A carbon material-wrapped spinel iron oxide in-situ growth mofs adsorption catalytic complex and its preparation method and application

An iron oxide, in-situ growth technology, applied in the application fields of water treatment and catalysis, can solve the problems of easy aggregation, affecting the catalytic efficiency, etc., and achieve the effects of simple process operation, efficient catalytic removal, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] A carbon material wrapped spinel iron oxide TFe 2 o 4 The preparation method of in-situ growth MOFs adsorption catalytic complex is characterized in that it comprises the following steps:

[0047] 1) preparing magnetic nanomaterials, said magnetic nanomaterials are nano spinel ferrite synthesized or purchased by synthetic method;

[0048] In some embodiments, as a preferred technical solution, the magnetic nanomaterial is spinel ferrite synthesized by hydrothermal synthesis.

[0049] 2) The nano-spinel ferrite obtained in step 1), carbon material, and ultrapure water are prepared in a certain ratio to prepare magnetic spinel iron oxide TFe wrapped in carbon material 2 o 4 ;

[0050] Wherein, T is a transition metal element;

[0051] In some embodiments, the T is one or more of Cu, Co, Mn, Zn, Ni;

[0052] As a preferred embodiment, the T is one or more of Cu, Co, Mn;

[0053] 3) The magnetic spinel iron oxide TFe wrapped by the carbon material obtained in step 2)...

Embodiment 1

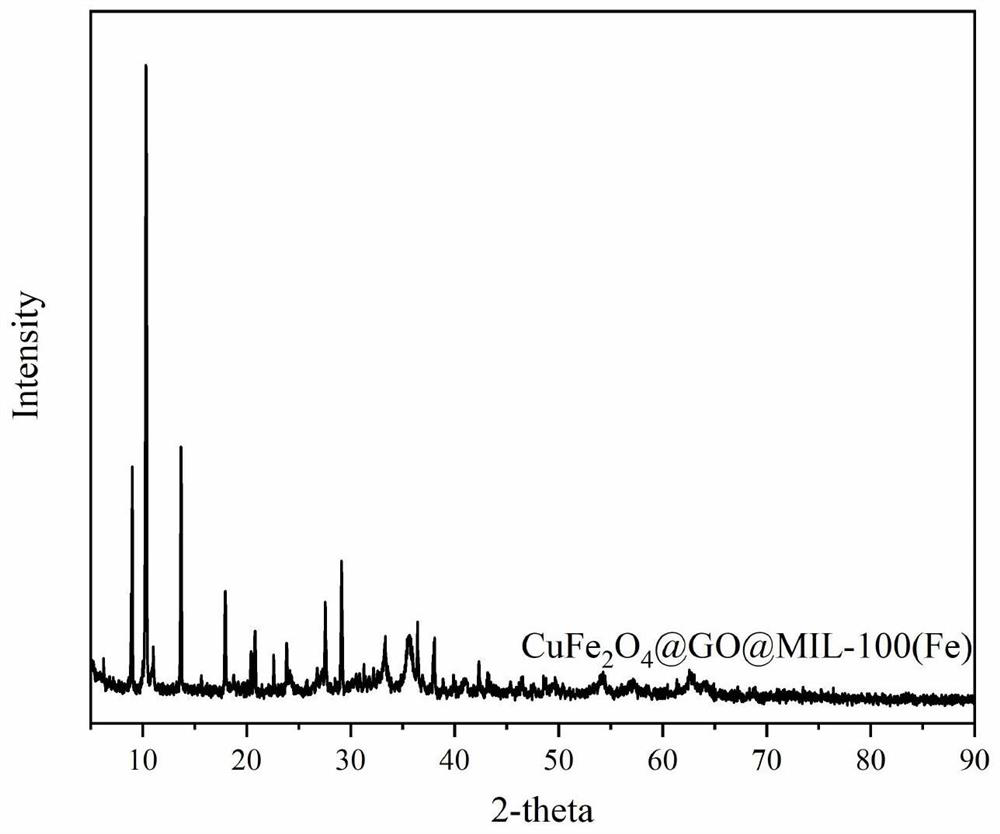

[0079] Carbon material wrapped spinel iron oxide TFe 2 o 4 In situ growth of MOFs adsorption catalytic complex (CuFe 2 o 4 @GO@MIL-100(Fe), the transition metal is copper, the carbon material is graphene oxide, and the organic ligand is trimesic acid) Preparation:

[0080] 1) Preparation of nano spinel ferrite: 3mMCu 2+ / Fe 3+ (molar ratio is 1:2) the solution uses NH 4 OH to adjust the pH to greater than 10, heat and stir in a water bath at 90°C for 90 minutes, keep the pH of the solution greater than 10 during the heating process, collect the magnetic black precipitate with a magnet after the reaction, wash with ethanol and ultrapure water for 3-4 times, and collect the product. Nano spinel ferrite CuFe 2 o 4 ; Wherein from ferric nitrate (nine water), Cu 2+ From copper nitrate (trihydrate).

[0081] 2) Mix the nano-spinel ferrite prepared in step 1) with the carbon material (GO, graphene oxide is selected in this embodiment) in ultrapure water, and the mixed soluti...

Embodiment 2

[0087] Compared with Example 1, the only difference is the choice of carbon material, which is multi-walled carbon nanotubes, which are commercially available and have a specific surface area of 80-250m 2 / g, the pore volume is 0.4-1.2cm 3 / g;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com