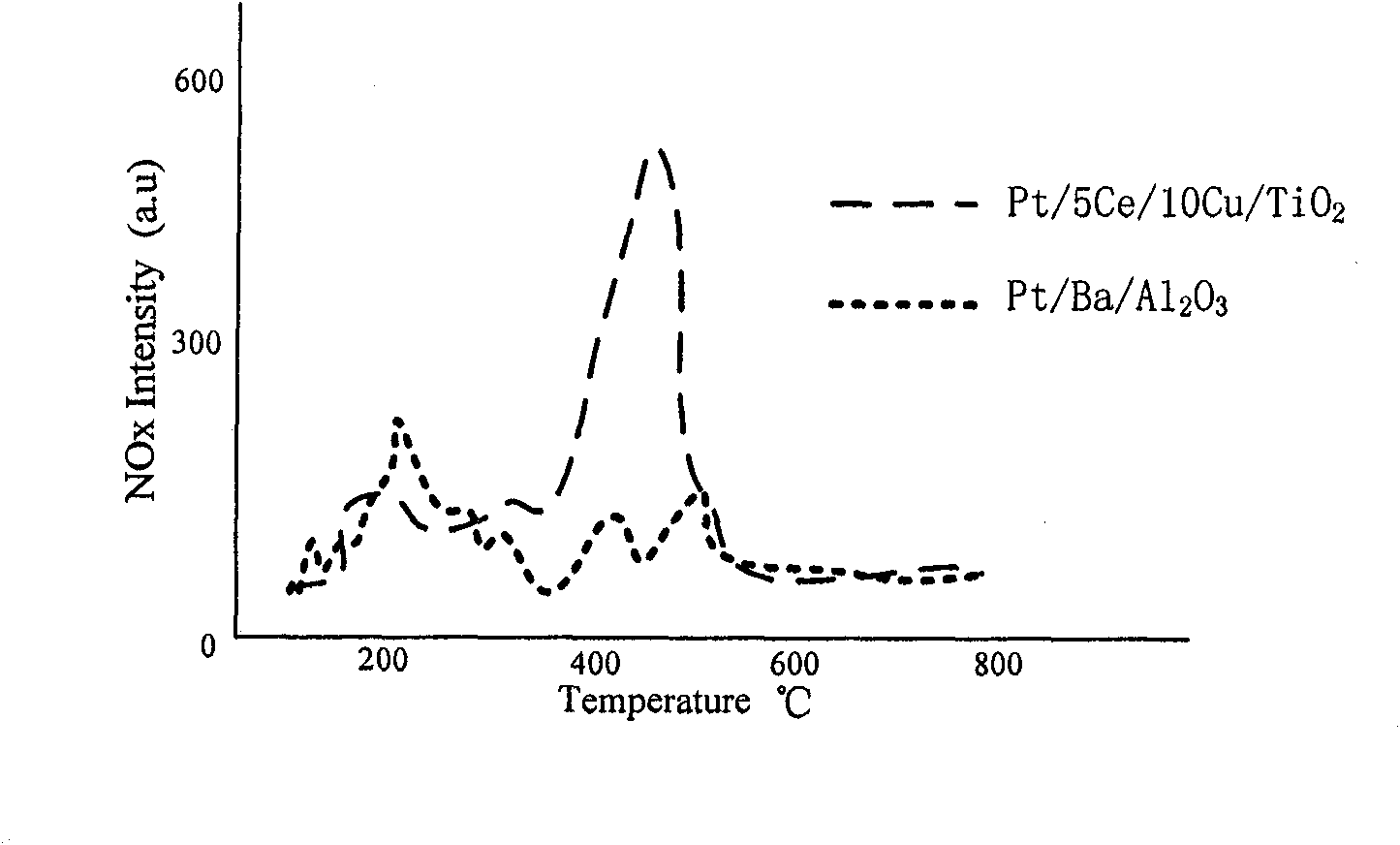

Catalytic complex for denitration of lean burn gasoline engine exhaust and preparation method thereof

A gasoline engine and composite technology, applied in the field of vehicles, can solve the problems of secondary pollution of precious metals, difficulty in adding reducing agents, and unsuitable lean-burn technology, etc., to improve the ability to resist sulfur poisoning, promote stability, and reduce temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

