Ruthenium-based catalytic complexes and the use of such complexes for olefin metathesis

A compound and alkyl technology, applied in the field of new ruthenium-based catalytic complexes and their synthesis, can solve problems such as difficult recycling of complexes, residual pollution of toxic metals, and harmful synthesis of high value-added products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

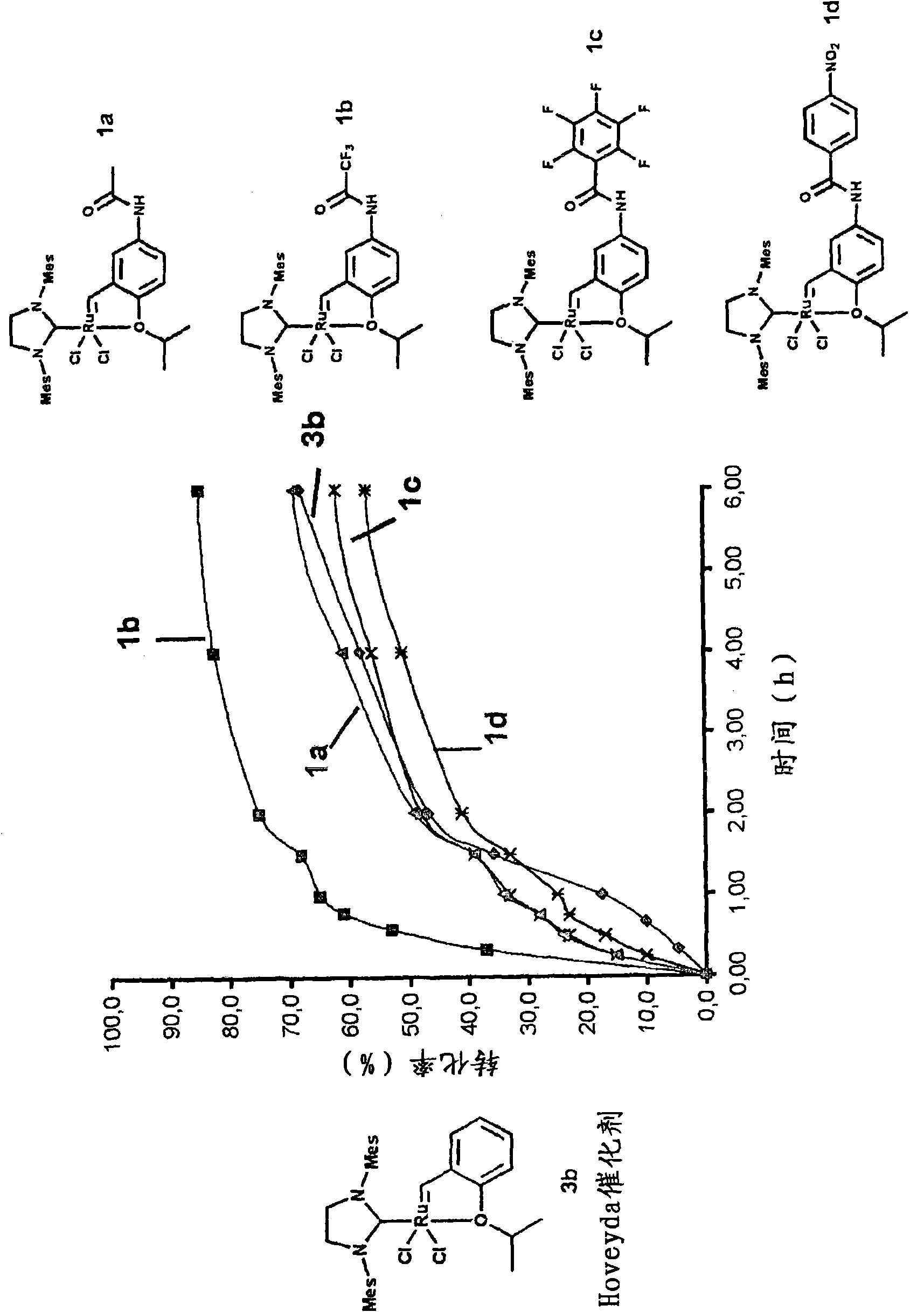

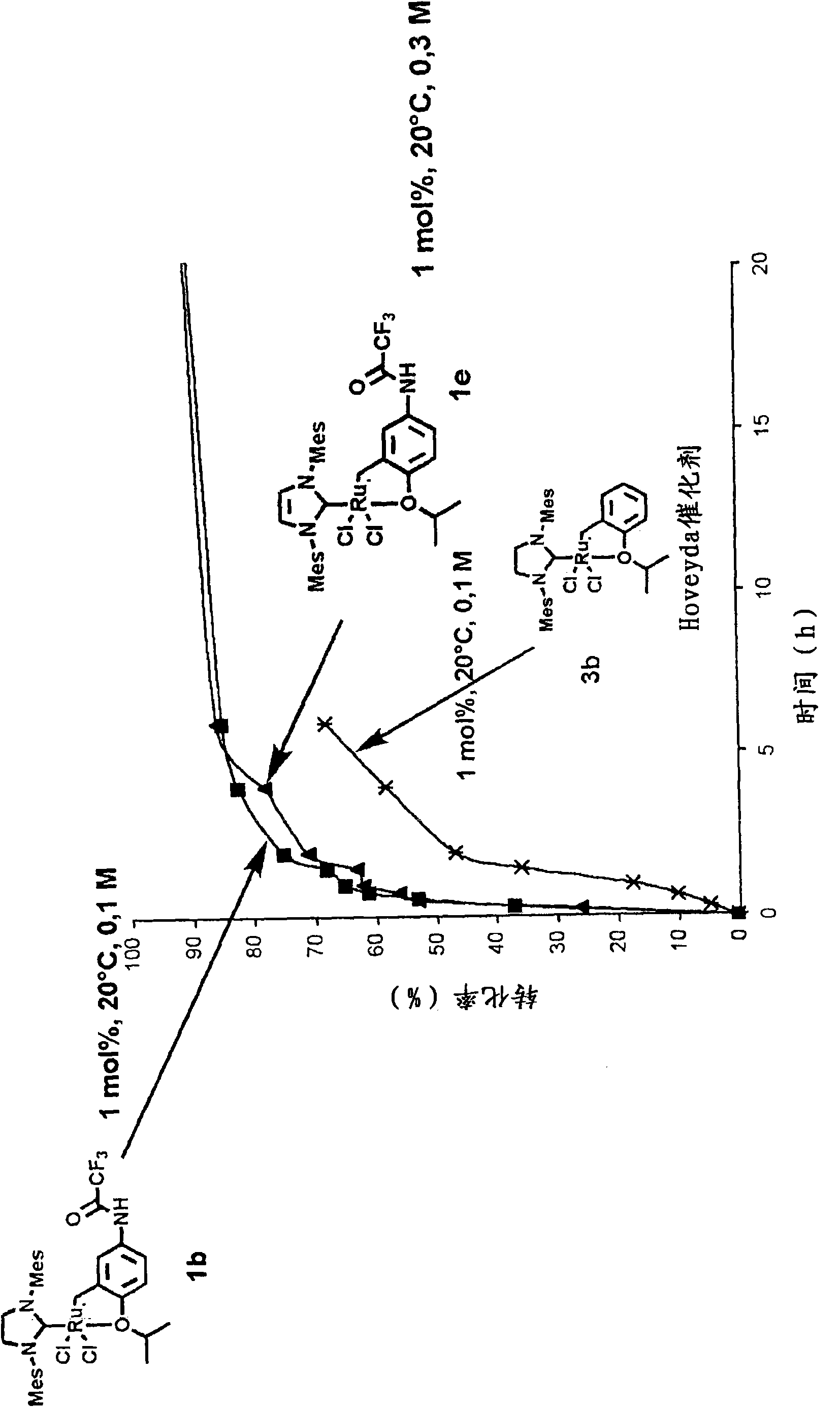

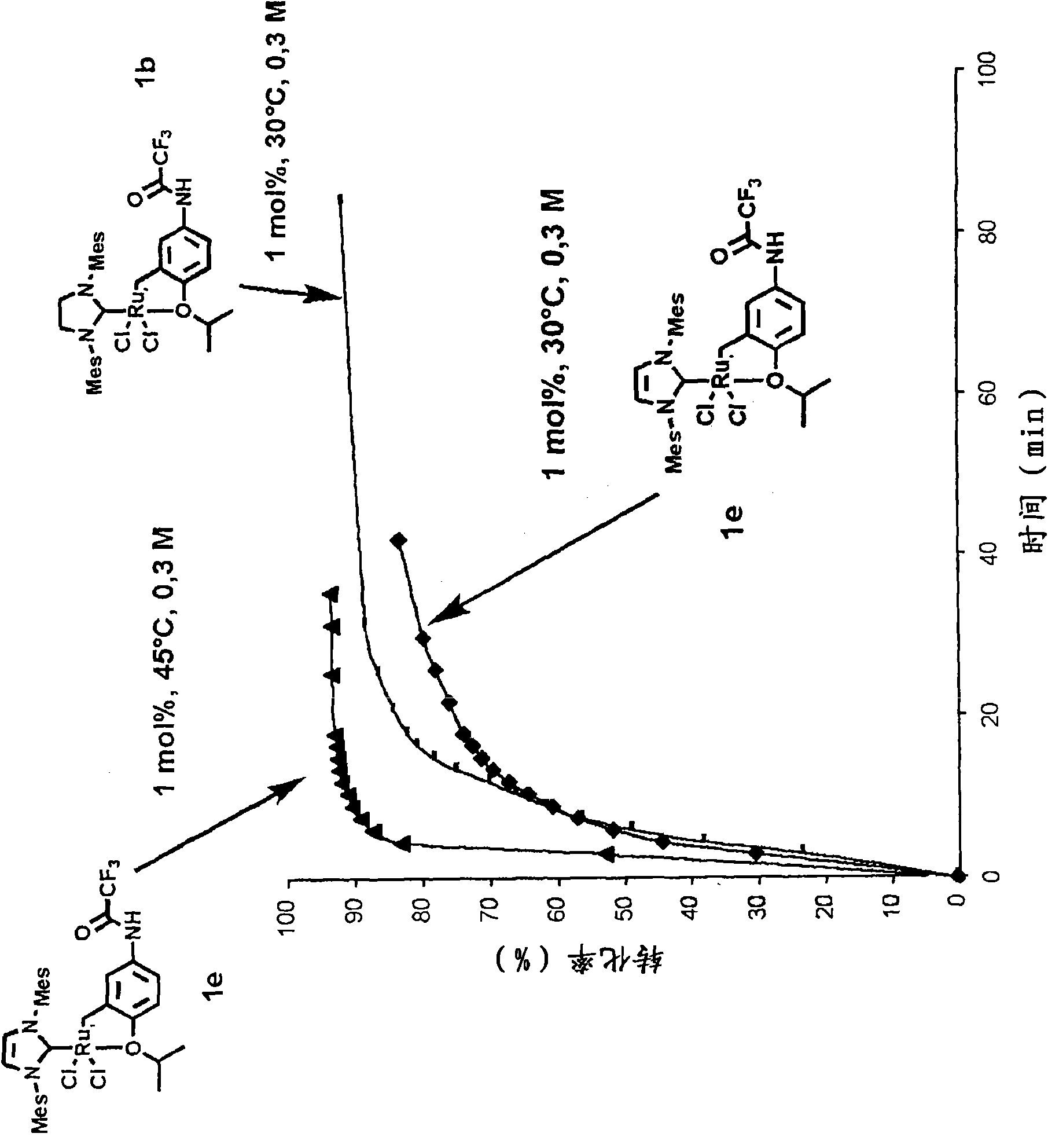

[0105] First, the synthesis of various examples of the complexes of the present invention will be described below.

[0106] Complexes 1a, 1b, 1c, 1d, 1e and 1f of the present invention were obtained from functionalized aniline 5 in two steps.

[0107] The method for synthesizing the functionalized aniline 5 from p-nitrophenol in 4 steps is described in the article "Activated pyridinium-tagged ruthenium complex as efficient catalyst for Ring-Closing Metathesis (activated pyridinium-tagged ruthenium complex as a ring-closing metathesis effective catalyst)" D. Rix, H. Clavier, Y. Coutard, L. Gulajski, K. Grela*, M. Mauduit*, J. Organomet. Chem., 2006, 691, 5397-5405.

[0108] The following roadmap outlines this two-step synthesis:

[0109]

[0110] Step 1: Synthesis of amides 6a, 6b, 6c, 6d, 6f, 9a, 9b, 10a and 10b from 4-isopropylhydrogen-3-vinylaniline 5

[0111] According to the general procedure, 4-isopropoxy-3-vinylaniline 5 (1 equiv; about 0.2 mmol) was added to a rou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com