Patents

Literature

44results about How to "Precise operation control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

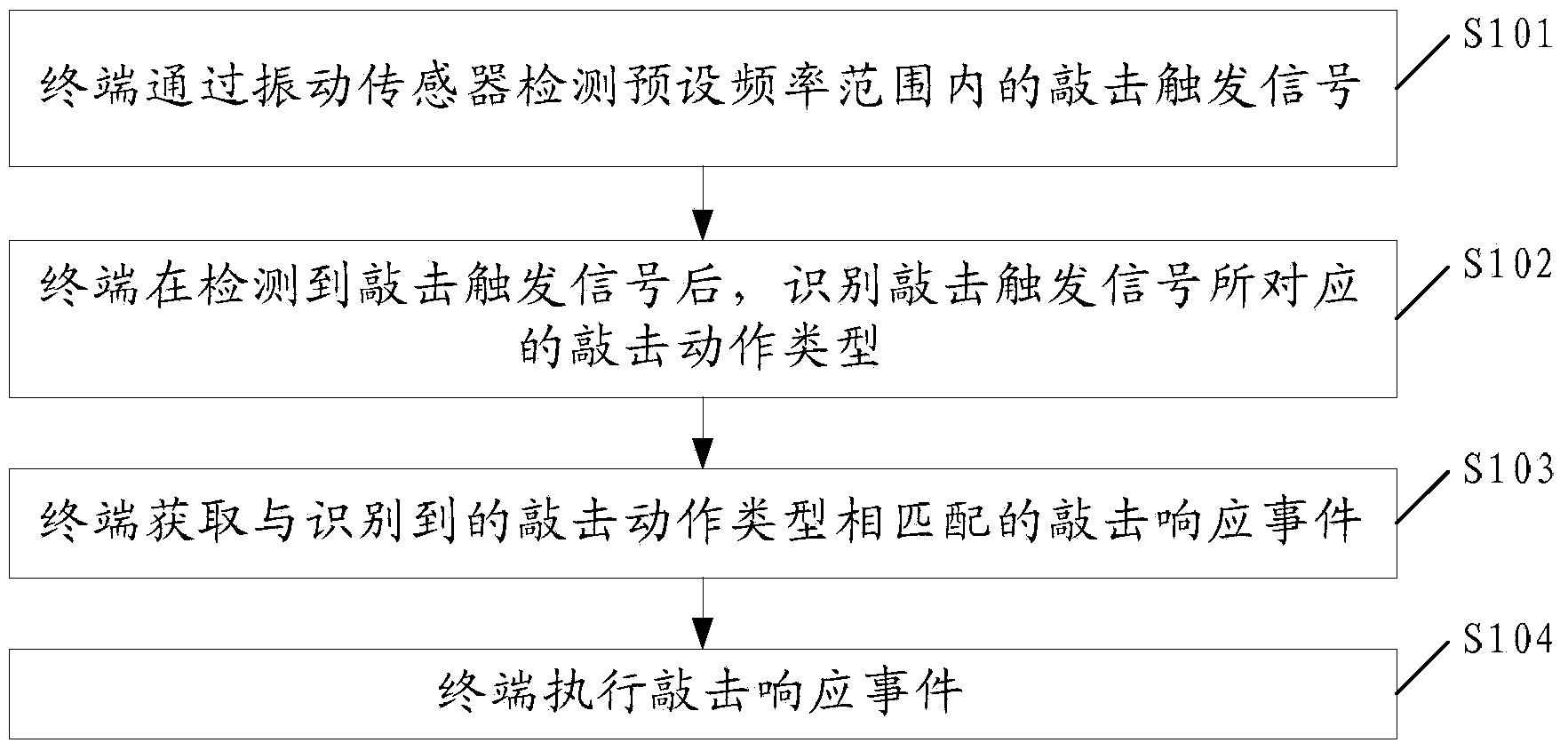

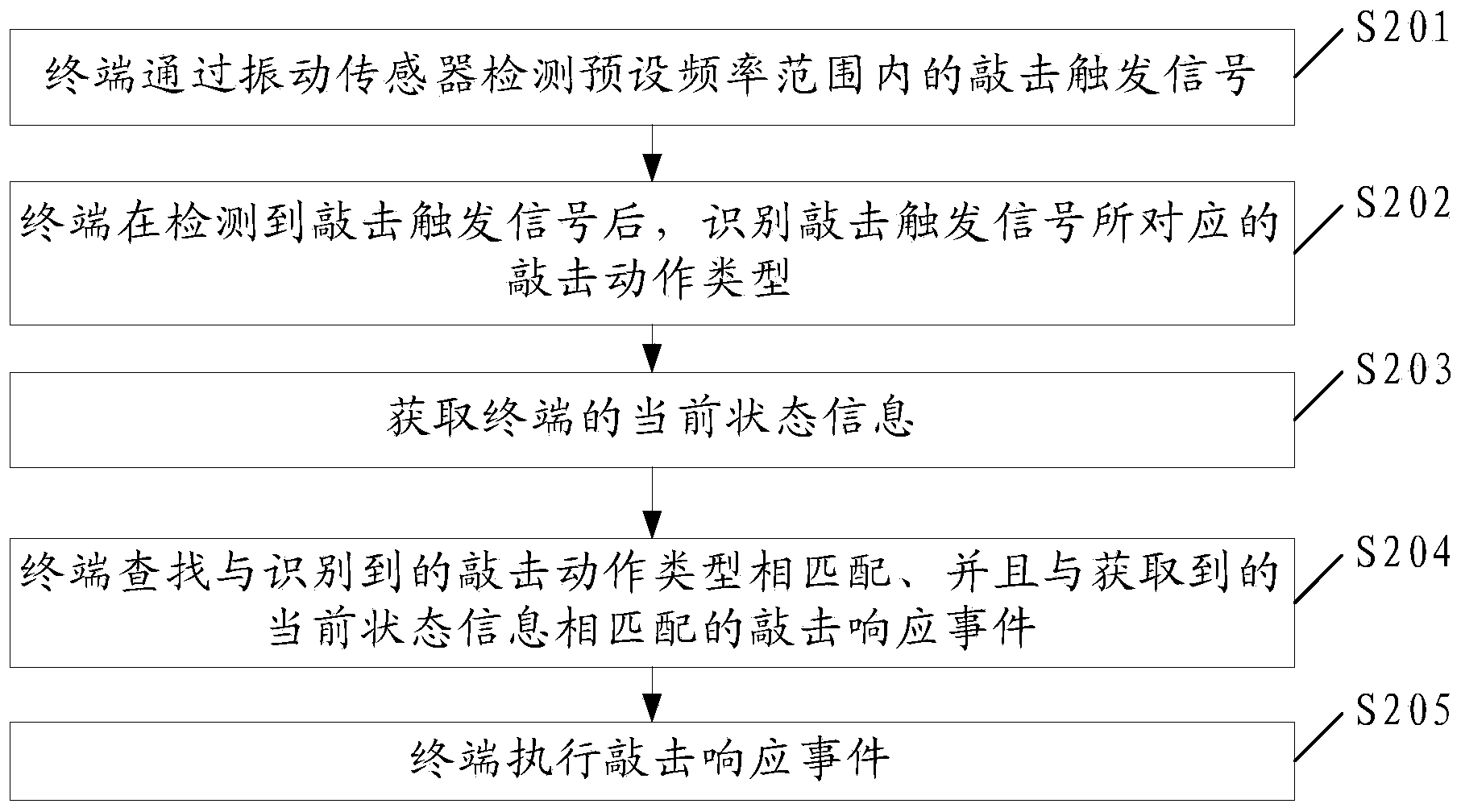

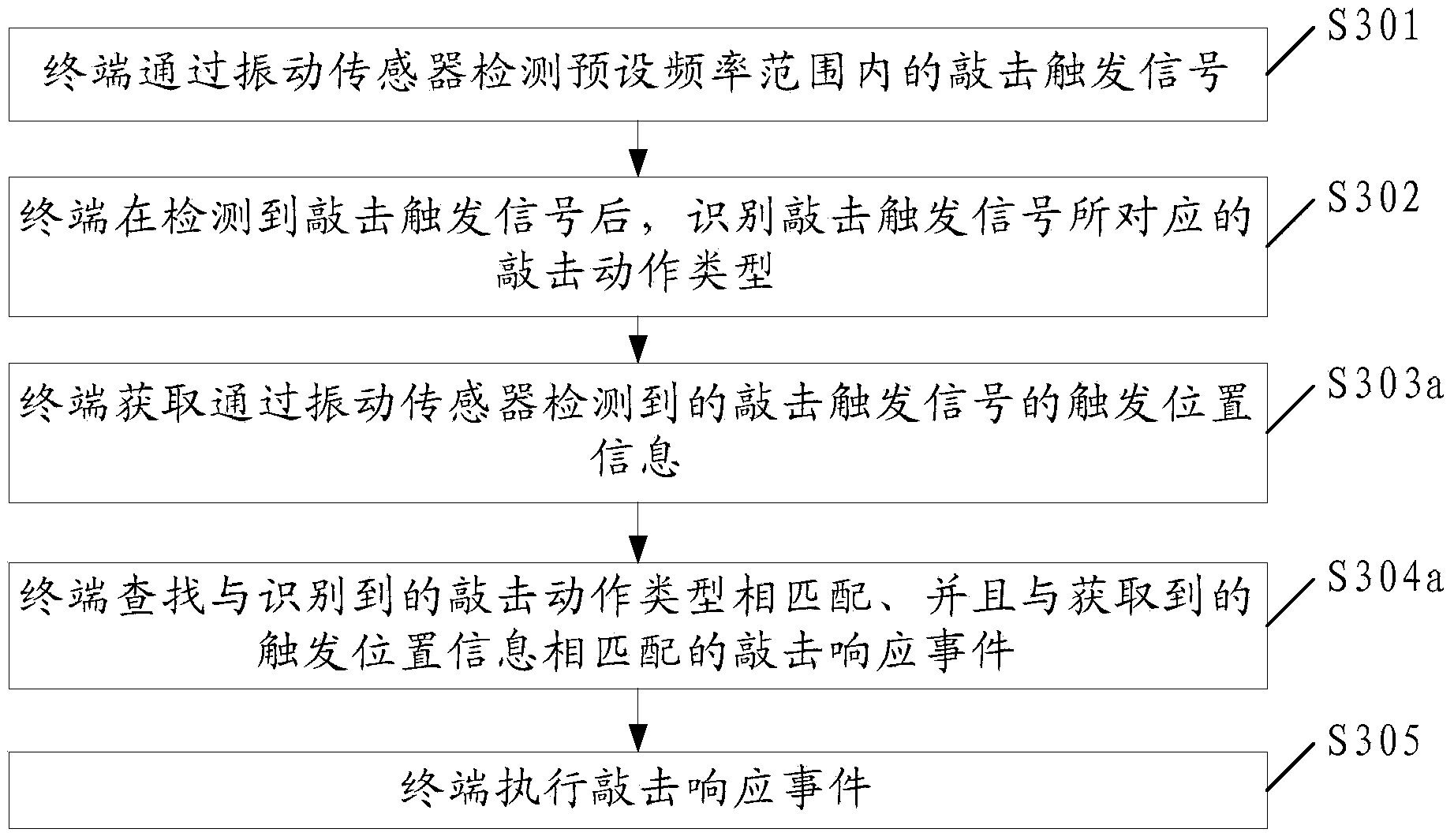

Knocking control method and terminal

ActiveCN103645845AAvoid frequent auto-setup issuesPrecise operation controlDigital data processing detailsInput/output processes for data processingReal-time computingVibration sensor

