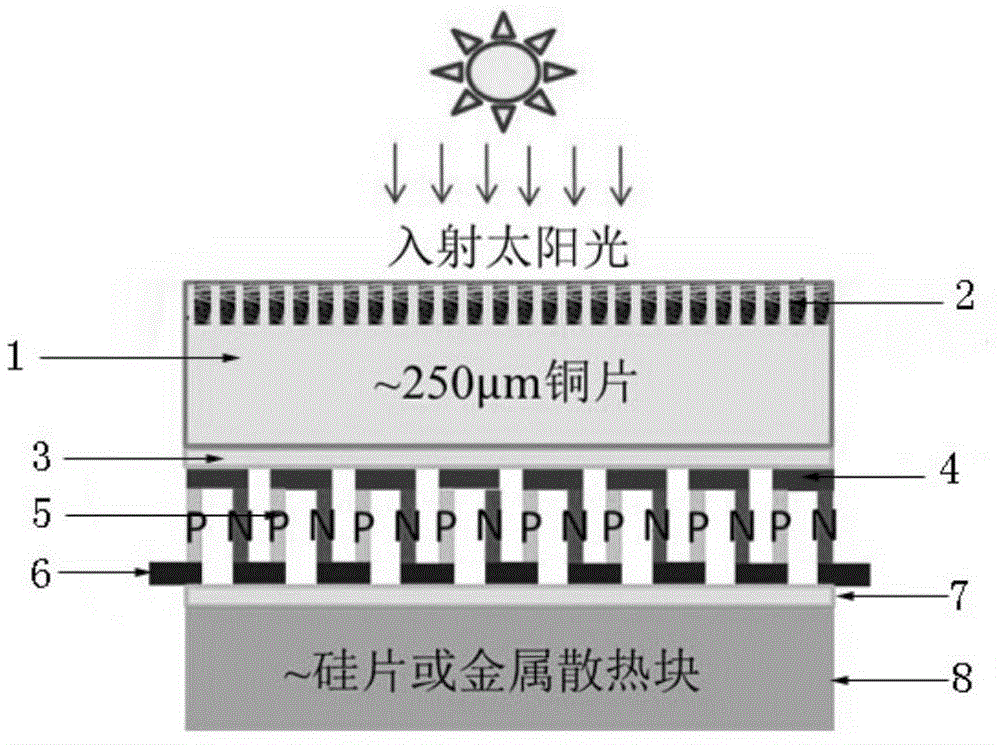

Carbon nano fiber/ copper composite material and application thereof in thermal battery energy conversion device

ActiveCN105720186AStructural regulationRegulation densityThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentFiberThermoelectric materials

The invention discloses a carbon nano fiber / copper composite material and application thereof in a thermal battery energy conversion device. Firstly, the surface of a copper sheet is polished to obtain a copper sheet material with a high specific surface, so that carbon nano fibers can be in well contact with copper and heat conduction is facilitated; and then carbon nano fibers are grown on the surface of copper to obtain the carbon nano fiber / copper sheet composite material. The carbon nano fibers grown by the method have very high absorption within nearly full sunlight bands, and can convert solar radiation energy into thermal energy; the copper substrate has good heat conductivity, and can quickly conduct the heat absorbed by the carbon nano fibers to a semiconductor thermoelectric material of a thermal battery, to integrate a solar energy-thermal battery device, thus realizing efficient solar energy-electric energy conversion. The composite material has good industrial application prospect and basic science research value.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Hydration-resistant magnesite-calcium refractory material and preparation method thereof

InactiveCN107285781AImproves hydration resistanceImprove slag resistanceRefractoryTemperature resistance

The invention relates to a hydration-resistant magnesite-calcium refractory material. The magnesia-calcium based refractory material is characterized in that a granular magnesite-calcium refractory material is used as a raw material, a layer of compact aluminum oxide film covers a surface of the magnesite-calcium refractory material through a physical vapor deposition method; by the film layer, contact between CaO freed in the magnesite-calcium refractory material and external moisture can be effectively isolated, thereby obviously improving the hydration-resistant performance of the magnesite-calcium refractory material. According to the material, the active CaO in the magnesite-calcium refractory material can be well preserved, and the damage to molten steel purification performance of the magnesite-calcium refractory material is avoided; meanwhile, an aluminum oxide component of the surface of the material has the advantages of low cost, little pollution, high-temperature resistance and low damage possibility; moreover, the service life of the material is prolonged, and the production cost is greatly reduced. A used coating method is already a very technologically-mature commonly-used coating technique; the process is stable and simple to control, the coating thickness, the coating density or a coating material are very convenient to regulat and control, and industrial production application is facilitated.

Owner:长兴泓矿炉料有限公司

Preparation method of black silicon substrate with ultra-low reflectivity micro-nano composite structure

ActiveCN110729379AEfficient preparationReduce surface reflectivityFinal product manufacturePhotovoltaic energy generationEtchingSolar battery

The invention relates to a preparation method of a black silicon substrate with an ultra-low reflectivity micro-nano composite structure, relates to the field of preparation of a low reflectivity black silicon substrate, and aims to solve the problem that the surface reflectivity of the existing silicon substrate is high, resulting in low efficiency of the solar cell. The method comprises the steps: a Cu metal catalysis-assisted chemical etching method is used and the silicon substrate is etched with the mixed solution of CuNO3, HF and H2O2 to generate a micron-sized trapped light structure; then the structure is placed in the mixed solution of AgNO3 and HF for self-assembly deposition of silver nanoparticles; and then the mixed solution of HF and H2O2 is adopted for Ag metal catalysis-assisted chemical etching so as to complete the preparation. The silicon substrate with the micro-nano pattern array realizes ultra-low surface reflectivity, efficiently prepares the micro-nano pattern array structure, has high repeatability and can adjust and control the reflectivity by optimizing etching conditions. The black silicon substrate with the ultra-low reflectivity micro-nano composite structure is used in solar cells.

