A three-way catalytic complex cleaning solution

A cleaning solution and complexation technology, applied in the direction of surface-active non-soap compounds and cleaning compositions, cationic surface-active compounds, detergent compositions, etc., can solve problems such as water pollution, three-way catalytic secondary poisoning, etc., to avoid Effects of eutrophication, less corrosion of metal materials, and excellent complexation cleaning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

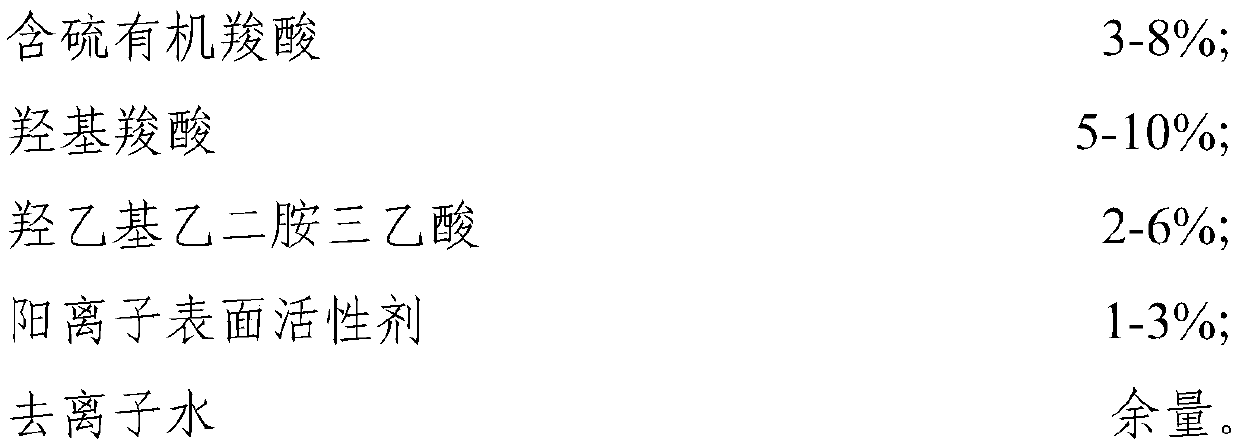

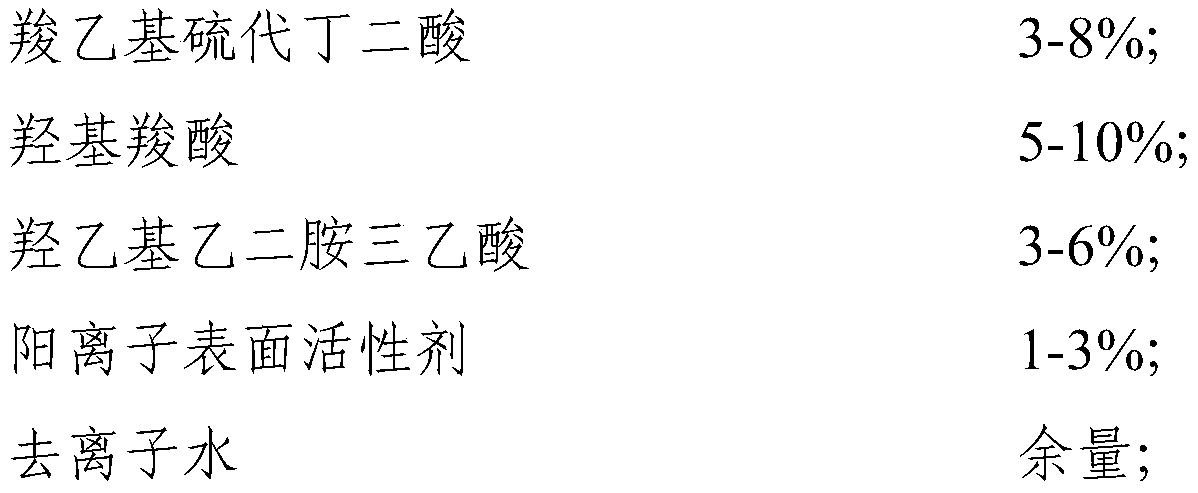

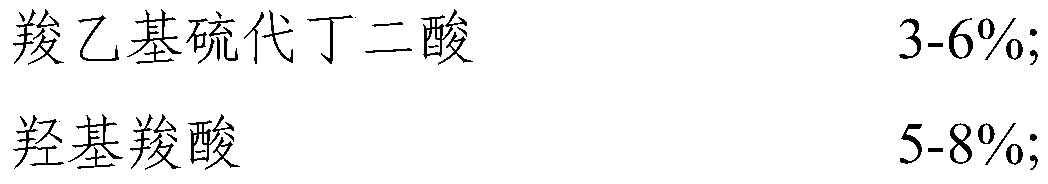

Method used

Image

Examples

Embodiment 1

[0034] This embodiment provides a three-way catalytic complexing cleaning solution, specifically: 6% carboxyethyl thiosuccinic acid, 6% citric acid, 4% glucoheptonic acid, 6% hydroxyethyl Ethylenediaminetriacetic acid, 1.5% REWOQUAT CPEM, and the rest of deionized water are mixed to obtain a three-way catalytic converter complex cleaning solution.

[0035] This embodiment also provides a specific method of using the three-way catalytic converter complex cleaning solution: disassemble the exhaust manifold assembly, place it in the cleaning container, and use a syringe to slowly and steadily inject the cleaning solution into the exhaust manifold. Opening, keep injecting for about 20 minutes, slowly inject clean water into the opening of the exhaust manifold, the injection time lasts for about 5 minutes, and the cleaning is completed.

Embodiment 2

[0037] The present embodiment provides a three-way catalytic complexing cleaning solution, specifically: 5% carboxymethylthiosuccinic acid, 3% citric acid, 5% glucoheptonic acid, 4% hydroxyethyl Ethylenediaminetriacetic acid, 1.5% REWOQUAT CPEM, and the rest of deionized water are mixed to obtain a three-way catalytic converter complex cleaning solution.

[0038] This embodiment also provides a specific method for using the three-way catalytic converter complex cleaning liquid: disassemble the exhaust manifold assembly, spray the cleaning agent directly into the three-way catalytic converter of the automobile with an aerosol, and then rinse it with clean water .

Embodiment 3

[0040] The present embodiment provides a three-way catalytic complexing cleaning solution, specifically: 3% carboxyethyl thiosuccinic acid, 2% citric acid, 3% glucoheptonic acid, 3% hydroxyethyl Ethylenediaminetriacetic acid, 1.5% REWOQUAT CPEM, and the rest of deionized water are mixed to obtain a three-way catalytic converter complex cleaning solution.

[0041] This embodiment also provides a specific method for using the three-way catalytic converter complex cleaning solution: disassemble the exhaust manifold assembly, place it in a cleaning container, pour the cleaning agent into the three-way catalytic converter and soak it for 30 minutes, then rinse with clean water rinse.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com