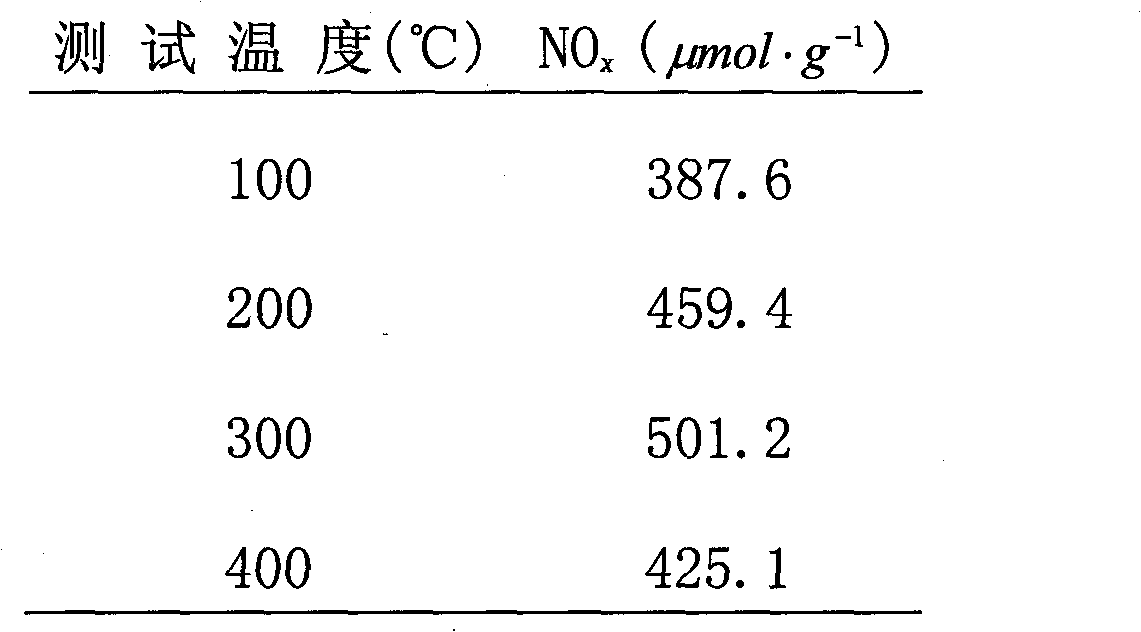

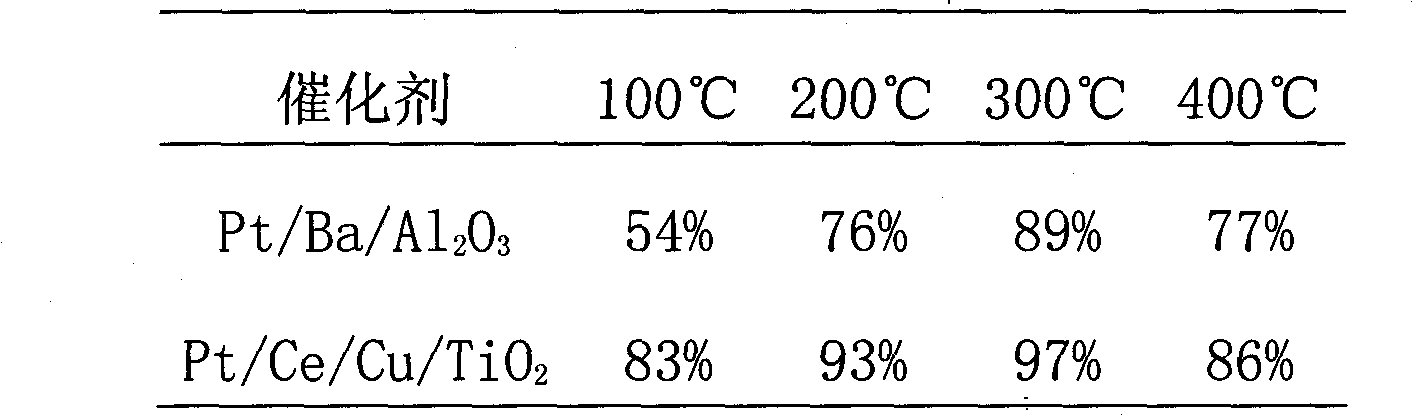

[0015] 1. Mix 15g of nanoscale titanium dioxide (TiO 2 ) is immersed in a 75% copper sulfate solution in which 35 grams of copper sulfate in 5 water is dissolved, and immersed at room temperature (18-25° C.) for more than 3 hours. The solution was spun dry at room temperature. The dried titanium dioxide carrier particles were put into a drying oven (110°C) for 15 hours of drying, and the dried particles were roasted in a muffle furnace (800°C) for 7 hours to obtain a loading capacity of 10 %Cu / TiO 2 composite oxides.

[0016] 2. Baked Cu / TiO 2 The composite oxide was immersed in 55% rare earth cerium salt (cerium acetate) aqueous solution in which 24 grams of rare earth cerium salt was dissolved, and immersed at room temperature for 5 hours. Through the same dehydration, drying, and roasting procedures as in Example 1, Ce / Cu / TiO with a loading capacity of 5% can be obtained 2 catalyst complex.

[0017] 3. The prepared 5Ce / 10Cu / TiO 2 Catalyst composite is immersed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com