Owner:HARBIN INST OF TECH

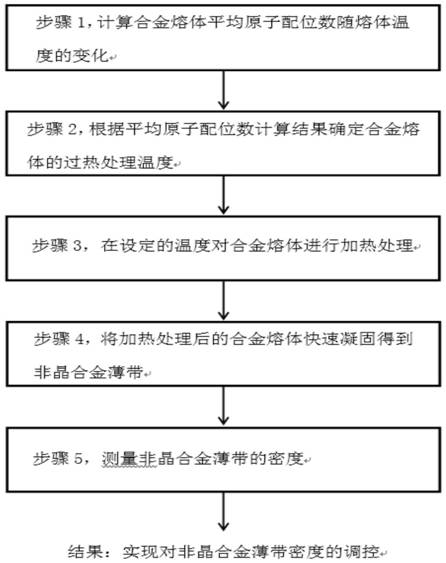

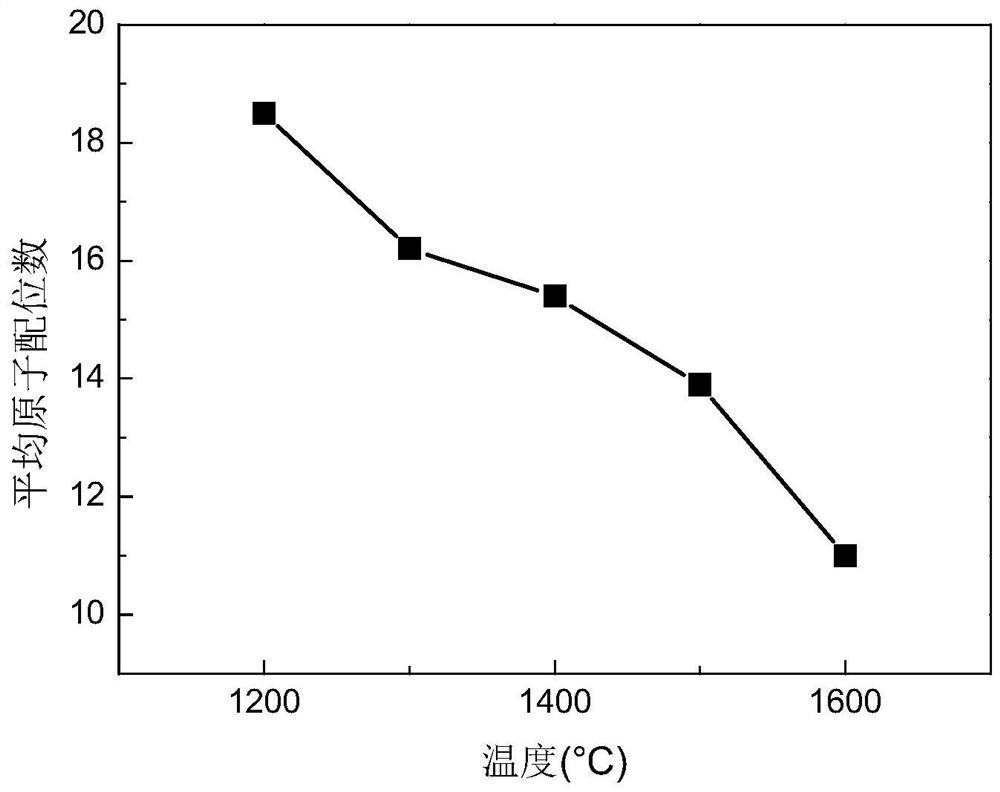

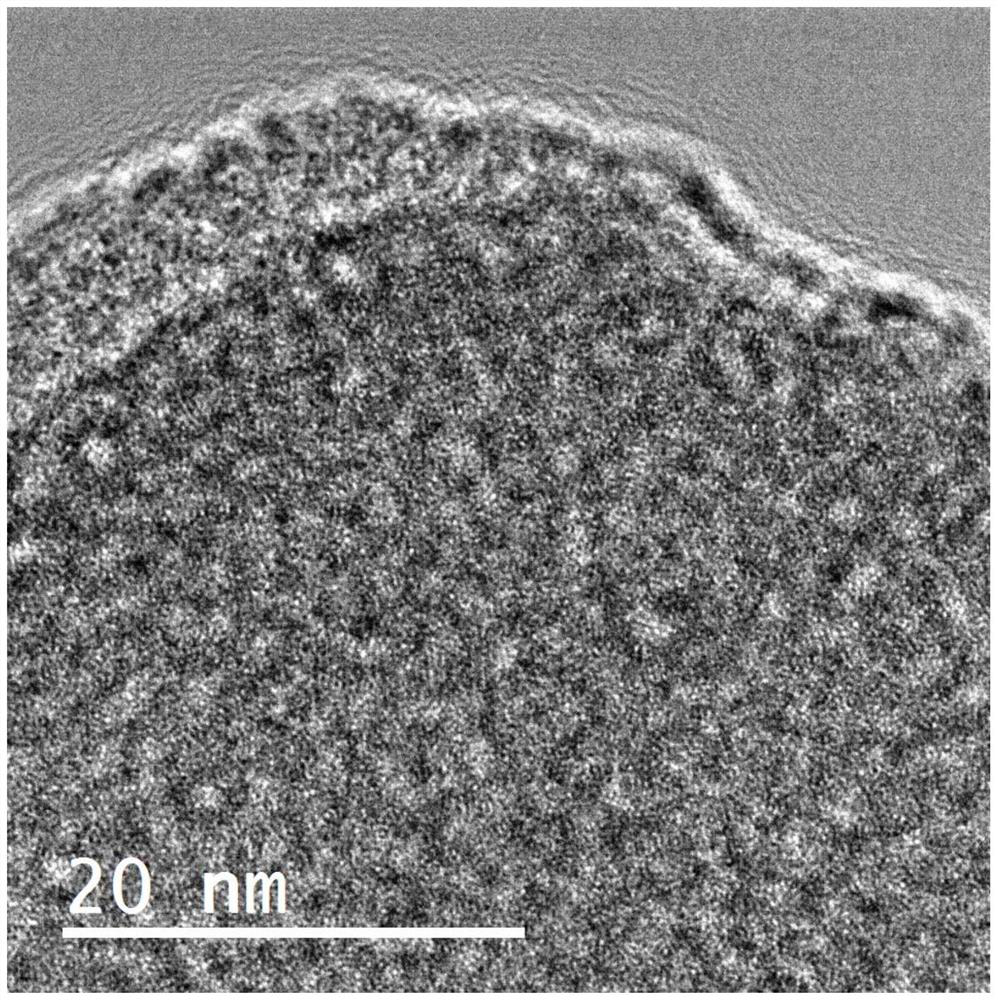

A control method for the density of amorphous alloy

The invention discloses a method for regulating and controlling the density of an amorphous alloy. The method comprises the steps that average atomic coordination numbers of an amorphous alloy melt are calculated, specifically, the average atomic coordination numbers of the amorphous alloy melt at different temperatures are calculated, and a calculation result of the average atomic coordination numbers varying with the temperatures is obtained; heat treatment is performed on the alloy melt, specifically, the required average atomic coordination number is selected according to the calculation result, the temperature corresponding to the selected average atomic coordination number is determined as a superheat treatment temperature of the alloy melt, the alloy melt is insulated at the superheat treatment temperature to obtain an alloy melt after superheat treatment; and rapid solidification is performed, specifically, rapid solidification is performed the amorphous alloy melt after the superheat treatment to obtain an amorphous solid alloy. According to the method for regulating and controlling the density of the amorphous alloy, a new concept and method for designing and preparing the microstructure of the amorphous alloy are provided, and the characteristics such as simple and convenient implementation, high efficiency, low cost, high controllability and repeatability and high technical reliability are achieved.

Owner:创明(韶关)绿色能源材料技术研究院有限公司

Plasma body cleaning device

InactiveCN101837357BImprove securityRegulation densityCleaning processes and apparatusMaterial typeEngineering