Owner:HUAWEI DEVICE CO LTD

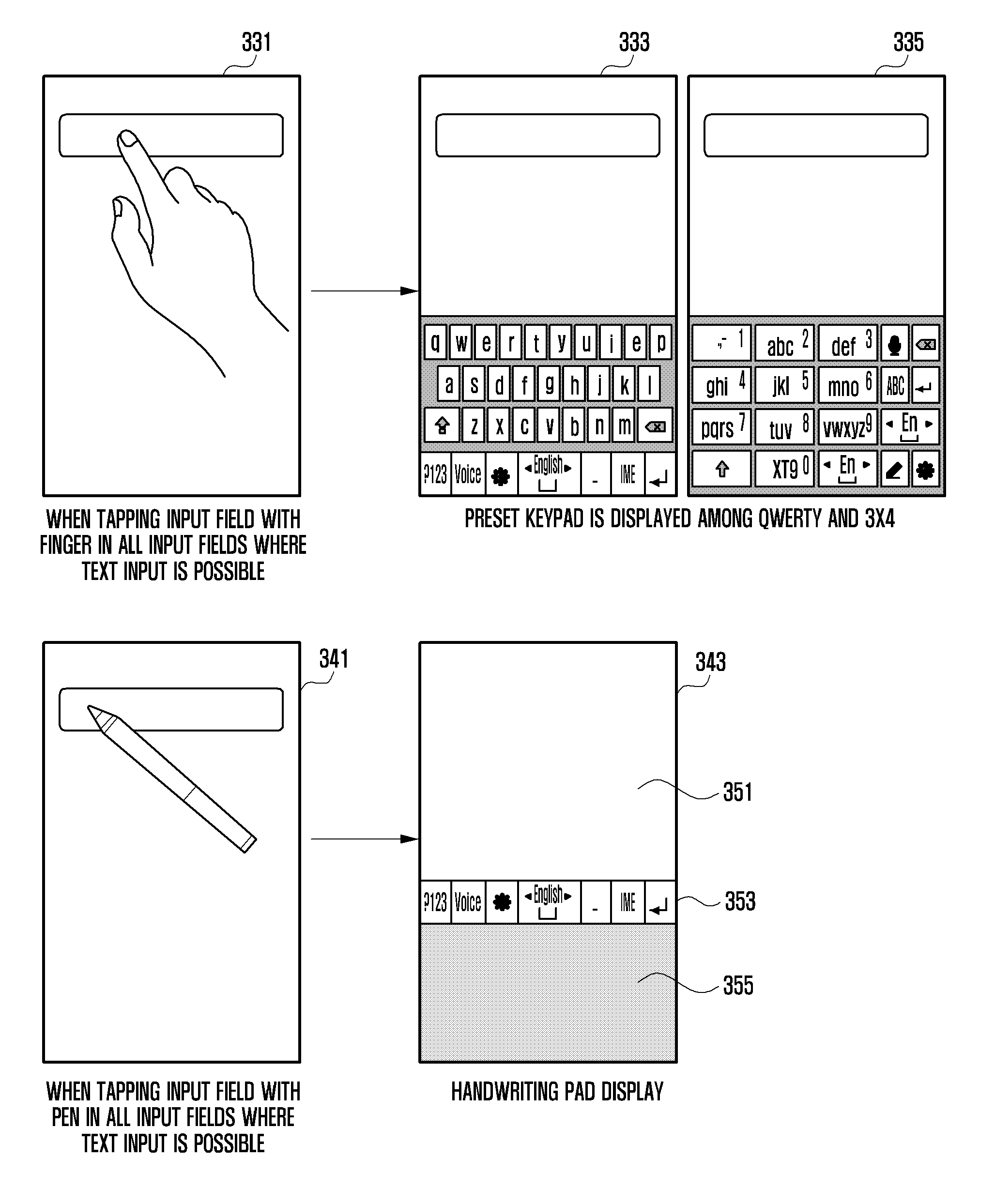

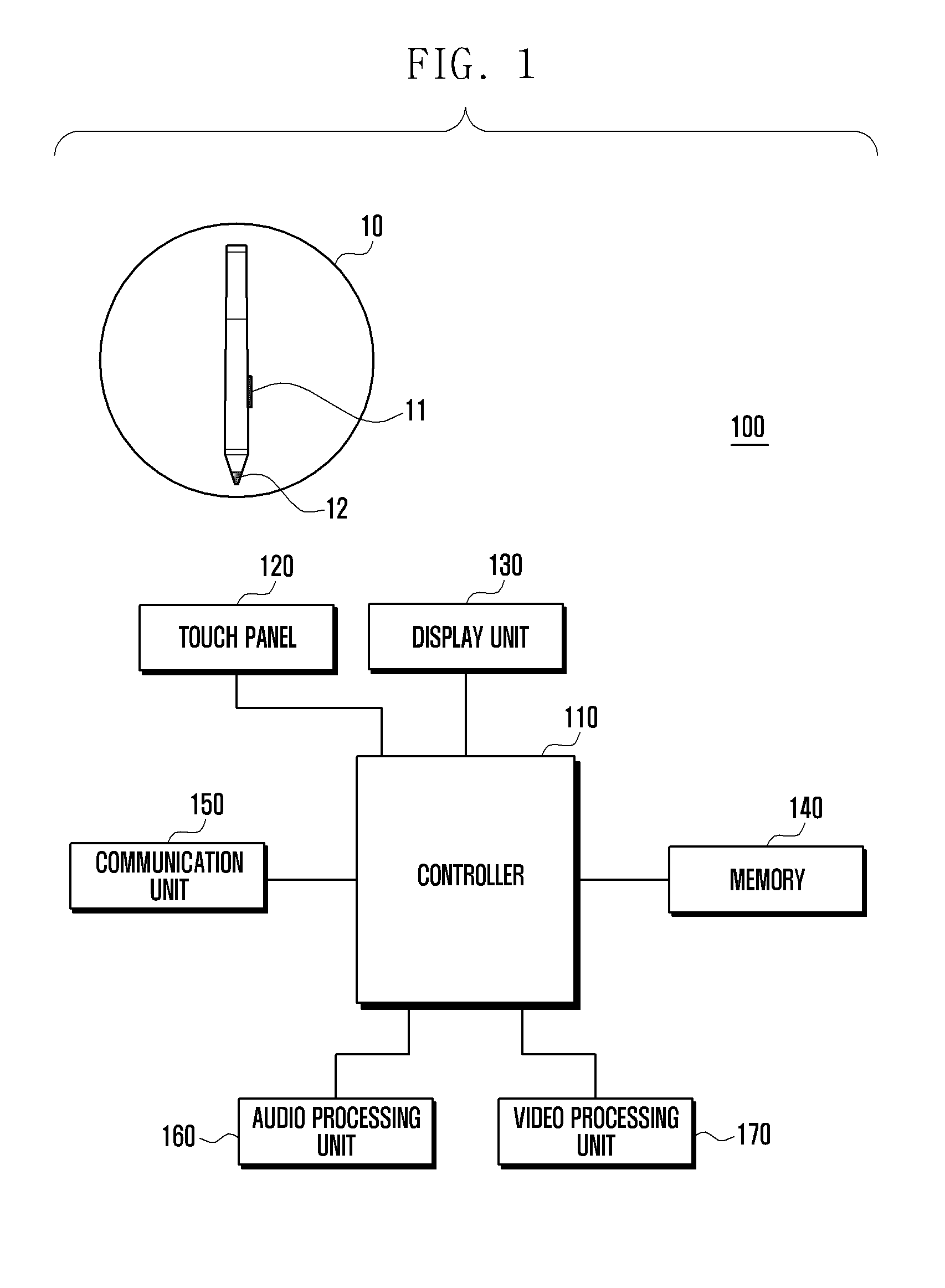

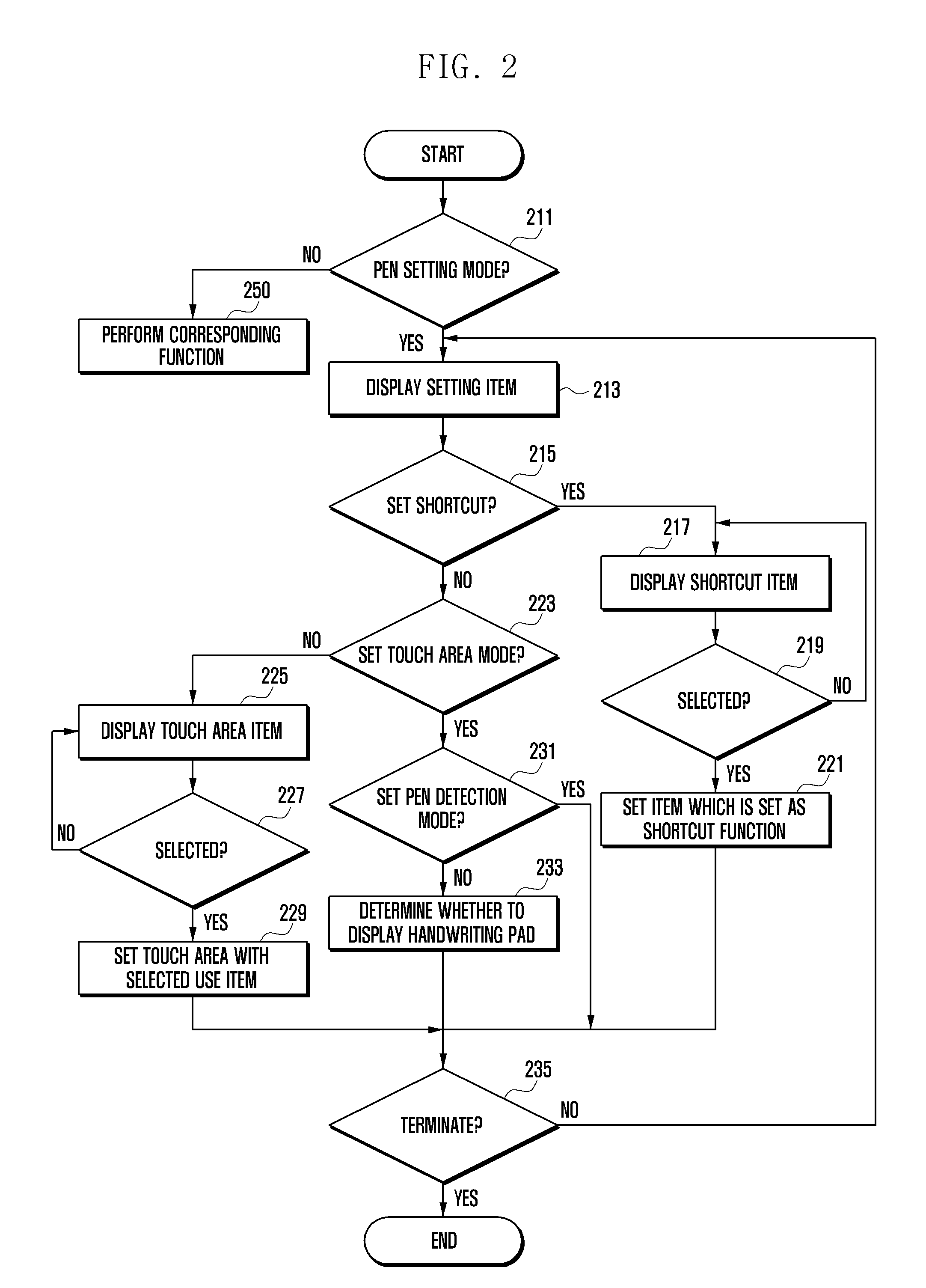

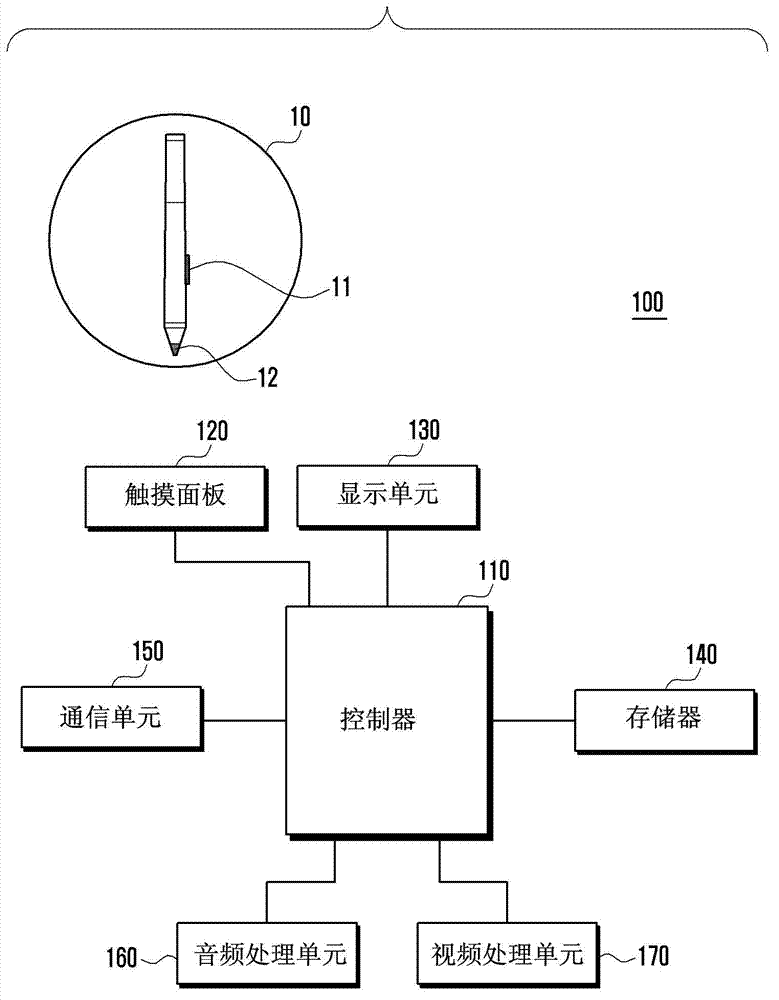

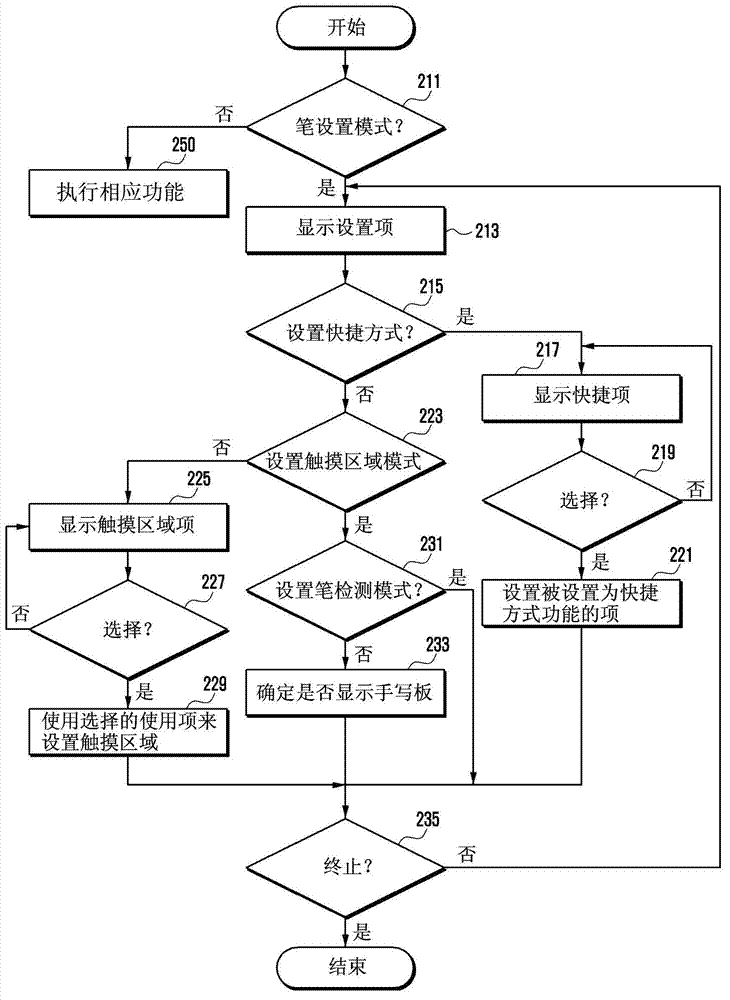

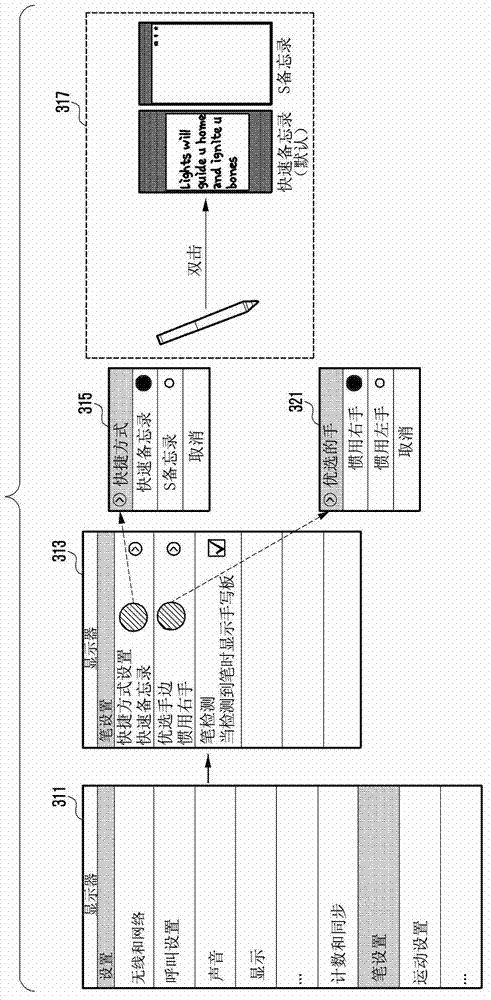

Input device and method for terminal equipment having a touch module

InactiveUS20130050141A1Improve user conveniencePrecise control of operationTransmissionDigital output to display deviceTouch panelCapacitance

An input device of a portable terminal has a pen with a button, and generates first and second inputs having first and second static electricity, respectively; a touch panel with a touch sensor whose capacitance is changed when touching the pen; a controller that performs a preset function corresponding to the first input in an executed application if an input inputted through the touch panel is the first input, and calls a preset application or performs a preset command if the input is the second input after analyzing the touch panel input; and a display unit that displays a screen processed according to the first and second inputs. The first input includes a general input that controls operation of the executed application, a handwritten letter and a drawing, and the second input is a command that calls a certain application and commands execution of a certain operation.

