Honeycomb-shaped carbon nano tube porous microsphere, and preparation method and application thereof

A technology of carbon nanotubes and porous microspheres, which is applied in the field of honeycomb carbon nanotube porous microspheres and its preparation, can solve the problems of easy folding and poor dispersion of carbon nanotubes, and achieve easy industrialized mass production, precise operation control, The effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

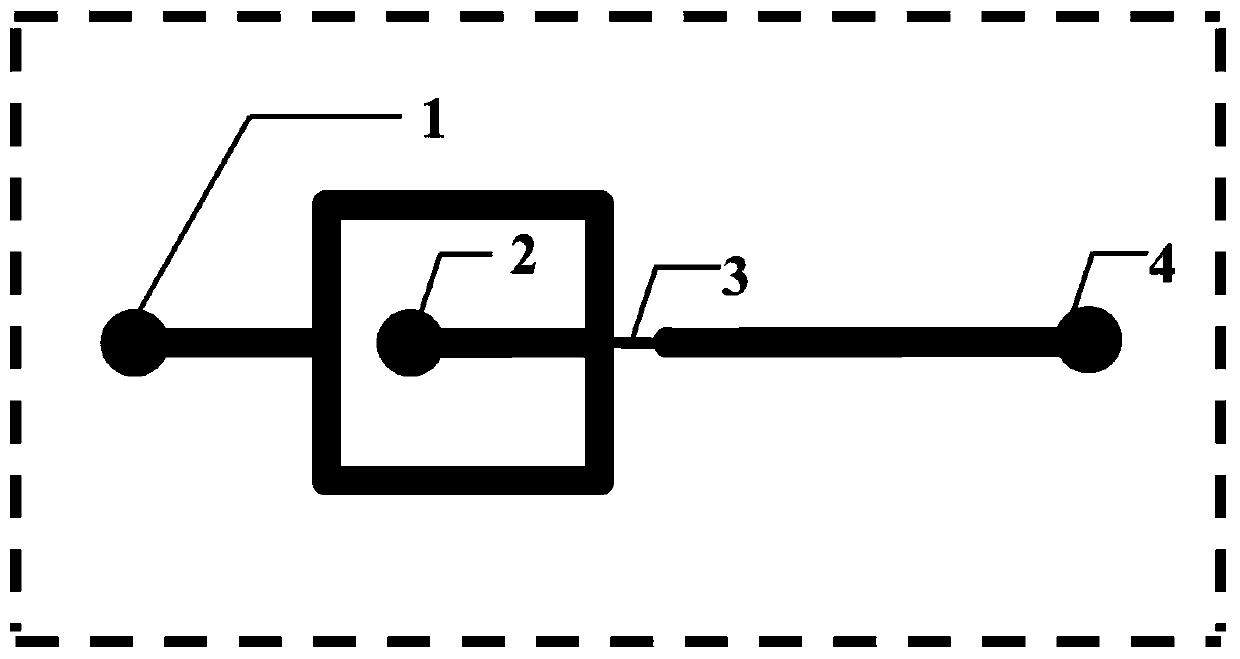

Image

Examples

preparation example Construction

[0055] In step 1) of the preparation method according to the present invention, a certain amount of carboxylated carbon nanotubes is first added to the nano-template particle dispersion with a mass fraction of 6w / v% to 15w / v%, and the ultrasonic treatment is configured to 1 mg / v mL to 20mg / mL carbon nanotube dispersion, in this process, carbon nanotubes and nano template particles are fully mixed.

[0056] Preferably, in step 1), the nano-template particles can be selected from SiO 2 , polystyrene beads, ZnO and Au metal nanoparticles, nanosheets and at least one of nanorods.

[0057] The nanotube in the present invention is a one-dimensional nanomaterial with light weight, perfect connection of hexagonal structure, and many abnormal mechanical, electrical and chemical properties. The carbon nanotubes mainly consist of carbon atoms arranged in a hexagon to form a coaxial circular tube with several to tens of layers. A fixed distance is maintained between the layers, about 0....

Embodiment 1

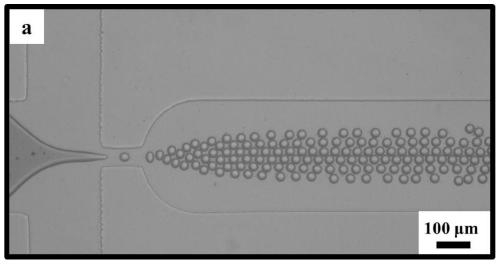

[0082] Example 1: Preparation of carbon nanotube porous microspheres with compact surface

[0083] (1) Add a certain amount of carboxylated carbon nanotubes to the 2 In the dispersion of nanoparticles (with a particle size of 200nm), ultrasonic treatment was used to configure a 7.5 mg / mL carbon nanotube dispersion as the water phase, and hexadecane containing 30 wt% of the surfactant Span 80 as the oil phase.

[0084] (2) The above-mentioned two-phase fluid is introduced into a polydimethylsiloxane (PDMS) flow-focused microfluidic chip through a fluid pump to prepare monodisperse droplets. Since the droplets are wrapped with a certain concentration of SiO 2 nanoparticles and carbon nanotubes, due to SiO 2 The electrostatic repulsion between nanoparticles and the reduction of droplet surface free energy make SiO 2 Nanoparticles and carbon nanotubes are closely arranged on the surface of the micron droplet, the flow rate ratio of the dispersion liquid and the oil phase is 1:5,...

Embodiment 2

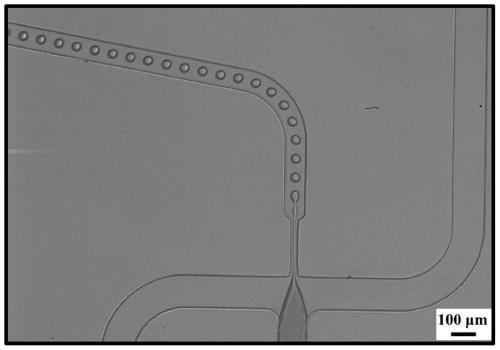

[0089] This embodiment is basically the same as Embodiment 1, except that: in this embodiment, a PDMS chip is used as a microfluidic chip. image 3 It is a schematic diagram of the droplet generated by the glass chip in this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com