Patents

Literature

32 results about "Catalytic complex" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A protein complex which is capable of catalytic activity. [GOC:bhm, GOC:TermGenie, PMID:8077207]

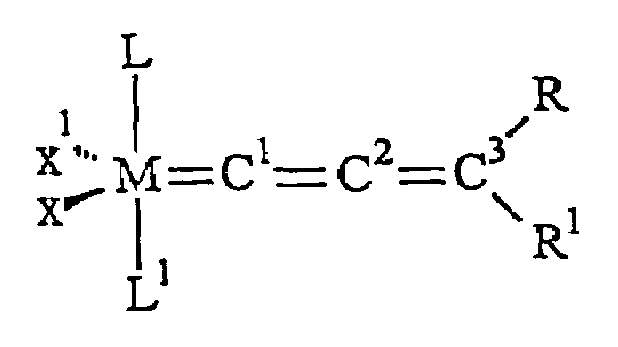

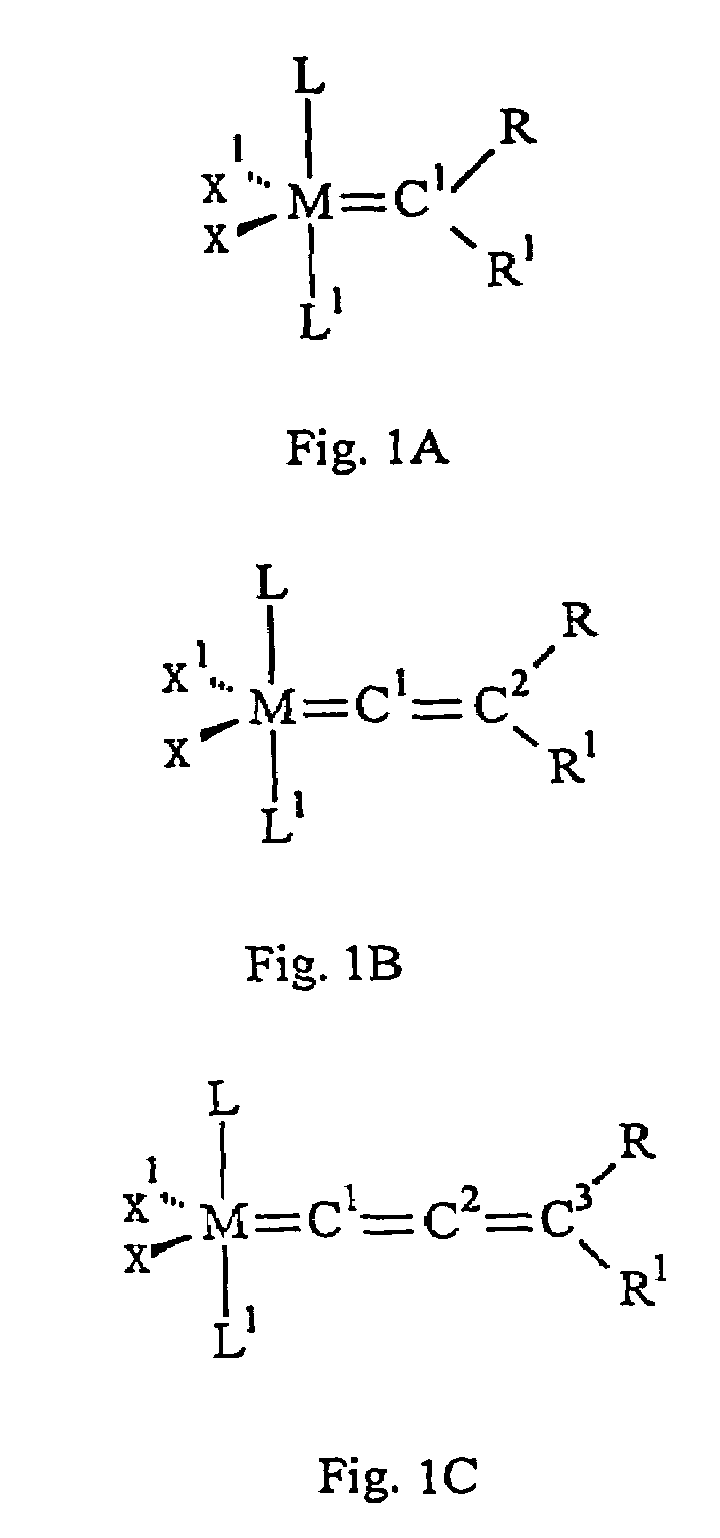

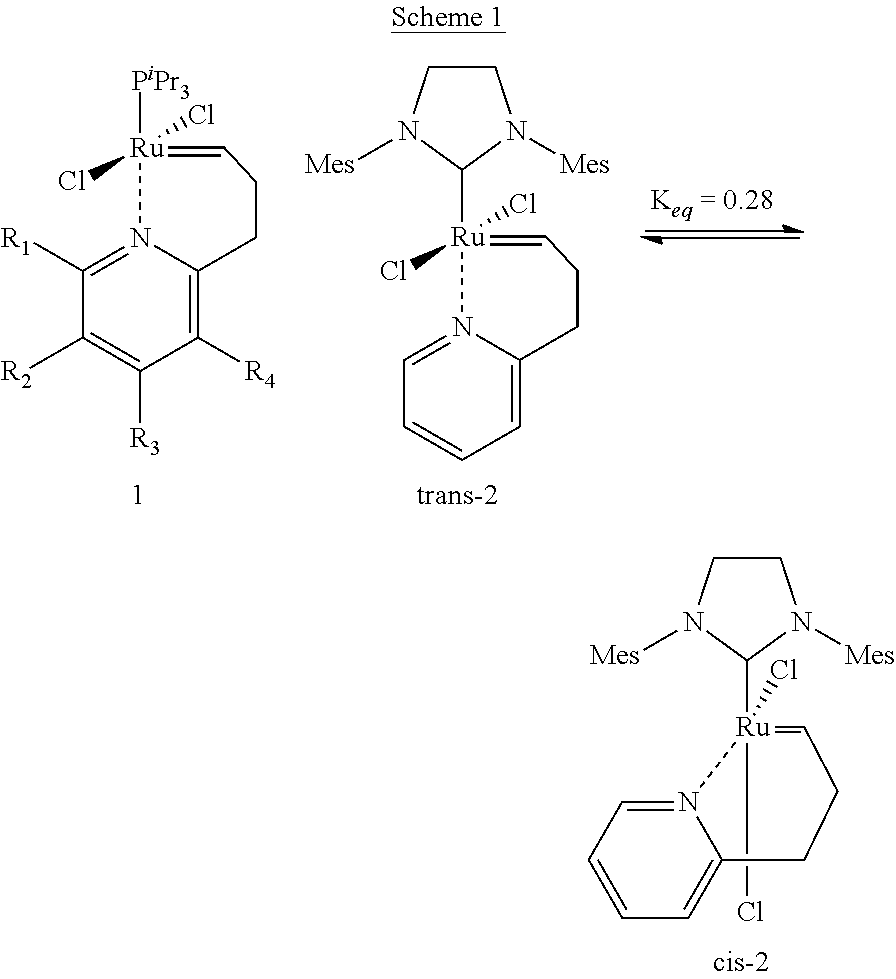

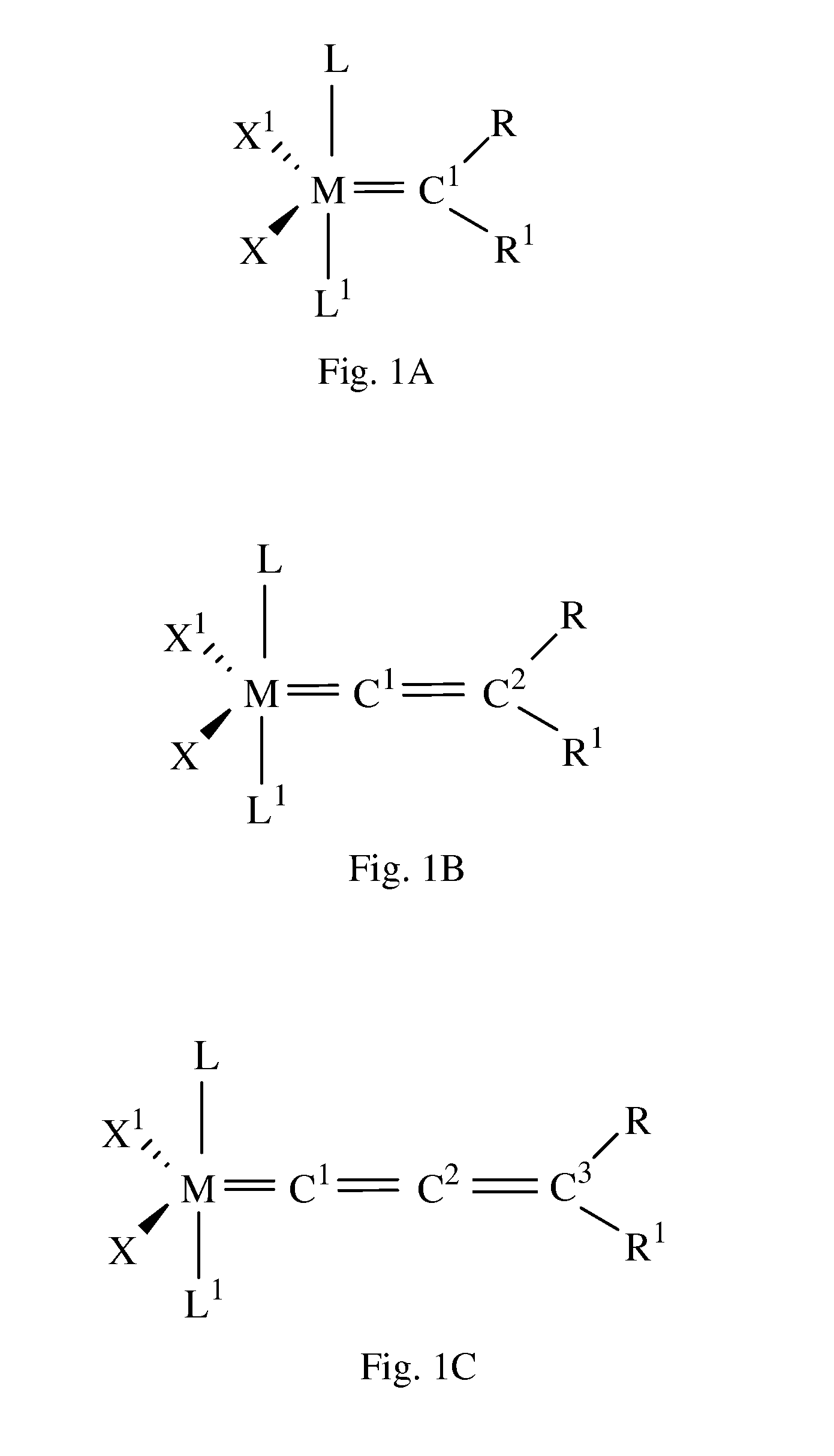

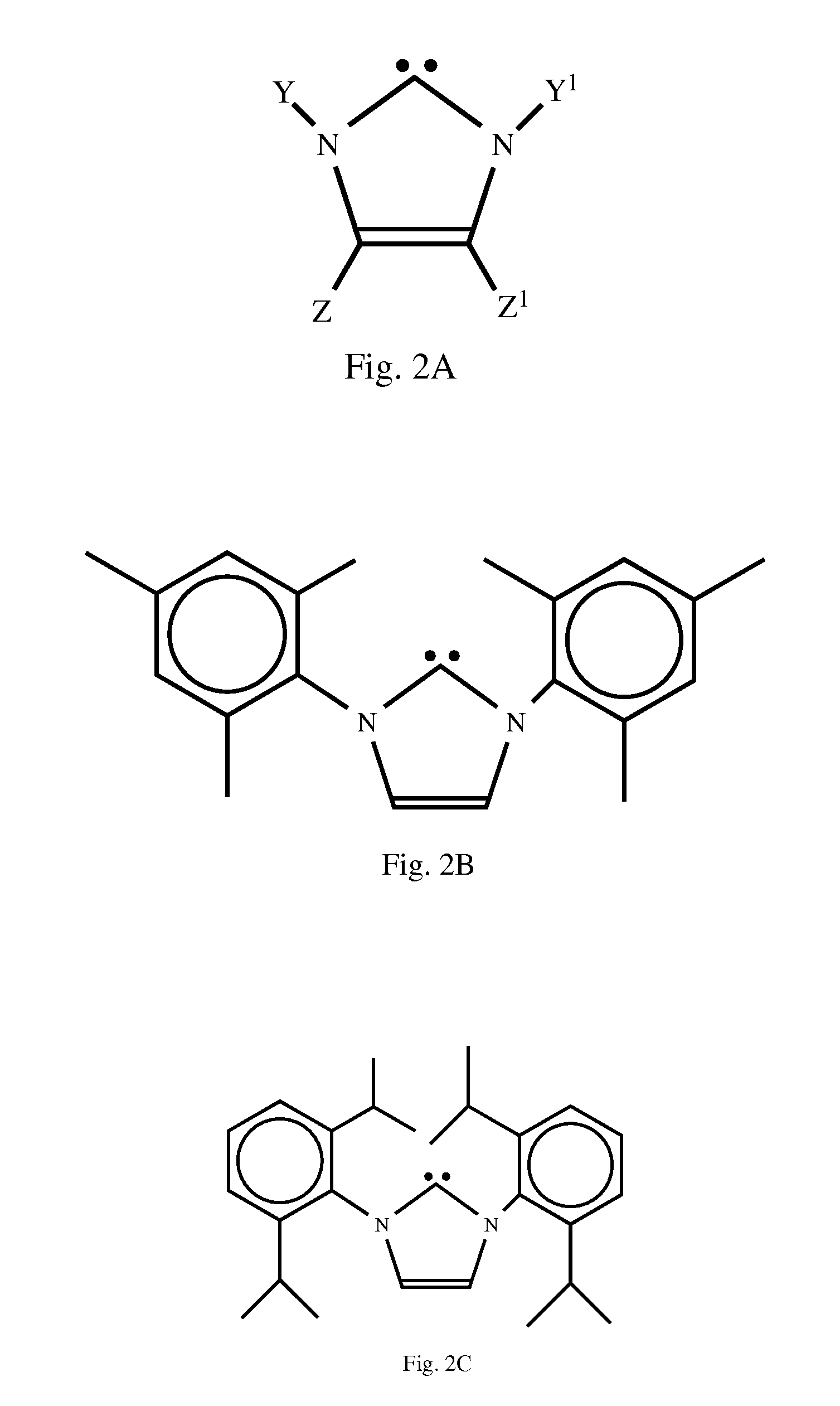

Catalyst complex with carbene ligand

InactiveUS7622590B1Increase response rateEasy to synthesizeHydrocarbon by isomerisationGroup 5/15 element organic compoundsCarbeneAlkene

Catalytic complexes including a metal atom having anionic ligands, at least one nucleophilic carbene ligand, and an alkylidene, vinylidene, or allenylidene ligand. The complexes are highly stable to air, moisture and thermal degradation. The complexes are designed to efficiently carry out a variety of olefin metathesis reactions.

Owner:MATERIA +1

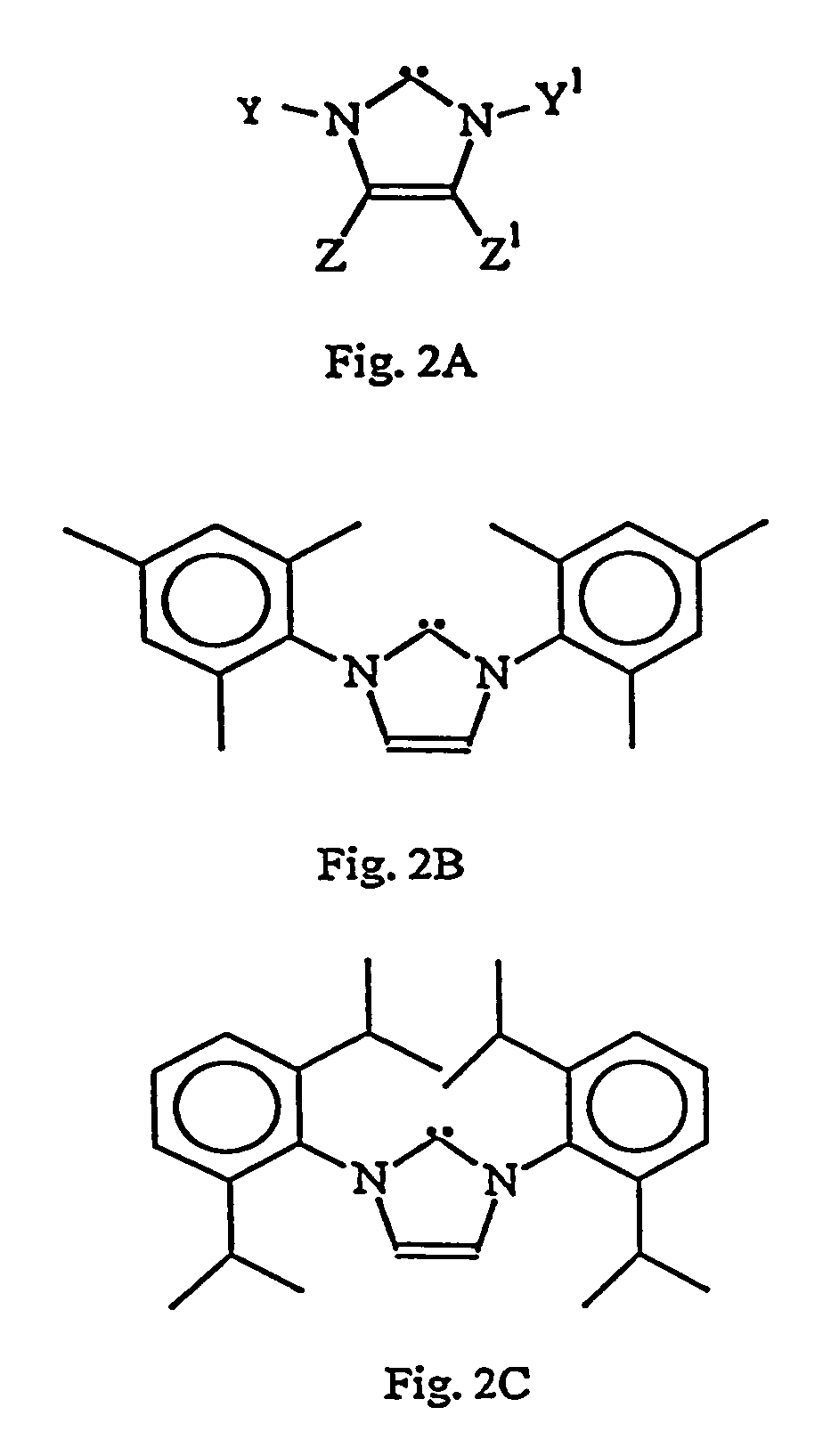

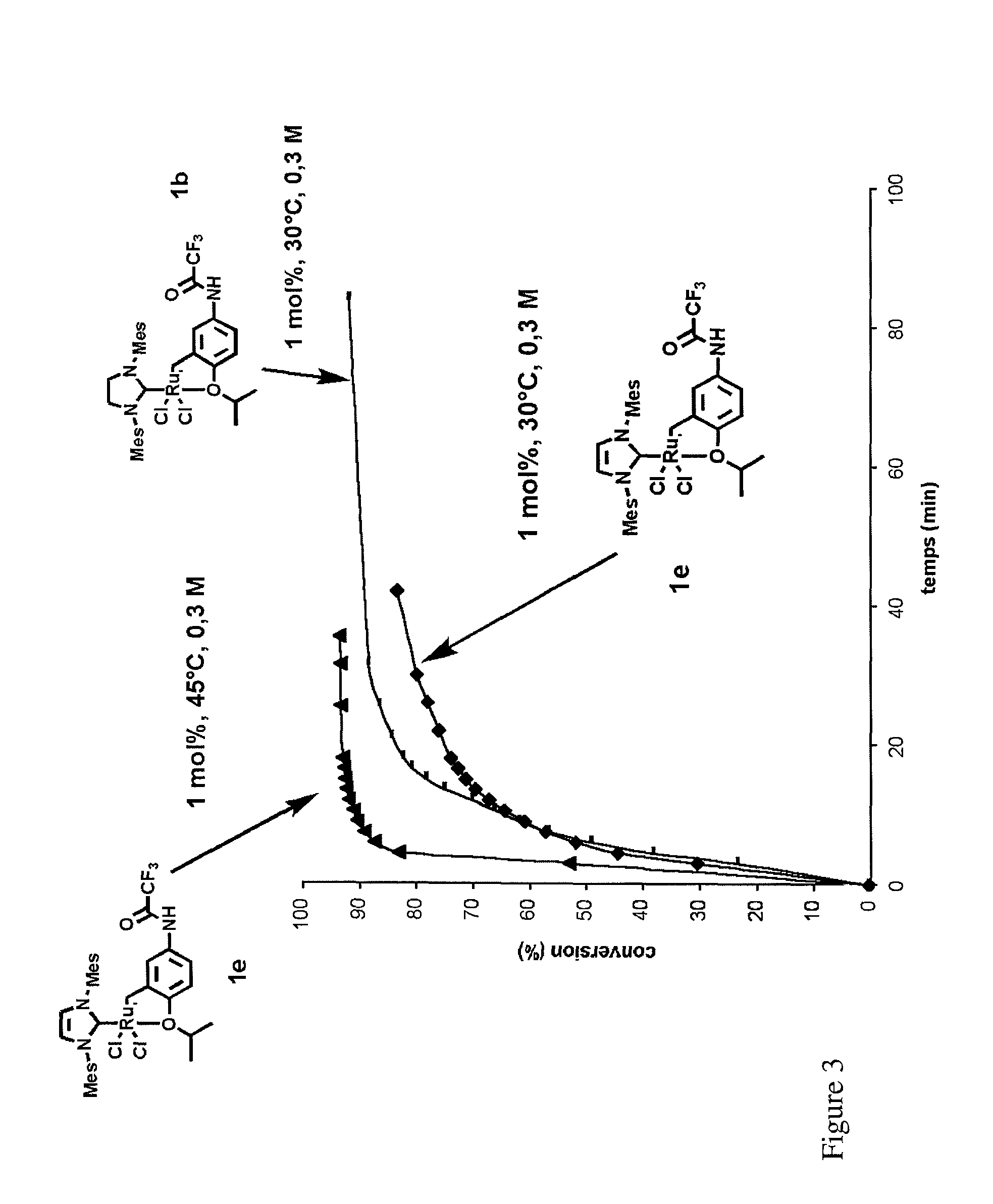

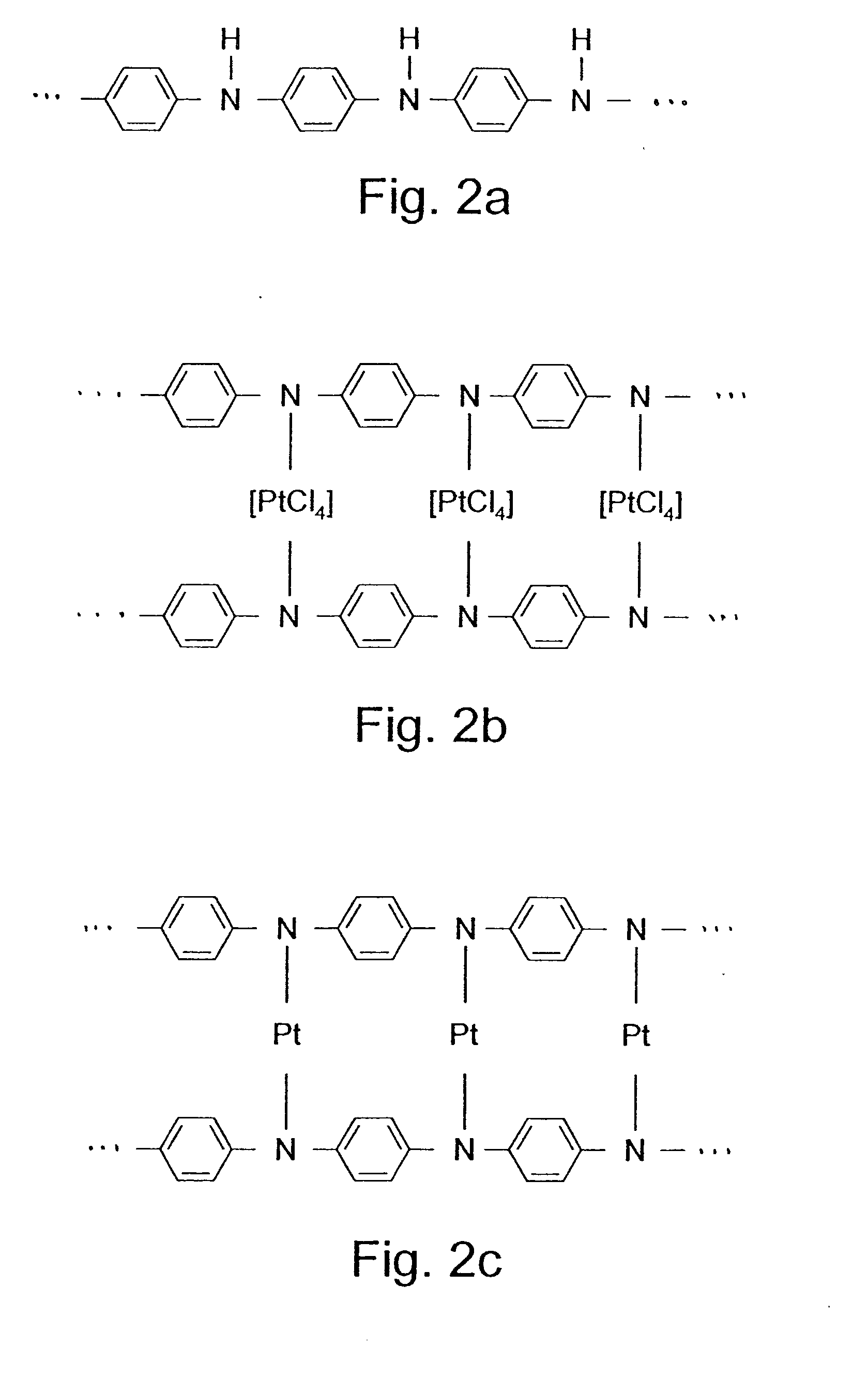

Class of electrocatalysts and a gas diffusion electrode based thereon for fuel cells