Owner:SAMSUNG ELECTRONICS CO LTD

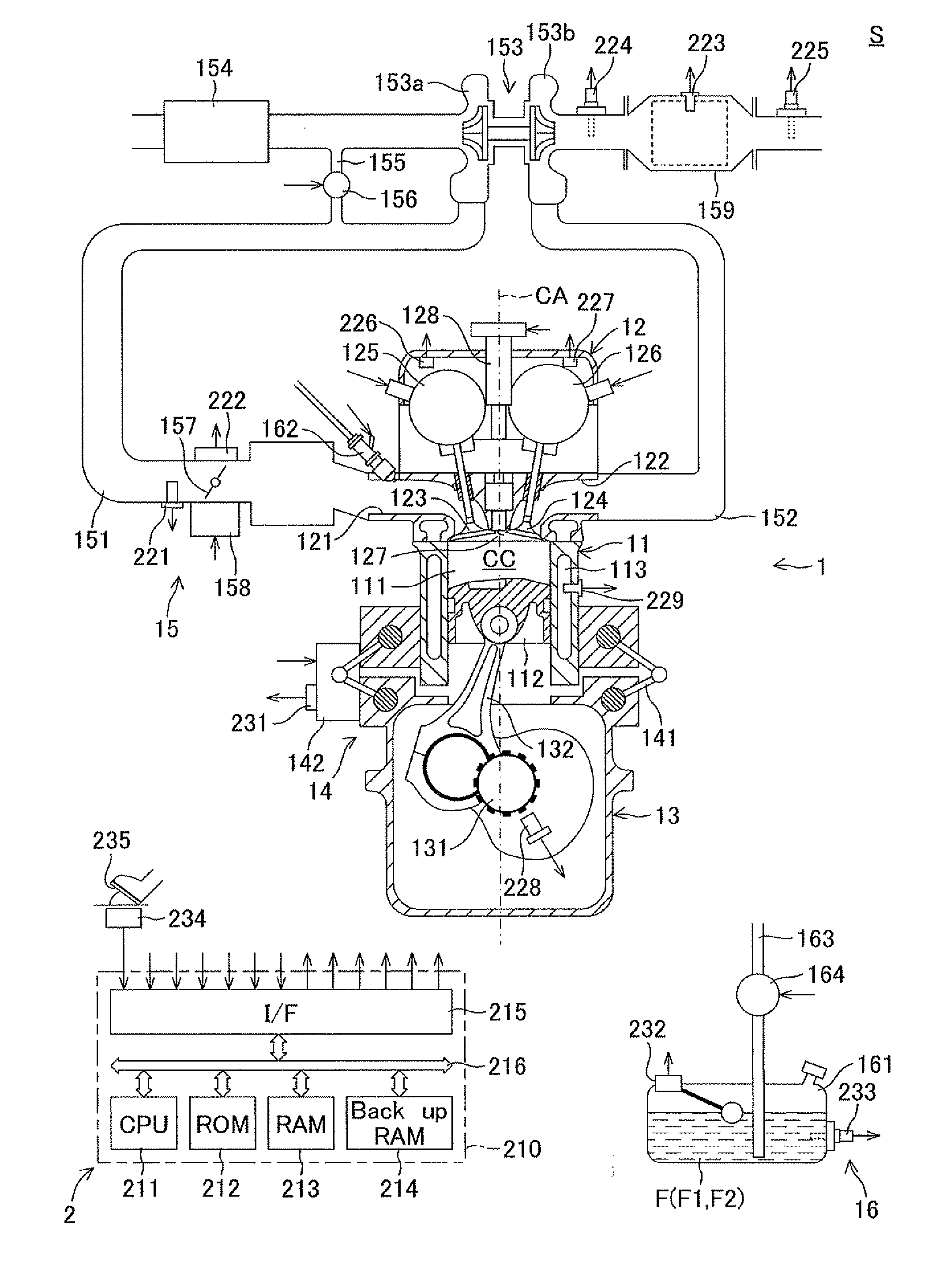

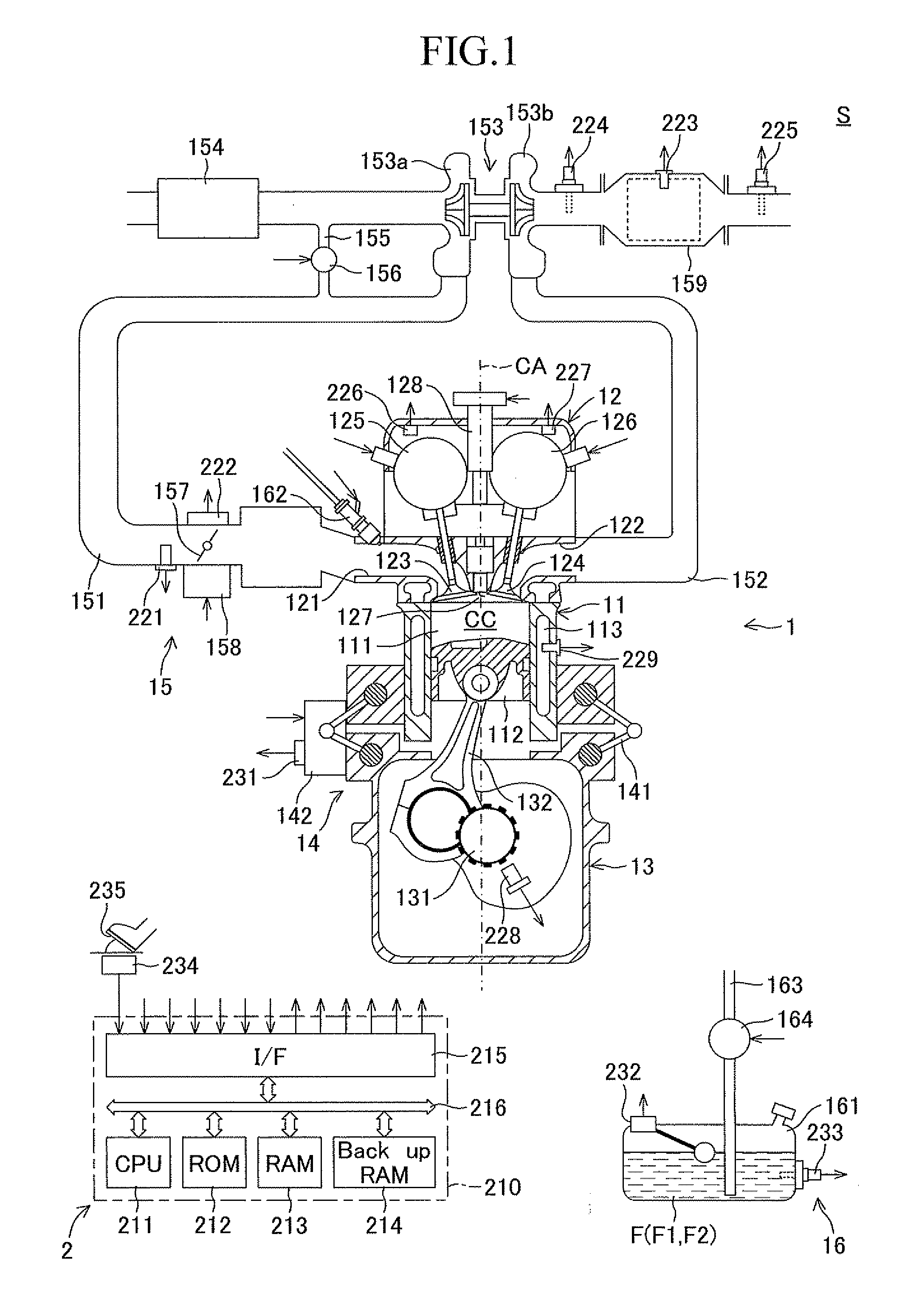

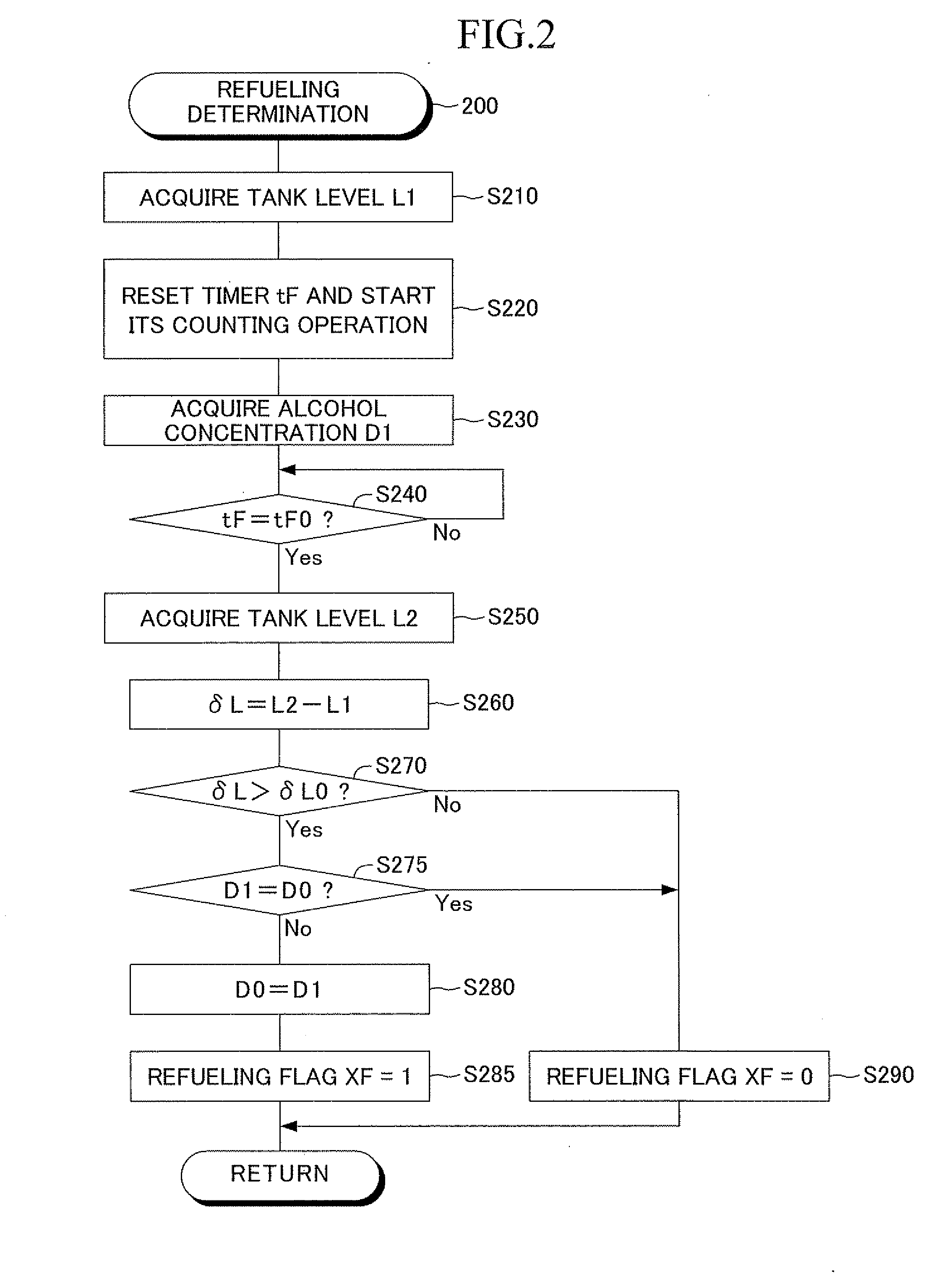

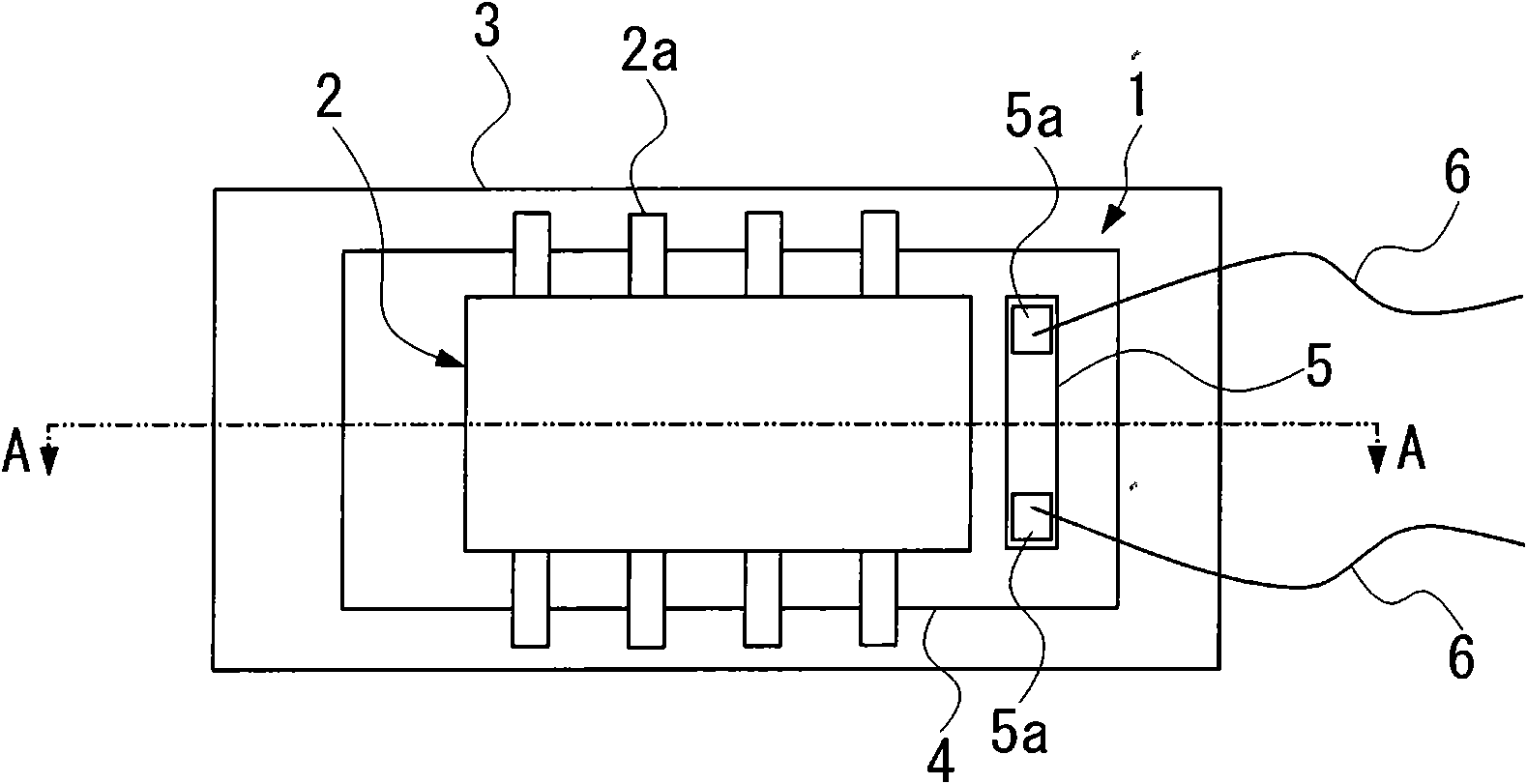

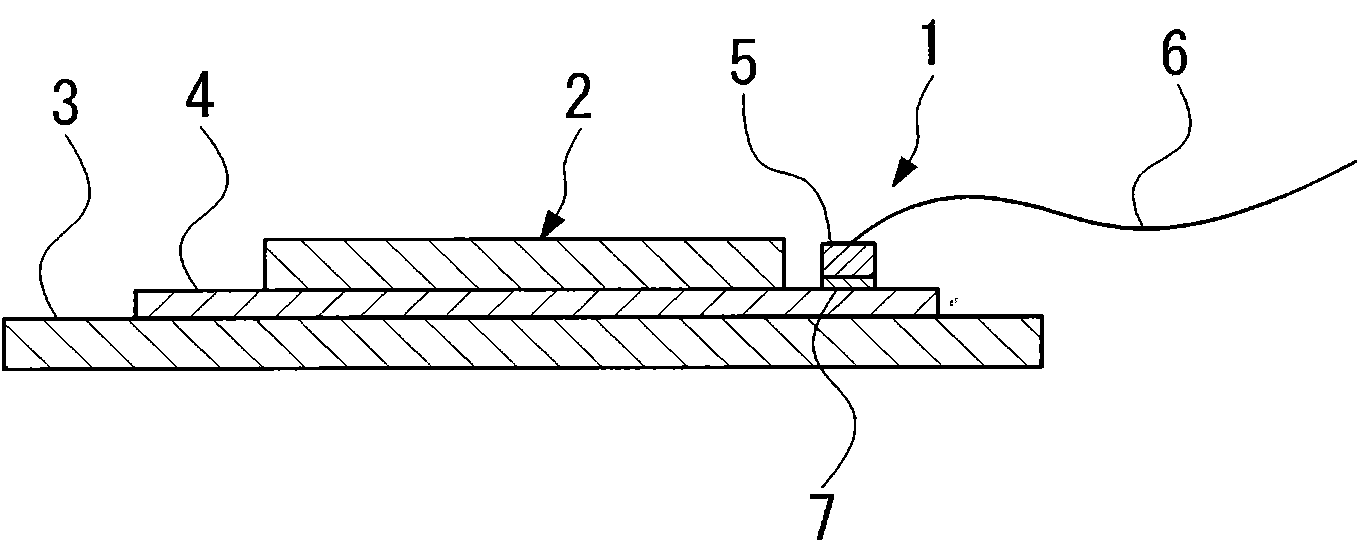

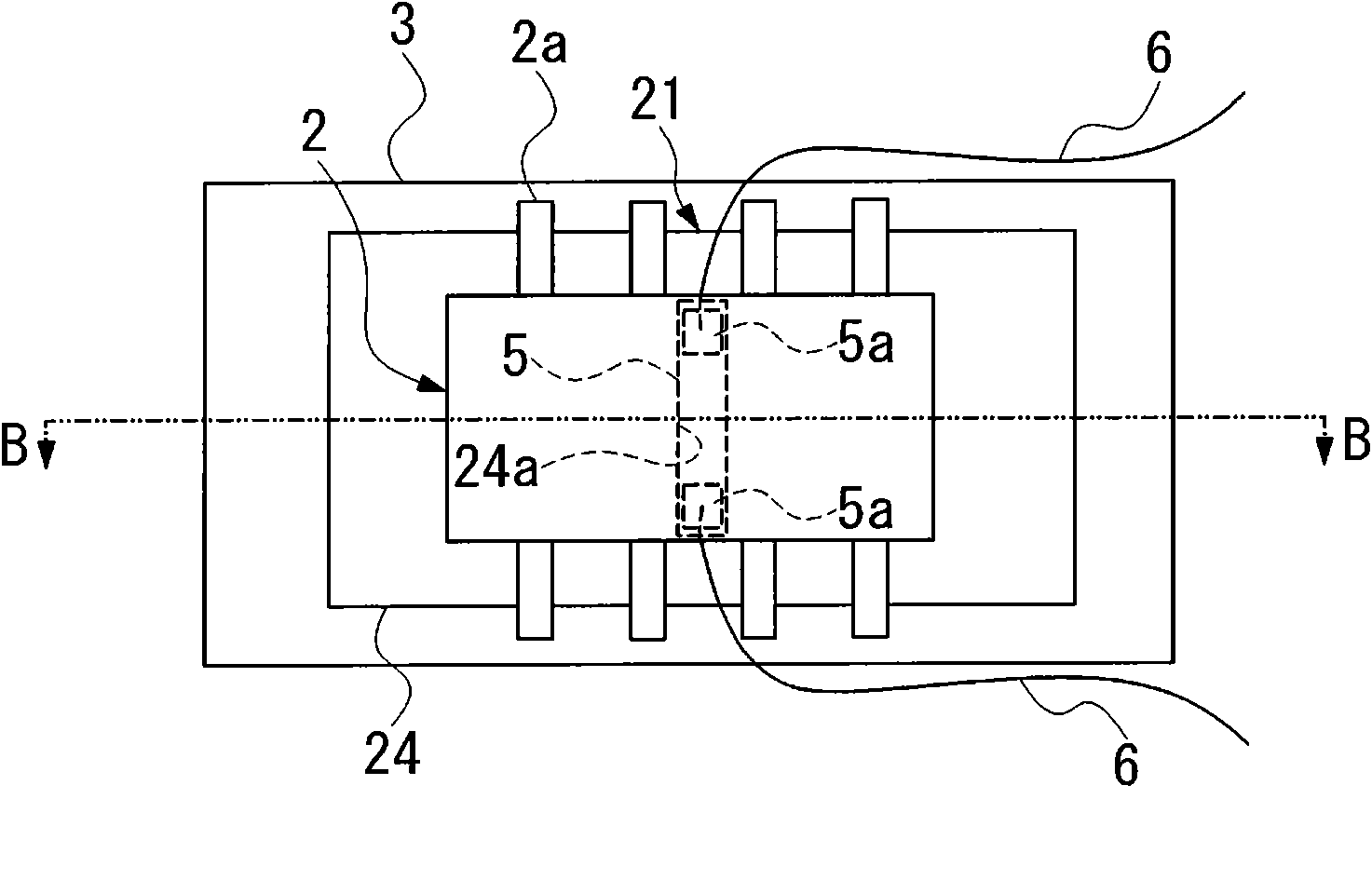

Internal combustion engine controller

InactiveUS20100312459A1Ensure correct executionEfficient operation controlElectrical controlInternal combustion piston enginesCombustion chamberIgnition timing

A controller (2) of the present invention includes a learning section which learns the property of fuel; a control section which controls combustion conditions (compression ratio, ignition timing, etc.) within a combustion chamber (CC) on the basis of the leaned property; and a supply-source-status detection section which detects a change in the statue of a fuel supply source (161) for supplying the fuel to a fuel injector (162). When a change in the status of the fuel supply source (161) is detected, before re-learning of the fuel property, the control section (2) shifts the combustion conditions based on the learned fuel property such that occurrence of anomalous combustion is suppressed.

Owner:TOYOTA JIDOSHA KK

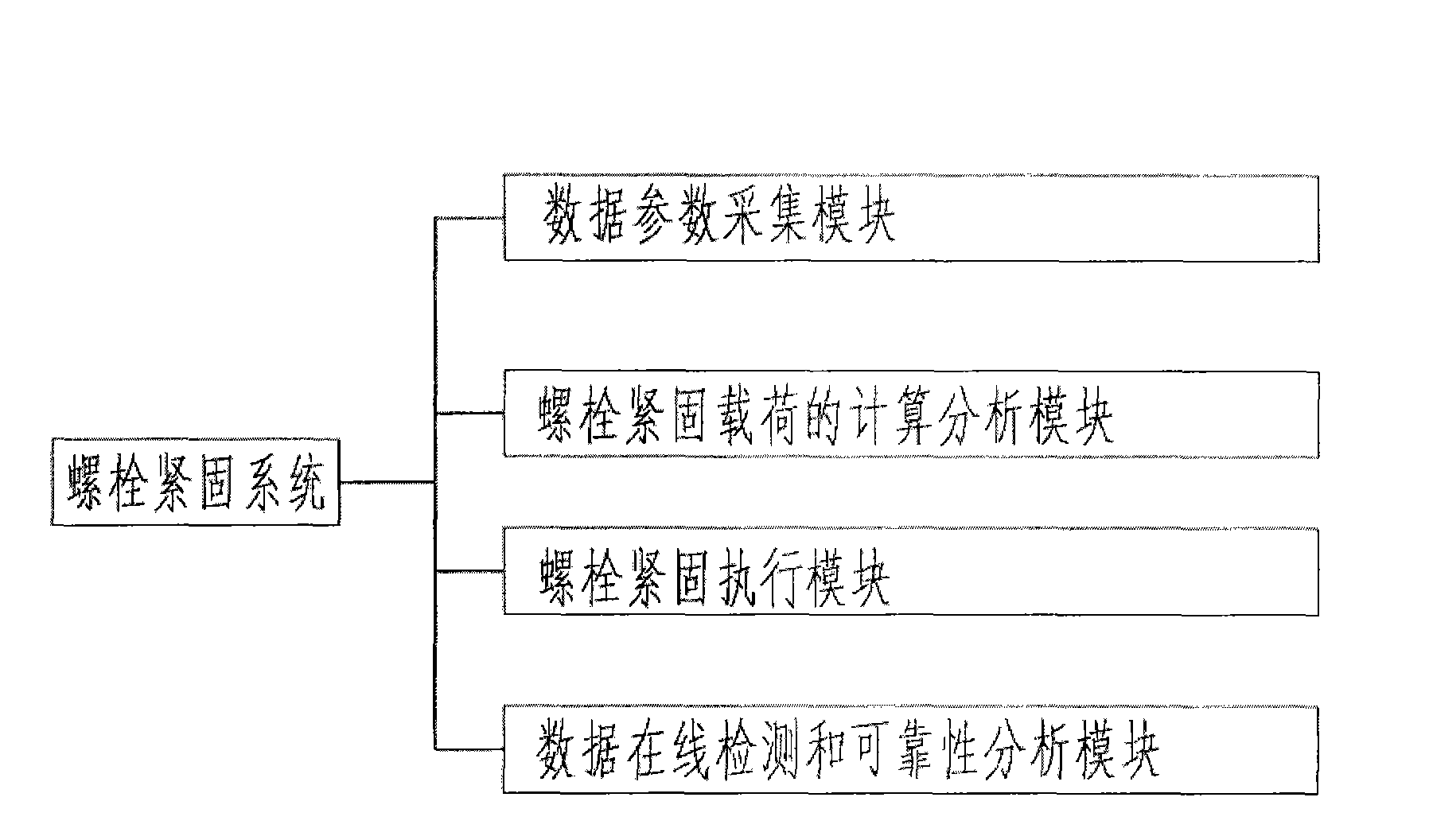