The invention discloses a plasma body cleaning device, which mainly consists of a microwave system and a reaction device, wherein the microwave system comprises a microwave chamber, a microwave source and a microwave control circuit, the microwave source can be regulated and controlled through the microwave control circuit, and the regulation and the control on the density of the plasma body can be realized. The cleaning device effectively avoids the electrode pollution by adopting a microwave excitation mode, and simultaneously enlarges the pressure intensity work range. Because the microwave technology is mature, the microwave leakage can be easily controlled and protected, the cleaning device has good safety performance. The work pressure intensity can be controlled through regulating and controlling the flow speed of the cleaning reaction gas and the gas pumping speed of a vacuum device, the power of the microwave source can be controlled through the microwave control circuit, andthe bombarding force on the surface of cleaning samples by the plasma body and the concentration of the plasma body can be effectively regulated. Thereby, the cleaning and the surface modification indifferent modes can be carried out according to the cleaning samples in different material types.

Owner:浙江尧瑶科技有限公司

Regulatory approaches to skyrmions in the hexagonal mnniga

ActiveCN106653262BRegulation densityProcess stabilityInorganic material magnetismLow dimensional magnetism materialsHigh densityRoom temperature

The invention provides a regulation and control method for a Skyrmion in a hexagonal MnNiGa. The regulation and control method comprises the following steps of 1) applying a magnetic field to the hexagonal MnNiGa, wherein the magnetic field is not strong enough to convert a strip-shaped magnetic domain in the hexagonal MnNiGa into the Skyrmion; and the direction of the magnetic field is not parallel to a family of crystal plane [001] in the hexagonal MnNiGa; and 2) applying a current to or / and heating the hexagonal MnNiGa to enable the strip-shaped magnetic domain to disappear. By virtue of the regulation and control method, a high-density Skyrmion array is formed in the hexagonal MnNiGa material system; and in addition, the high-density Skyrmion can exist in both of a null field and a wide-temperature-range room temperature.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

