Flexible polyimide foam and preparation method and applications thereof

A polyimide, polyimide precursor technology, applied in the field of polyimide, can solve the problems of uneven foam density, poor uniformity, holes, etc., and achieve the effect of uniform density and pore size, and uniform pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

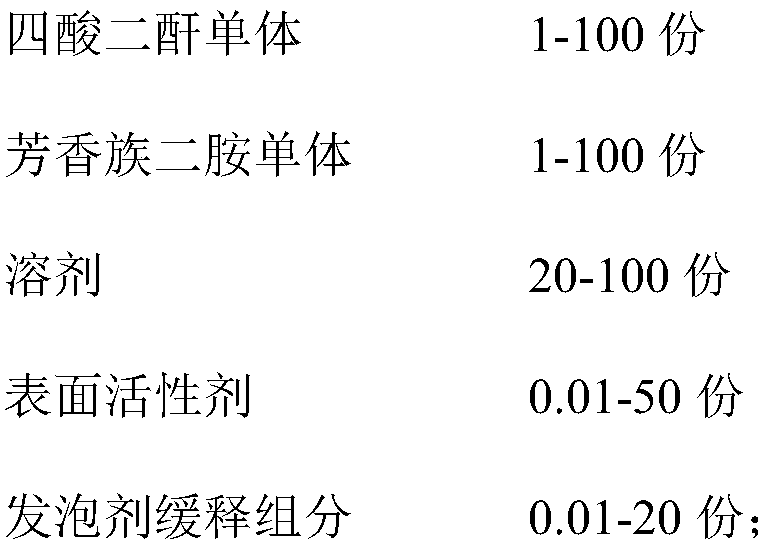

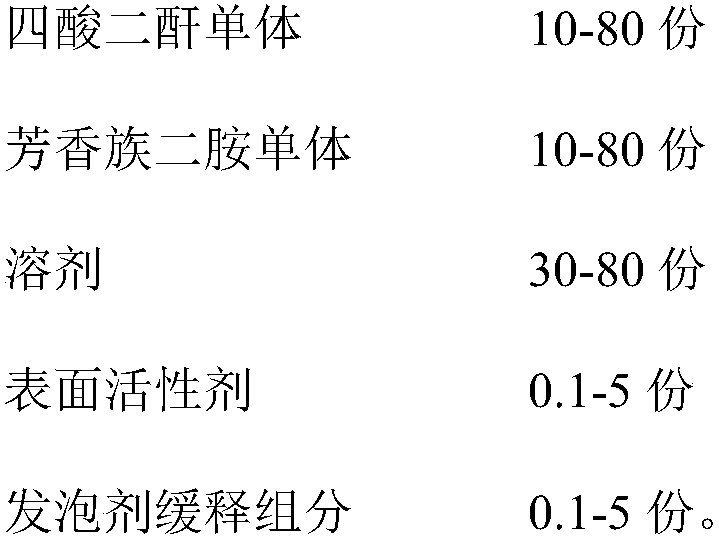

Method used

Image

Examples

Embodiment 1

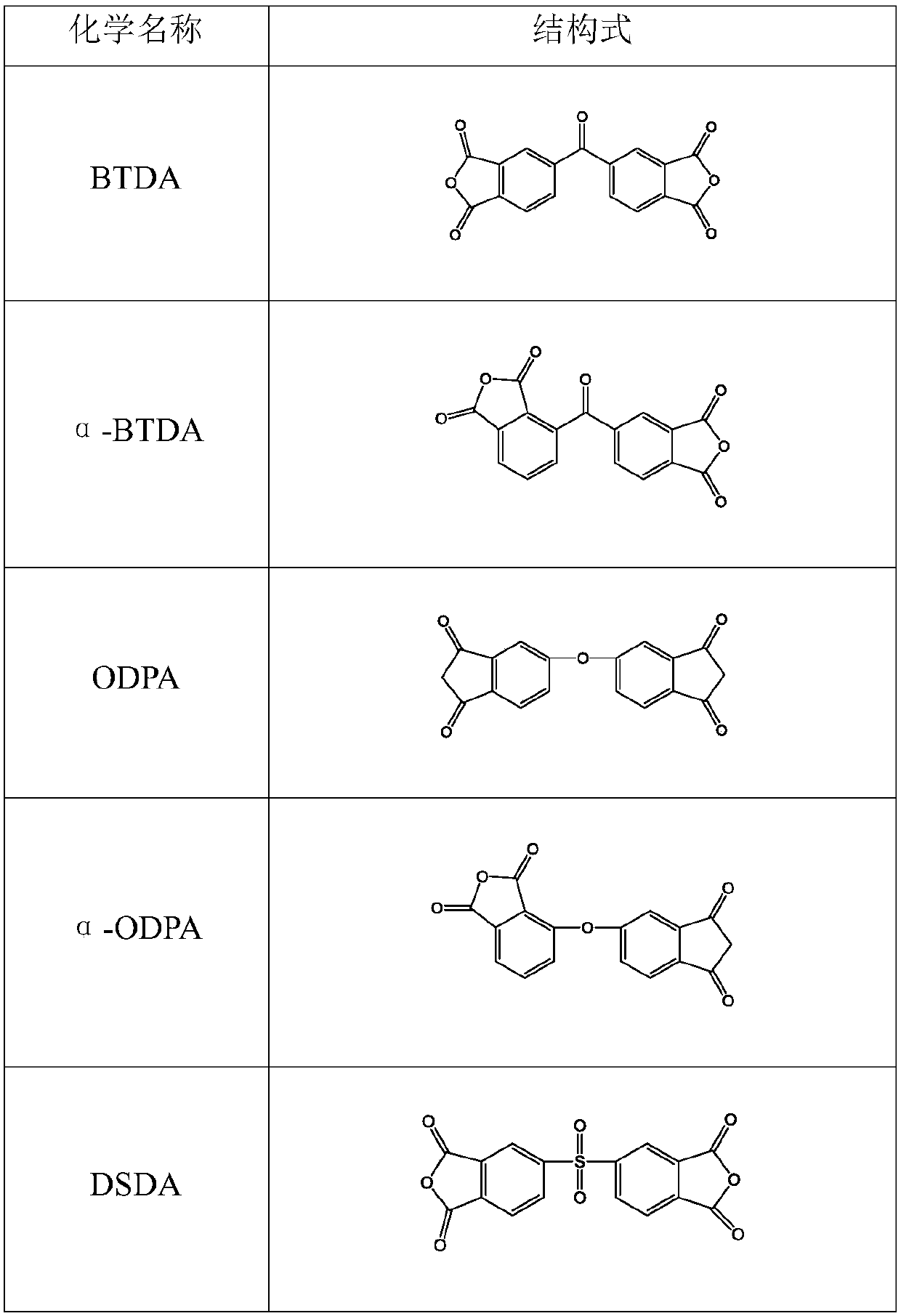

[0066] 1) Add 40 parts of BTDA, 50 parts of low-boiling point solvent absolute ethanol, and 45 parts of low-boiling point solvent tetrahydrofuran into a there-necked flask equipped with a mechanical stirrer, a spherical condenser and a thermometer, and heat and reflux for 3 hours under stirring to obtain Homogeneous solution of diesters of aromatic diacids.

[0067] 2) Add 40 parts of 4,4'-ODA to the homogeneous solution obtained in step 1), and add 0.1 part of imidization accelerator isoquinoline, and 1.5 parts of polyethylene glycol 600, under the condition of nitrogen protection Under stirring and reflux for 20 minutes to carry out polycondensation reaction, a homogeneous solution was obtained.

[0068] 3) 0.5 parts of polyoxyethylene ether nonionic fluorocarbon surfactant FSO-100 was stirred and refluxed for 20 minutes under nitrogen protection to obtain a polyimide precursor resin solution.

[0069] 4) The polyimide precursor resin solution in step 3) was rotary evapor...

Embodiment 2

[0092] 1) Add 80 parts of BTDA, 60 parts of low-boiling point solvent absolute ethanol, and 50 parts of low-boiling point solvent tetrahydrofuran into a there-necked flask equipped with a mechanical stirrer, a spherical condenser and a thermometer, and heat and reflux for 3 hours under stirring to obtain Homogeneous solution of diesters of aromatic diacids.