InactiveUS20020132157A1Organic-compounds/hydrides/coordination-complexes catalystsConductive materialFuel cellsConductive polymer

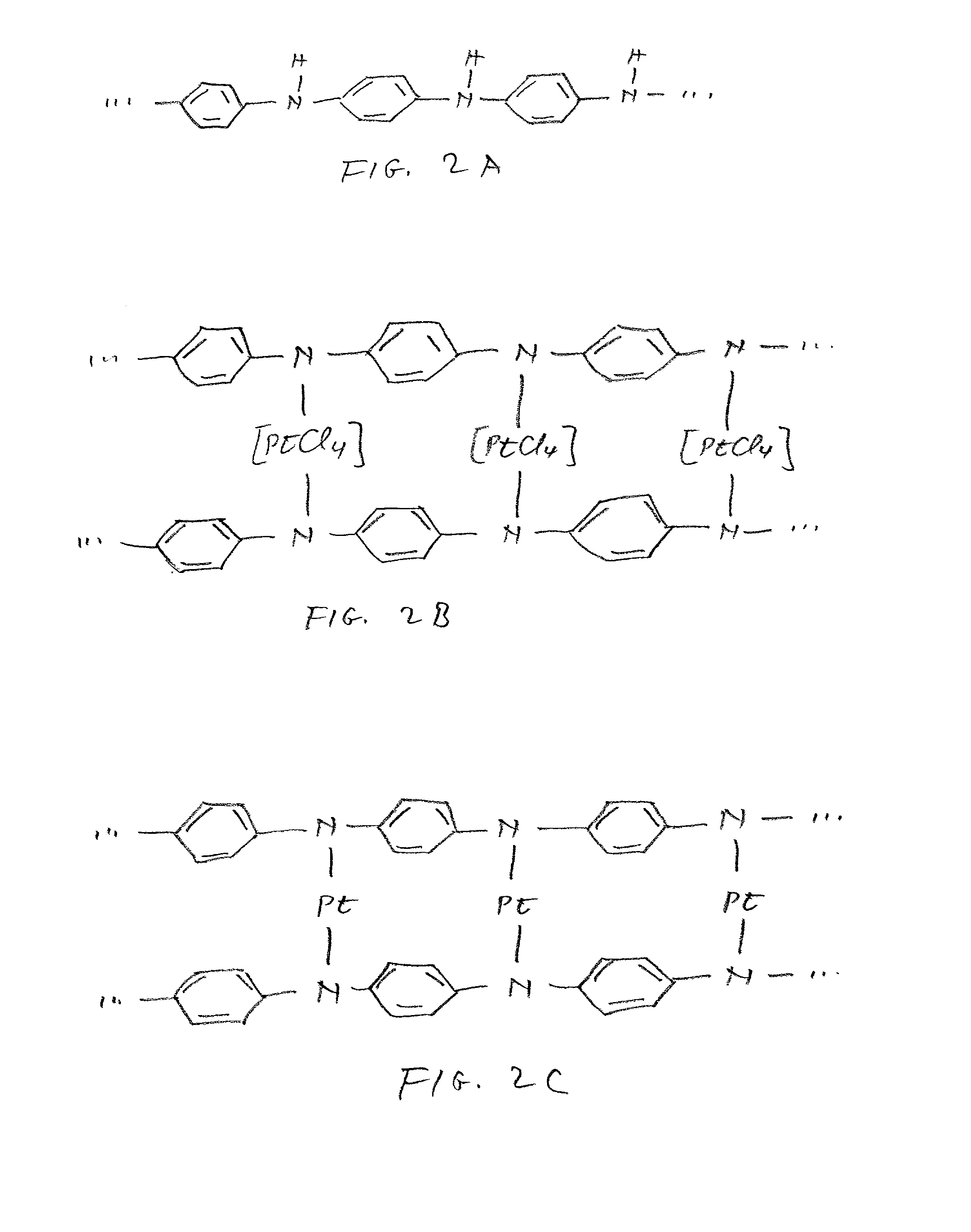

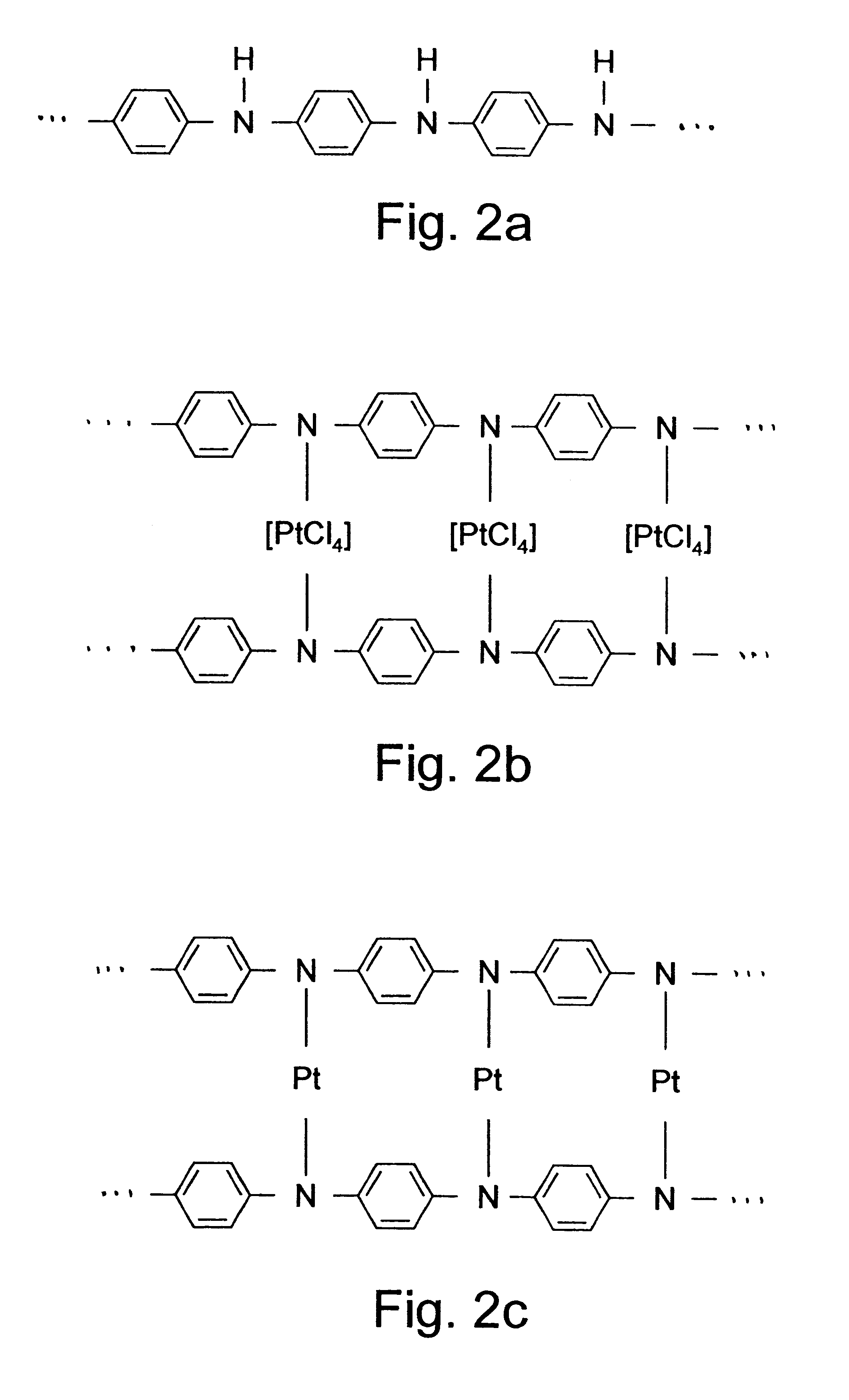

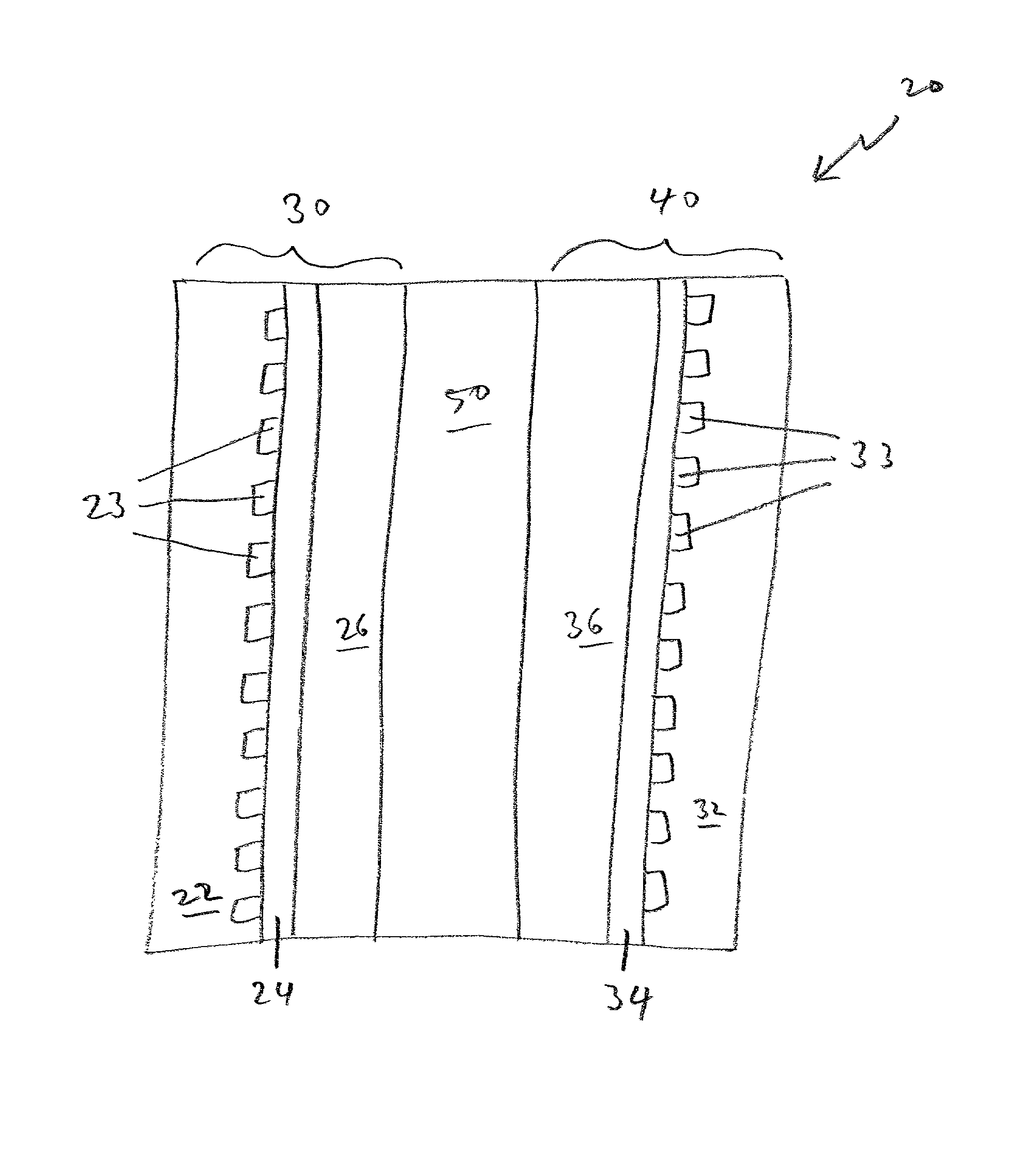

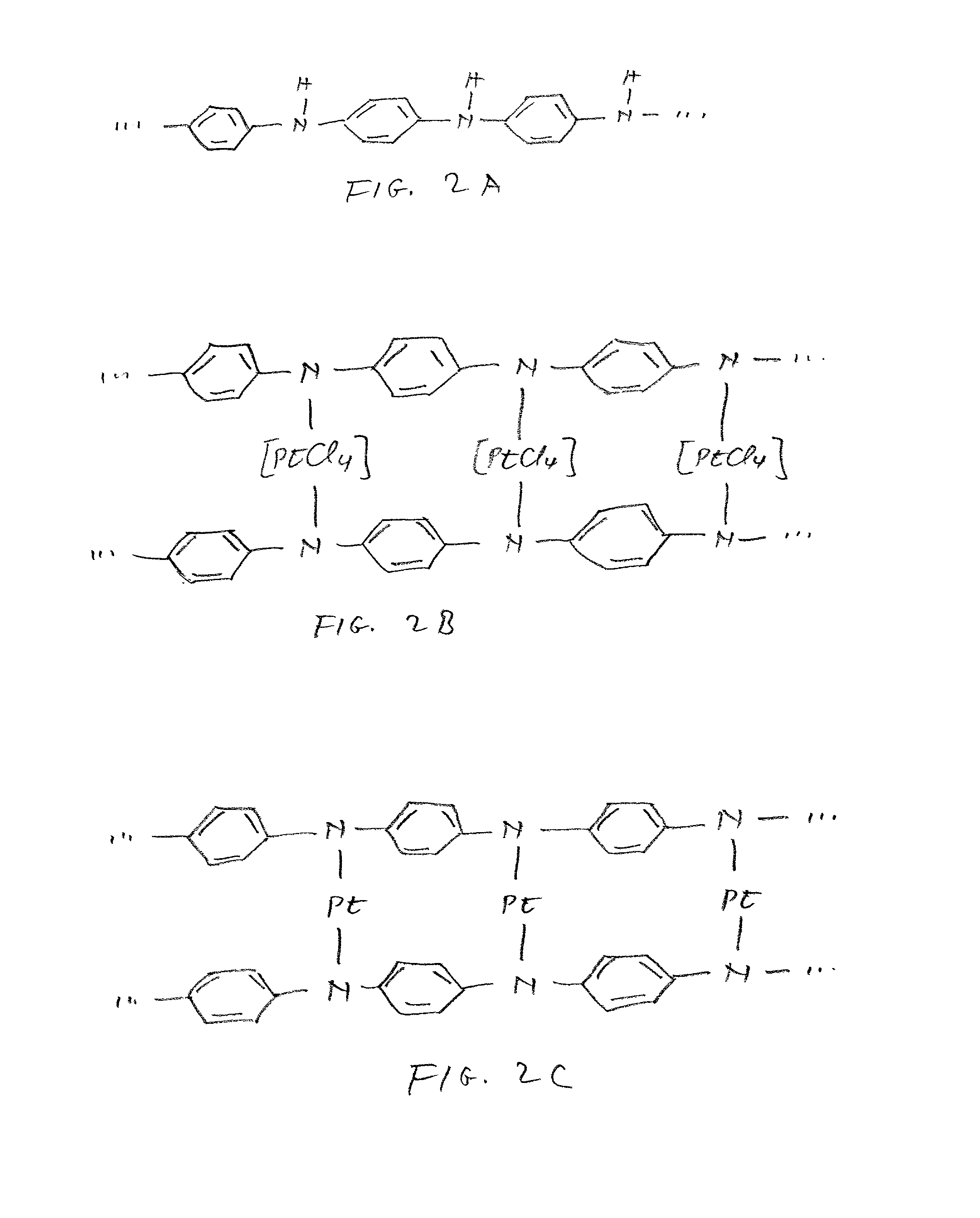

An electrocatalyst based on a highly electroconducting polymer and a transition metal, in which transition metal atoms are covalently bonded to heteroatoms of the backbone monomers of the polymer. The covalently bonded transition metal atoms are nucleation sites for catalytically active transition metal particles. The complex is prepared by complexing a highly electroconducting polymer with transition metal coordination ions and then reducing the transition metal ions to neutral atoms. An electrode for a fuel cell is made by impregnating an electrically conducting sheet with the catalytic complex and drying the impregnated sheet. The scope of the present invention includes such electrodes and the fuel cells that incorporate these electrodes.

Owner:MEDIS EL

Class of electrocatalysts and a gas diffusion electrode based thereon for fuel cells

InactiveUS6380126B1Good electrical contactEvenly dispersedOrganic-compounds/hydrides/coordination-complexes catalystsConductive materialFuel cellsConductive polymer

An electrocatalyst based on a highly electroconducting polymer and a transition metal, in which transition metal atoms are covalently bonded to heteroatoms of the backbone monomers of the polymer. The covalently bonded transition metal atoms are nucleation sites for catalytically active transition metal particles. The complex is prepared by complexing a highly electroconducting polymer with transition metal coordination ions and then reducing the transition metal ions to neutral atoms. An electrode for a fuel cell is made by impregnating an electrically conducting sheet with the catalytic complex and drying the impregnated sheet. The scope of the present invention includes such electrodes and the fuel cells that incorporate these electrodes.

Owner:MEDIS EL

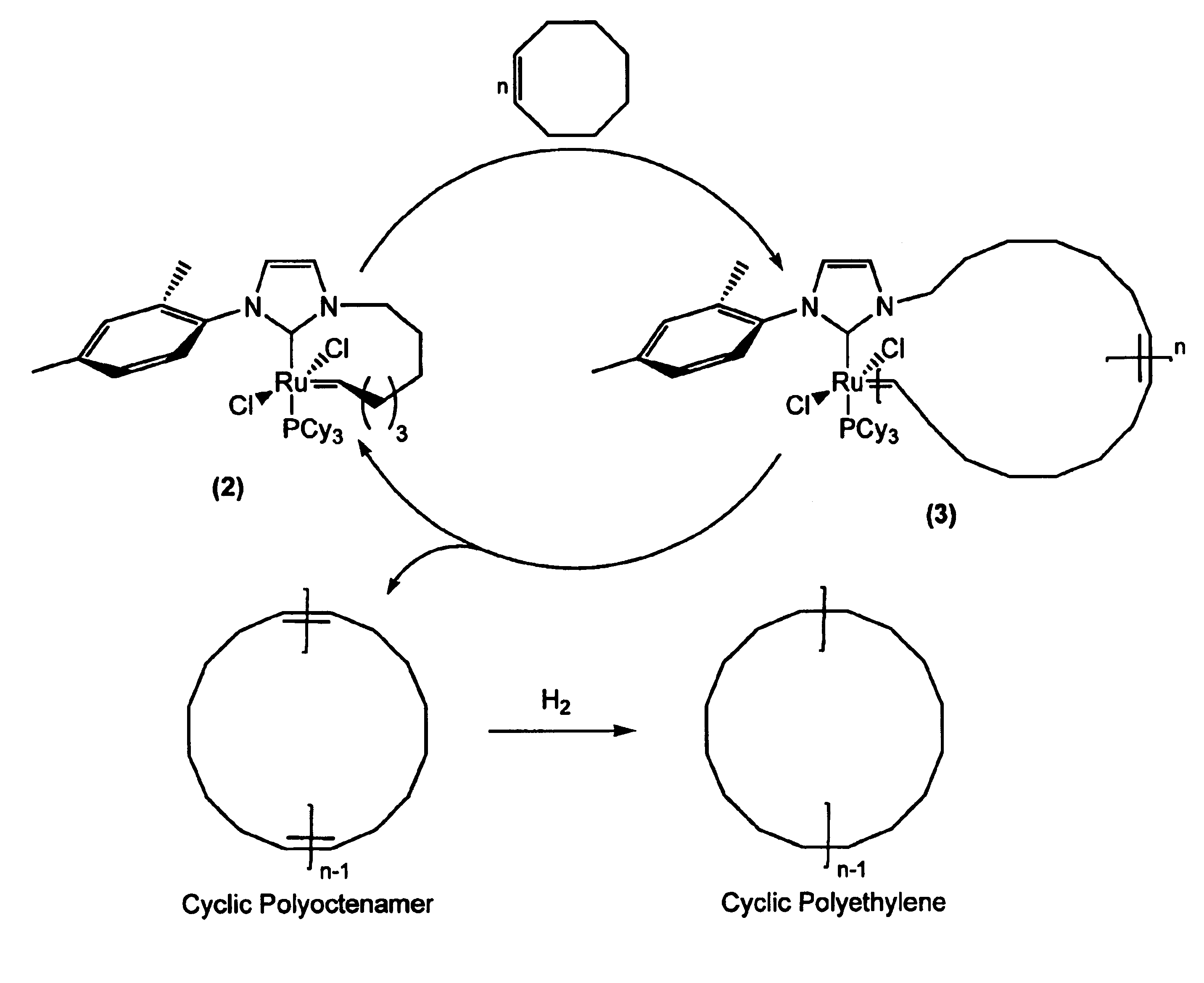

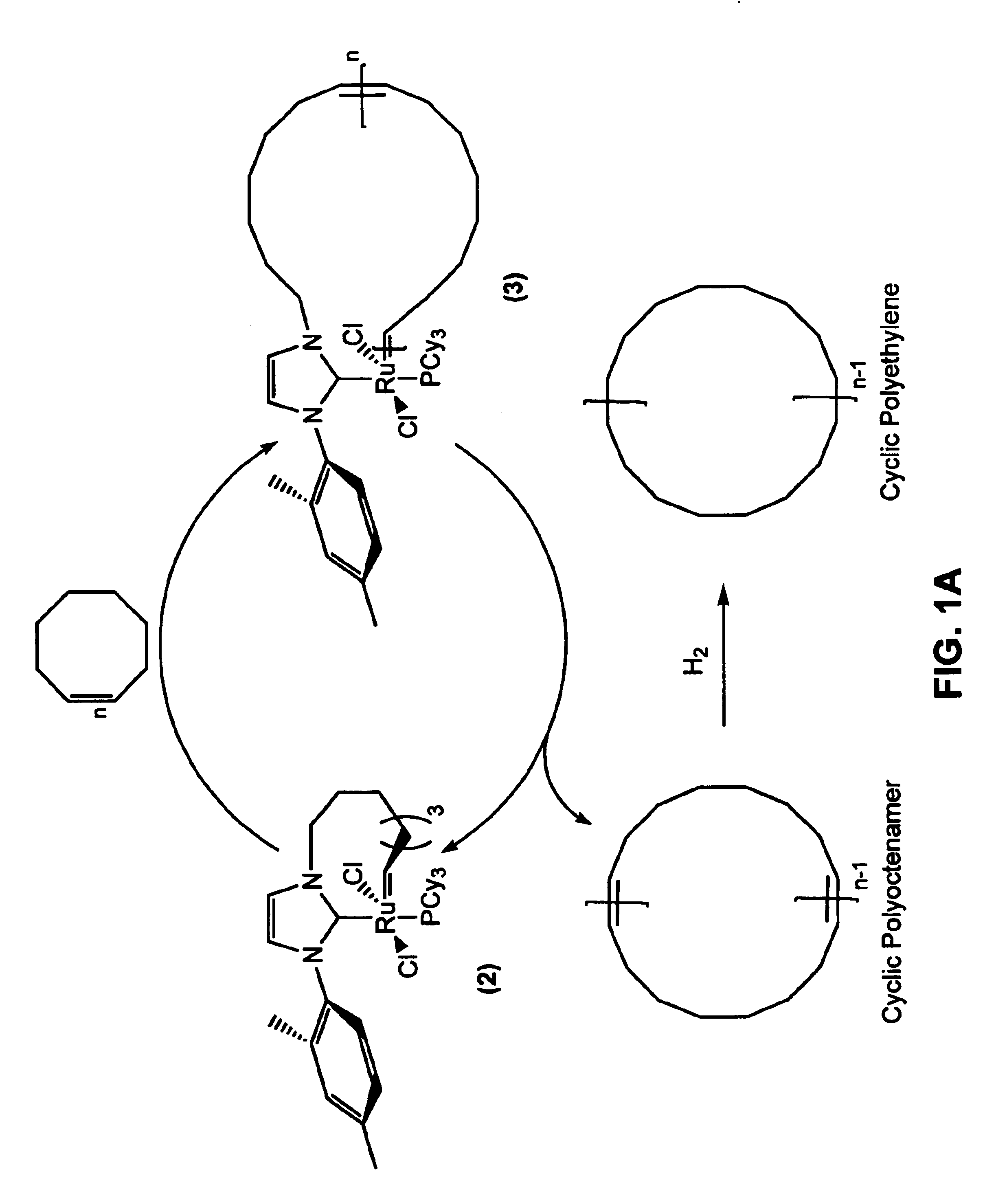

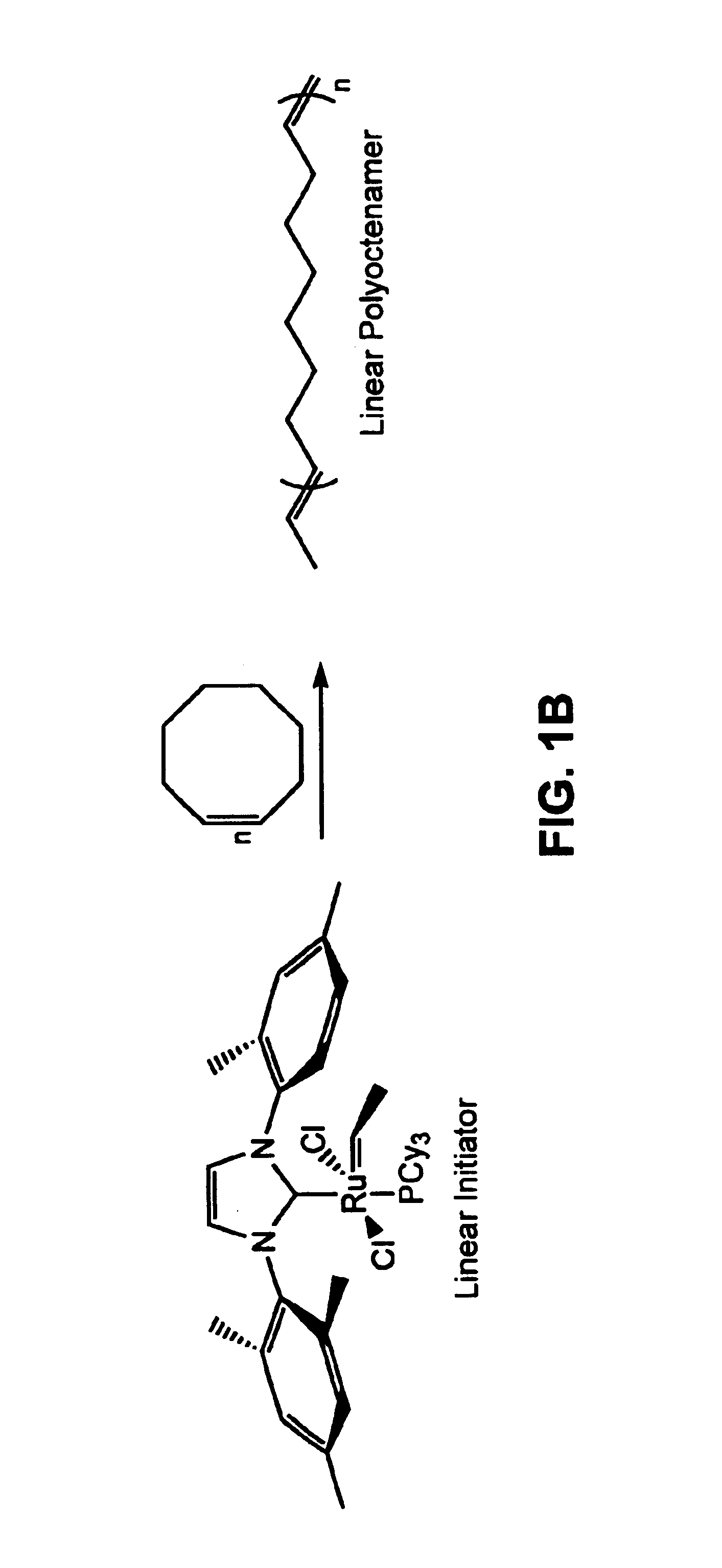

Synthesis of macrocyclic polymers by ring insertion polymerization of cyclic olefin monomers

ActiveUS6946533B2Organic-compounds/hydrides/coordination-complexes catalystsGroup 8/9/10/18 element organic compoundsEmulsion polymerizationSolution polymerization

A method for synthesizing cyclic polymers using transition metal alkylidene complexes as reaction catalysts is provided, wherein the complexes contain a cyclic group. Polymerization is carried out on the catalyst, using cyclic olefin monomers that undergo ring insertion polymerization, and no linear intermediates are generated. Following completion of polymerization, the cyclic polymer detaches from the complex via an intramolecular chain transfer reaction and the catalytic complex is regenerated. The invention also provides novel transition metal alkylidene complexes useful as catalysts in the aforementioned process, as well as novel cyclic hydrocarbons.