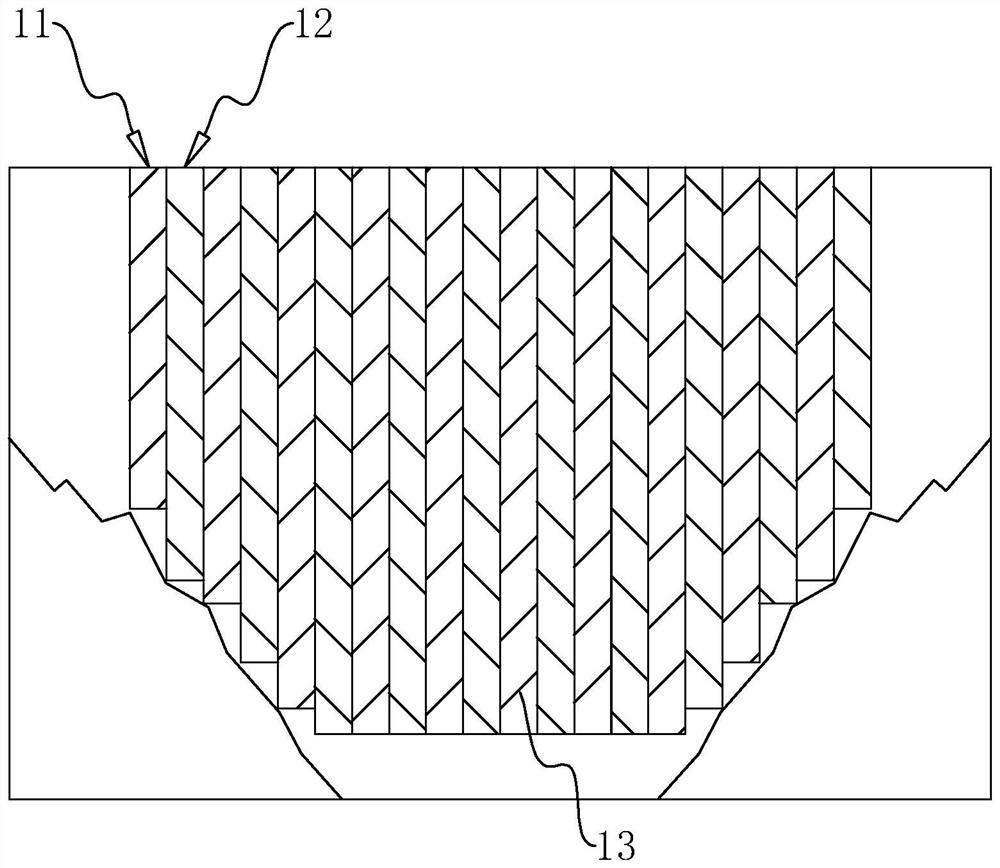

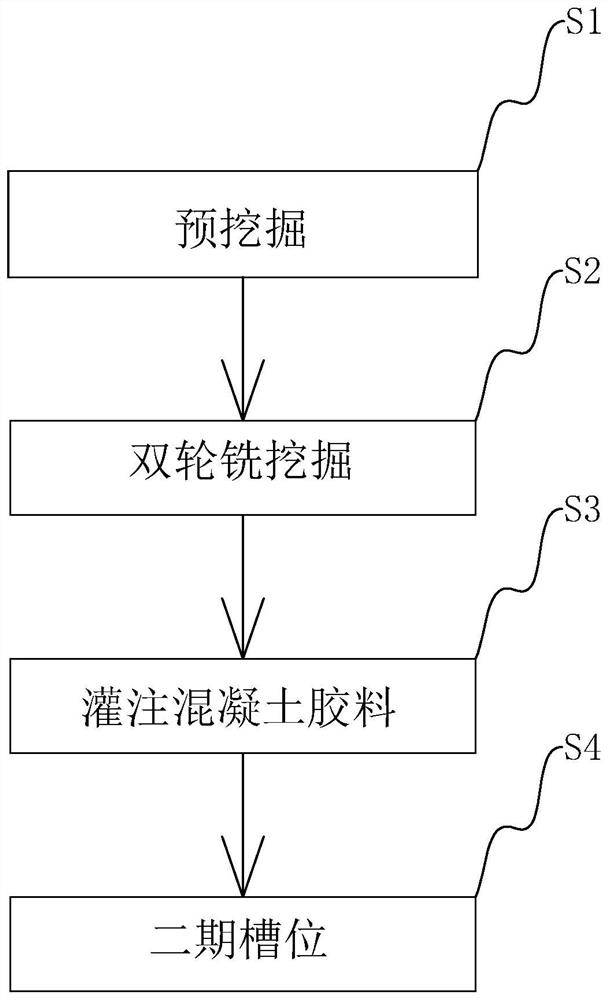

Double-wheel milling diaphragm wall structure and construction process thereof

ActiveCN114032883AGuaranteed liquid levelRegulation densityBulkheads/pilesSludgeStructural engineering

The invention discloses a double-wheel milling diaphragm wall structure and a construction process thereof. The construction process comprises the following steps that S1, pre-excavation is conducted, specifically, a plurality of first-stage groove positions which are arranged at intervals are formed firstly, excavation is conducted on the first-stage groove positions in the vertical direction, corresponding soil is carried out of the groove holes, and meanwhile slurry is poured into the groove holes; S2, double-wheel milling excavation is conducted, specifically, the groove holes are further excavated through double-wheel milling, and meanwhile slurry is poured into the groove holes; S3, concrete slurry is poured, specifically, the concrete slurry is gradually poured into the bottom of the groove holes, and meanwhile, slurry is injected, pumped out and temporarily stored; and S4, second-stage groove position forming is carried out, a second-stage groove position is formed between two adjacent first-stage groove positions, and the above operation is repeated. The double-wheel milling diaphragm wall structure has the effect of reducing the risk that the soil layer on the peripheral side of the groove hole is prone to collapse, and the risk of sludge accumulation at the bottom of the groove hole can be reduced.