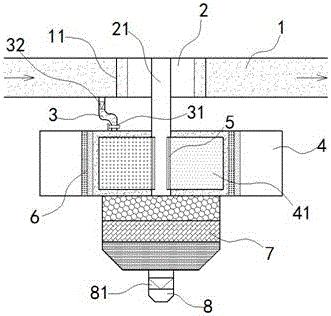

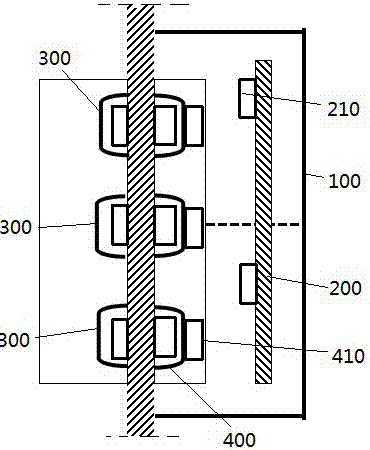

Bolt fastening system

InactiveCN101648336AEasy to operatePrecise operation controlMetal working apparatusStress conditionsSafety control

The invention provides a bolt fastening system which belongs to the safety control field of bolt flanges of petroleum and petrifaction devices. The bolt fastening device comprises a data parameter acquisition module, a computation analysis module of bolt fastening loads, a bolt fastening execution module and a data on-line detection and reliability analysis module. The computation analysis moduleof bolt fastening loads computes and analyzes load data required by fastening a bolt according to data parameters in a database and transmits the computed load data to the bolt fastening execution module; and the bolt fastening execution module automatically selects a used fastening mode according to the computed load data, thereby guiding the fastening execution operation. The bolt fastening system has convenient and reliable operation, accurately controls the bolt fastening operation, can reflect the stress condition of the bolt in real time and alarm when exceeding the safety guard, therebyradically controlling the safety of flanges.