[0093] 2) Add 80 parts of 4,4'-ODA to the homogeneous solution obtained in step 1), and add 0.5 parts of imidization accelerator isoquinoline, and 3 parts of polyethylene glycol 600, under the condition of nitrogen protection Under stirring and reflux for 20 minutes to carry out polycondensation reaction, a homogeneous solution was obtained.

[0094] 3) 1 part of polyoxyethylene ether nonionic fluorocarbon surfactant FSO-100 was stirred and refluxed for 30 minutes under nitrogen protection to obtain a polyimide precursor resin solution.

[0095] 4) The polyimide precursor resin solution in step 3) was rotary evaporated...

Embodiment 3

[0101] 1) Add 40 parts of ODPA, 60 parts of low boiling point solvent absolute ethanol, and 30 parts of low boiling point solvent tetrahydrofuran in a there-necked flask equipped with a mechanical stirrer, a spherical condenser and a thermometer, and heat and reflux for 4 hours under stirring to obtain Homogeneous solution of diesters of aromatic diacids.

[0102] 2) Add 40 parts of 3,4'-ODA to the homogeneous solution obtained in step 1), add 0.1 part of imidization accelerator isoquinoline, and 1 part of silicone oil, and stir and reflux for 40 minutes under nitrogen protection. Polycondensation reaction to obtain a homogeneous solution.

[0103] 3) 0.1 part of polyoxyethylene ether nonionic fluorocarbon surfactant FSO-100 was stirred and refluxed for 40 minutes under nitrogen protection to obtain a polyimide precursor resin solution.

[0104] 4) Rotate the polyimide precursor resin solution in step 3) to a viscous state at 60°C and pour it into a porcelain dish, then cov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com