Owner:红安县水电建筑安装公司

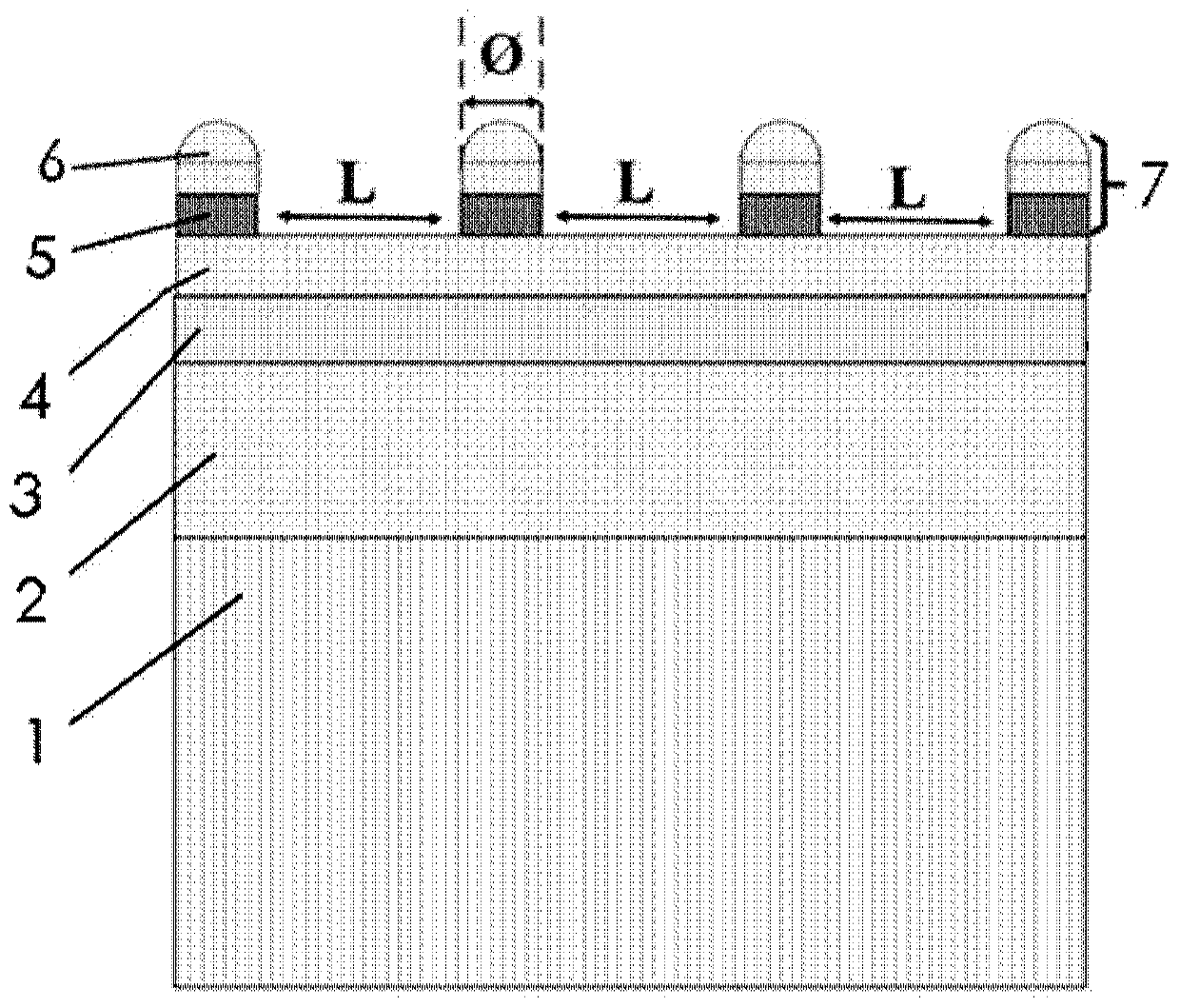

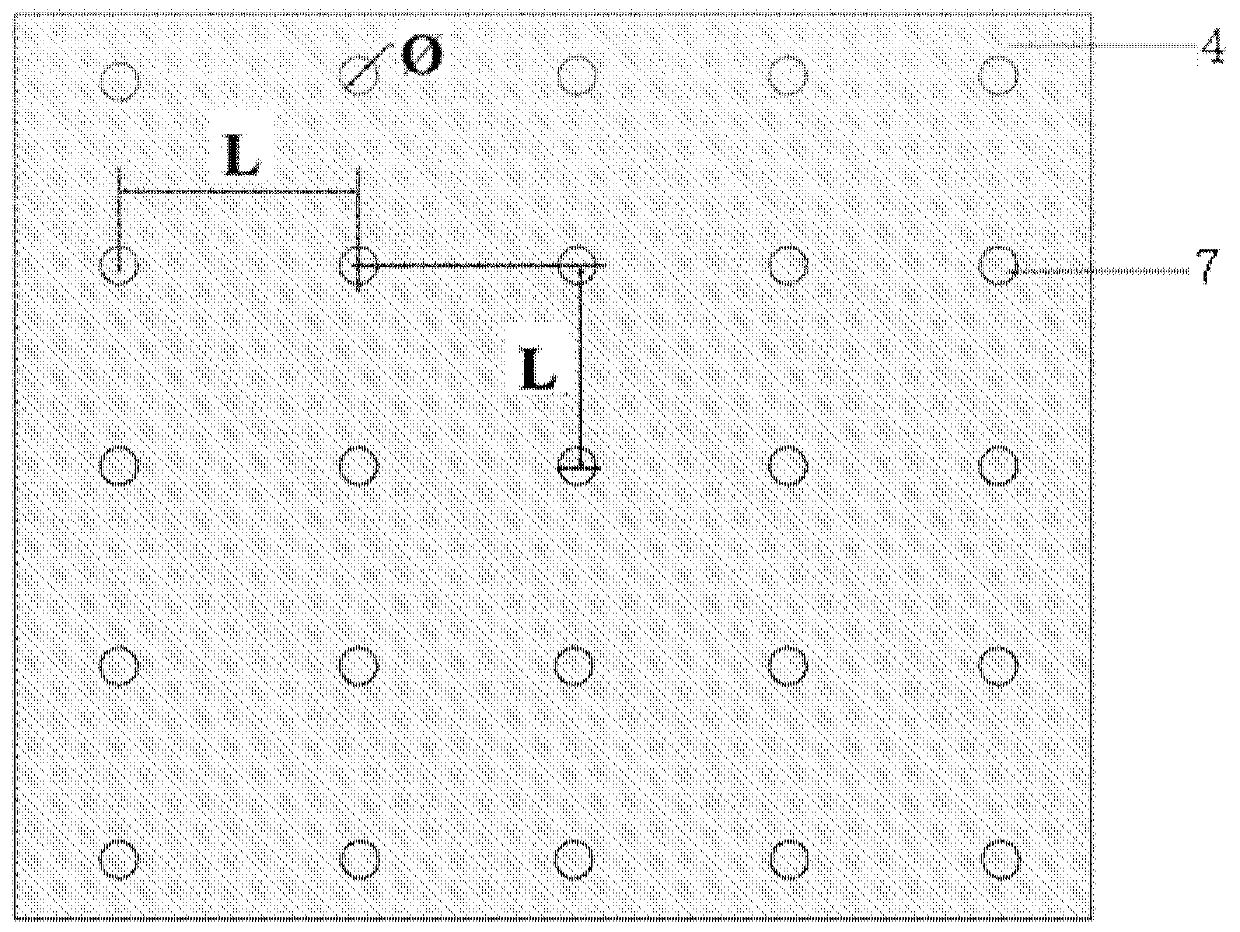

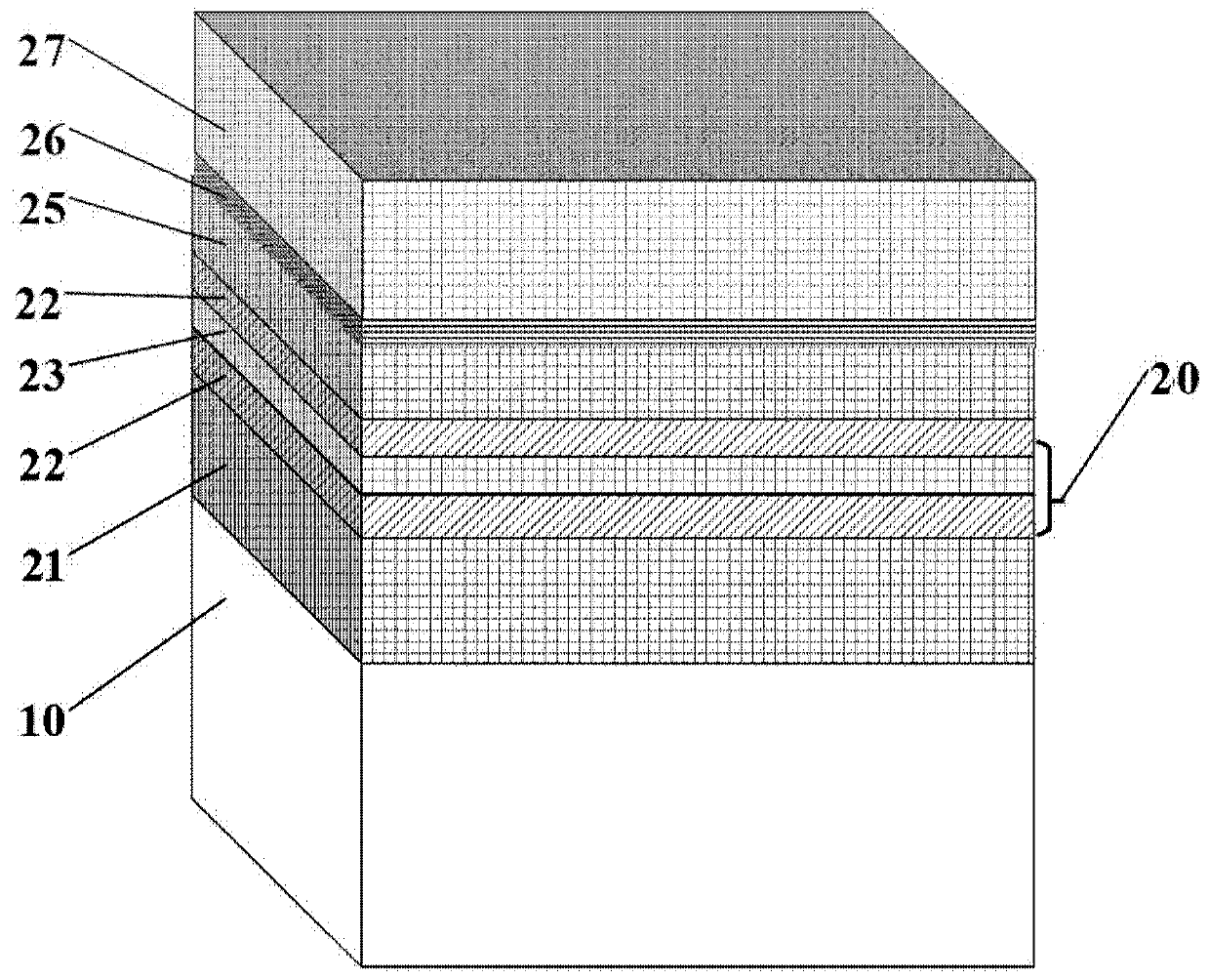

Quantum dot single photon source, preparation method and preparation method of device thereof

ActiveCN111525005ARegulation densityStructural regulationSemiconductor devicesFluorescenceParticle physics

The invention provides a quantum dot single photon source and a preparation method thereof, and a preparation method of a device of the quantum dot single photon source. The quantum dot single photonsource comprises a substrate, a buffer layer, and / or a DBR reflection layer, an absorption layer, an active layer, a cover layer, and a quantum dot array, wherein the buffer layer is arranged on the substrate, the DBR reflection layer is arranged on the buffer layer, the absorption layer is arranged on the DBR reflection layer, the active layer is arranged on the absorption layer, the cover layeris arranged on the active layer, the quantum dot array is obtained by etching the cover layer and the active layer, and the quantum dot array is located on the absorption layer. The fluorescence emissivity of the quantum dot single-photon source device is improved, and the yield of the manufactured quantum dot single-photon source device is improved.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Metal foam composite material and preparation method thereof

The invention provides a metal foam composite material and a preparation method thereof. The metal foam composite material comprises an inner core layer and a metal layer arranged on at least part of the surface of the inner core layer, wherein the density of the metal layer is not lower than 90%, the inner core layer comprises metal and a hollow inorganic material, and the hollow inorganic material is selected from at least one of fly ash, Al2O3 hollow ceramic balls or hollow silicon carbide. According to the invention, the inner core layer of the metal foam composite material comprises the metal and the hollow inorganic material, the pores exist in the inner cavity of the hollow inorganic material, and the density of the metal layer of the metal foam composite material is not lower than 90%, so that the metal foam composite material is small in density, high in strength and excellent in energy absorption and buffering performance; and the preparation method of the metal foam composite material is simple and easy to implement, and the metal foam composite material can be efficiently prepared.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