Owner:北京海泰斯工程设备股份有限公司

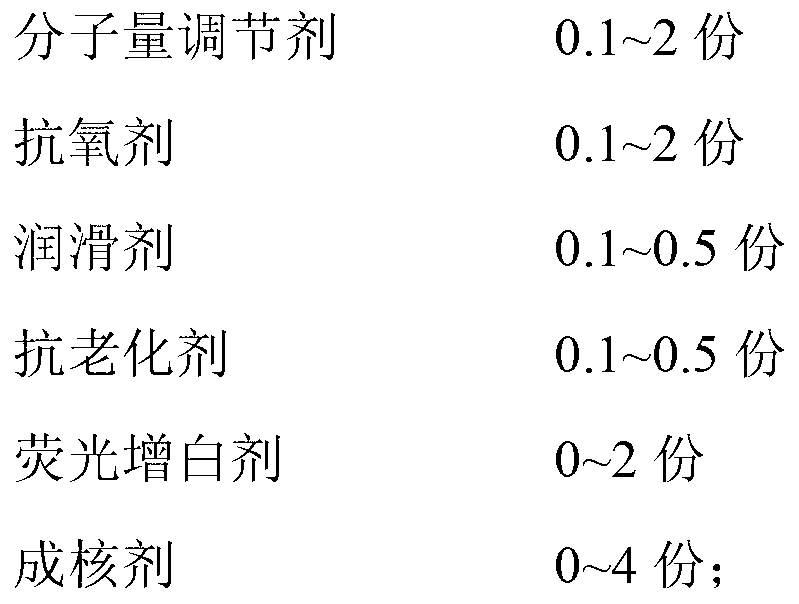

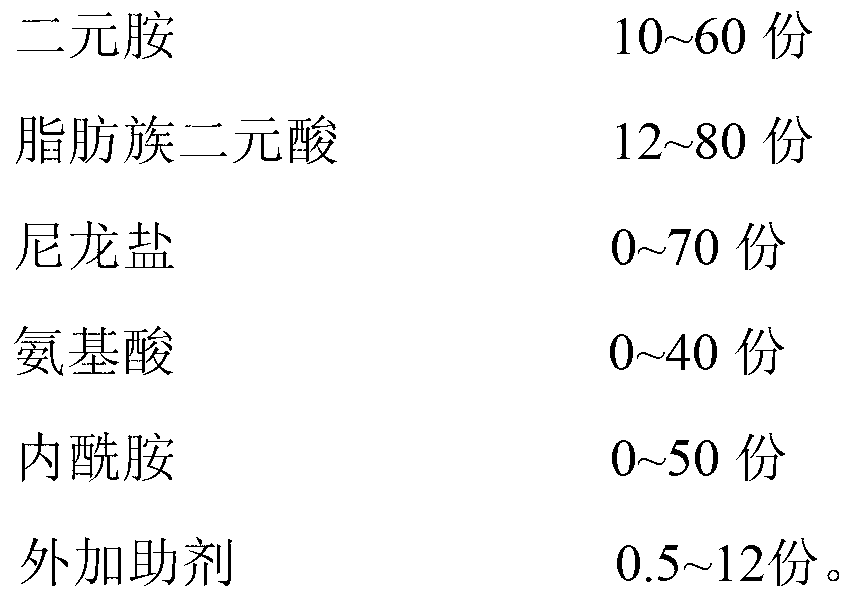

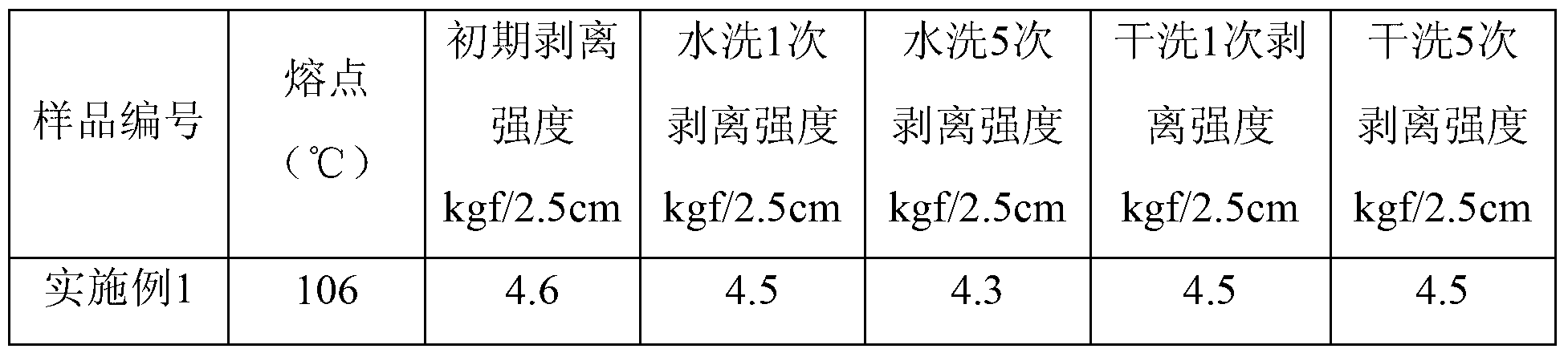

Hot melt adhesive

ActiveCN103254868AEasily damagedGreen and renewableNon-macromolecular adhesive additivesFiberPolyamide

The invention discloses polyamide hot melt adhesive. Main raw materials of the polyamide hot melt adhesive are pentamethylene diamine and aliphatic dicarboxylic acid, wherein at least one of the main raw materials is prepared through a biological method. The hot melt adhesive has the advantages of environmental friendliness and renewability, the mechanics property is equivalent to that of the existing hot melt adhesive, and the hot melt adhesive can substitute the existing hot melt adhesive to be applied to the fields such as fiber textile adhesion, shoemaking lasting, electric appliances, mechanical industry, metal, manufacturing of plastic layering composite material, automobile, civil construction and furniture and has a promising application prospect.

Owner:CATHAY R&D CENT CO LTD +1

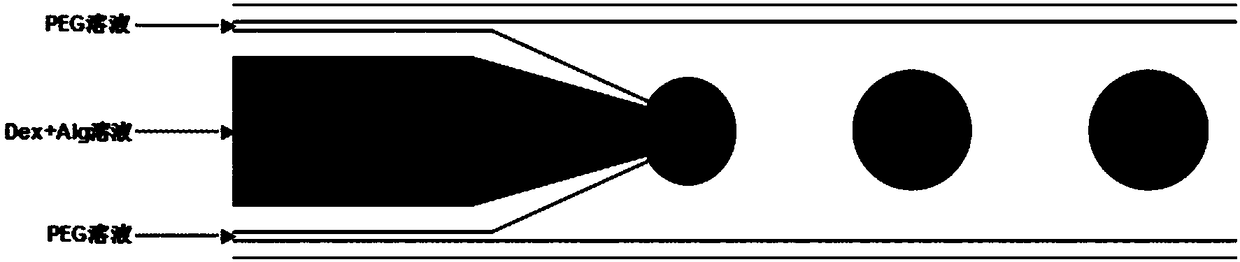

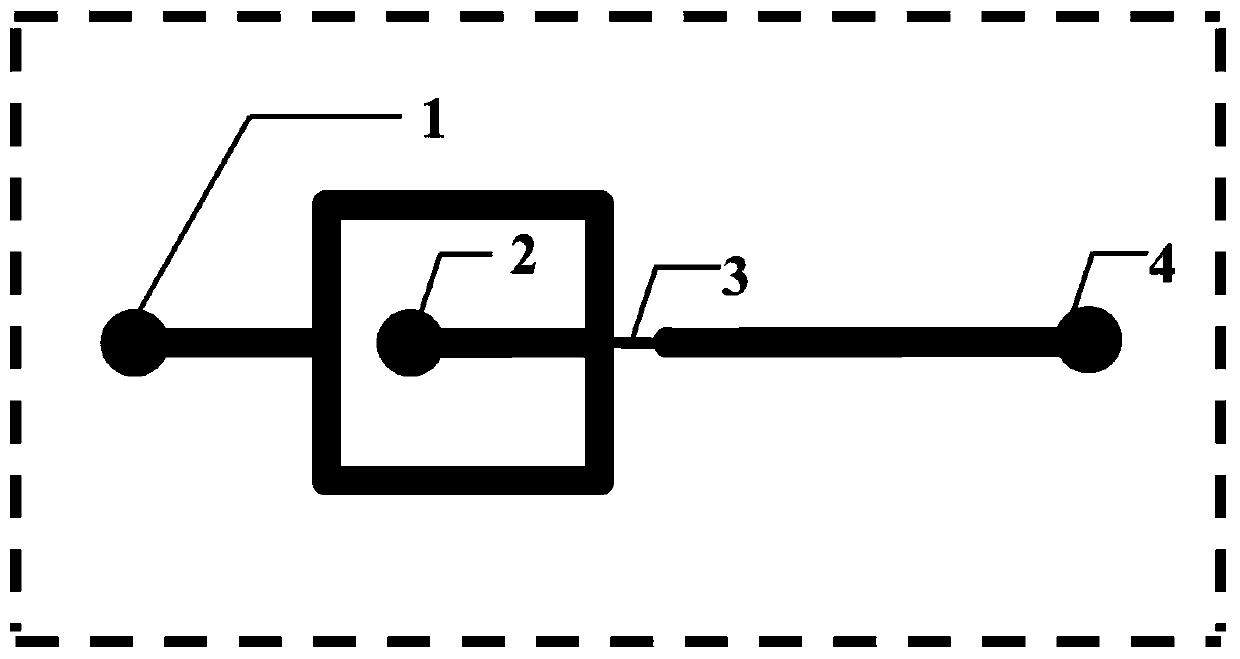

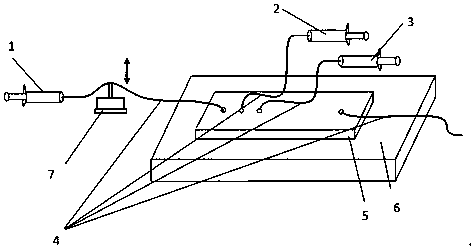

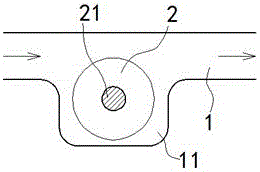

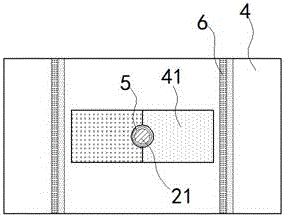

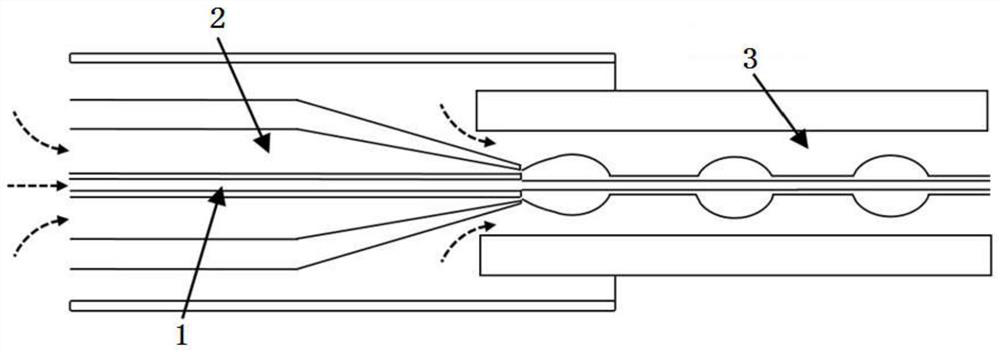

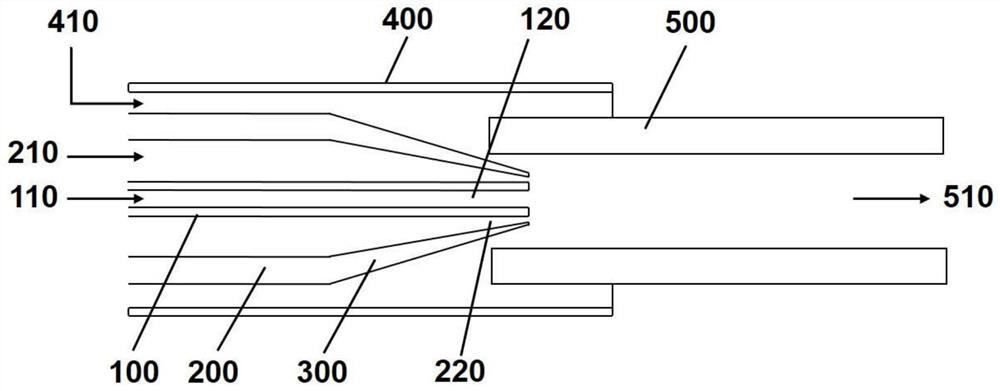

Preparation method and device of micro-fluidic dual-aqueous-phase monodisperse calcium alginate microspheres

ActiveCN108514896ASimple and fast way to generateGood biocompatibilityLaboratory glasswaresPharmaceutical non-active ingredientsMicrospherePolyethylene glycol

The invention discloses a preparation method of micro-fluidic dual-aqueous-phase monodisperse calcium alginate microspheres. The preparation method comprises the following steps: taking a polyethyleneglycol water solution as an outer aqueous phase, and glucan and a sodium alginate water solution as an inner aqueous phase; generating dual-aqueous-phase sodium alginate liquid drops at a conical sharp point through a coaxial capillary tube device; wherein the outer aqueous phase is continuous sample feeding; the inner aqueous phase is periodicity and intermittence sample feeding; introducing thedual-aqueous-phase sodium alginate liquid drops into a calcium chloride water solution to generate the needed monodisperse calcium alginate microspheres. According to the preparation method disclosedby the invention, sodium alginate or dual aqueous phases do not need to be subjected to a complicated pre-treatment process and a production manner is simple and rapid and has good biocompatibility;the formed microspheres are stable and the size of the microspheres is controllable; a device has the advantages of simple structure, flexibility and convenience for production, accuracy in operationand control and easiness for batch production.