Owner:CALIFORNIA INST OF TECH

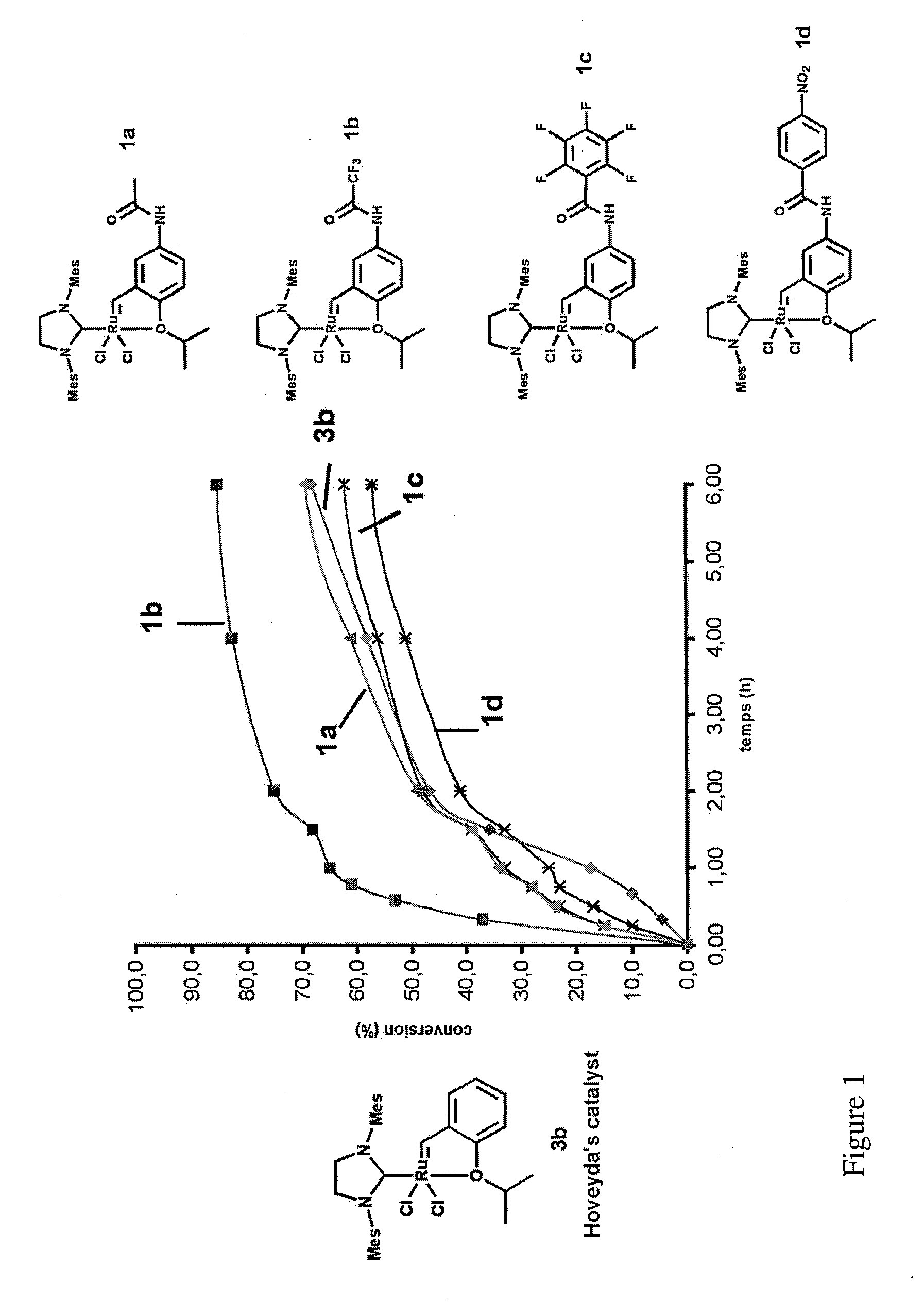

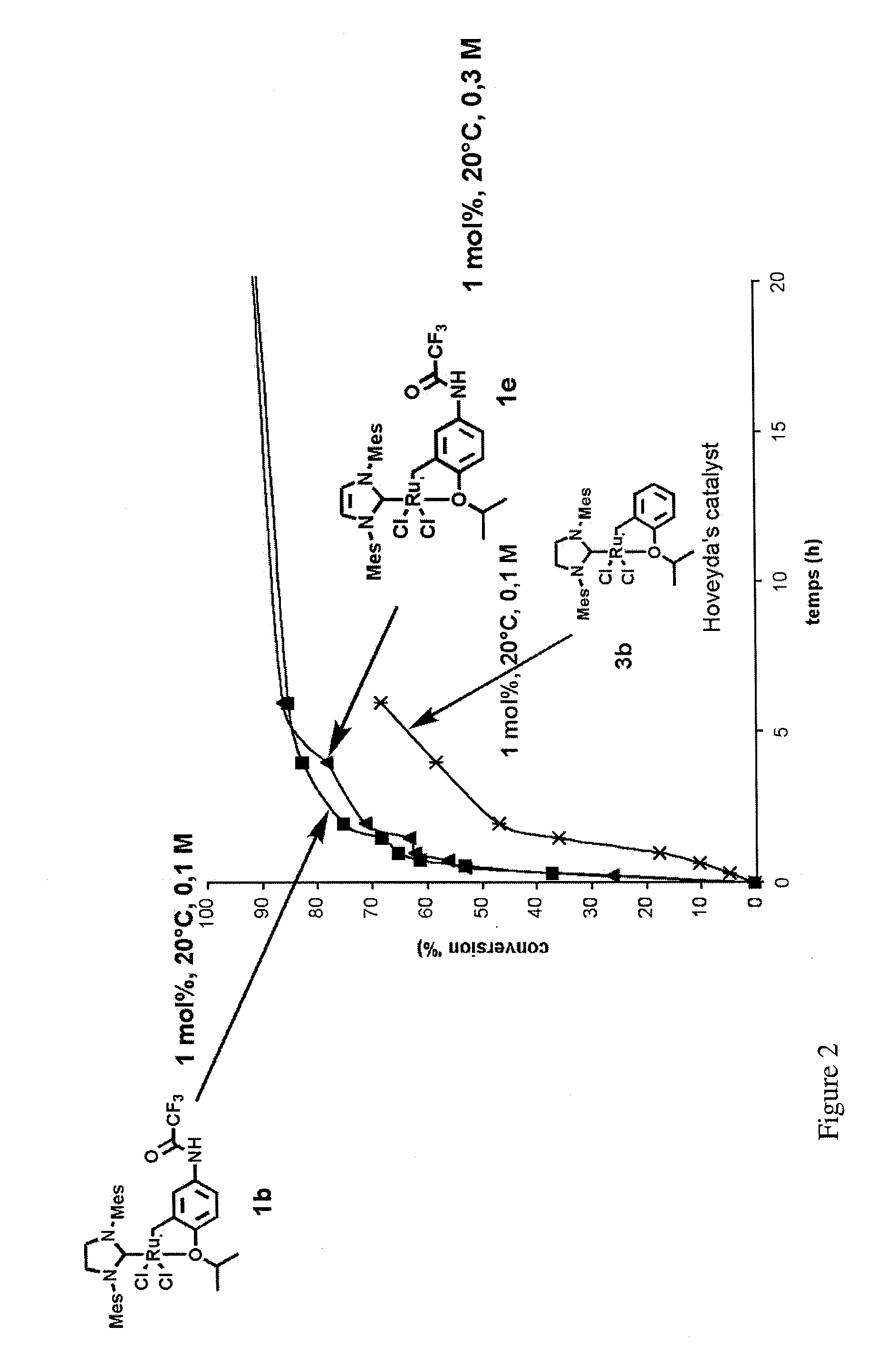

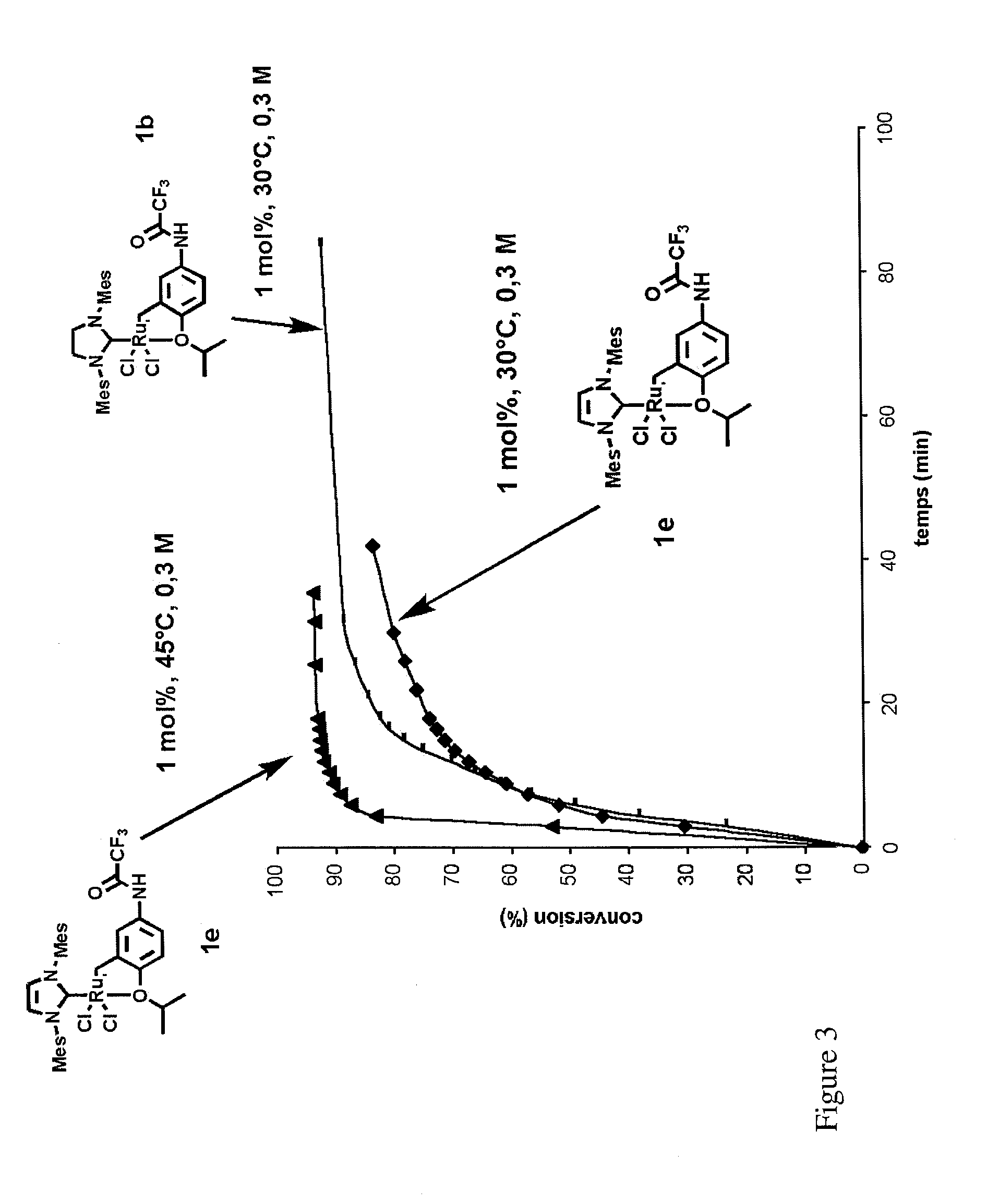

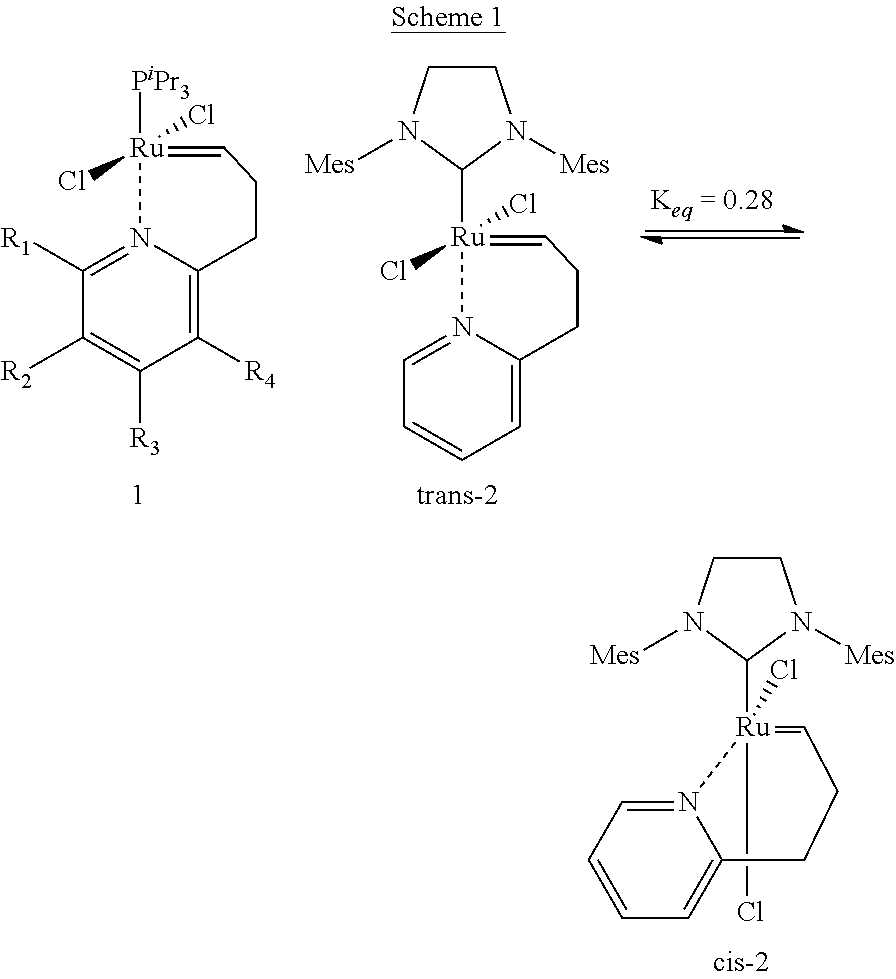

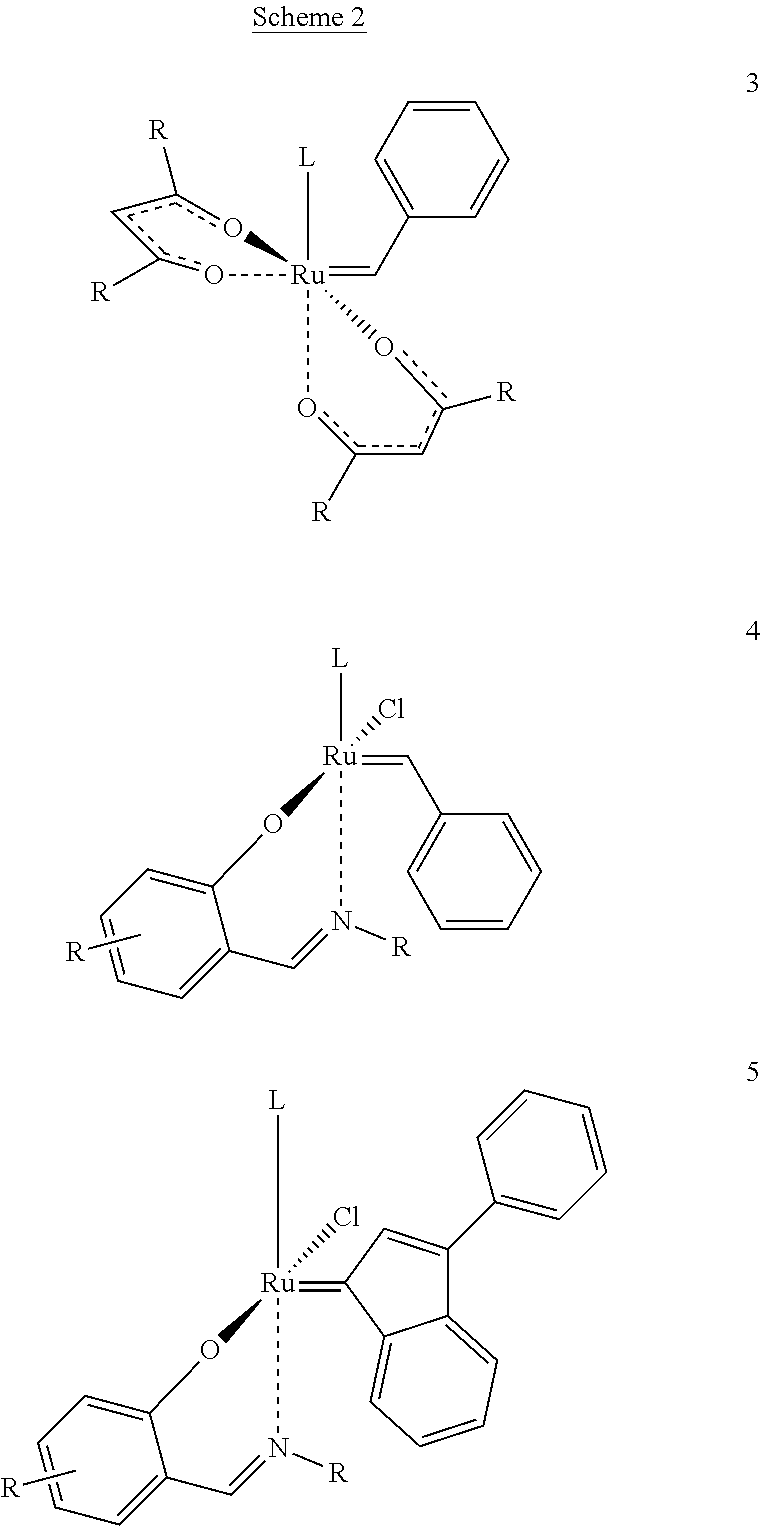

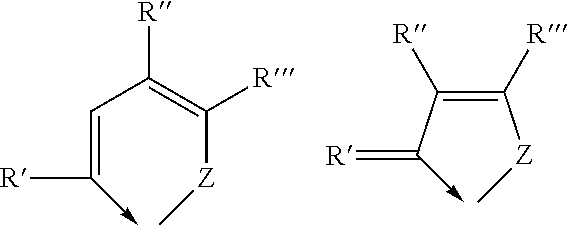

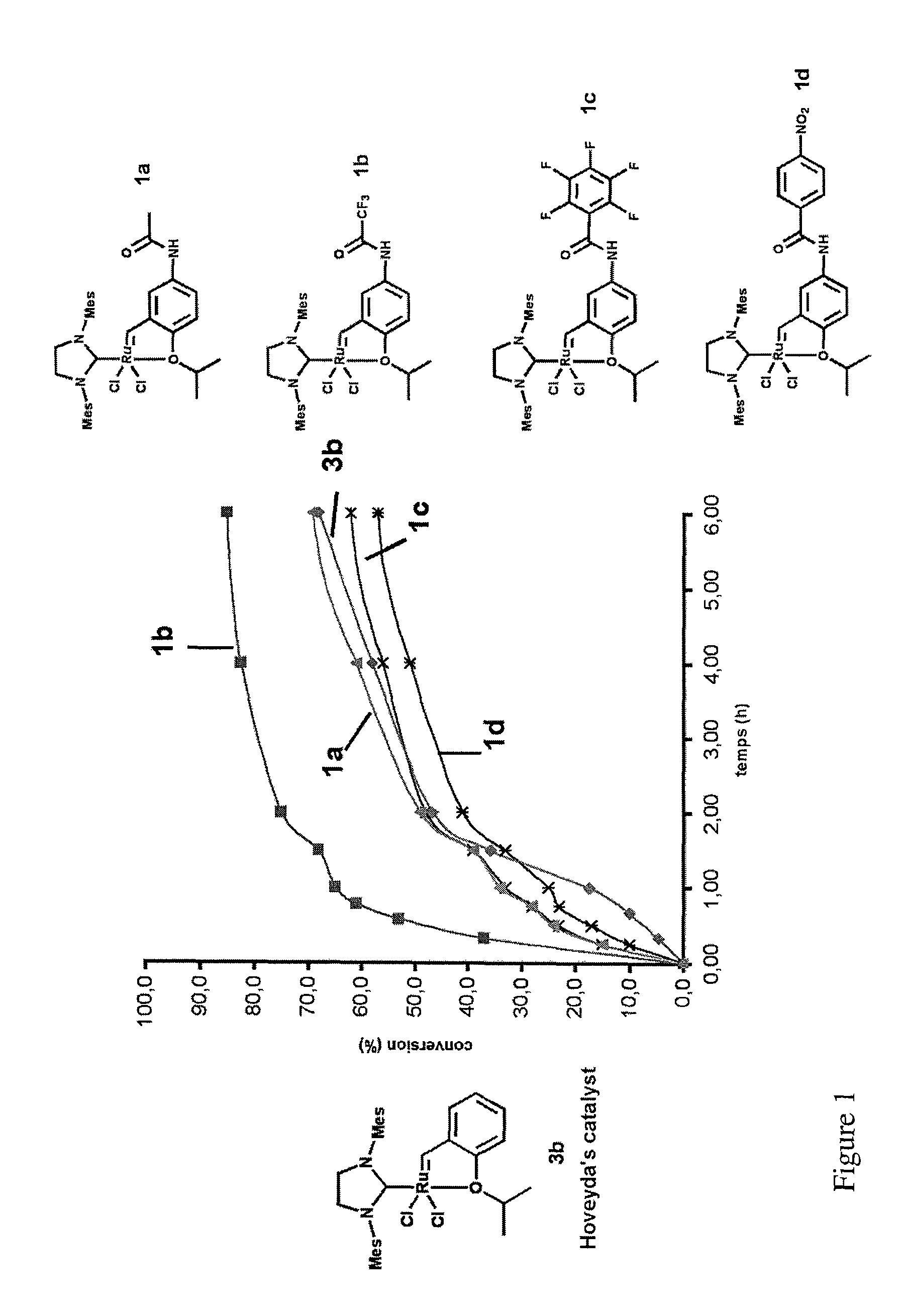

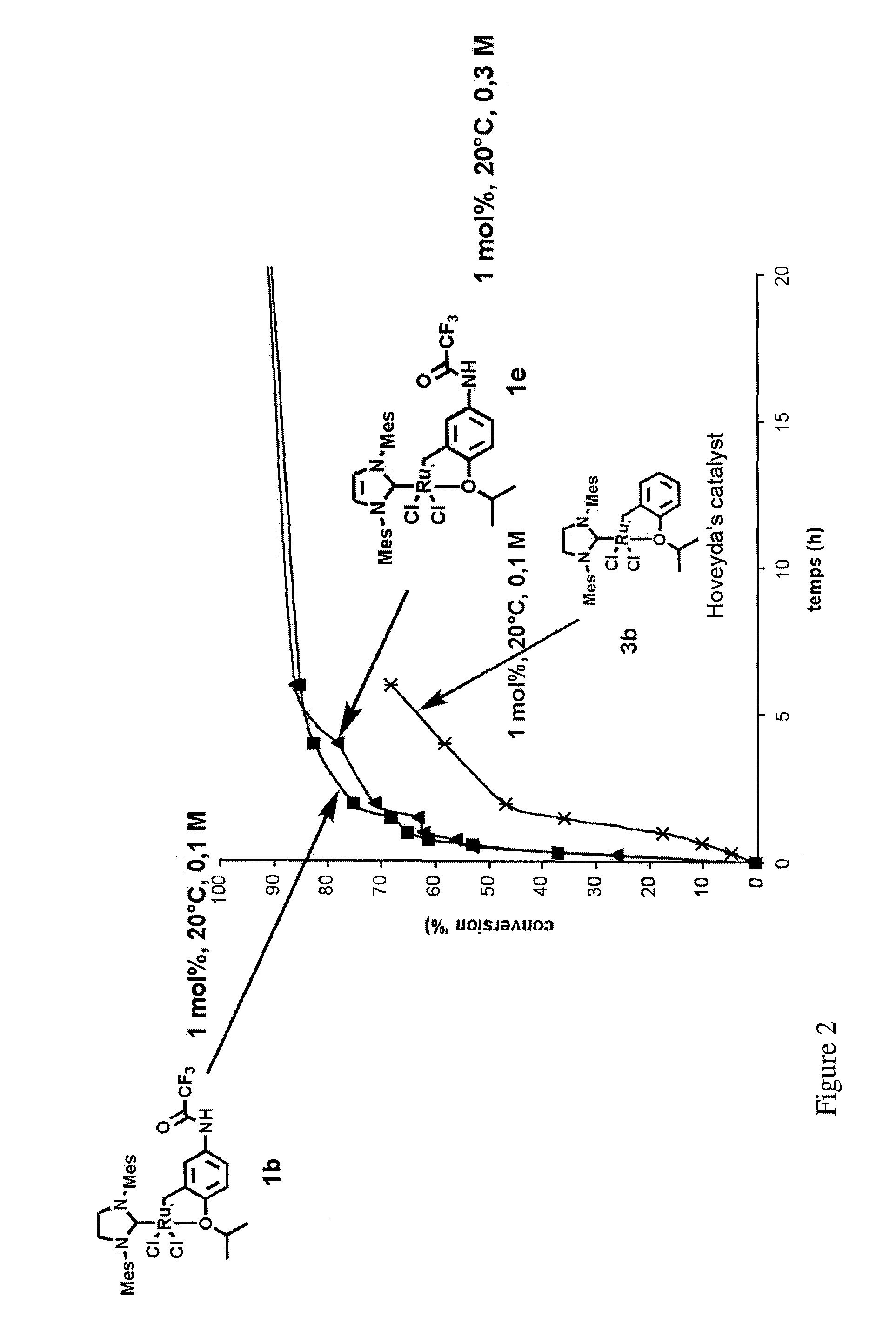

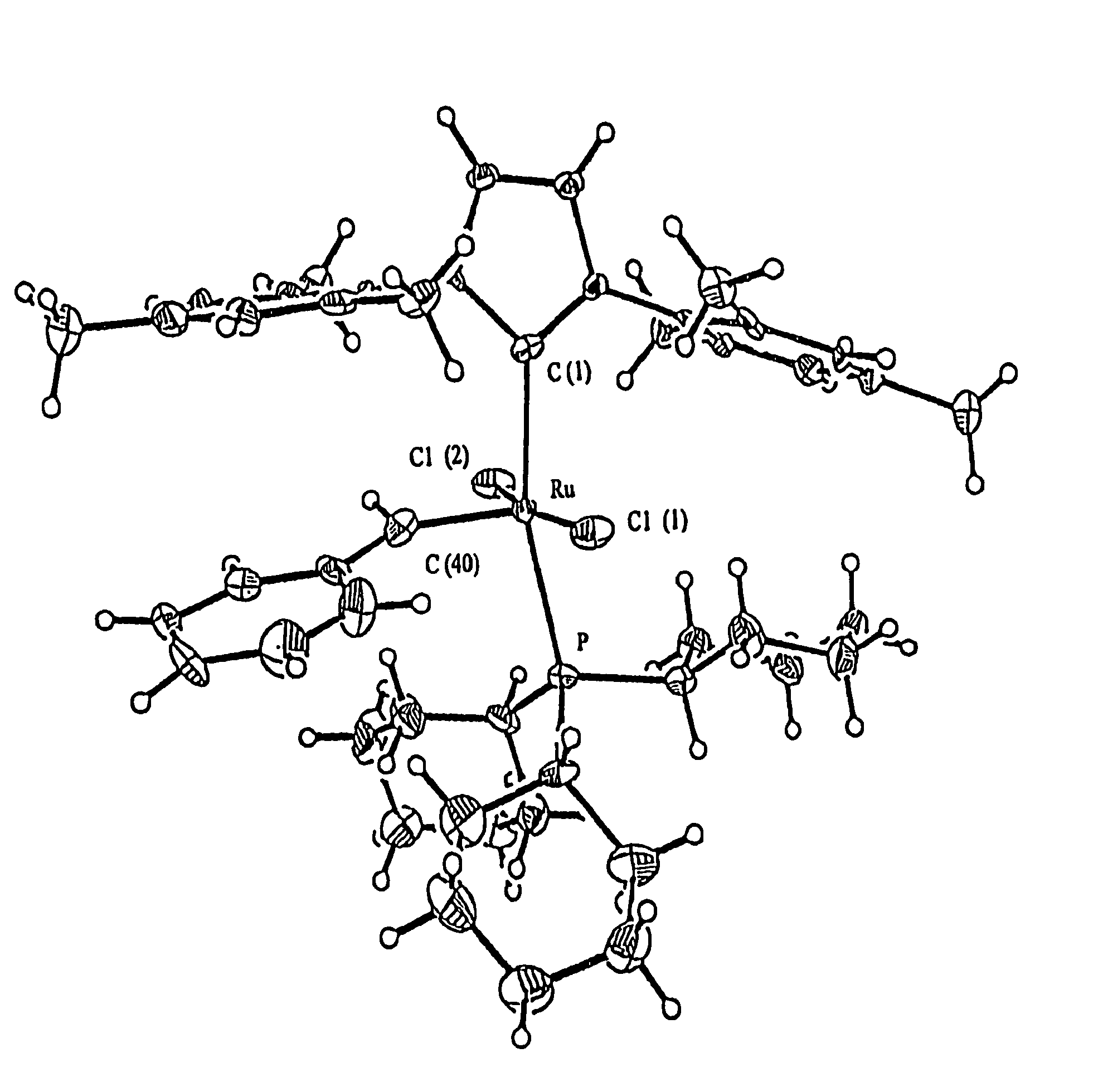

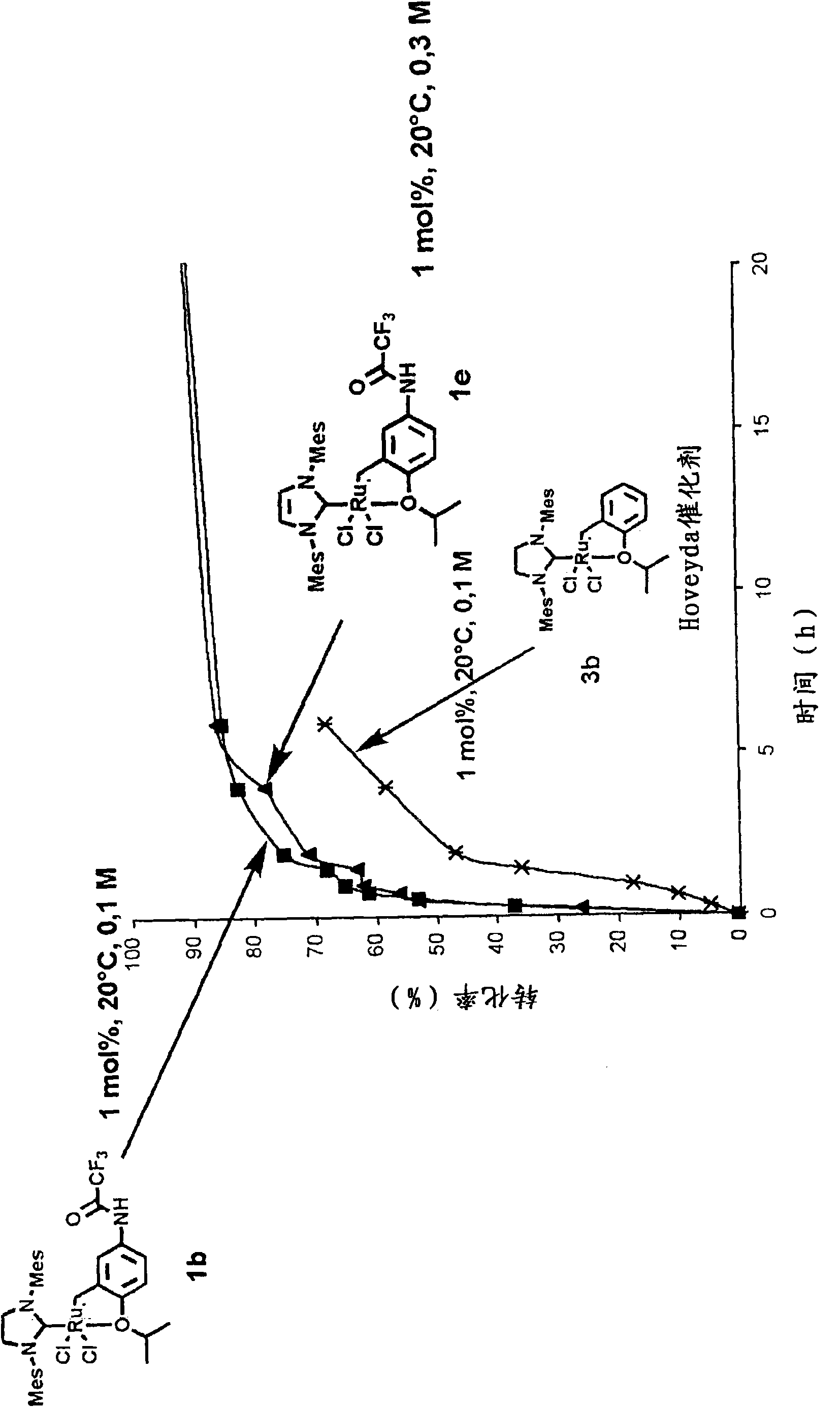

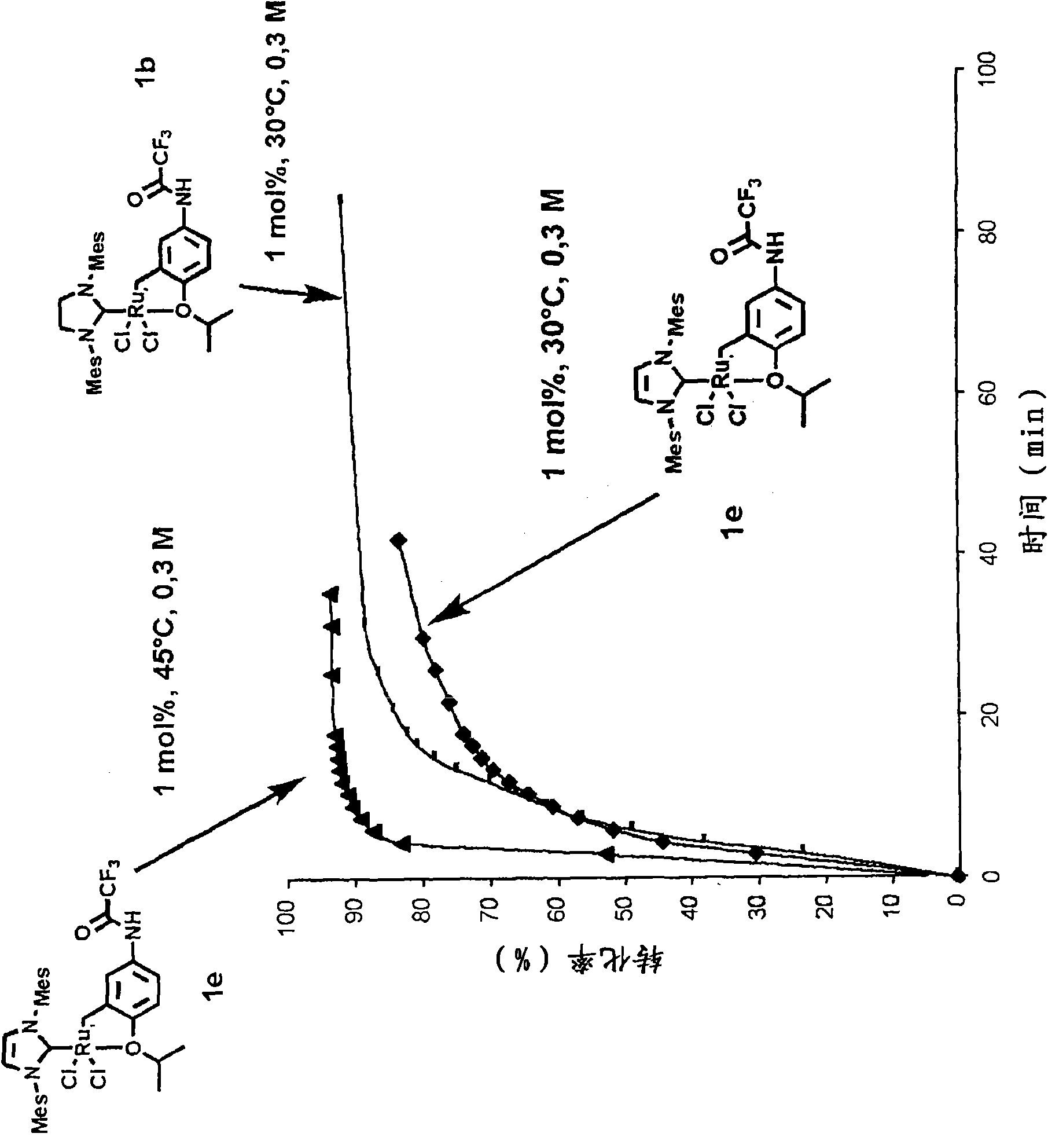

Ruthenium-Based Catalytic Complexes and the Use of Such Complexes for Olefin Metathesis

ActiveUS20130144060A1High activityEasy to recycleRuthenium organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsHydrogenPyridinium

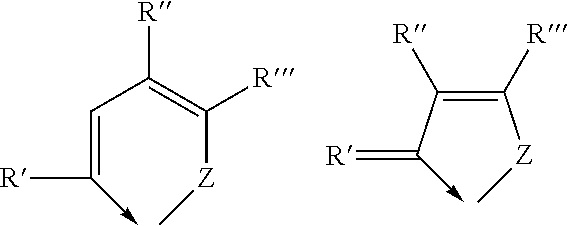

Disclosed herein are compounds of the formula (I) or (II) in which: L is a neutral ligand; X, X′ are anionic ligands; R1 and R2 are, separately, a hydrogen, a C1-C6 alkyl, a C1-C6 perhalogenoalkyl, a aldehyde, a ketone, an ester, a nitrile, an aryl, a pyridinium alkyl, an optionally substituted C5 or C6 pyridinium alkyl, perhalogenoalkyl or cyclohexyl, a Cnh2NY radical 10 with n between 1 and 6 and y an iconic marker, or a radical having the formula: wherein R1 can be a radical of formula (Ibis) when the compound has formula (I) or of formula (IIbis) when the compound has formula (II), R3 is a C1-C6 alkyl, or a C5 or C6 cycloalkyl or a C5 or