Method for modifying polyamide composite thin film

A composite film and polyamide technology, which is applied in the field of post-treatment modified polyamide composite film, can solve the problems of reduced membrane effluent flux, increased membrane cleaning frequency, increased operating costs, etc., to achieve simple operation and reduce membrane pollution , the effect of great controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

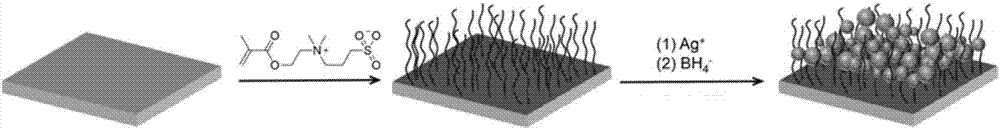

[0025] Specific embodiment one: the method for the modified polyamide composite film of this embodiment is carried out according to the following steps:

[0026] 1. Coupling dopamine and initiator: dissolving dopamine hydrochloride in dimethylformamide, then adding 2-bromoisobutyryl bromide and triethylamine under the protection of dryness and nitrogen and stirring to react to obtain the initiator dopamine coupling solution;

[0027] 2. Introduction of the initiator on the surface of the membrane: Tris buffer solution is added to the initiator dopamine coupling solution to obtain a mixed solution, and then the active layer on the surface of the polyamide TFC membrane is reacted with the mixed solution, and the active layer Initiator is grafted to form polymerized dopamine;

[0028] 3. Graft zwitterionic polymers on the surface of the membrane: Dissolve the zwitterionic monomers in isopropanol aqueous solution, pass nitrogen gas for 10 minutes, add copper chloride catalytic com...

specific Embodiment approach 2

[0032] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the dopamine hydrochloride described in step one is 800 mg, the volume of dimethylformamide is 40 mL, the volume of 2-bromoisobutyryl bromide is 0.26 mL, and the volume of triethyl bromide is 0.26 mL. The amine volume was 0.3 mL. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0033] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the quality of the zwitterionic monomer described in step three is 15.64g, and the volume of isopropanol aqueous solution with a mass concentration of 50% is 200mL. The volume of the copper chloride catalytic complex is 20 mL, and the volume of the ascorbic acid solution is 12 mL. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com