Owner:SOUTHWEST JIAOTONG UNIV

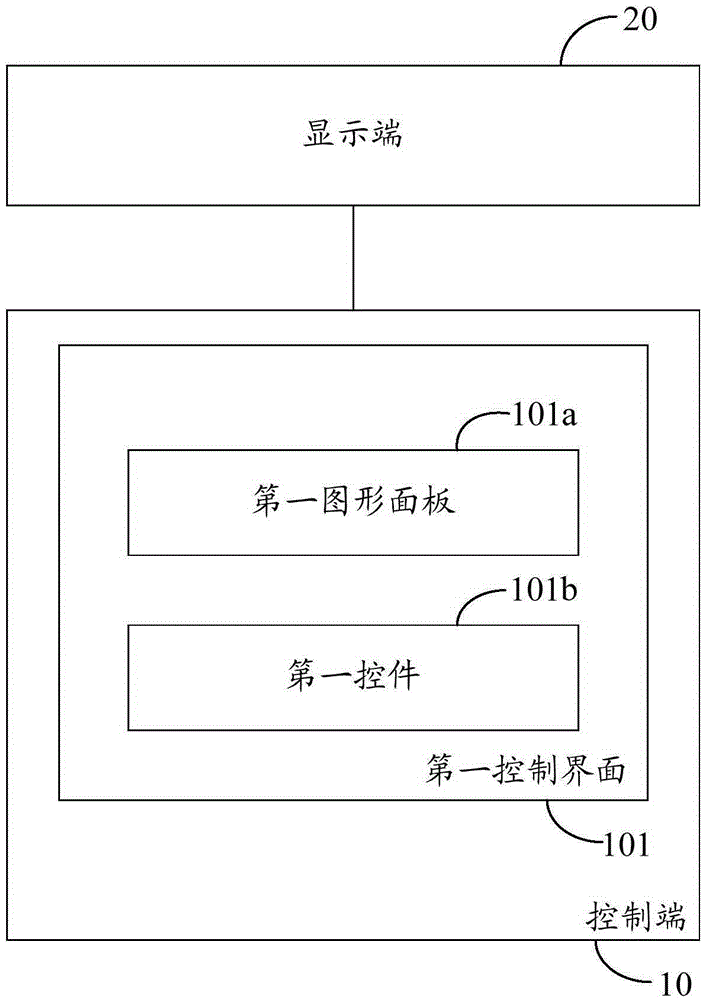

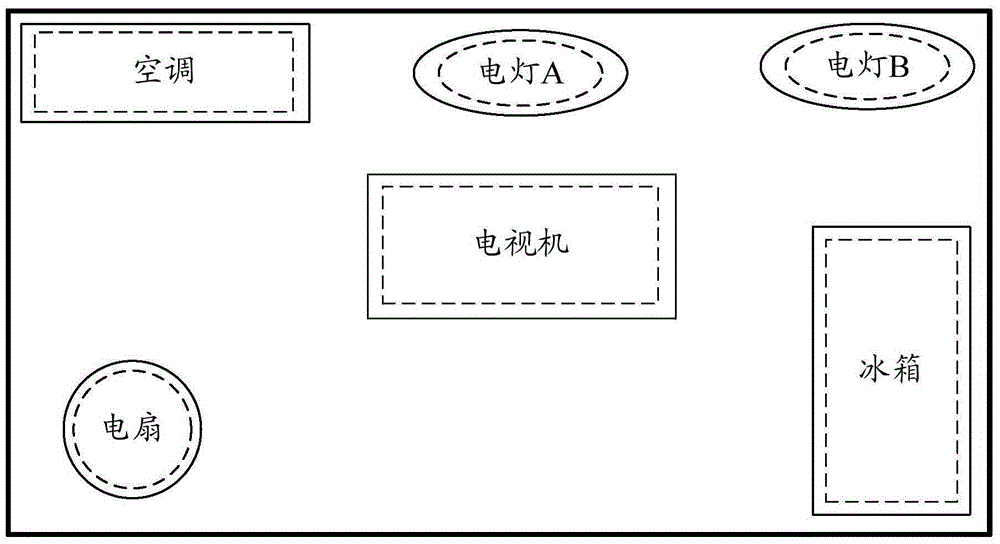

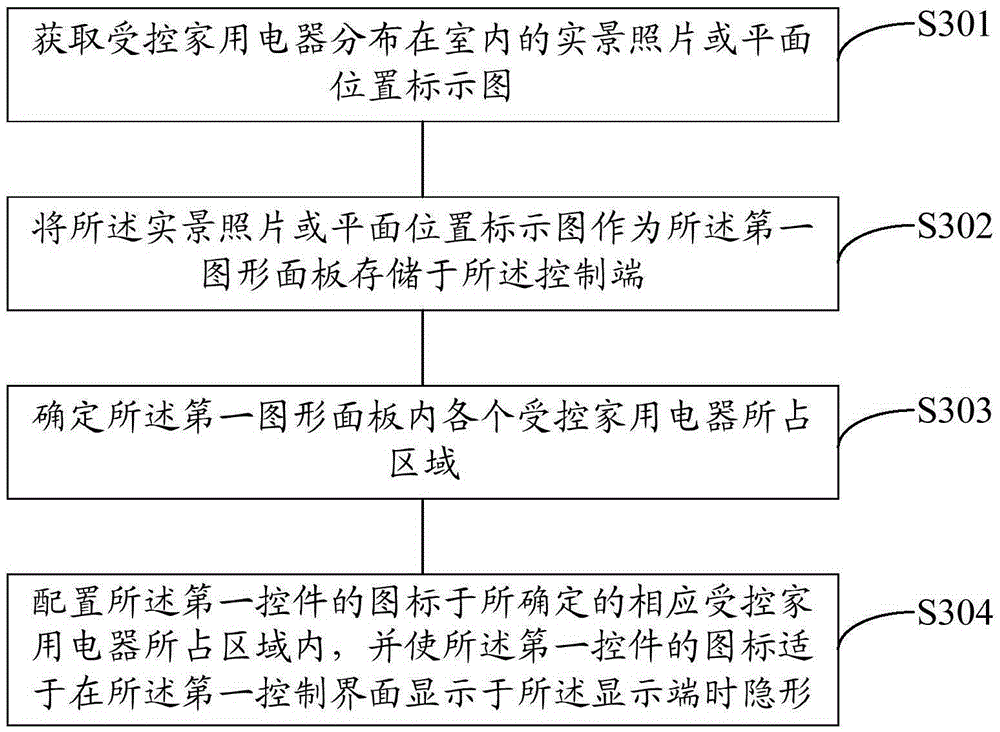

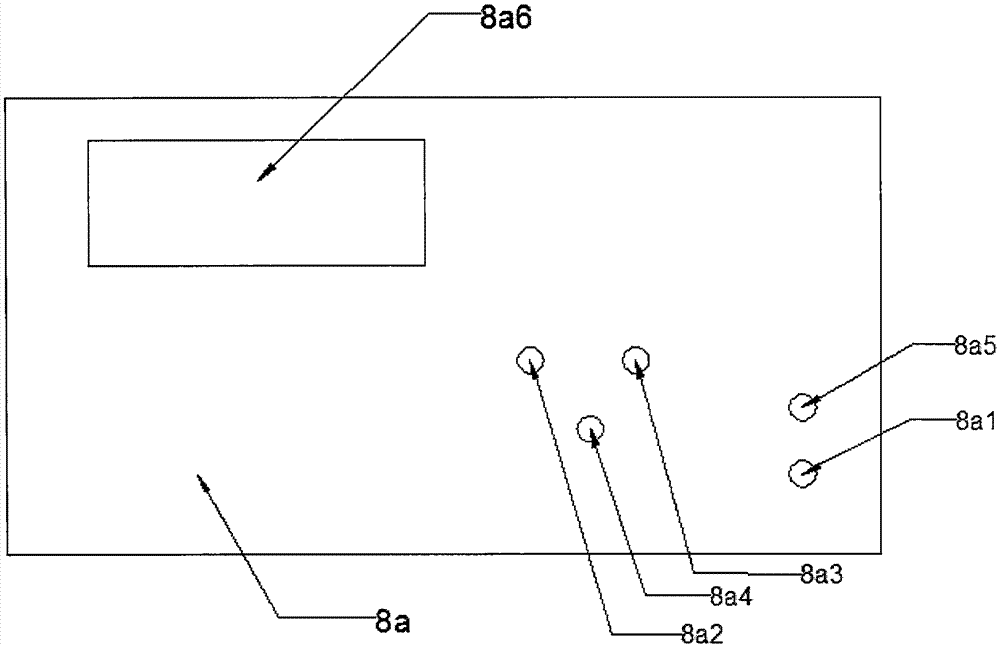

Household electrical appliance control system, and control device, construction method and control method thereof

InactiveCN106597860AIntuitive operating controlsPrecise operation controlComputer controlProgramme total factory controlControl systemHome control

The invention discloses a household electrical appliance control system, a household electrical appliance control device, and a construction method and a control method of the household electrical appliance system. The household electrical appliance control device comprises a control end and a display end, wherein the control end stores a first control interface of controlled household electrical appliances, the first control interface is an operation interface used for triggering call instructions for the controlled household electrical appliances, the first control interface comprises a first graphic panel and first controls in one-to-one correspondence with the controlled household electrical appliances, the first graphic panel is a real-scene photo or plane position marking graph of the controlled household electrical appliances distributed indoors, and the first controls are used for triggering call instructions for the corresponding controlled household electrical appliances; and icons of the first controls are invisible in regions occupied by the controlled household electrical appliances in the first graphic panel when the display end is displayed on the first control interface. The technical schemes provided by the invention can conveniently realize the effect of providing the intelligent home control system with the control interface which can identify each controlled household electrical appliance easily.

Owner:上海澜腾智能科技有限公司

Temperature sensor

InactiveCN101988854ASuppresses the influence of thermal resistanceAccurate temperatureThermometer detailsElectricityEngineering