C6 aryl; R0, R4, R5, R6, R7, R8, R9, R10, R11, are, separately, a hydrogen, C1-C6 alkyl, a C1-C6 perhalogenoalkyl, or a C5 or C6 aryl; wherein R9, R10, R11 can be a heterocycle; X1 is anion. R1 and R2 can form, with the N and the C to which they are attached, a heterocycle.

Owner:UMICORE AG & CO KG

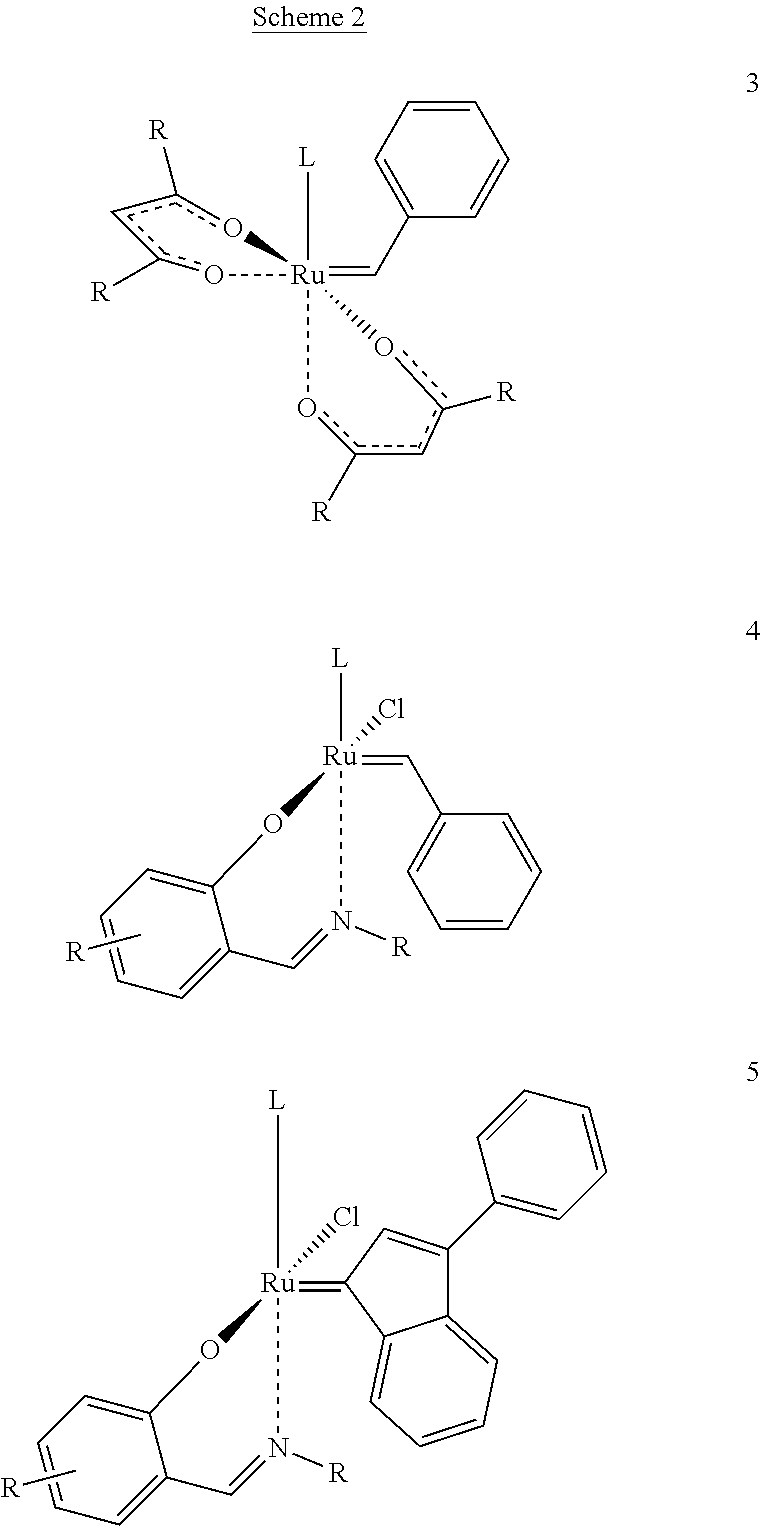

Catalytic complex for olefin metathesis reactions, process for the preparation thereof and use thereof

ActiveUS20120271019A1Easily and efficiently activatedExceptional activityRuthenium organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsAlkeneCoordination complex

The present invention relates to a catalytic complex for olefin metathesis reactions, to a process for its preparation and to its use in olefin metathesis reactions, particularly in ring opening metathesis polymerisation (ROMP) reactions.

Owner:RIMTEC CORP

Catalytic complex for olefin metathesis reactions, process for the preparation thereof and use thereof

ActiveUS8519069B2Easily and efficiently activatedSimple, efficient, green and highly yieldingRuthenium organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsAlkeneCoordination complex

The present invention relates to a catalytic complex for olefin metathesis reactions, to a process for its preparation and to its use in olefin metathesis reactions, particularly in ring opening metathesis polymerisation (ROMP) reactions.