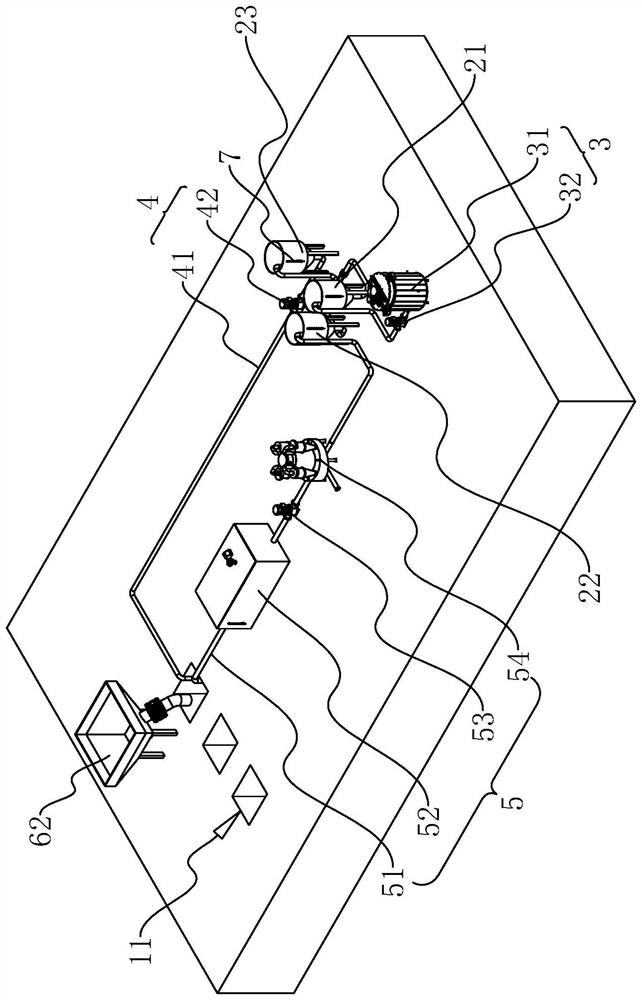

Preparation device and method for three-dimensional electrostatic spinning

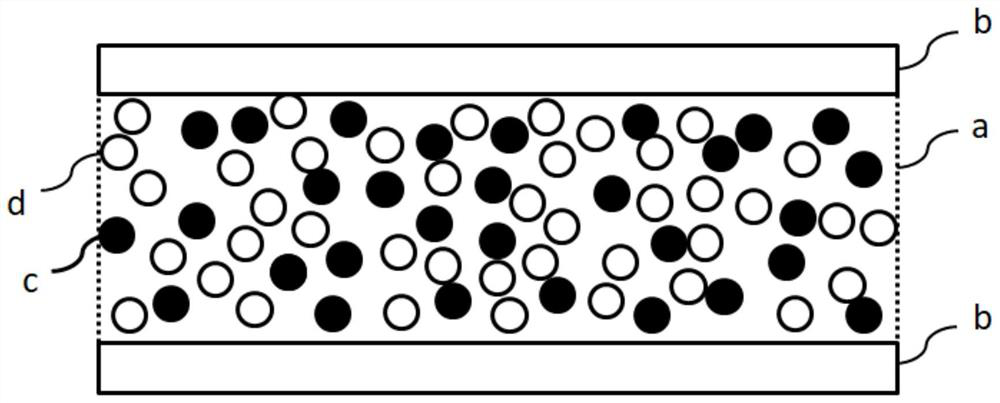

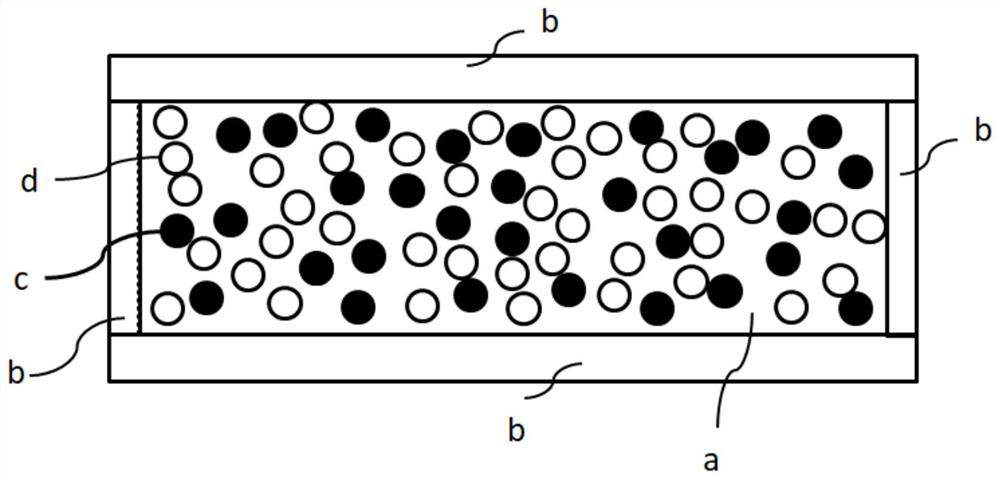

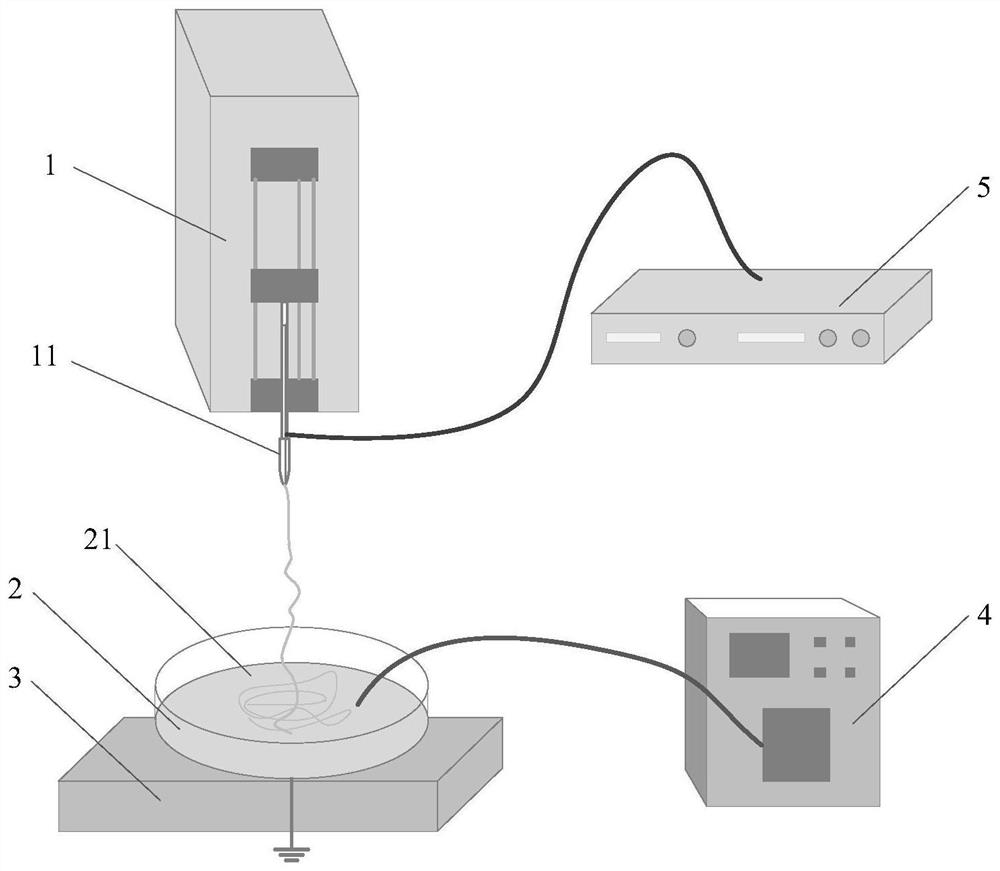

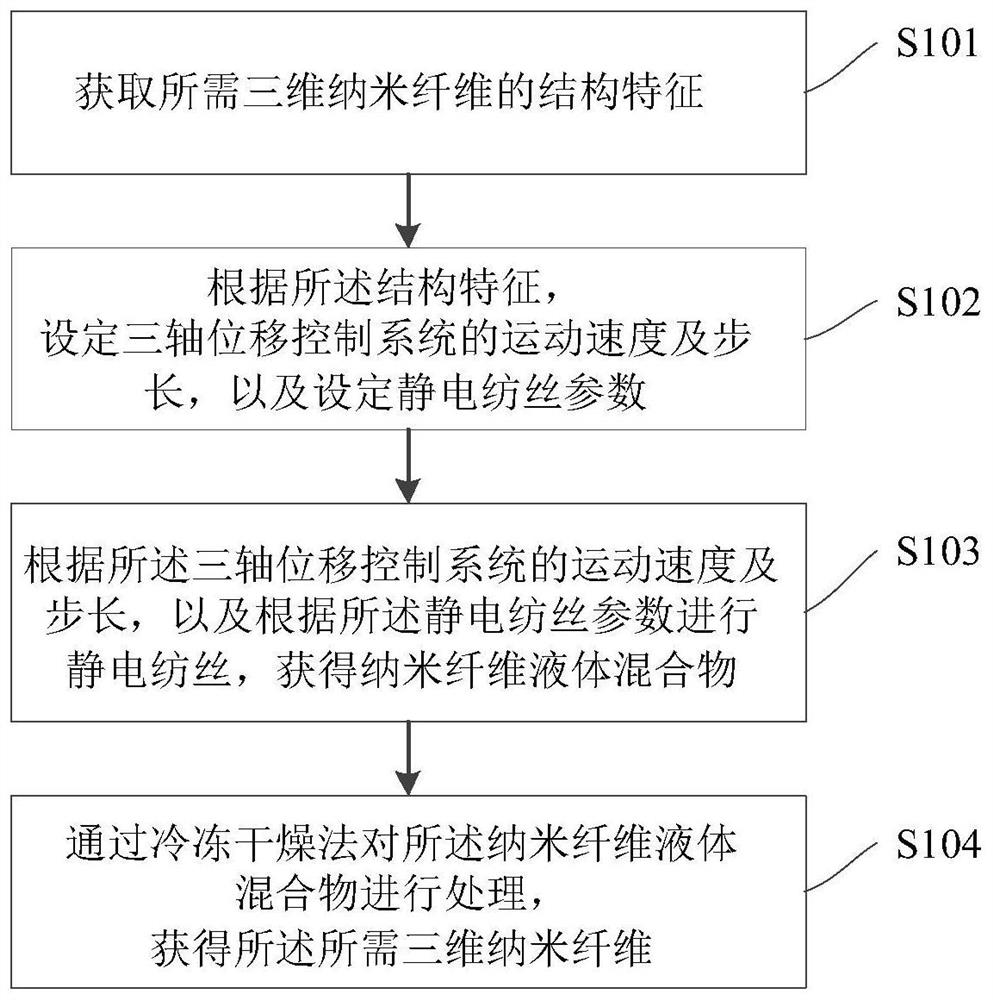

InactiveCN113308748ARegulation densityControl thicknessArtificial filament washing/dryingFilament/thread formingPhysicsPeristaltic pump

The invention relates to the technical field of electrostatic spinning, and provides a preparation device and method for three-dimensional electrostatic spinning. The preparation device for the three-dimensional electrostatic spinning comprises a peristaltic pump liquid pushing system, a liquid collecting device, a three-axis displacement control system and a liquid flow controller; a metal needle head is arranged on the peristaltic pump liquid pushing system, and the metal needle head is suspended above the liquid collecting device; the liquid collecting device is fixed to the surface of the three-axis displacement control system; a liquid pool connected with the liquid flow controller is arranged on the liquid collecting device and used for receiving the spinning solution ejected by the metal needle head; and collecting liquid is contained in the liquid pool and used for depositing nanofibers. By regulating and controlling the electrostatic spinning parameters and collecting the physicochemical properties of the liquid, the density and thickness of the three-dimensional nanofiber are regulated and controlled, the practicability and feasibility of the nanofiber are enhanced, and the application field of the nanofiber is widened.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com