Owner:MITSUBISHI MATERIALS CORP

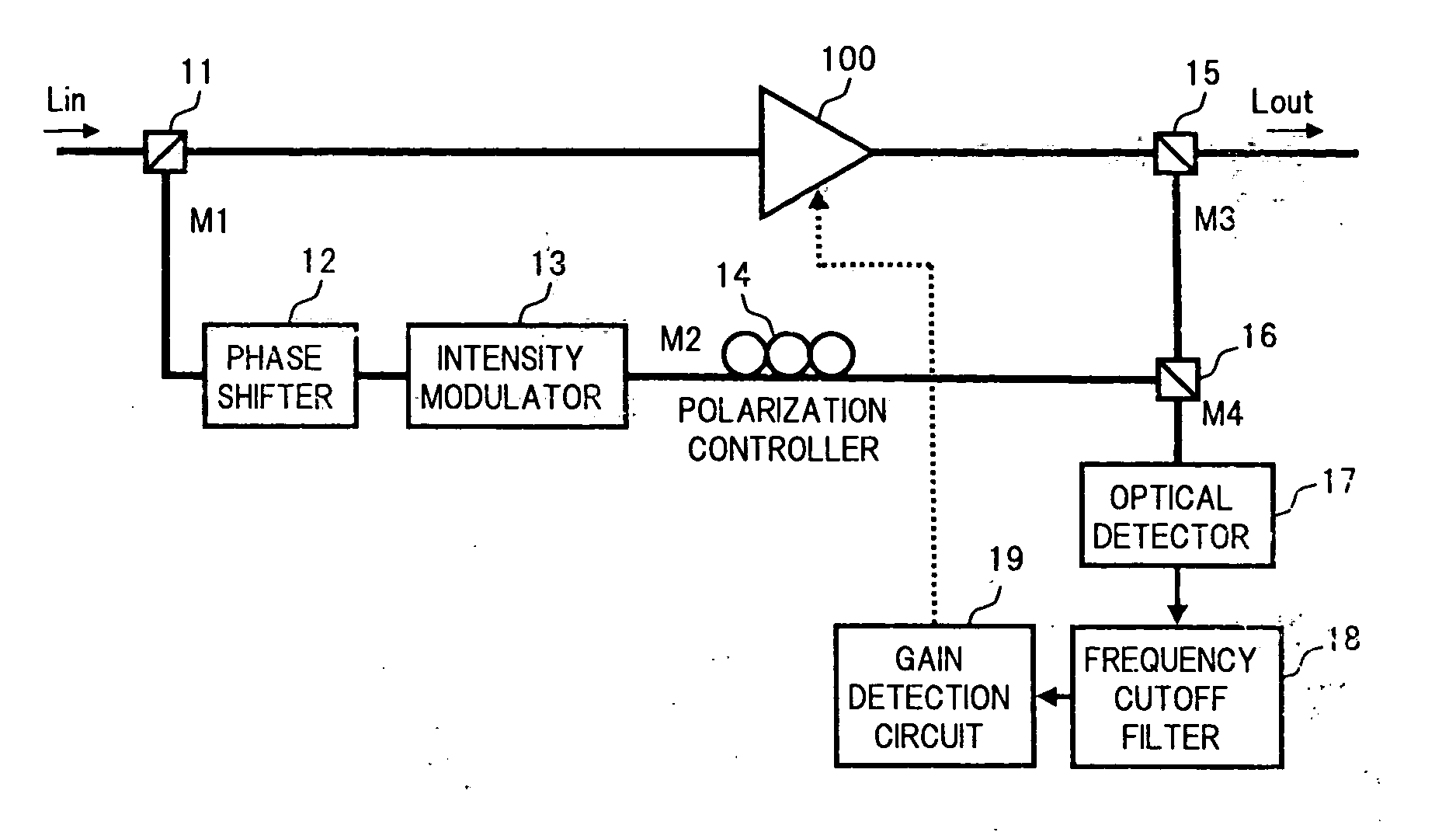

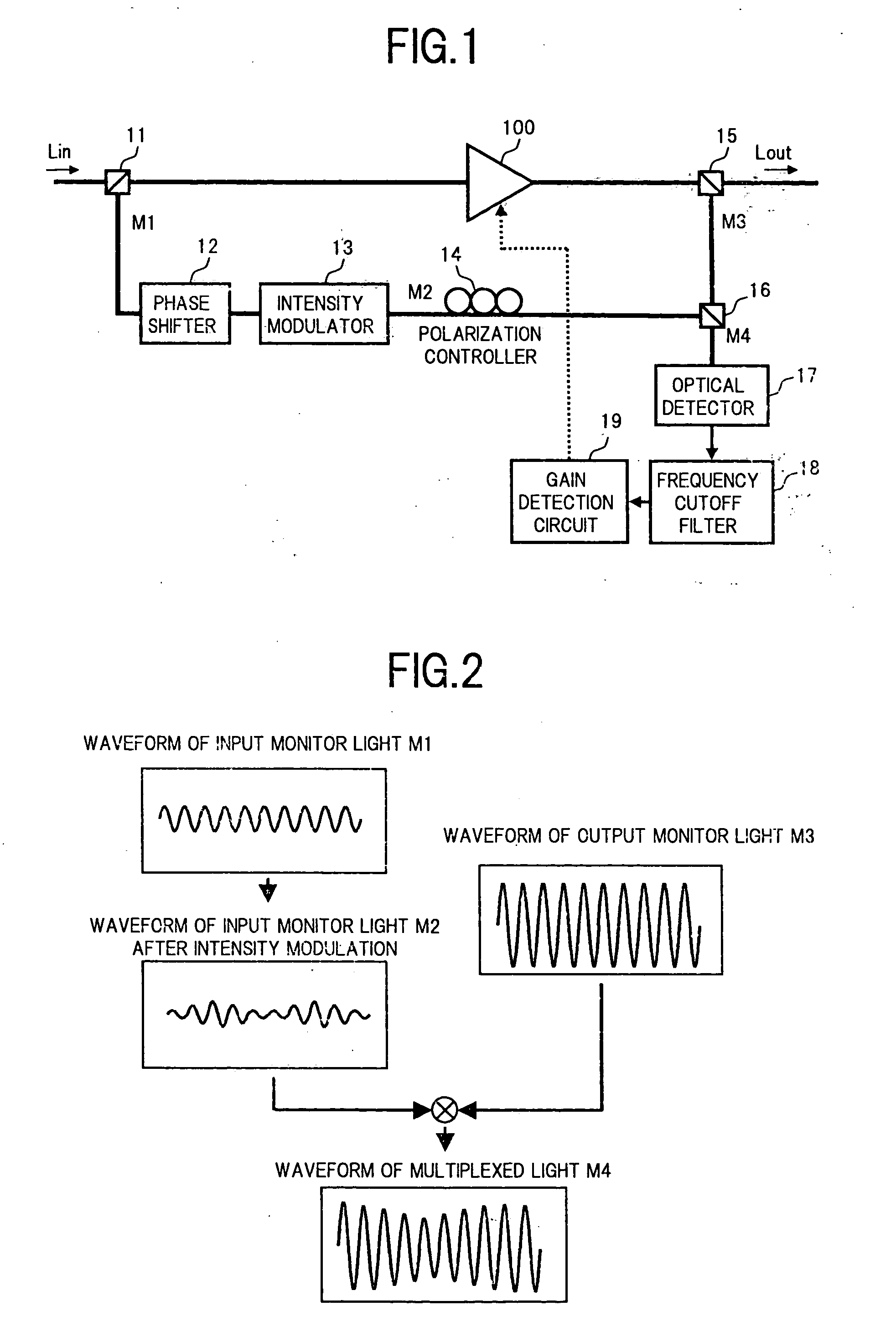

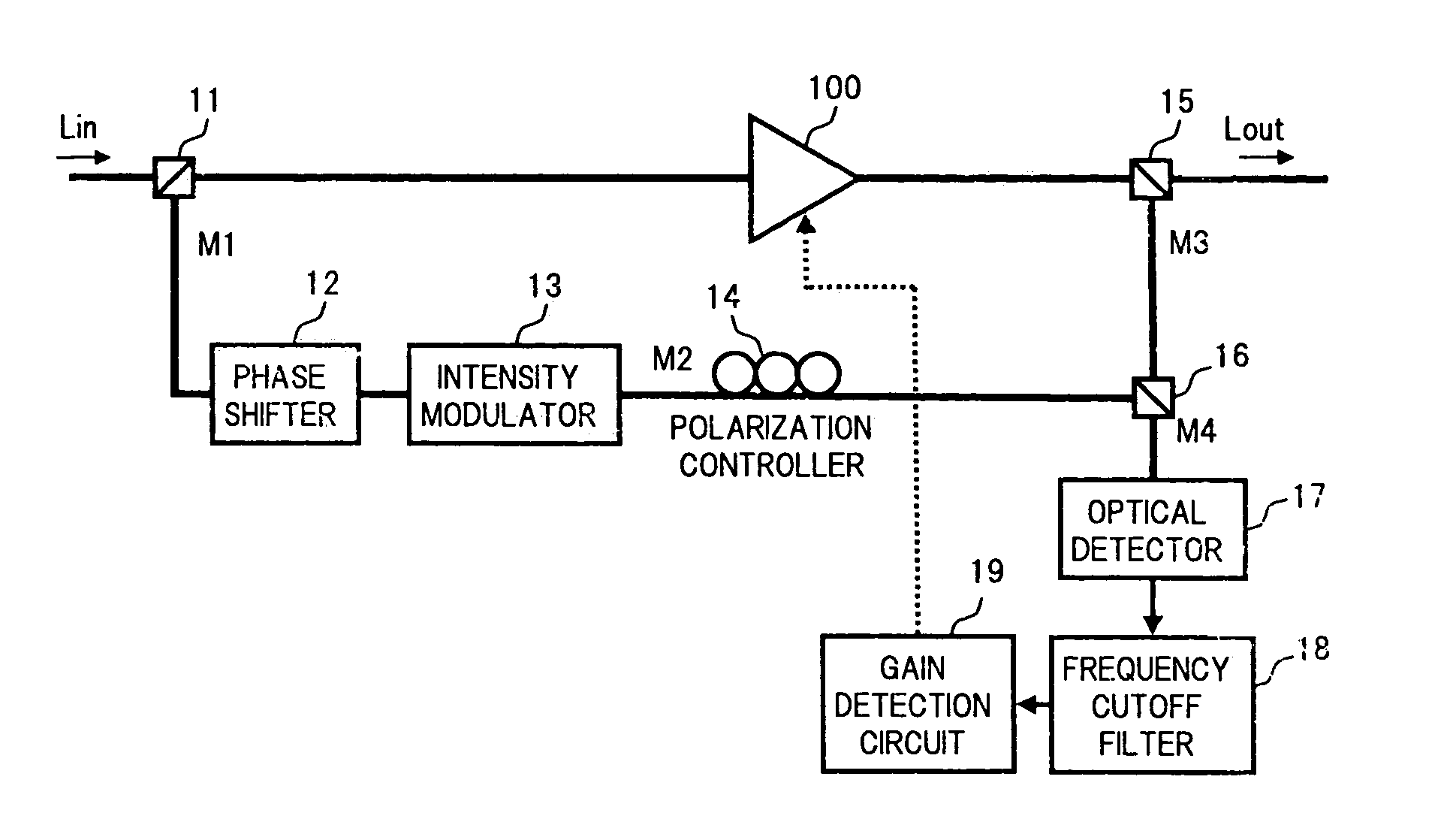

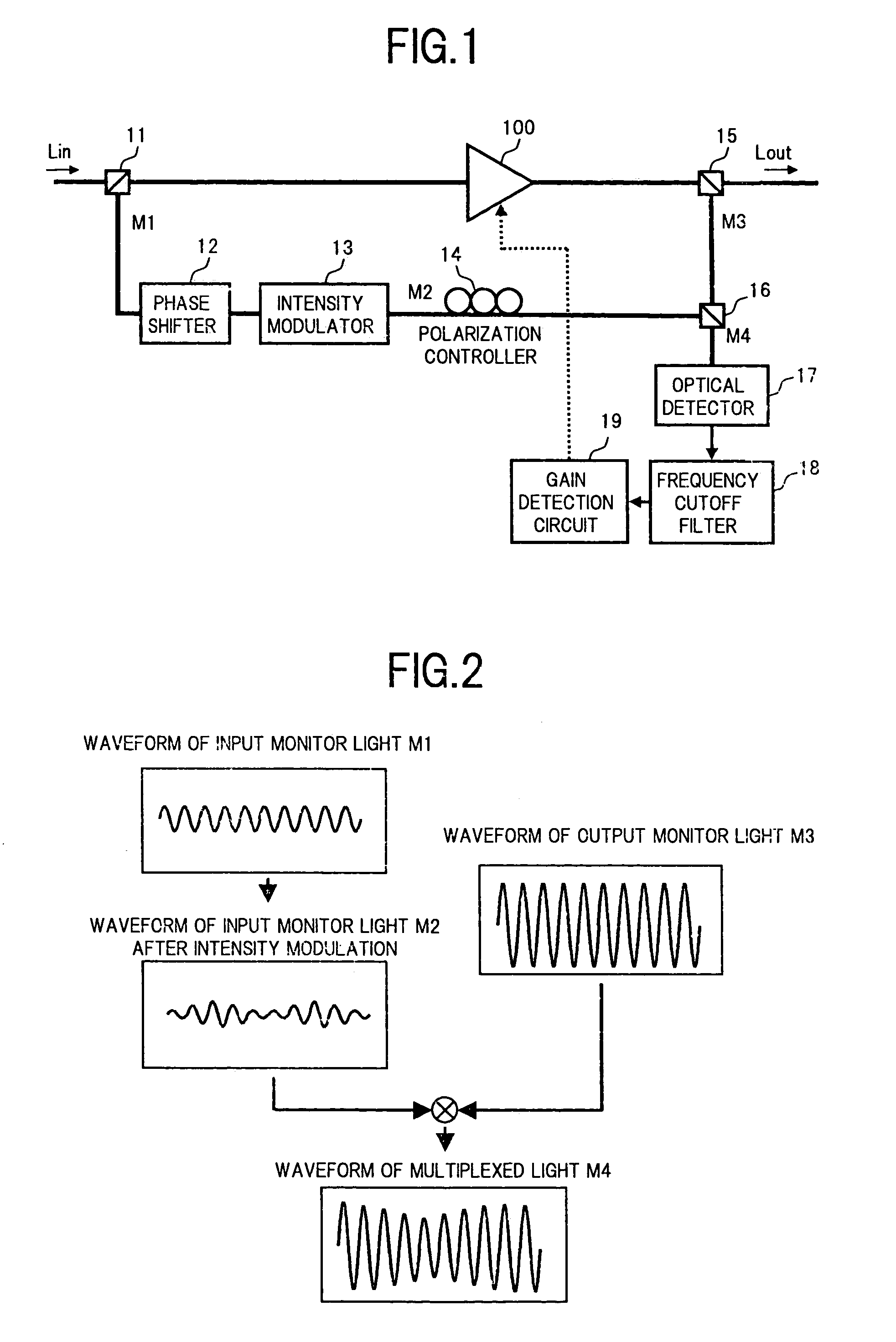

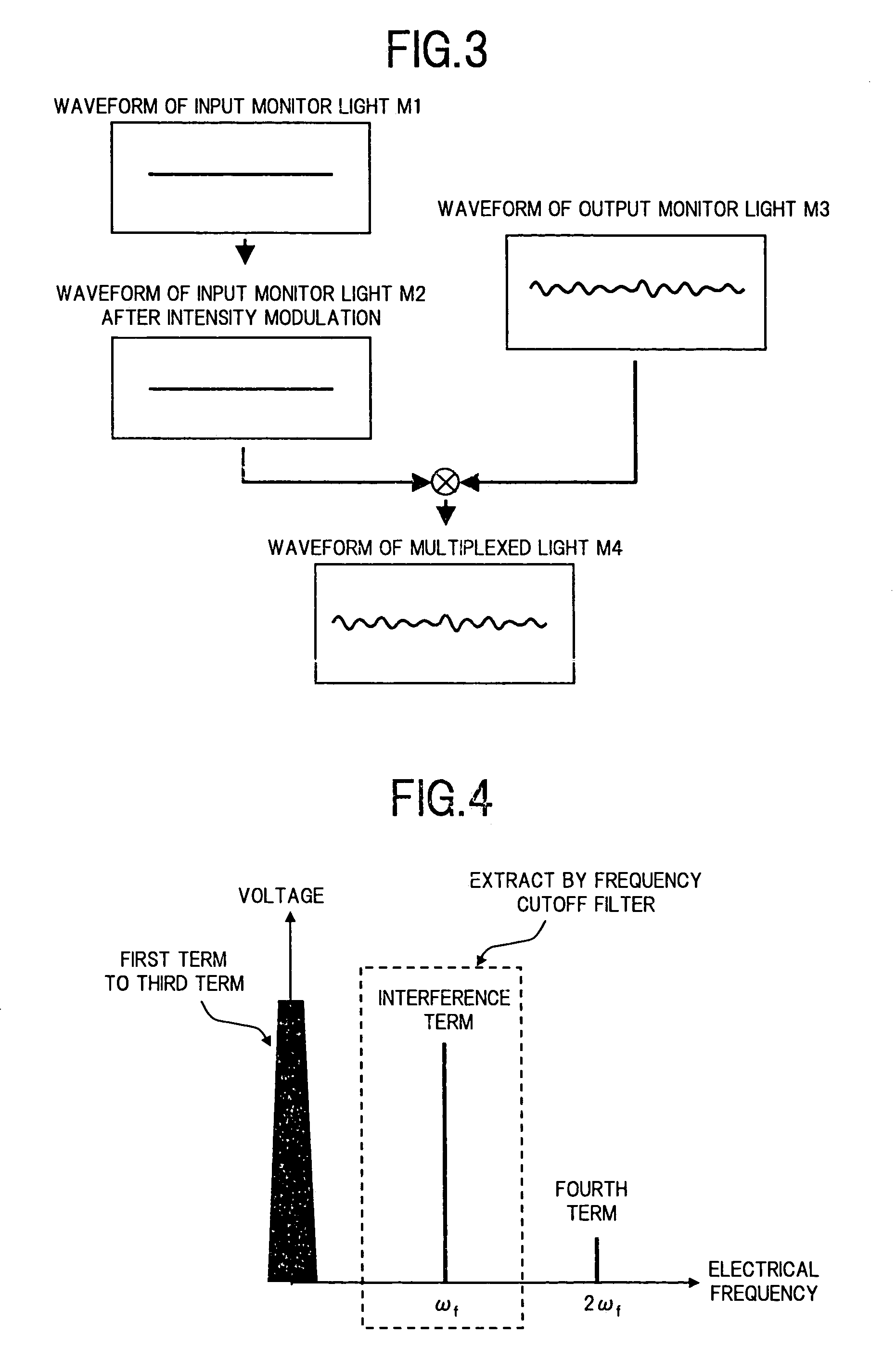

Gain monitoring method for optical amplifier and apparatus thereof

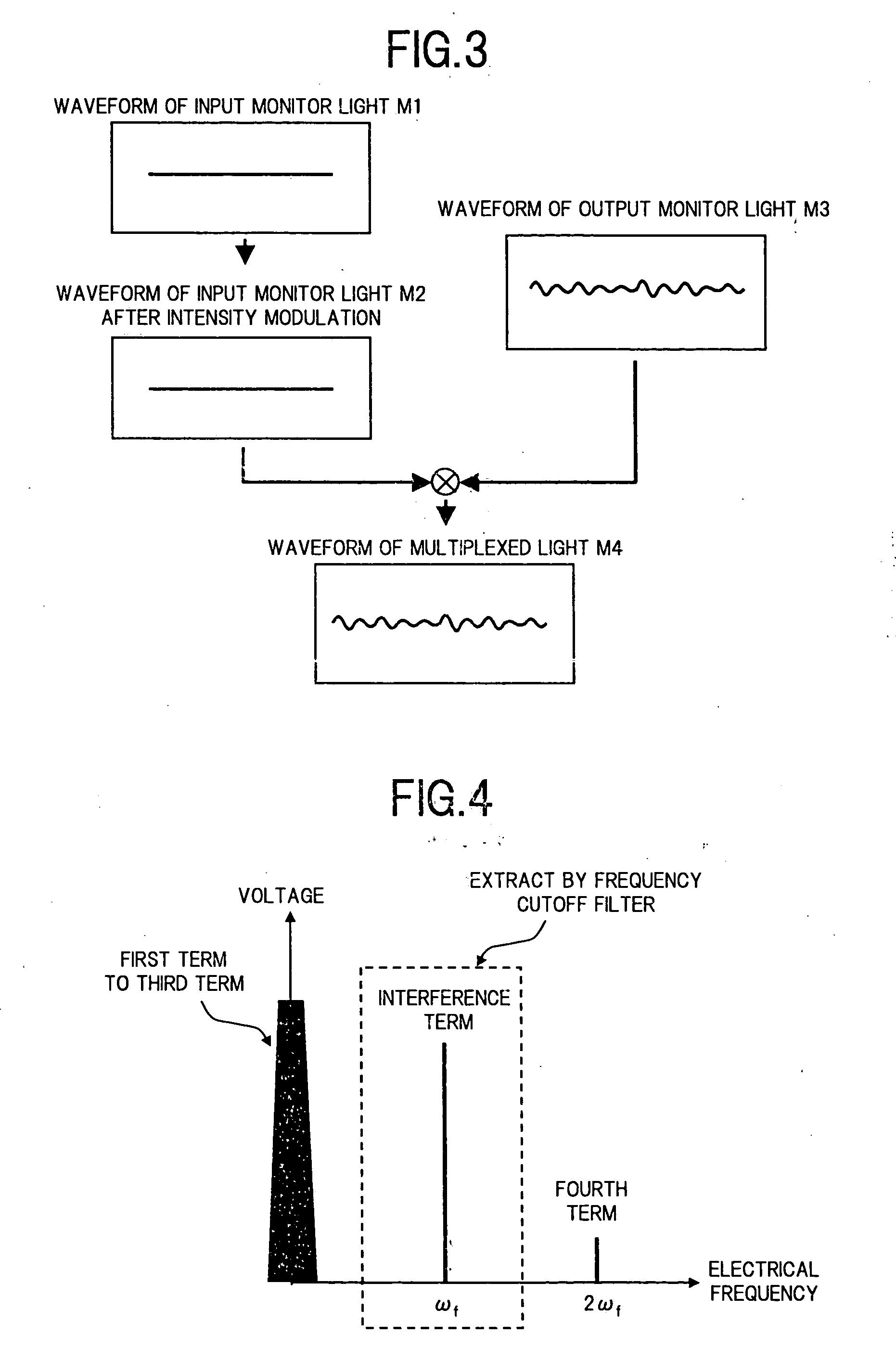

InactiveUS20050213990A1Accurate detectionHigh accurate operation controlFibre transmissionTransmission monitoringMultiplexingAudio power amplifier

An object of the invention is to realize a gain monitoring method for an optical amplifier and an apparatus thereof, capable of detecting a gain for a signal light regardless of a noise light generated inside the optical amplifier. To this end, in the gain monitoring method according to the present invention, a part of a signal light input to an optical amplifier is branched as an input monitor light, and the input monitor light is modulated, and also a part of a light output from the optical amplifier is branched as an output monitor light, so that the modulated input monitor light and the output monitor light are multiplexed. Then, the multiplexed light is converted into an electrical signal, an interference component contained in the electrical signal is extracted, and a gain for the signal light in the optical amplifier is detected based on the interference component.

Owner:FUJITSU LTD

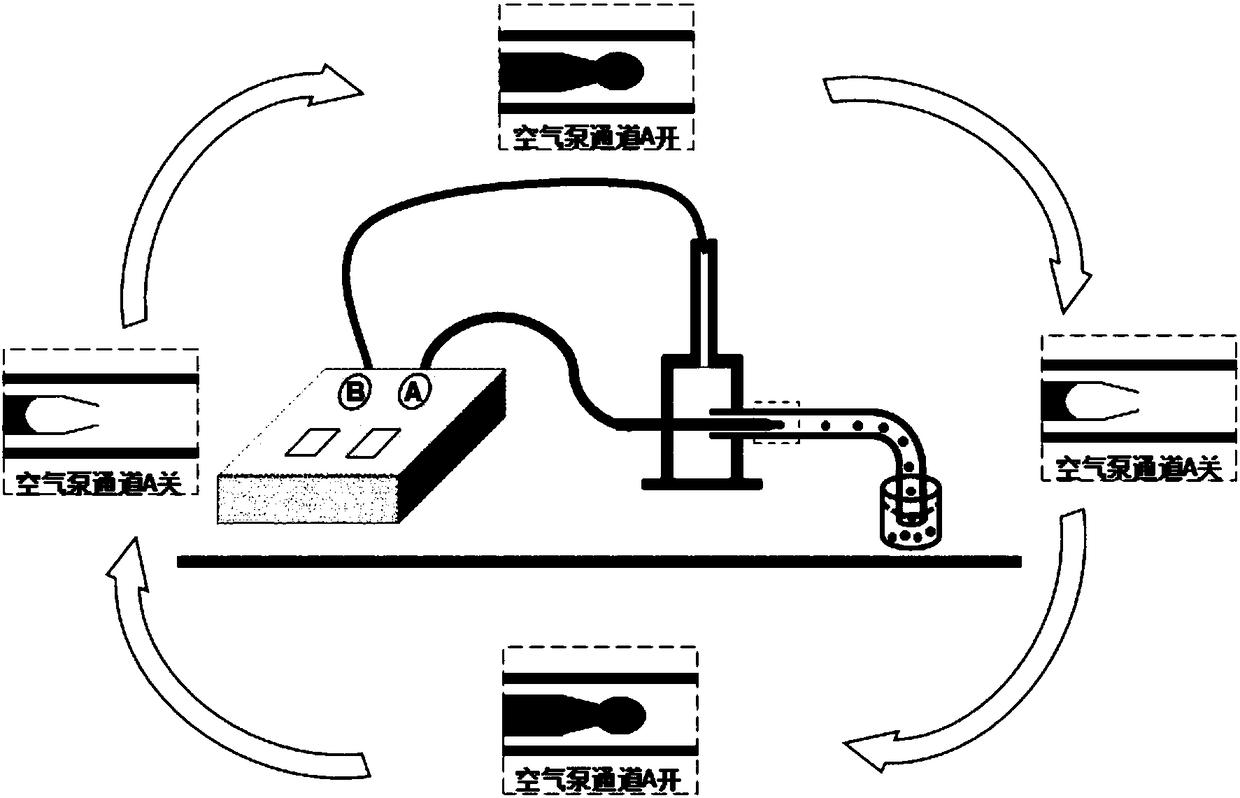