Owner:RIMTEC CORP

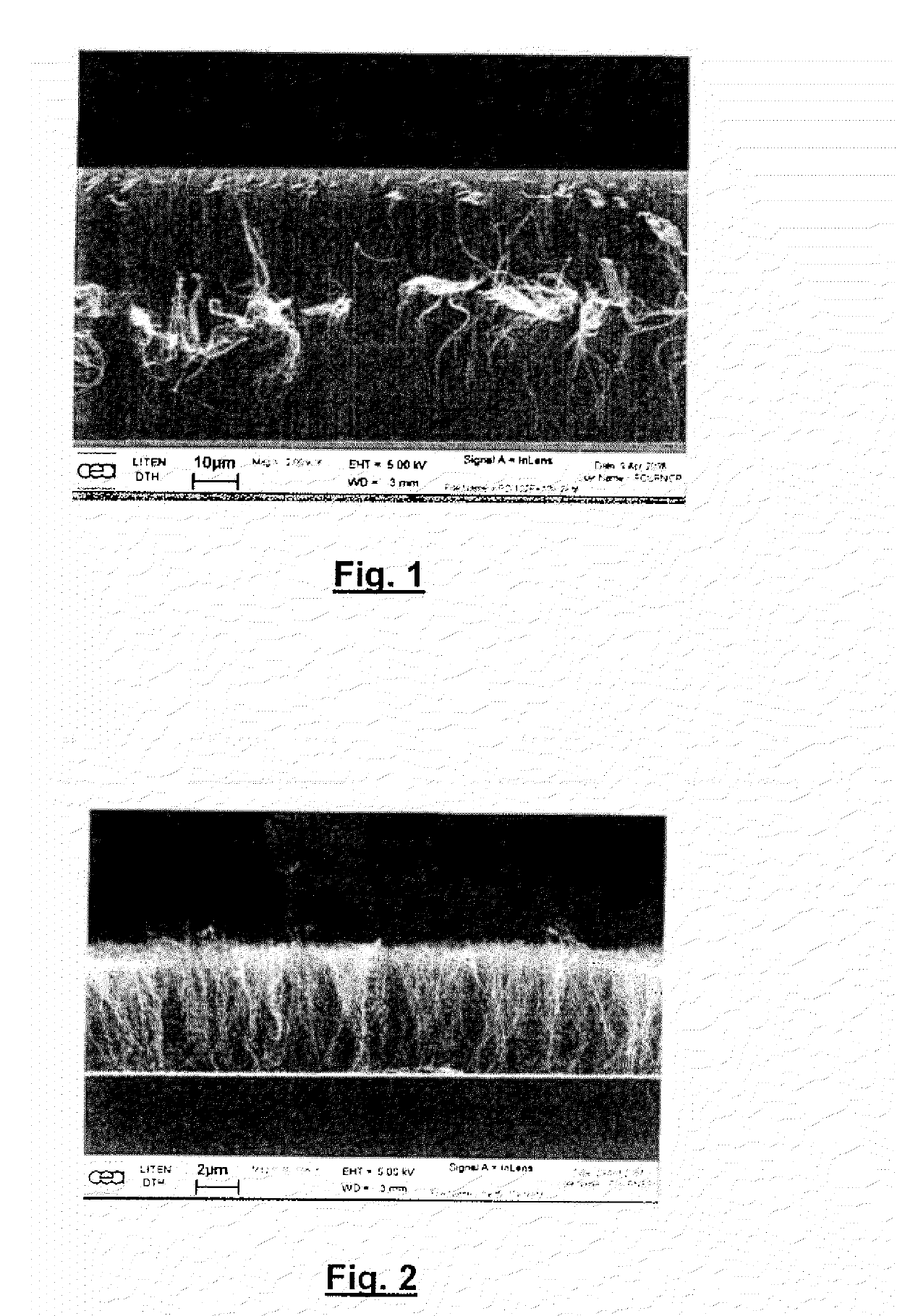

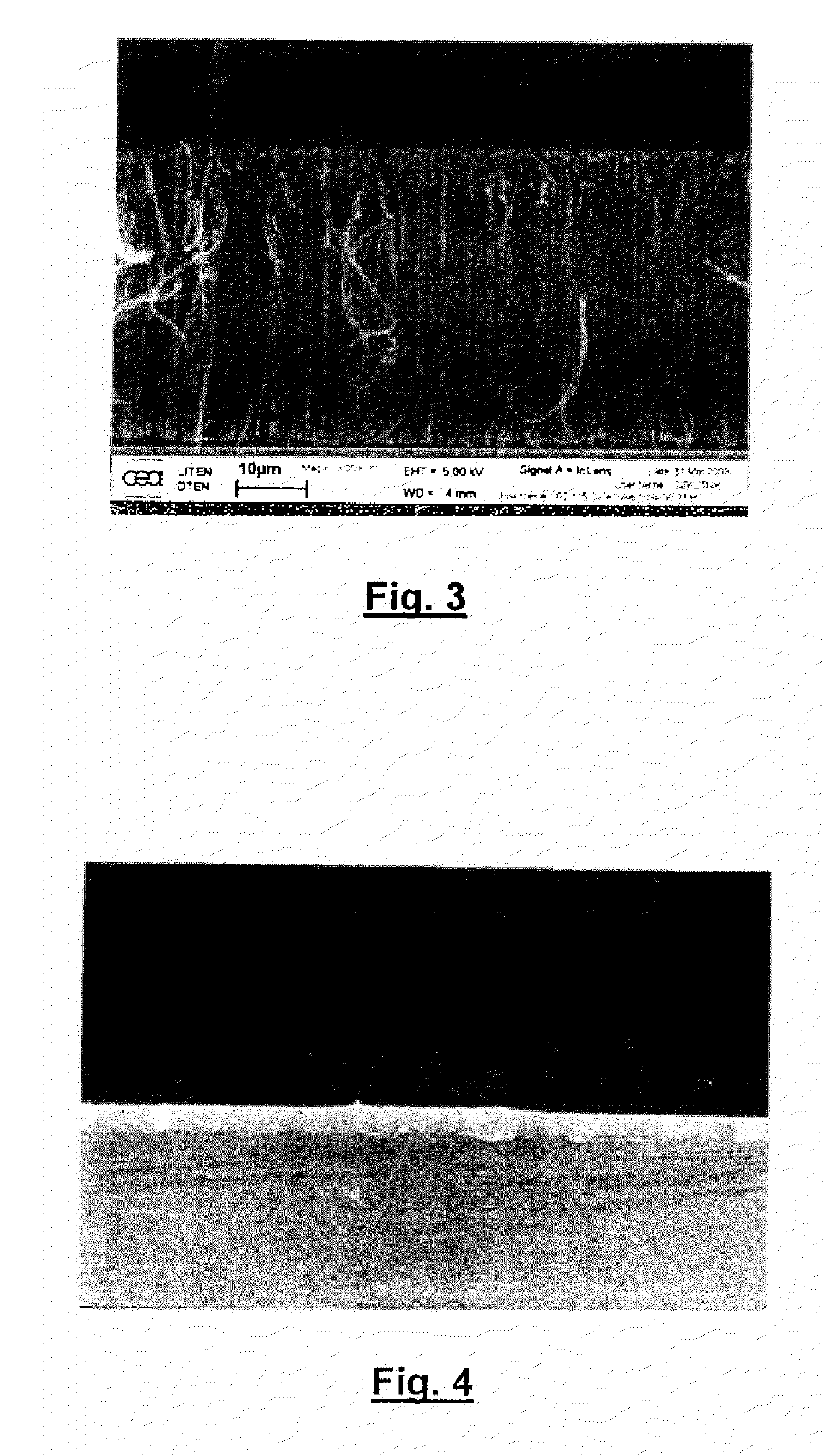

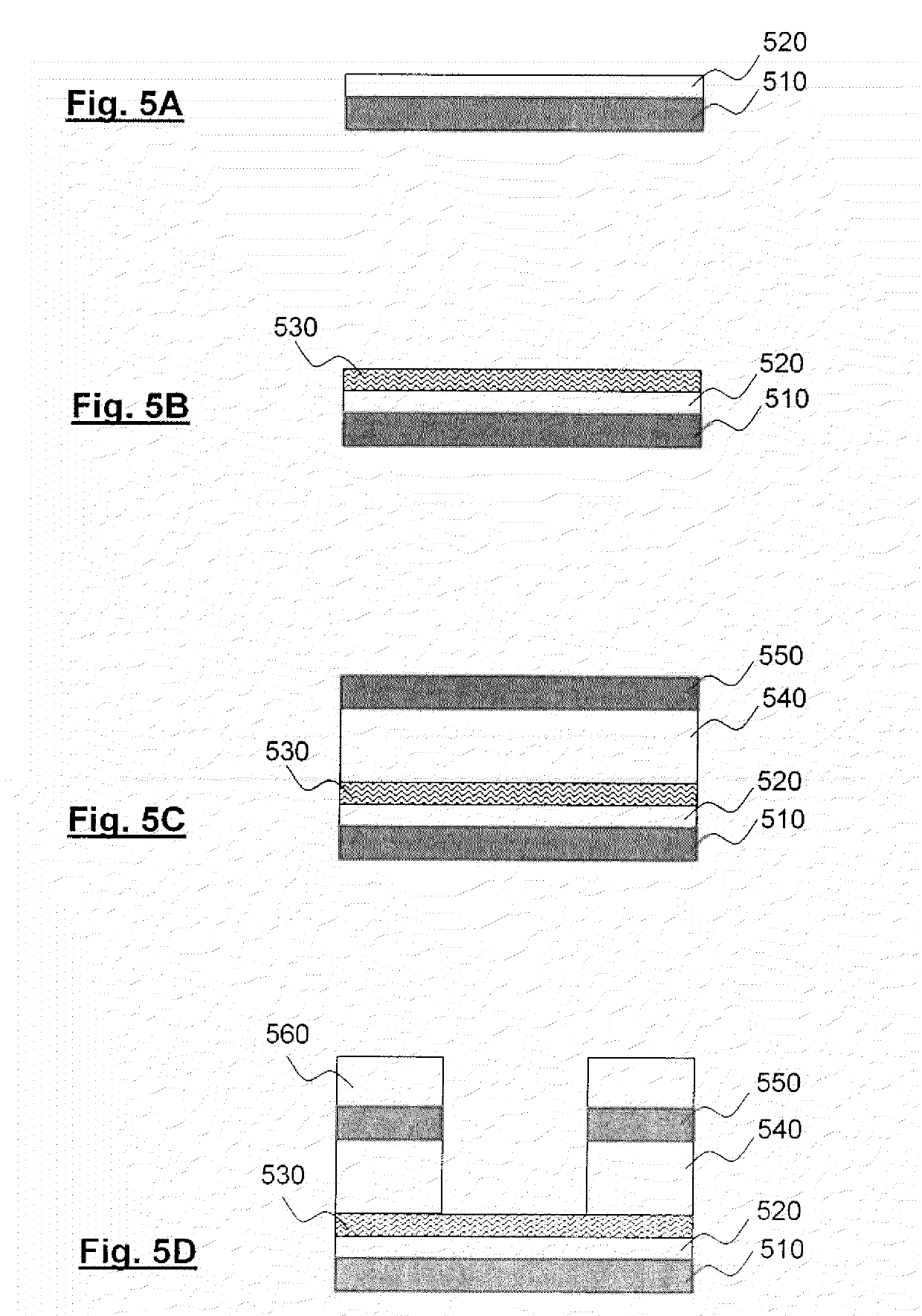

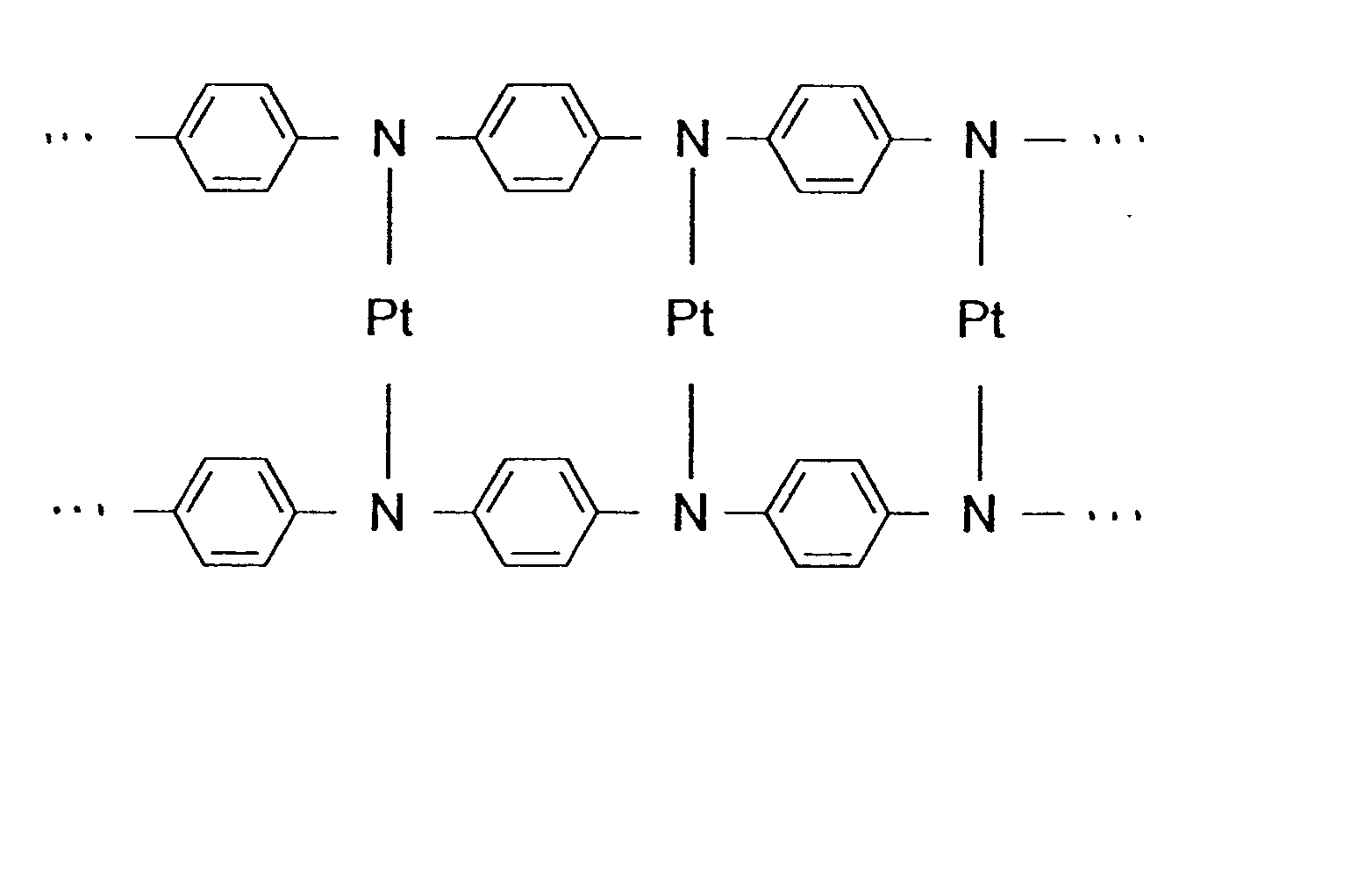

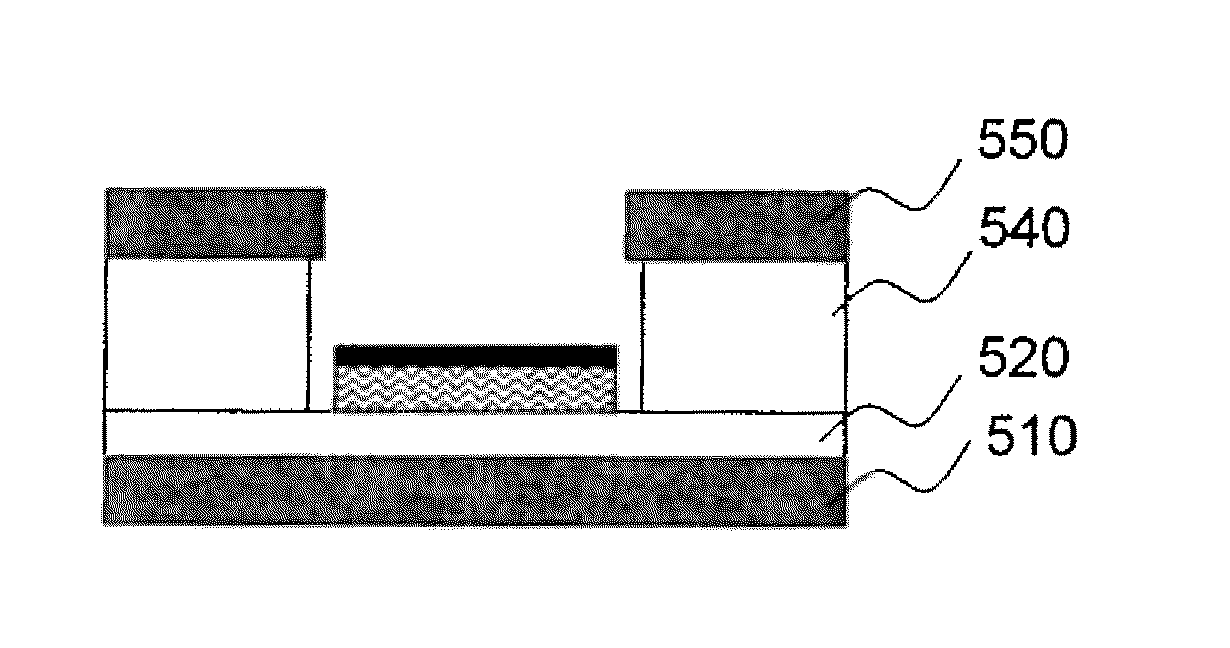

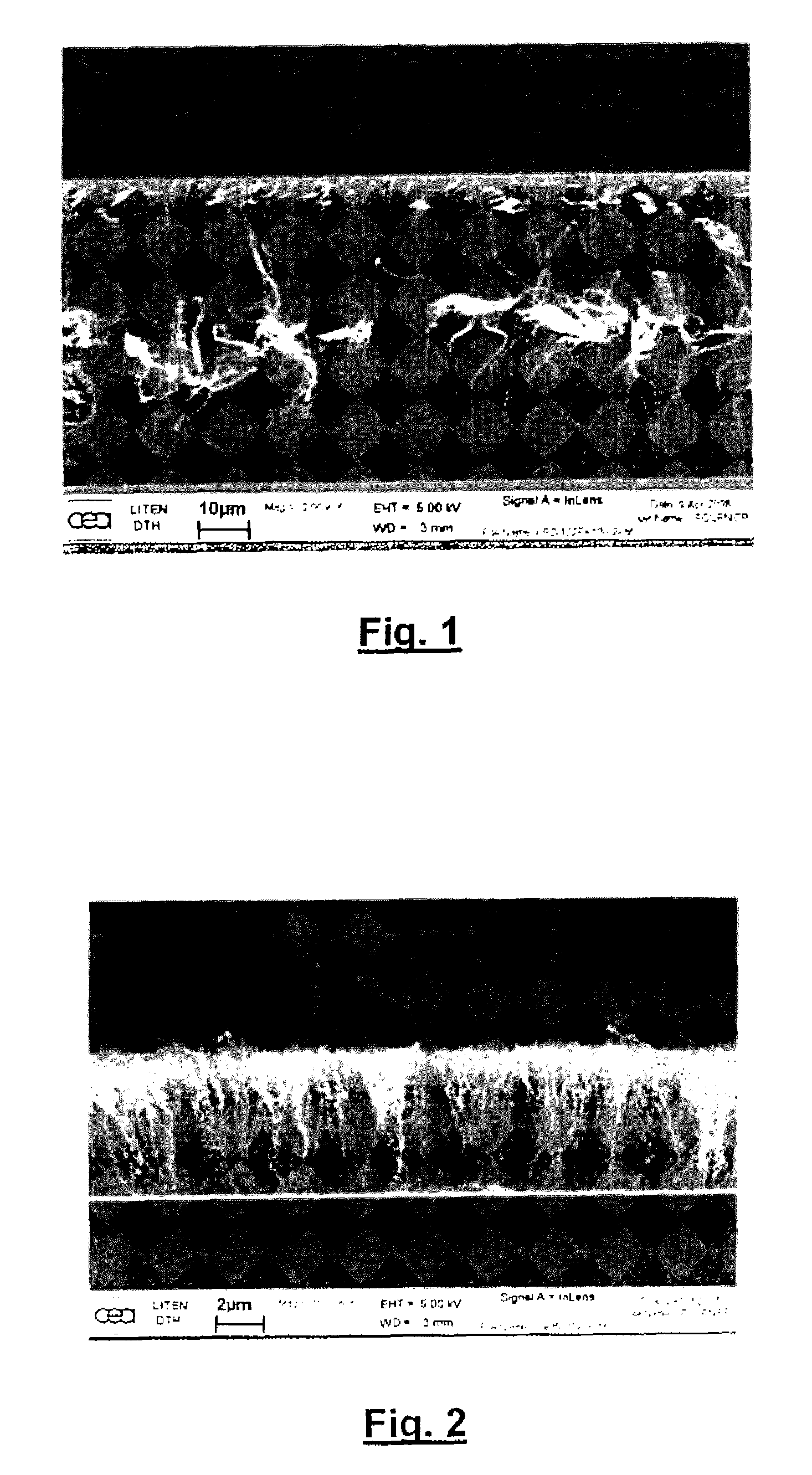

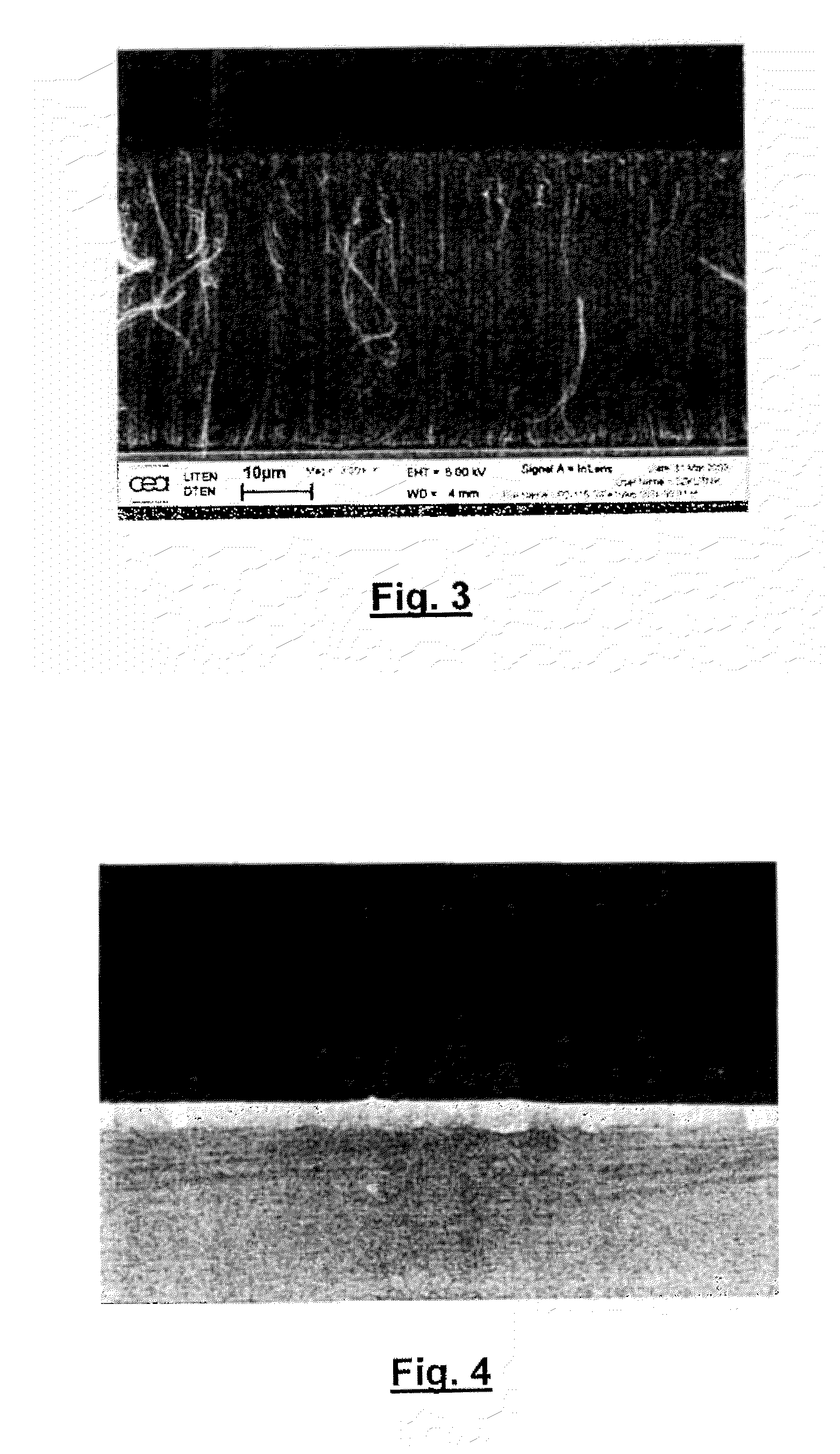

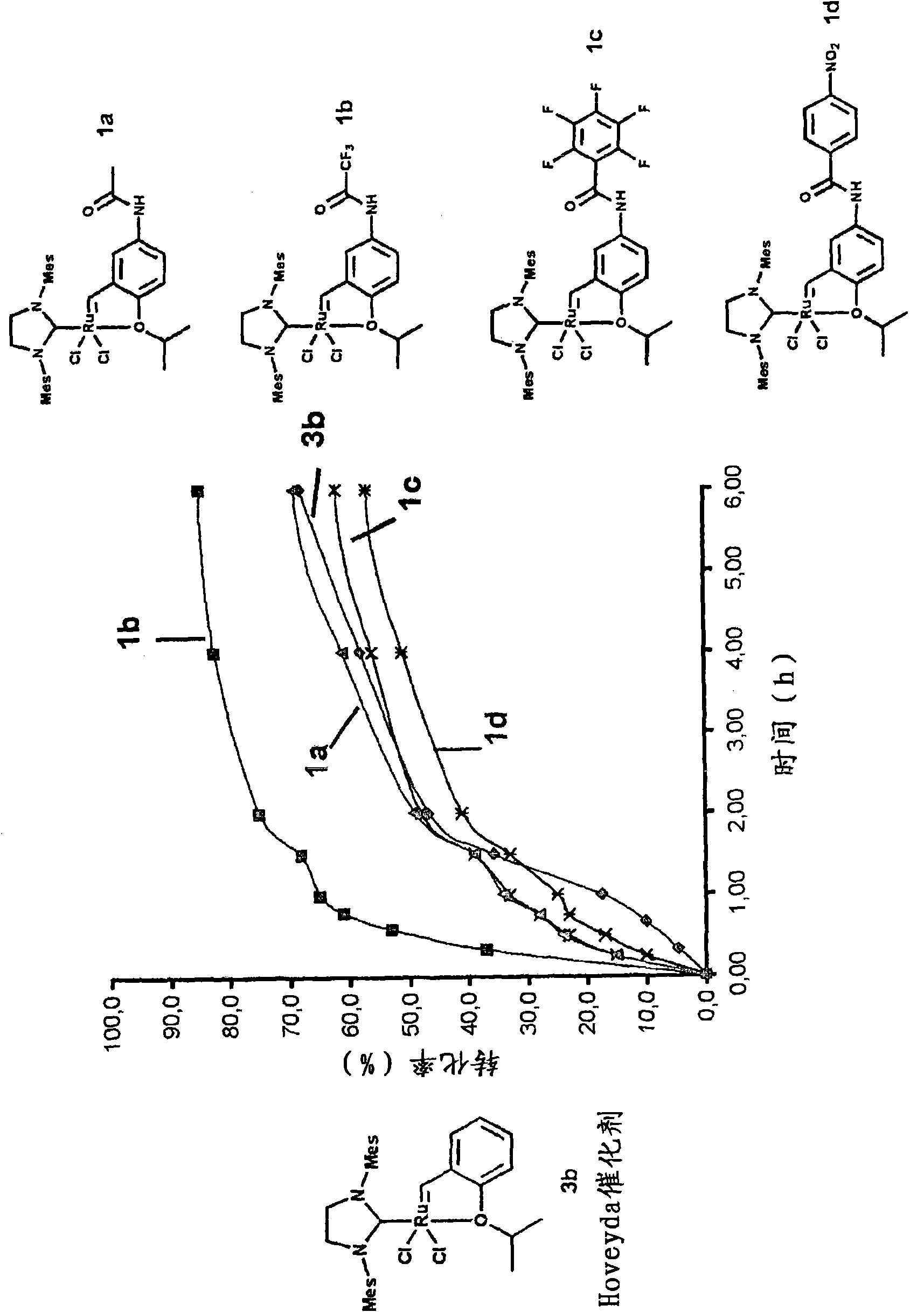

Procedure for Obtaining Nanotube Layers of Carbon with Conductor or Semiconductor Substrate

ActiveUS20090325377A1Material nanotechnologySemiconductor/solid-state device detailsElectrical conductorNanotube

The present invention relates to a process for producing a carbon nanotube (CNT) mat (580) on a conductive or semiconductor substrate (510). According to this process, a catalytic complex (530,570) comprising at least one metal layer (570) is firstly deposited on said substrate. Said metal layer then undergoes an oxidizing treatment. Finally, carbon nanotubes are grown from the metal layer thus oxidized.The present invention also relates to a process for producing a via using said CNT mat production process.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

New class of electrocatalysts and a gas diffusion electrode based thereon for fuel cells

An electrocatalyst based on a highly electroconducting polymer and a transition metal, in which transition metal atoms are covalently bonded to heteroatoms of the backbone monomers of the polymer. The covalently bonded transition metal atoms are nucleation sites for catalytically active transition metal particles. The complex is prepared by complexing a highly electroconducting polymer with transition metal coordination ions and then reducing the transition metal ions to neutral atoms. An electrode for a fuel cell is made by impregnating an electrically conducting sheet with the catalytic complex and drying the impregnated sheet. The scope of the present invention includes such electrodes and the fuel cells that incorporate these electrodes.

Owner:MEDIS EL

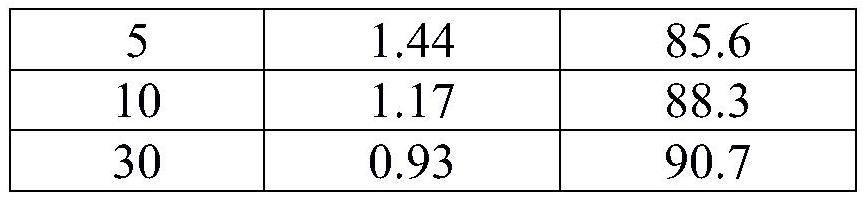

Ruthenium-based catalytic complexes and the use of such complexes for olefin metathesis

ActiveUS8394965B2Easy to recycleClear in cost of reactionRuthenium organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsHydrogenPyridinium

The invention relates to all compounds of the formula (I) or (II) in which: L is a neutral ligand; X, X′ are anionic ligands; R1 and R2 are, separately, a hydrogen, a C1-C6 alkyl, a C1-C6 perhalogenoalkyl, a aldehyde, a ketone, an ester, a nitrile, an aryl, a pyridinium alkyl, an optionally substituted C5 or C6 pyridinium alkyl, perhalogenoalkyl or cyclohexyl, a Cnh2NY radical 10 with n between 1 and 6 and y an i8onic marker, or a radical having the formula: wherein R1 can be a radical of formula (Ibis) when the compound has formula (I) or of formula (IIbis) when the compound has formula (II), R3 is a C1-C6 alkyl, or a C5 or C6 cycloalkyl or a C5 or C6 aryl; R0, R4, R5, R6, R7, R8, R9, R10, R11, are, separately, a hydrogen, C1-C6 alkyl, a C1-C6 perhalogenoalkyl, or a C5 or C6 aryl; wherein R9, R10, R11 can be a heterocycle; X1 is anion. R1 and R2 can form, with the N and the C to which they are attached, a heterocycle.

Owner:UMICORE AG & CO KG

Class of electrocatalysts and a gas diffusion electrode based thereon

InactiveUS20030008199A1Good electrical contactEasy to produceActive material electrodesAqueous electrolyte fuel cellsConductive polymerCoordination complex

An electrocatalyst based on a highly electroconducting polymer and a transition metal, in which transition metal atoms are covalently bonded to heteroatoms of the backbone monomers of the polymer. The covalently bonded transition metal atoms are nucleation sites for catalytically active transition metal particles. The complex is prepared by complexing a highly electroconducting polymer with transition metal coordination ions and then reducing the transition metal ions to neutral atoms. An electrode for a fuel cell is made by impregnating an electrically conducting sheet with the catalytic complex and drying the impregnated sheet. A fuel cell with a liquid anolyte uses the electrode as its cathode. The anolyte includes an aqueous solution of conjugate polybasic acids buffer, such as H3PO4-NaH2PO4-Na2HPO4, and an alcohol such as methanol as a reductant.

