Environmental-friendly energy-saving nano electro nickel-plating technology

A nickel electroplating and process technology, applied in the direction of electrolysis process, electrolysis components, etc., can solve the problems of poor filling and leveling effect, low potential walking effect, high waste water treatment cost, and many nickel electroplating processes, etc., and achieves excellent walking ability and saving. Process, the effect of strong wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to enable examiners to further understand the purpose of the present invention, a preferred embodiment is now attached for detailed description as follows. This embodiment is only used to illustrate the technical solution of the present invention, not to limit the present invention.

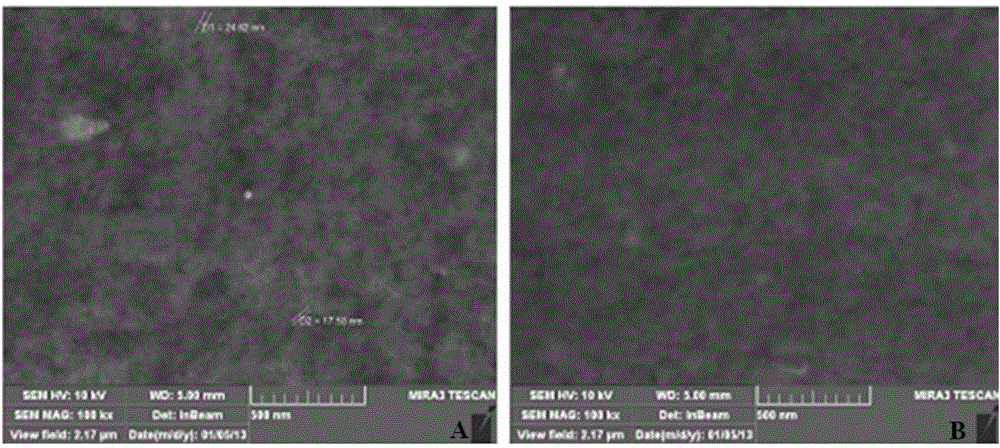

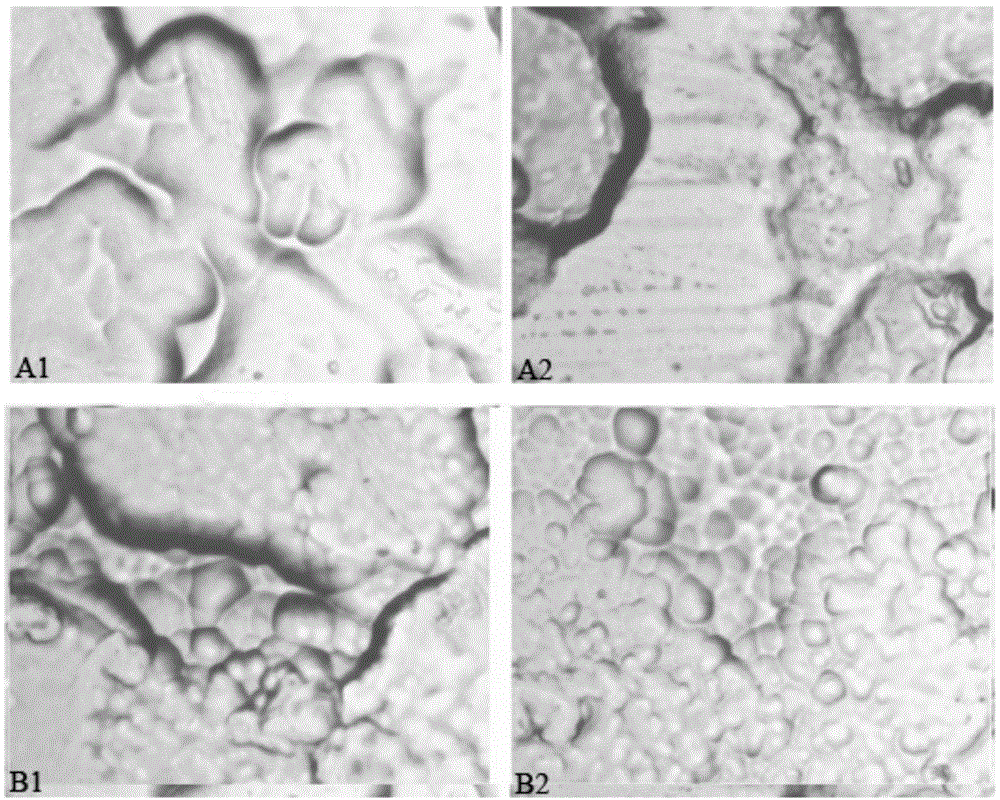

[0015] The nano-nickel electroplating process of the present invention is improved on the basis of the existing electro-nickel plating process. Specifically, a nano-catalyzed complexing additive comprising a metal ion-type crystal crystallization inhibitor is added to the existing electro-nickel plating bath, and in Superconducting magnetic state effect reaction equipment is placed in the electroplating tank. In the nickel electroplating process of the present invention, other electroplating conditions are the same as the prior art. In this example, the superconducting magnetic state effect reaction equipment is a superconducting magnetic state effect reaction rod made of supercon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com