Owner:MEDIS EL

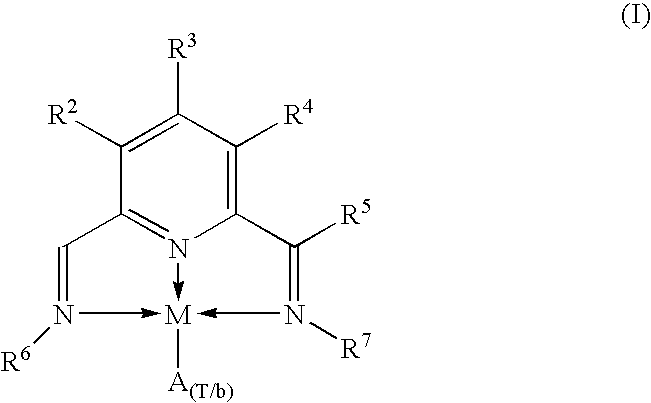

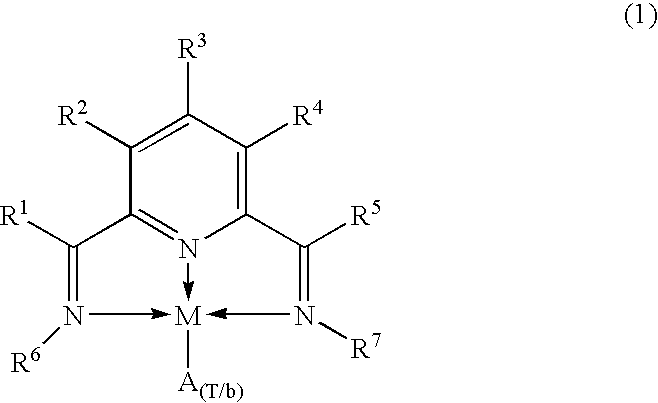

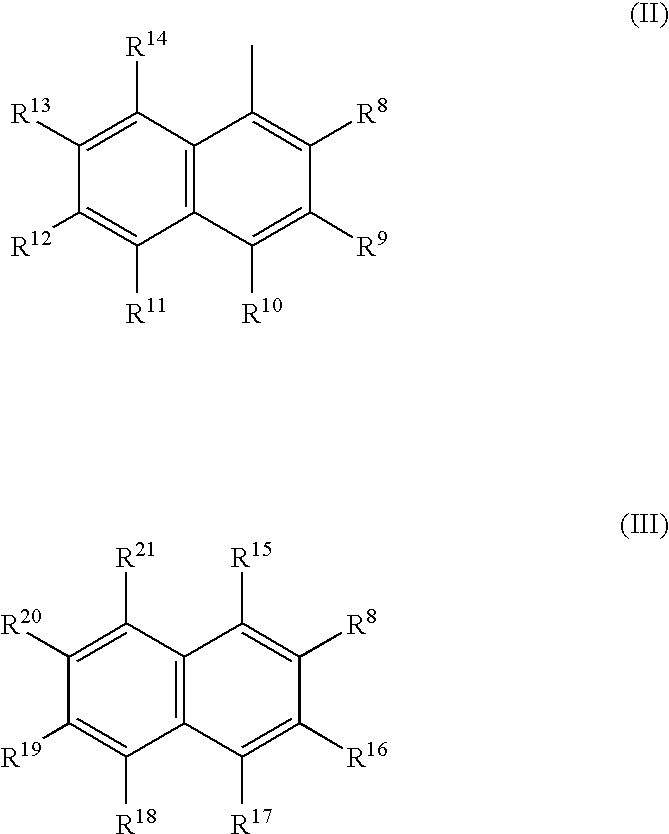

Catalytic complexes and their use for polymerizing alpha-olefins

InactiveUS6670434B2Organic-compounds/hydrides/coordination-complexes catalystsIron group organic compounds without C-metal linkagesHydrogen atomPolyatomic ion

A complex of a transition metal complying with the general formula (I)in whichM is a transition metal of groups 6 to 12,T is the oxidation state of M,each A, which may be identical with or differ from each other, is an atom or an atomic grouping bonded covalently or ionically to the transition metal M,b is the valency of A,each R<1>, R<2>, R<3>, R<4 >and R<5 >is independently a hydrogen atom, an unsubstituted or substituted hydrocarbon group, an unsubstituted or substituted heterohydrocarbon group, or an inert functional group,R<6 >and R<7 >are, independently of one another, a polynuclear aromatic hydrocarbon group containing at least two condensed benzene nuclei, substituted with at least one hydrocarbon group.

Owner:SOLVAY POLYOLEFINS EURO BELGIUM SA

Catalytic complex for preparing isocyanurate foam from bagasse ployol

The invention relates to a catalytic complex for preparing isocyanurate foam from bagasse ployol comprising the constituents (by mass ratio) of solvent 100 parts, foaming catalyst 0-20 parts, chain growth catalyst 1-15 parts and foam stabilizer 15-60 parts. The catalytic compound is suitable for the water foaming system of cane trash polyhydric alcohols, the reaction speed can be regulated well.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

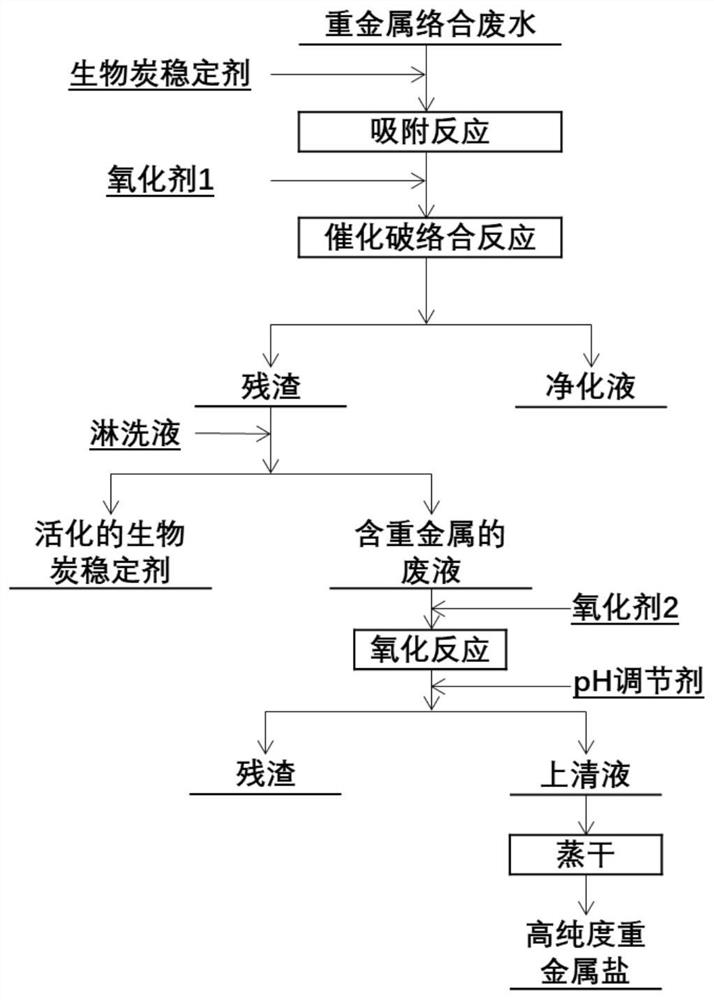

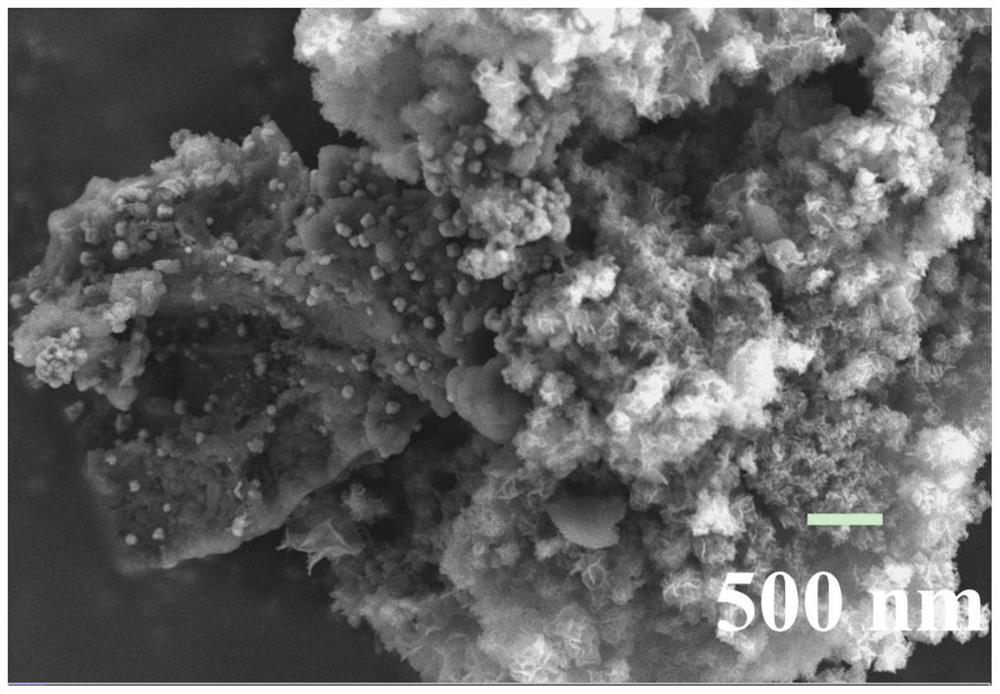

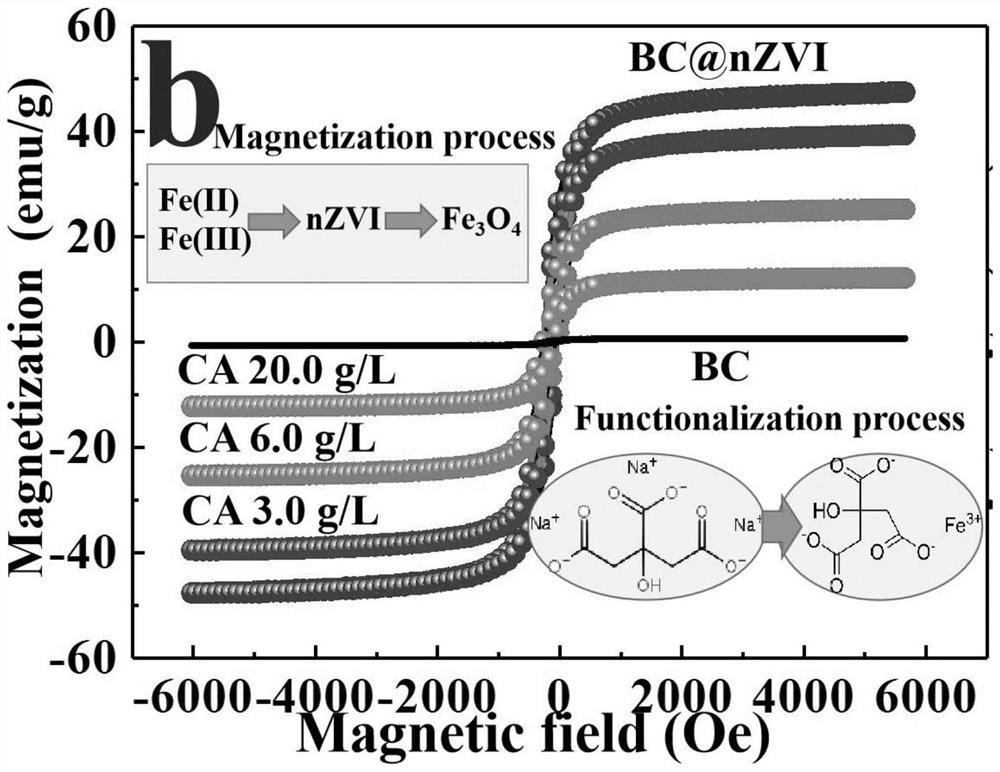

Heavy metal complex wastewater treatment and recycling process based on iron-based biochar

ActiveCN112978983AReduce utilizationAchieve adsorptionOther chemical processesSpecific water treatment objectivesEngineeringAdsorption reaction

The invention discloses a heavy metal complex wastewater treatment and recycling process based on iron-based biochar. The heavy metal complex wastewater treatment and recycling process comprises a heavy metal complex wastewater treatment process and a heavy metal recycling process. The heavy metal complex wastewater treatment process comprises the following steps: firstly, adding iron-based biochar into heavy metal complex wastewater to carry out adsorption reaction, then adding an oxidant 1 to carry out catalytic complex breaking reaction, separating residues and purified liquid after the reaction is completed, discharging the purified liquid, and feeding the residues to the heavy metal resourceful treatment process. The heavy metal resourceful treatment process comprises the following steps: leaching residues with a leaching solution to obtain activated iron-based biochar and a heavy metal-containing waste liquid, reutilizing the activated iron-based biochar, adding an oxidizing agent 2 into the heavy metal-containing waste liquid to carry out an oxidation reaction, then adjusting the pH value, separating the residues and a supernatant, and evaporating the supernatant to dryness to obtain high-purity heavy metal salt. The process solves the problems of low oxidation efficiency and difficulty in recycling after heavy metal separation in the prior art, and is easy for large-scale popularization and application.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Environmental-friendly energy-saving nano electro nickel-plating technology

InactiveCN103603017AReduce stressGood extensibilityElectrolysis componentsCatalytic complexLight intensity

The invention discloses a nano electro nickel-plating technology, and according to the nano electro nickel-plating technology, a nano catalytic complex additive is added into a nickel plating solution, and electroplating is performed under the reaction effect of a superconducting magnetic field effect. The nano electro nickel-plating technology uses a magnetic field generated by a superconducting effect reaction, and under the promoting effect of the nano catalytic complex additive, the metal deposition crystal nucleus size is 18-25nm, and 80% of metal deposition crystal nucleuses are strip shaped and non crystalline. The nano electro nickel-plating technology is excellent in electroplating walking ability, has deep-plating ability, and is small in nickel layer stress, and strong in extensibility. Compared with a traditional nickel plating technology, when a nickel layer with the same thickness is plated, the nickel layer plated by the nano electro nickel-plating technology has significantly improved hardness, wear resistance, light intensity, ductility and corrosion resistance, and can withstand a longer-time corrosion resistant test. In addition, the nano electro nickel-plating technology can be used for subsequent processing only by one process, traditional semi-finished nickel, totally-finished nickel, high-sulfur nickel, nickel sealing and other multiple processes are not needed, the electroplating process is saving, the production efficiency is improved, the cost is reduced, at the same time emissions are also reduced, and the nano electro nickel-plating technology is economic and environmental-friendly.

Owner:DONGGUAN KOE NANO TECH CO LTD

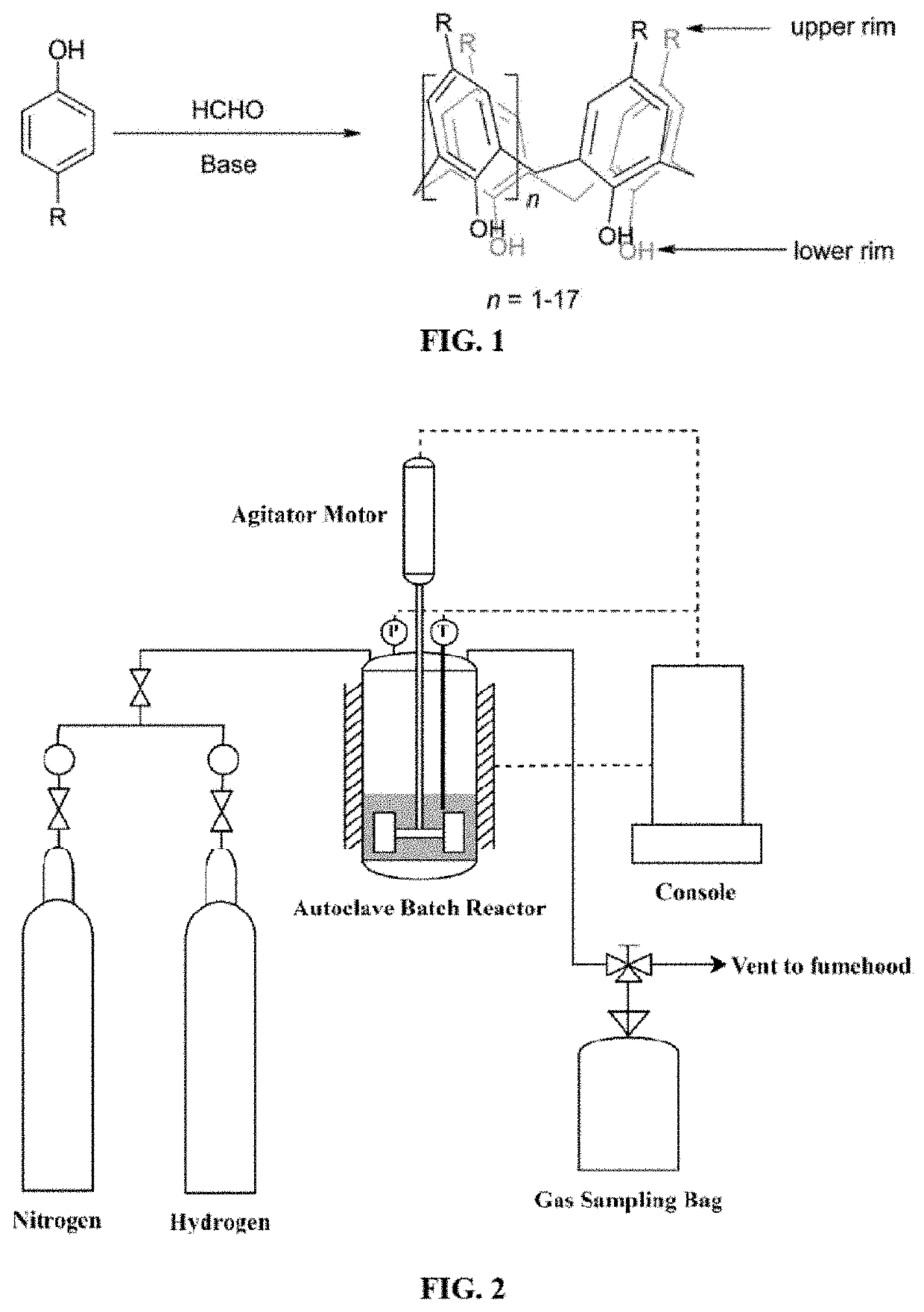

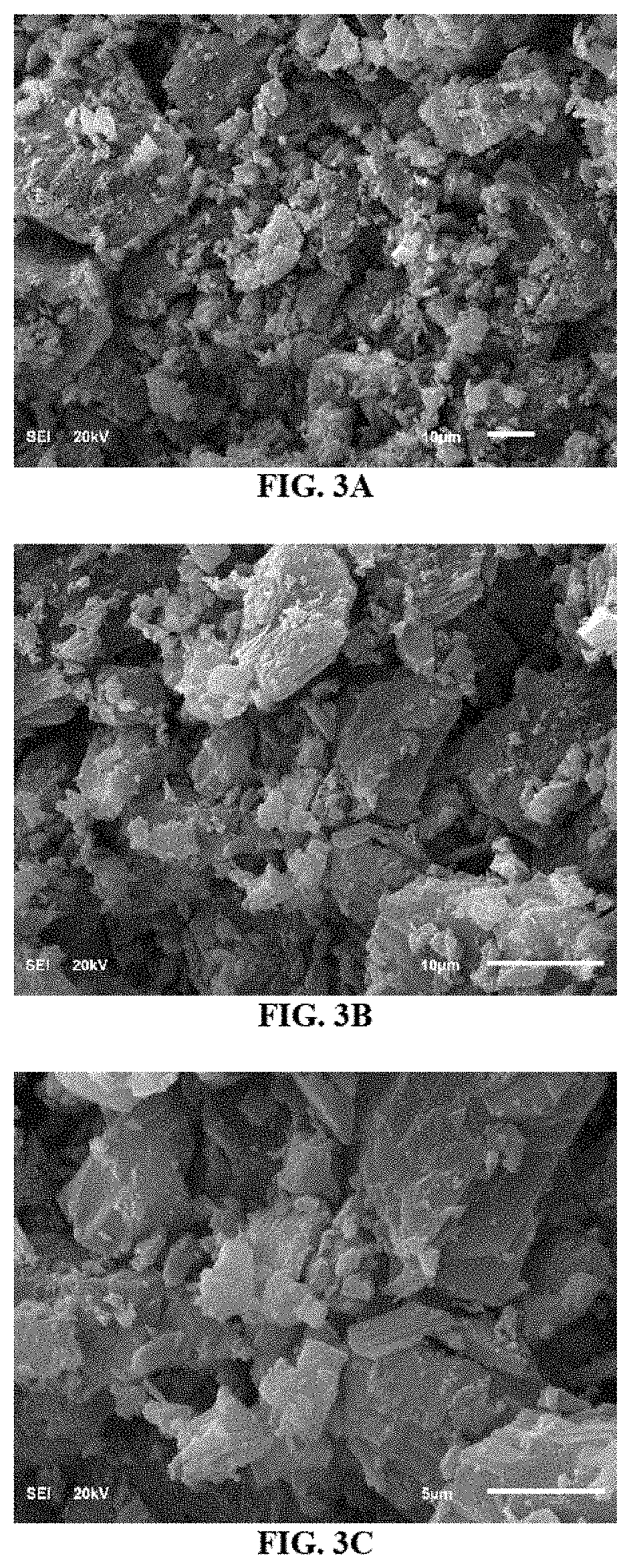

Hydrocracking processes using a metal-calixarene based catalyst

InactiveUS20200270534A1Organic-compounds/hydrides/coordination-complexes catalystsHydrocarbon oil crackingNaphthaPtru catalyst

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

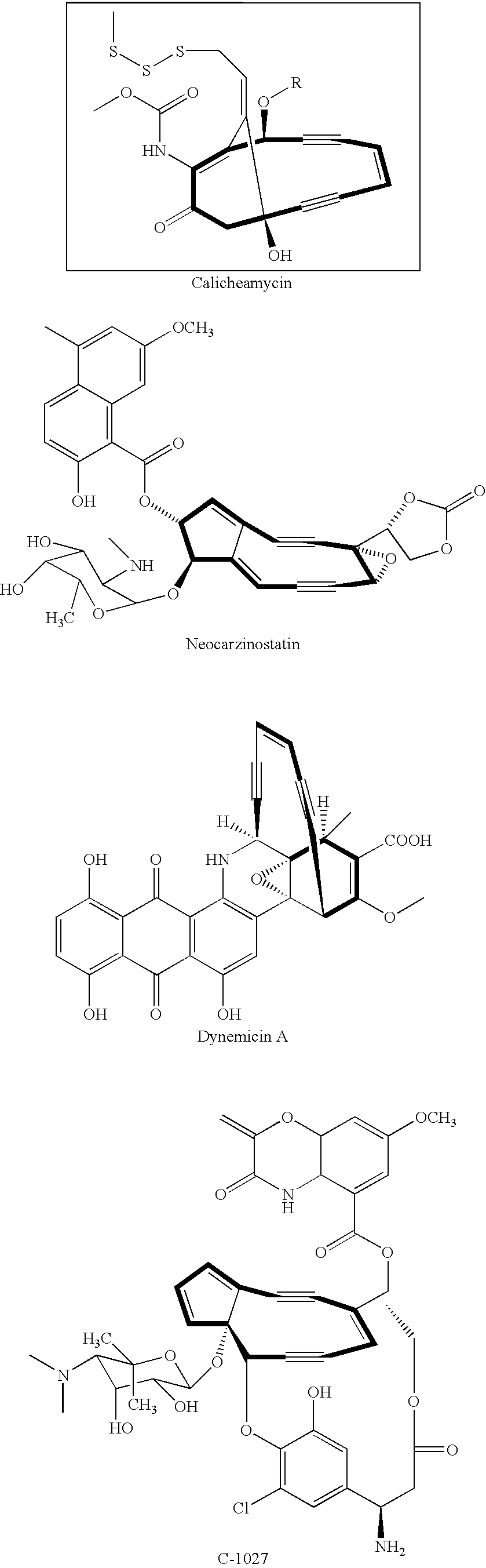

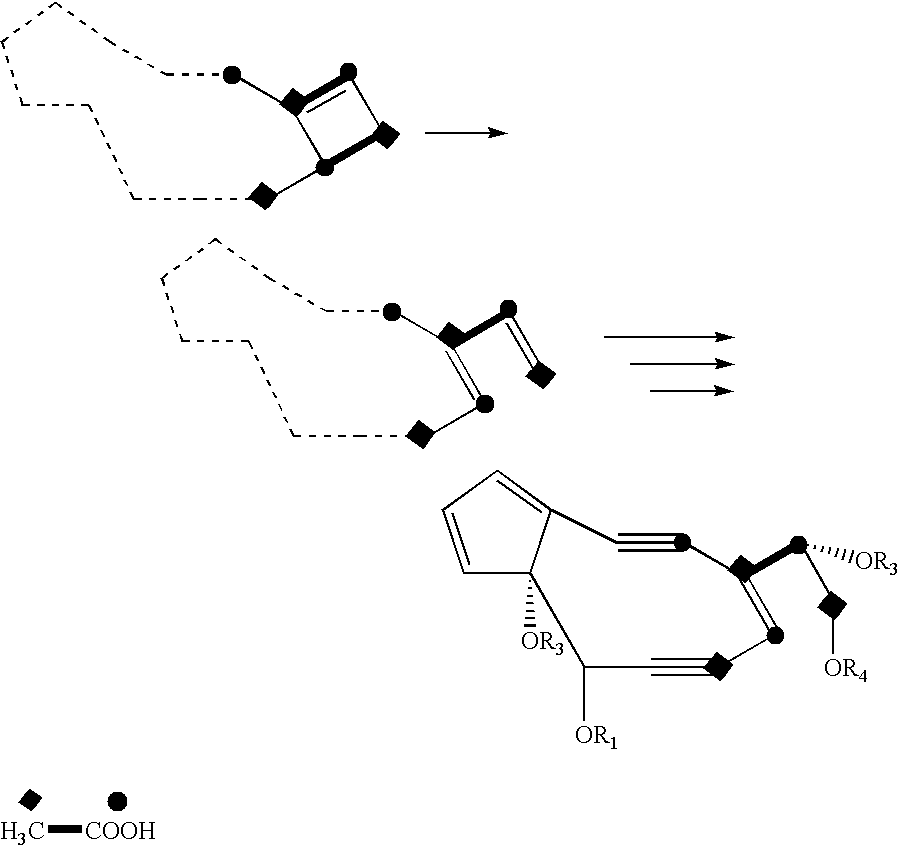

Genes and proteins involved in the biosynthesis of enediyne ring structures

Five protein families cooperate to form the warhead structure that characterizes enediyne compounds, both chromoprotein enediynes and non-chromoprotein enediynes. The protein families include a polyketide synthase and thioesterase protein which form a polyketide synthase catalytic complex involved in warhead formation in enediynes. Genes encoding a member of each of the five protein families are found in all enediyne biosynthetic loci. The genes and proteins may be used in genetic engineering applications to design new enediyne compounds and in methods to identify new enediyne biosynthetic loci.

Owner:ECOPIA BIOSCIENCES INC

Catalytic complex for preparing isocyanurate foam from bagasse ployol

The invention relates to a catalytic complex for preparing isocyanurate foam from bagasse ployol comprising the constituents (by mass ratio) of solvent 100 parts, foaming catalyst 0-20 parts, chain growth catalyst 1-15 parts and foam stabilizer 15-60 parts. The catalytic compound is suitable for the water foaming system of cane trash polyhydric alcohols, the reaction speed can be regulated well.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

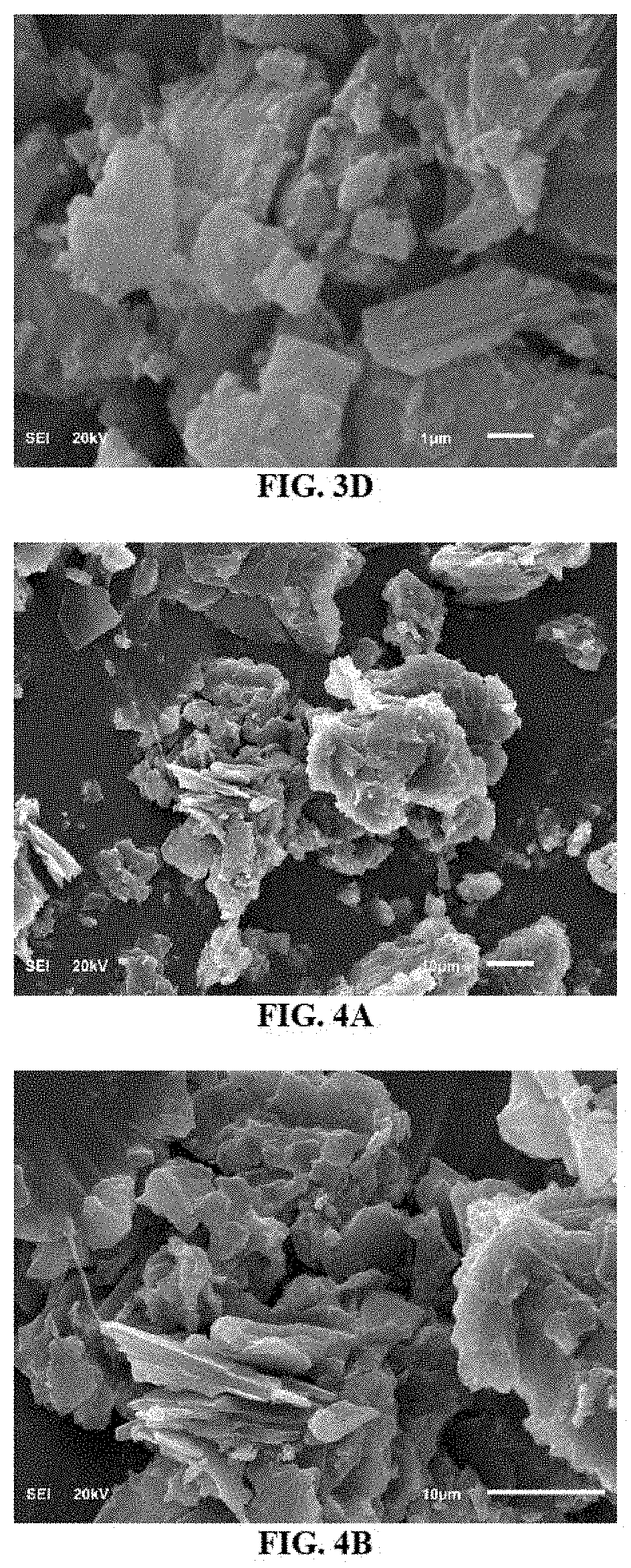

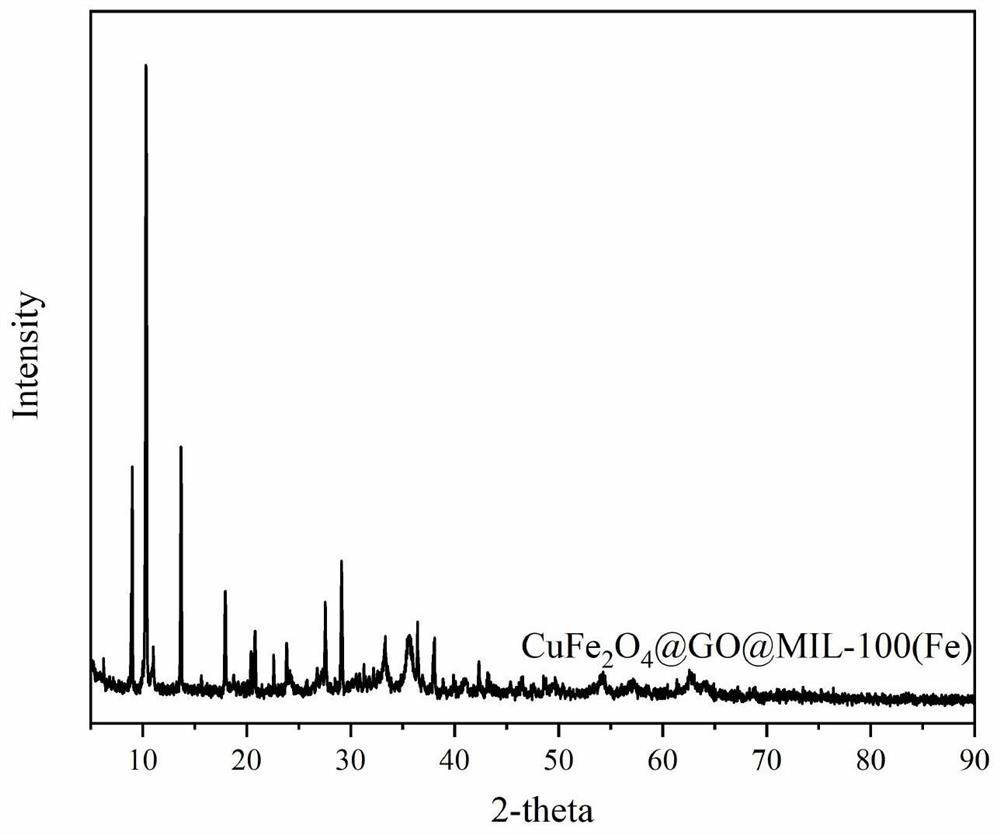

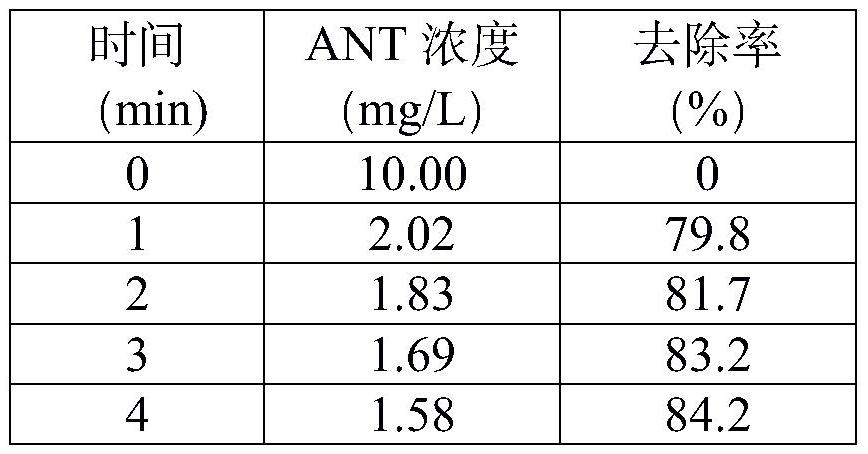

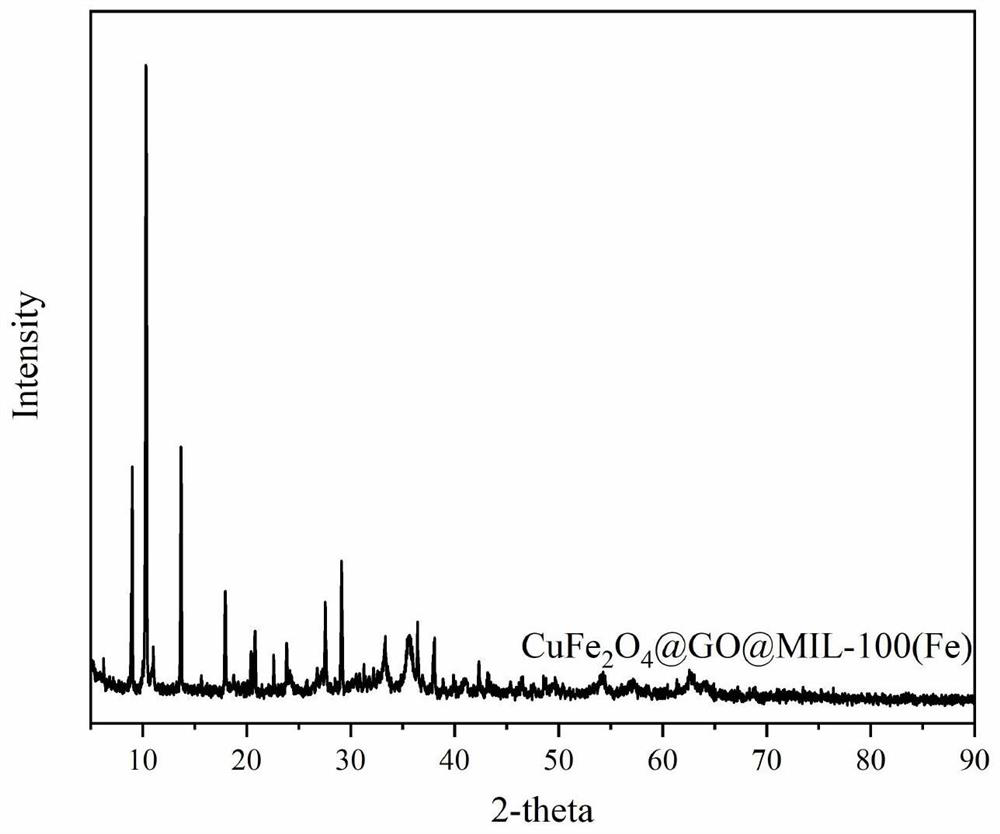

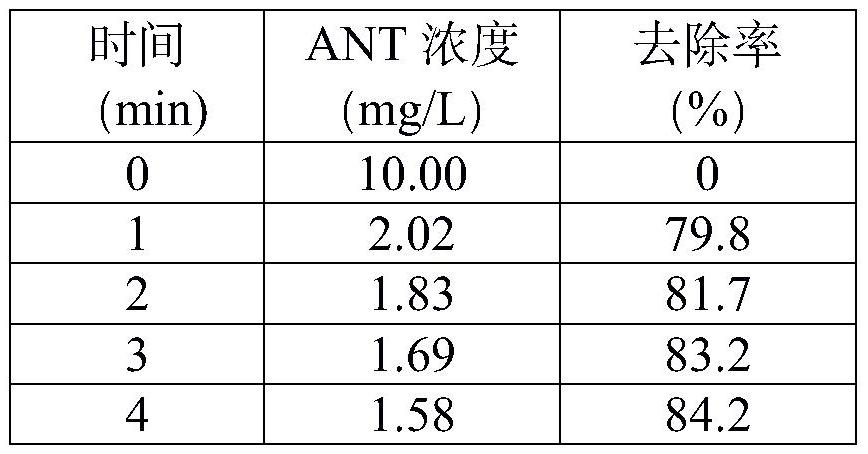

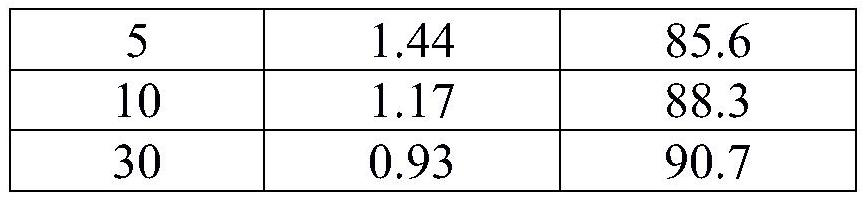

Carbon material coated spinel iron oxide in-situ growth MOFs adsorption catalytic complex as well as preparation method and application thereof

ActiveCN112844320ARich sourcesEasy to prepareOther chemical processesWater treatment compoundsMagnetic carbonPhysical chemistry

The invention discloses a carbon material coated spinel iron oxide in-situ growth MOFs adsorption catalytic complex, a preparation method of the carbon material coated spinel iron oxide in-situ growth MOFs adsorption catalytic complex and application of the carbon material coated spinel iron oxide in water treatment catalysis. The preparation method comprises the steps of 1) preparing a magnetic nanomaterial; 2) preparing carbon material-coated magnetic spinel iron oxide TFe2O4 from the nano spinel ferrite obtained in the step 1), the carbon material and ultrapure water according to a certain proportion; and 3) preparing a carbon material-coated magnetic carbon material in-situ growth MOFs material from the carbon material-coated magnetic TFe2O4 obtained in the step 2), an organic ligand and ultrapure water according to a certain proportion, namely the carbon material-coated spinel iron oxide TFe2O4 in-situ growth MOFs adsorption catalytic complex. The complex is simple in preparation process operation, rich in raw material source, low in manufacturing cost, high in magnetic recovery capacity, excellent in regeneration performance and capable of efficiently adsorbing and removing heavy metal and trace organic matter in water.

Owner:CENT SOUTH UNIV

A Catalyst Catalyzing the Conversion of Complex Sugars to Produce Lactate

InactiveCN109289909BUnlimited optionsHigh yieldMolecular sieve catalystsOrganic compound preparationMolecular sievePtru catalyst

The invention provides a catalyst for preparation of lactic acid ester by catalyzing conversion of complex sugars. The catalyst is composed of a tin-containing silicate molecular sieve as a main catalyst and WO3 as a co-catalyst. The catalyst can catalyze the conversion of sugars, especially hexose, into lactic acid ester in high yield. The catalyst can be easily separated and recovered, and can still obtain good results for a high-concentration sugar solution.

Owner:ZHENGZHOU UNIV

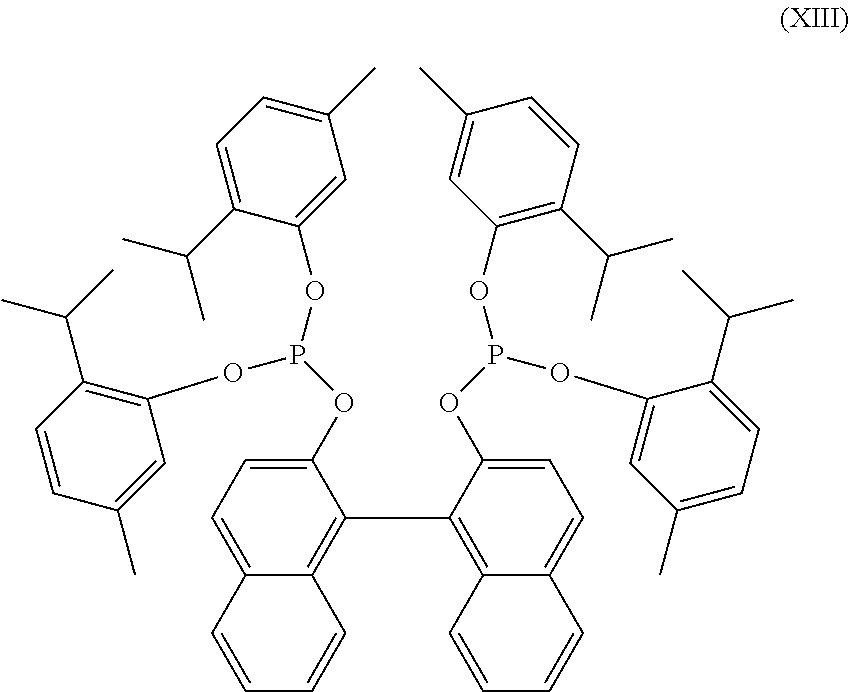

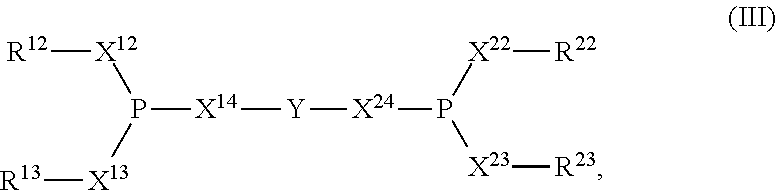

Composition for improved nickel-ligand solubility

ActiveUS9687835B2Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationHydrogenReaction rate

In the hydrocyanation reaction of butadiene proceeding through pentenenitriles to adiponitrile, catalysis by complexes of zerovalent nickel with bidentate phosphorus-based ligands of the NiL2A type wherein L2 is a bidentate ligand and A is an unsaturated compound, can be rate-limited by the solubility of the catalytic complex. The present invention concerns solvent compositions for the nickel-ligand complex comprising mixtures of unsaturated nitriles that provide for increased metal solubility, particularly in the absence of a Lewis acid promoter, resulting in higher hydrocyanation reaction rates in an industrial-scale process for production of important nylon manufacturing intermediates. The mixed nitrile solvent compositions can include mixtures of pentenenitriles and / or methylbutenenitriles. The mixtures of mixed unsaturated nitriles can be, at least in part, from recycle streams from the hydrocyanation reaction for which the nickel-bidentate ligand complexes are used as catalysts.

Owner:INV NYLON CHEM AMERICAS LLC

Process for the polymerization of olefins

Olefins are polymerised in contact with a catalyst system contg. (a) a solid catalytic complex based on Mg, a transition metal and a halogen, obtd. by (i) reacting (I) an oxygenated organo-Mg cpd. or a halogenated Mg cpd. with (II) an oxygenated organic cpd. or a halogenated cpd. of a transition metal of Gps. IVB or VB, to give a liq. complex, (ii) precipitating. the complex by means of a cpd. of formula AlRnX3-n, to give a solid catalytic complex, (iii) sepg. the solid complex, and (iv) treating the solid complex with a cpd. of formula AlRnX3-n, and (b) an organic cpd. of a metal of Gps. IA, IIA, IIB, IIIA or IVB. R = hydrocarbo gp.; X = halogen; n = less than 3. This method has an effect to improve the apparent density of polyolefin.

Owner:INNOVENE MFG BELGIUM NV

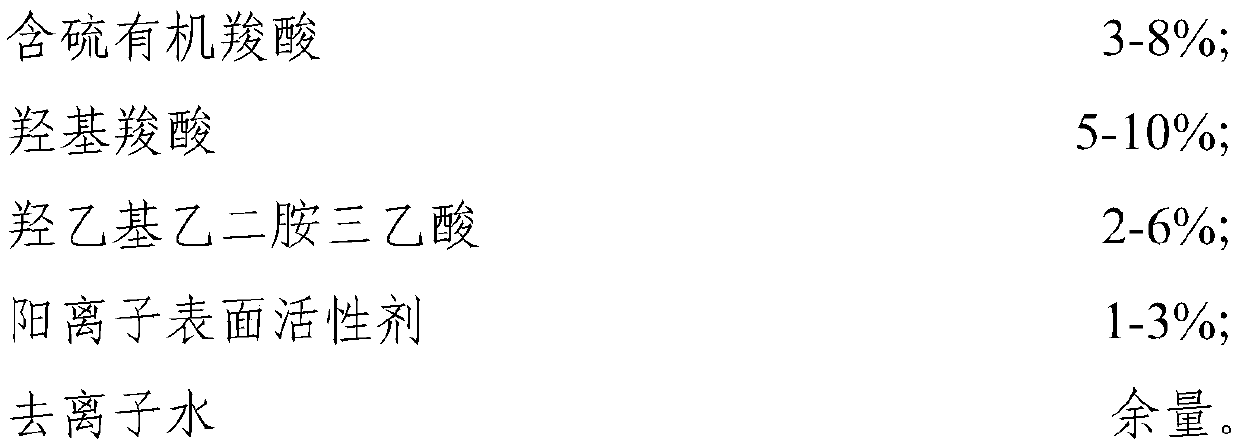

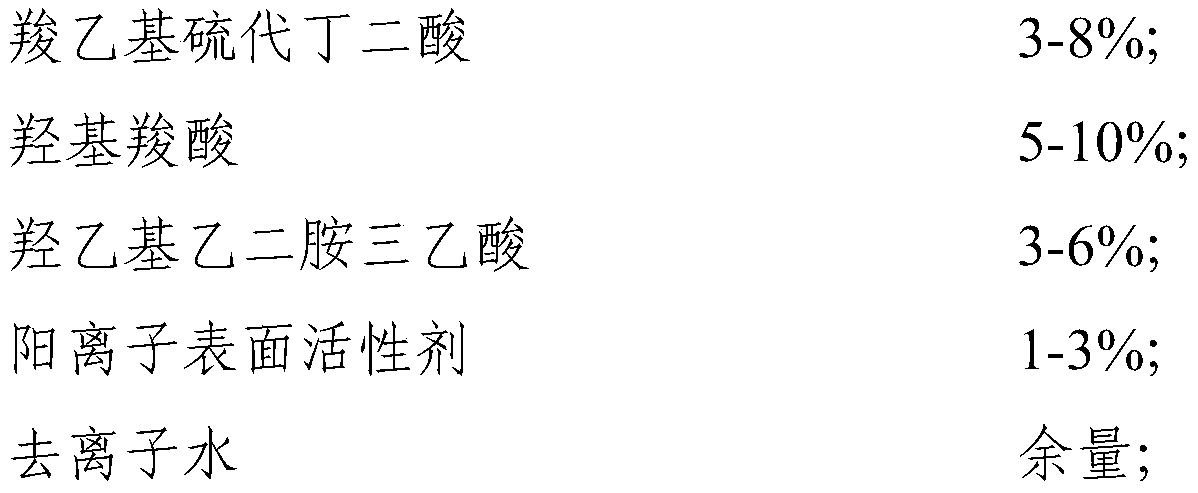

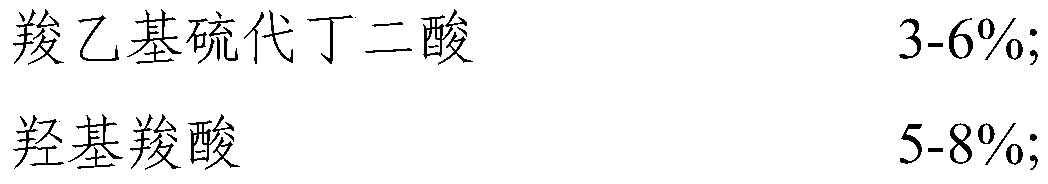

A three-way catalytic complex cleaning solution

ActiveCN107881037BEfficient removalImprove pickling effectCationic surface-active compoundsOrganic detergent compounding agentsActive agentCarboxylic acid

Owner:CHINA PETROLEUM & CHEM CORP

A carbon material-wrapped spinel iron oxide in-situ growth mofs adsorption catalytic complex and its preparation method and application

ActiveCN112844320BRich sourcesEasy to prepareOther chemical processesWater treatment compoundsEngineeringSpinel ferrite

Owner:CENT SOUTH UNIV

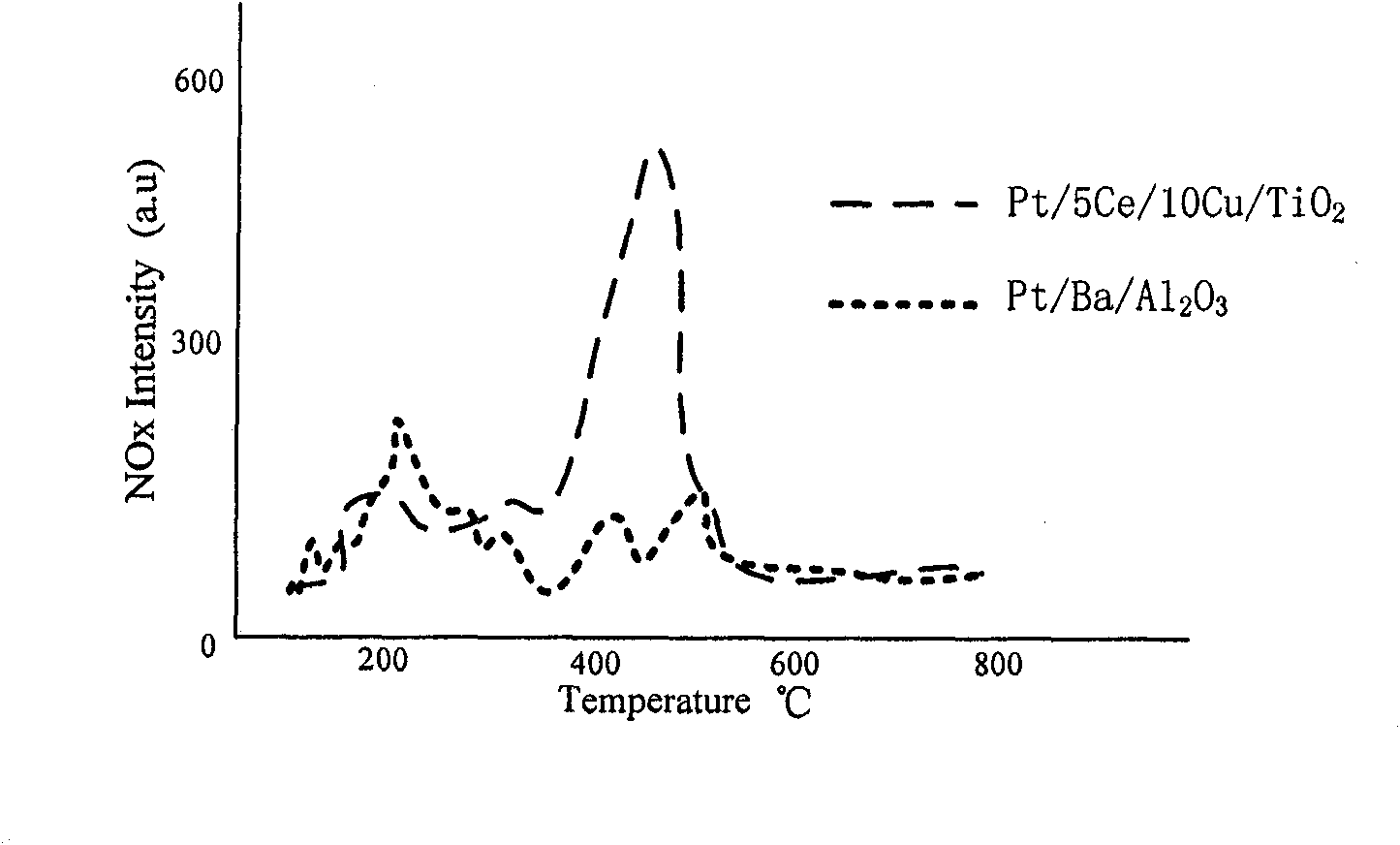

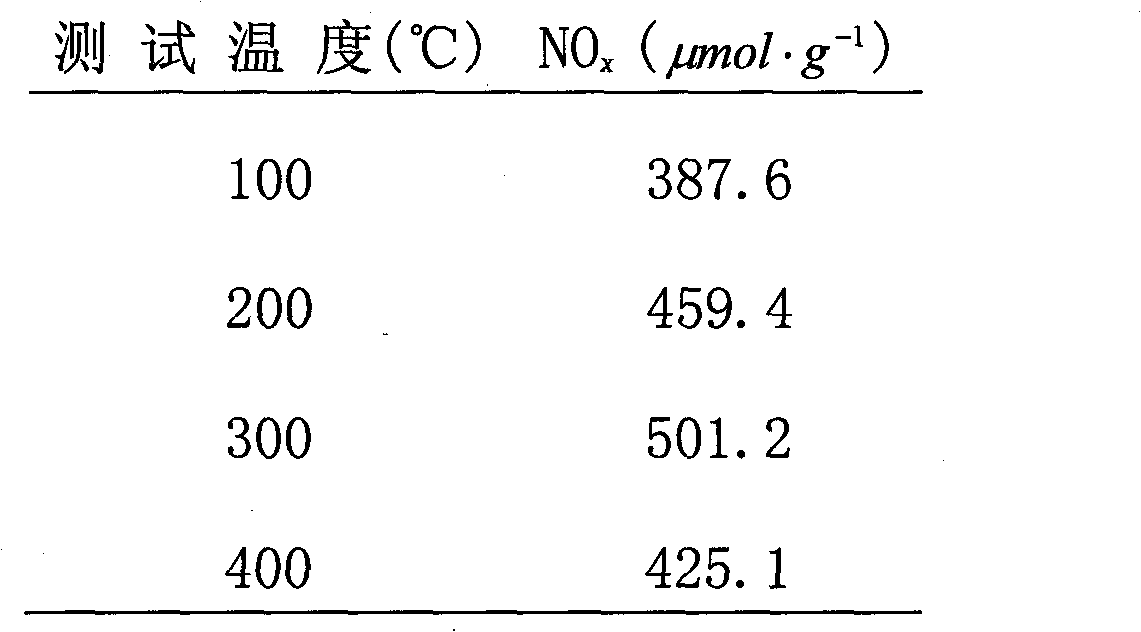

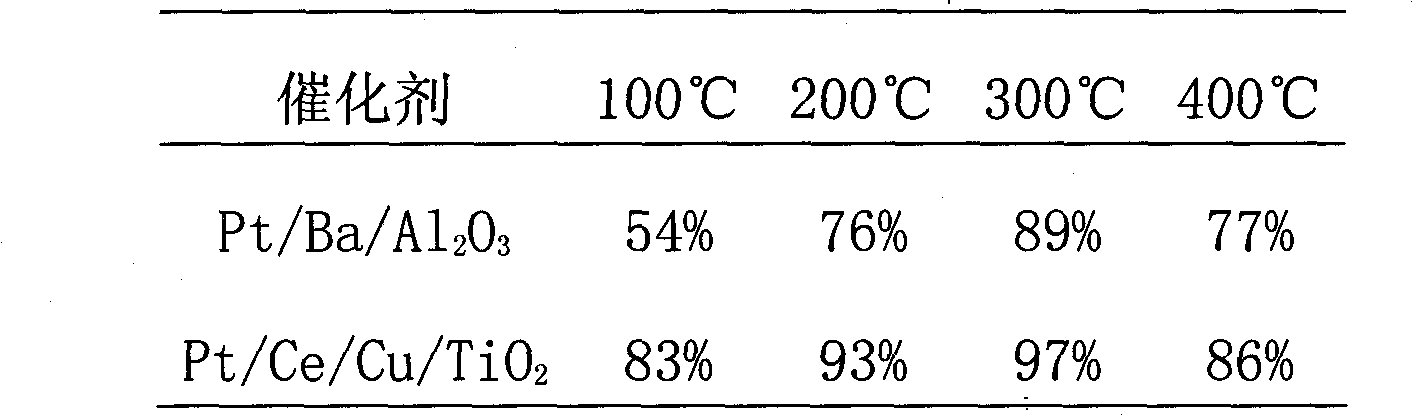

Catalytic complex for denitration of lean burn gasoline engine exhaust and preparation method thereof

InactiveCN102728382AImprove stabilityBenefitExhaust apparatusDispersed particle separationCeriumPt element

A catalytic complex for denitration of lean burn gasoline engine exhaust and a preparation method thereof aim to overcome unsuitability of an existing ternary composite catalyst catalytic complex for lean burn technology. The catalytic complex comprises a cellular titanium dioxide carrier and metal platinum, rare earth metal, and metal copper that are attached to the carrier. The preparation method includes steps of: immersing titanium dioxide into a copper sulfate pentahydrate solution with a concentration of 75%, and drying and roasting to obtain a copper / titanium dioxide catalyst complex; immersing the copper / titanium dioxide catalyst complex in a rare earth cerium solution, and then drying and roasting to obtain a cerium / copper / titanium dioxide catalyst complex; and immersing the cerium / copper / titanium dioxide catalyst into a platinum nitrate salt solution, and drying and roasting to obtain a nitrate platinum / cerium / copper / titanium dioxide catalyst complex. The invention is beneficial to nitrogen oxides and reduction thereof, and significantly reduces temperature of harmless transformation of nitrogen oxides, and improves the ability of resistance to sulfur poisoning of the catalyst. Besides, the catalytic complex reduces use amount of noble metal platinum and cost of catalyst, and conducts efficient reduction on NOx in lean burn of gasoline engine exhaust.

Owner:刘瑞军

Catalyst Complex With Carbene Ligand

InactiveUS20100160642A1Increase response rateEasy to synthesizeGroup 5/15 element organic compoundsCarboxylic acid esters preparationCarbeneAlkene

Catalytic complexes including a metal atom having anionic ligands, at least one nucleophilic carbine ligand, and an alkylidene, vinylidene, or allenylidene ligand. The complexes are highly stable to air, moisture and thermal degradation. The complexes are designed to efficiently carry out a variety of olefin metathesis reactions.

Owner:MATERIA

Procedure for obtaining nanotube layers of carbon with conductor or semiconductor substrate

ActiveUS8039380B2Material nanotechnologySemiconductor/solid-state device detailsElectrical conductorNanotube

The present invention relates to a process for producing a carbon nanotube (CNT) mat on a conductive or semiconductor substrate. According to this process, a catalytic complex comprising at least one metal layer is firstly deposited on said substrate. Said metal layer then undergoes an oxidizing treatment. Finally, carbon nanotubes are grown from the metal layer thus oxidized. The present invention also relates to a process for producing a via using said CNT mat production process.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Ruthenium-based catalytic complexes and the use of such complexes for olefin metathesis

ActiveCN101595116BAchieve recyclabilityAvoid pollutionRuthenium organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsArylRuthenium

Ruthenium complex (I), are new. Ruthenium complex of formula (I) are new. L : imidazolidine compound of formula (a) or 2,3-dihydro-1H-imidazole of formula (b); R : alkyl or aryl; either R1>alkyl, perfluoroalkyl, aryl or ruthenium complex of formula (c); and R2>alkyl, perfluoroalkyl or aryl; or R1>, R2>form a cycle. An independent claim is included for a molecule constituted by (I) substituted by an ionic unit. [Image] [Image]

Owner:UMICORE AG & CO KG +1

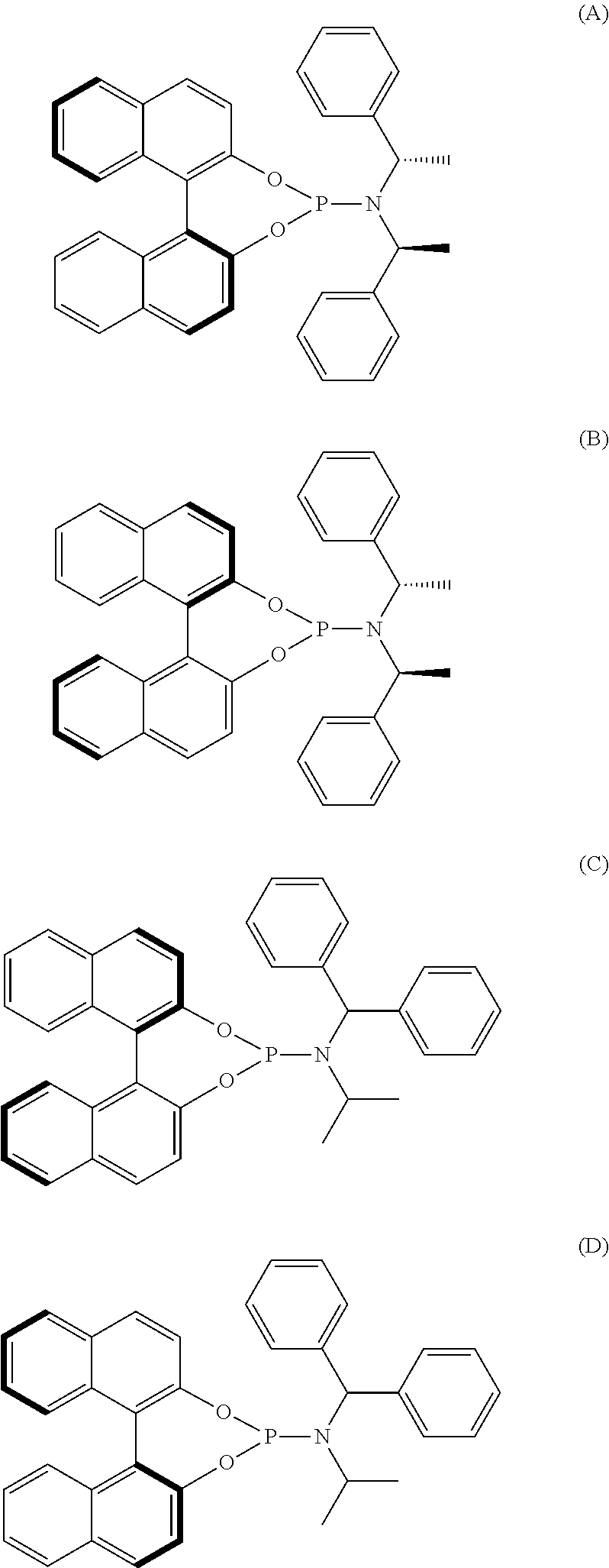

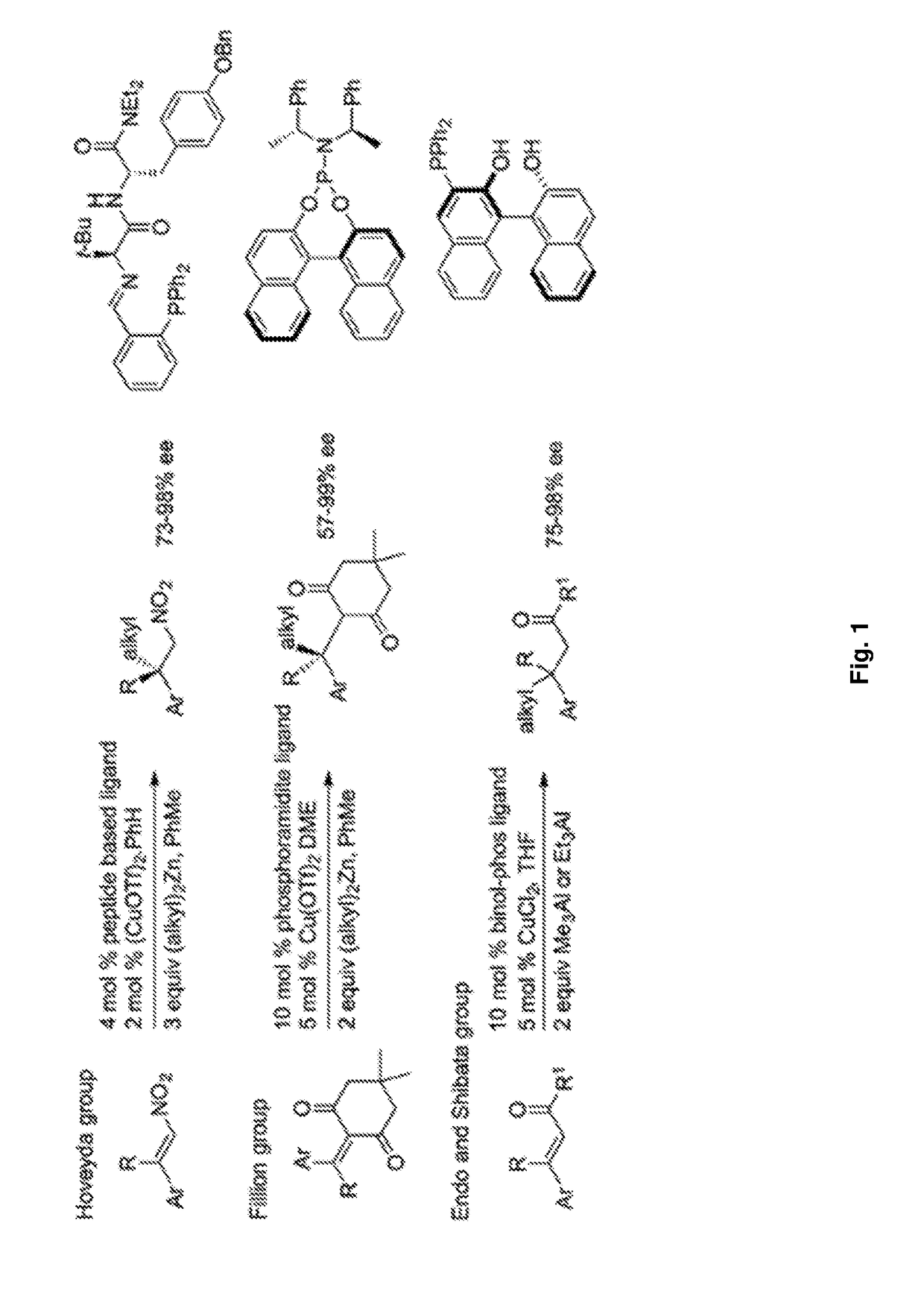

Catalysts, ligands and use thereof

InactiveUS9636670B2High stereoselectivityIncreased stereoisomeric excessSilicon organic compoundsOrganic compound preparationCounterionMetal

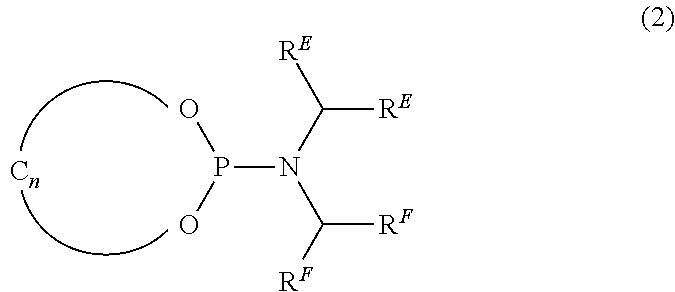

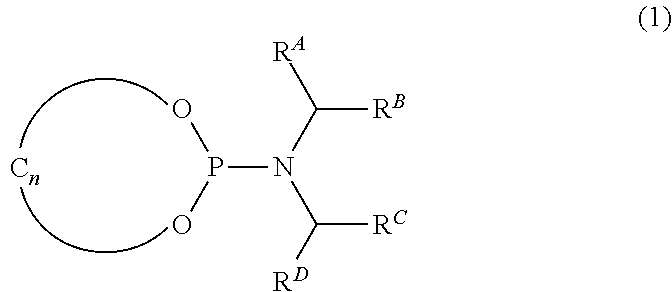

According to the present invention, there is provided a catalytic complex comprising a metal, one or more ligands and one or more counterions, wherein said one or more ligands include a non-racemic chiral ligand and wherein said one or more counterions include a triflimide counterion. Also provided are methods of making said catalytic complex and processes for producing chiral compounds which involve the use of said catalytic complex. In addition, the present invention provides compounds of the formula (2) as defined herein. The compounds of formula (2) may be useful as ligands in catalytic complexes.

Owner:OXFORD UNIV INNOVATION LTD

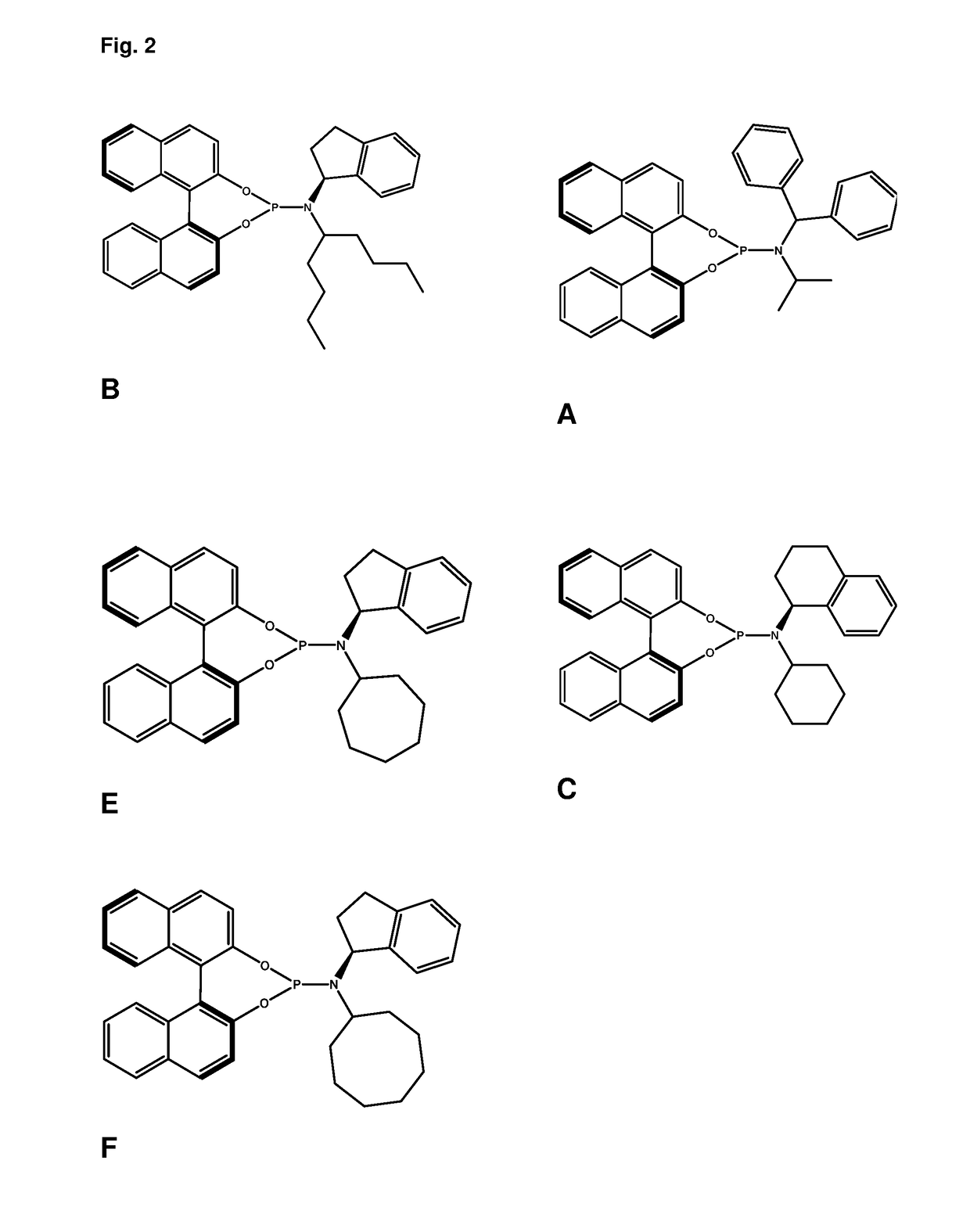

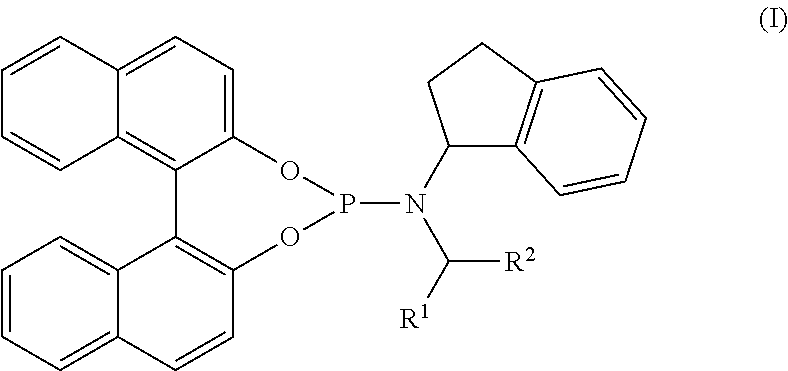

Ligands and catalysts

InactiveUS20190009259A1Group 5/15 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsCoordination complexCatalytic complex

The present invention relates to a compound of formula (I) and salts thereof,The present invention further relates to catalytic complexes comprising a compound of formula I and uses thereof in the stereoselective synthesis of stereocentres, in particular, all-carbon quaternary stereocentres.

Owner:OXFORD UNIV INNOVATION LTD

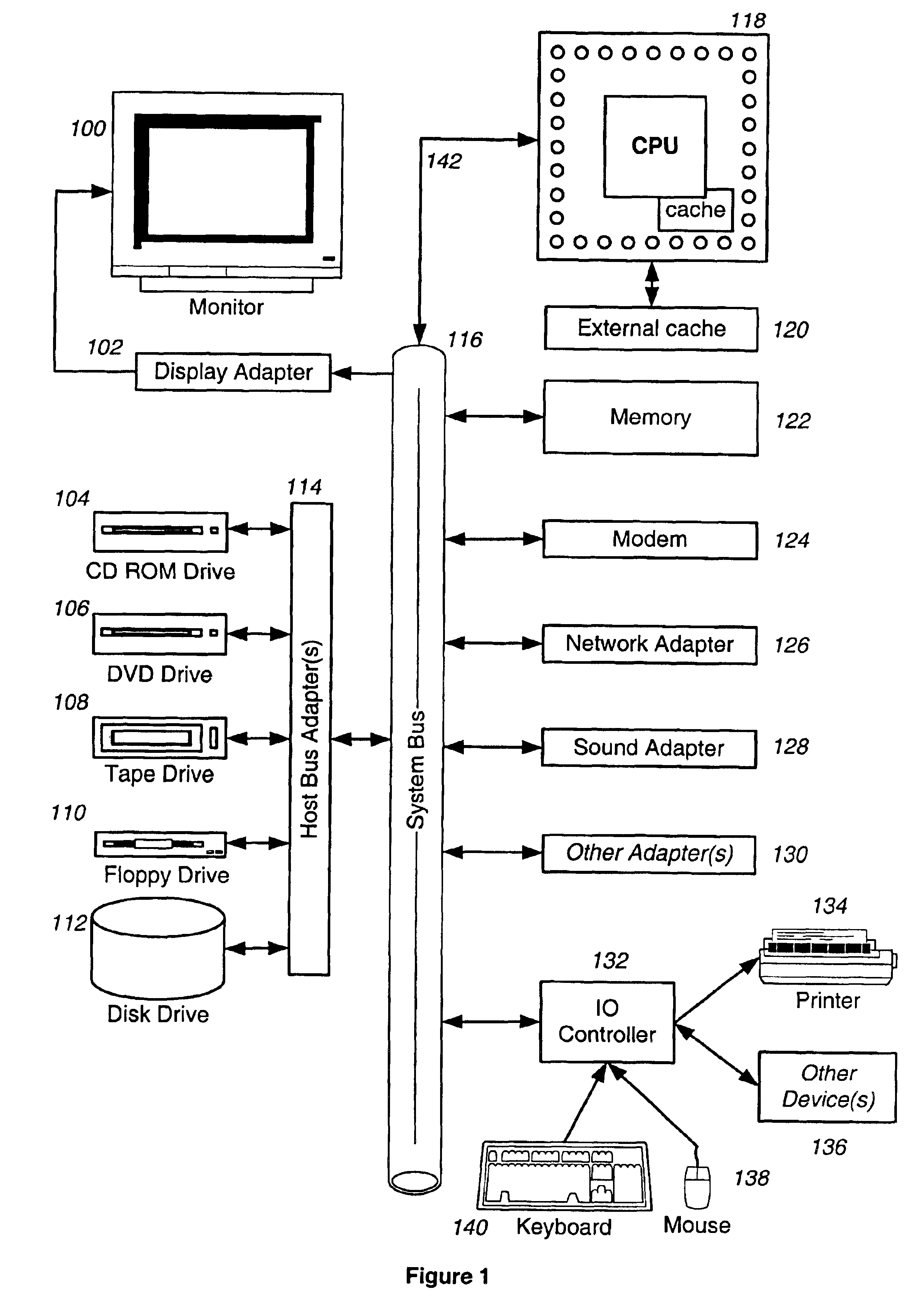

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com