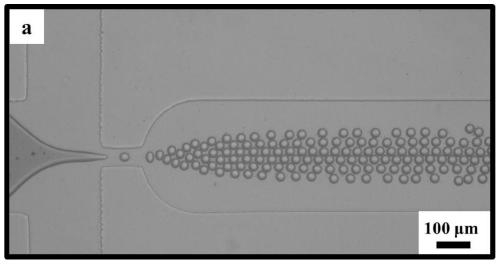

Honeycomb-shaped carbon nano tube porous microsphere, and preparation method and application thereof

ActiveCN110237787AUniform sizeReduce sizeOther chemical processesMicroballoon preparationNanoparticleCarbon nanotube

The invention discloses a honeycomb-shaped carbon nano tube porous microsphere, and a preparation method and application thereof. The honeycomb-shaped carbon nano tube porous microsphere is a three-dimensional porous structure formed by carbon nano tubes, has a diameter in a range of 5-200 microns, and contains a large amount of micropores with diameters in a range of of 20-1000 nm. A droplet micro-fluidic technology is adopted, and a porous microsphere structure is constructed by using micro droplets as soft templates and using SiO2 nano particle as hard templates. The honeycomb-shaped carbon nanotube porous microspheres prepared by the method are uniform in size, and the size, shape and density of ''honeycombs'' are controllable. Meanwhile, the preparation method disclosed by the invention is simple, and preparation is flexible and convenient. The flow speed is controlled through an injection pump, so that the advantages of accurate operation control, easy industrial batch production and the like are achieved.

Owner:SOUTH CHINA NORMAL UNIVERSITY

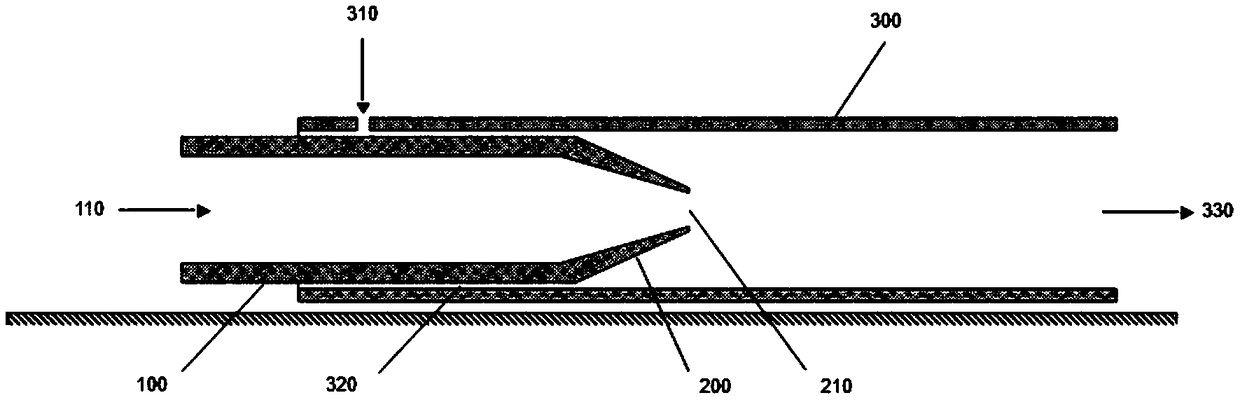

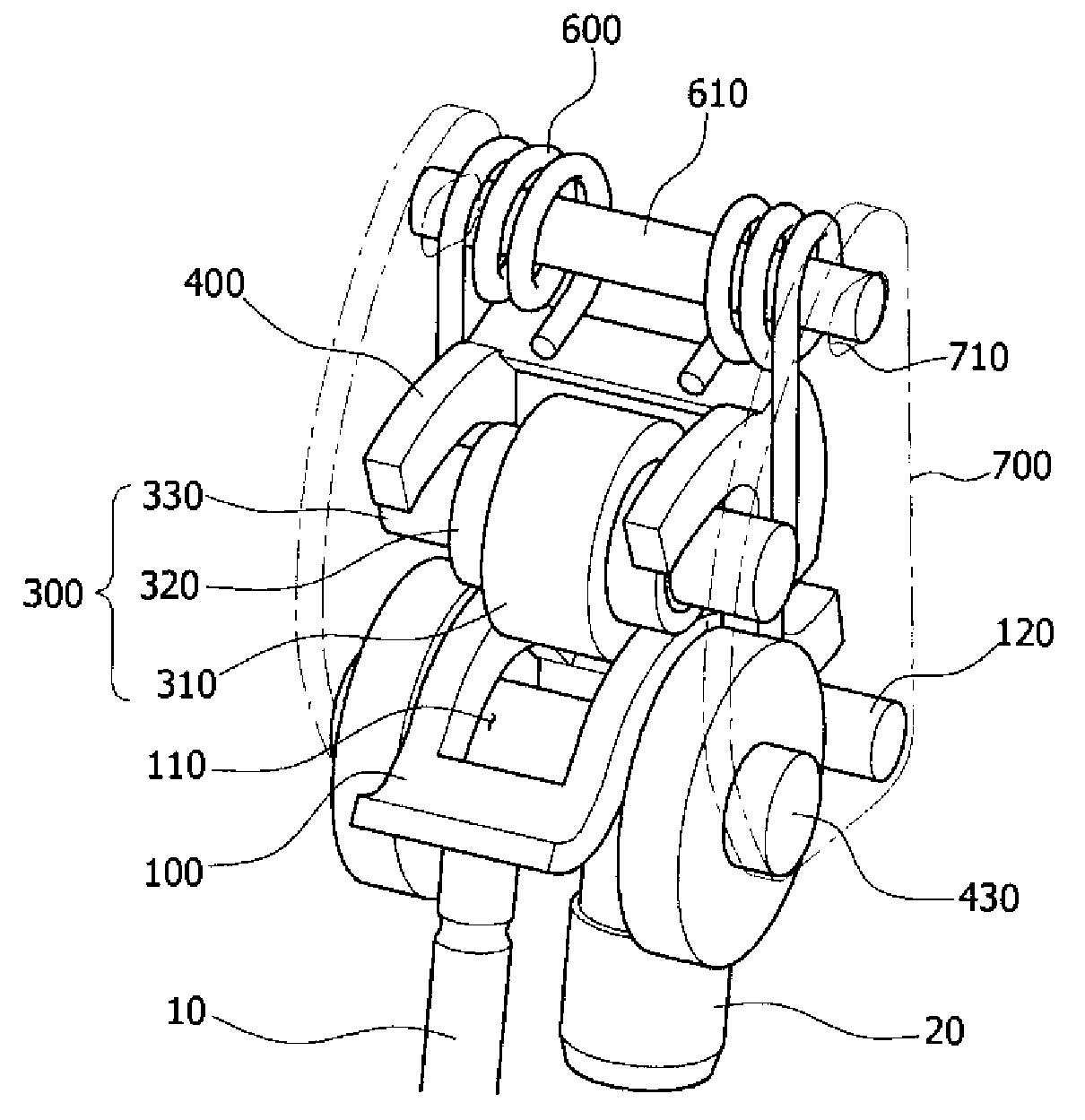

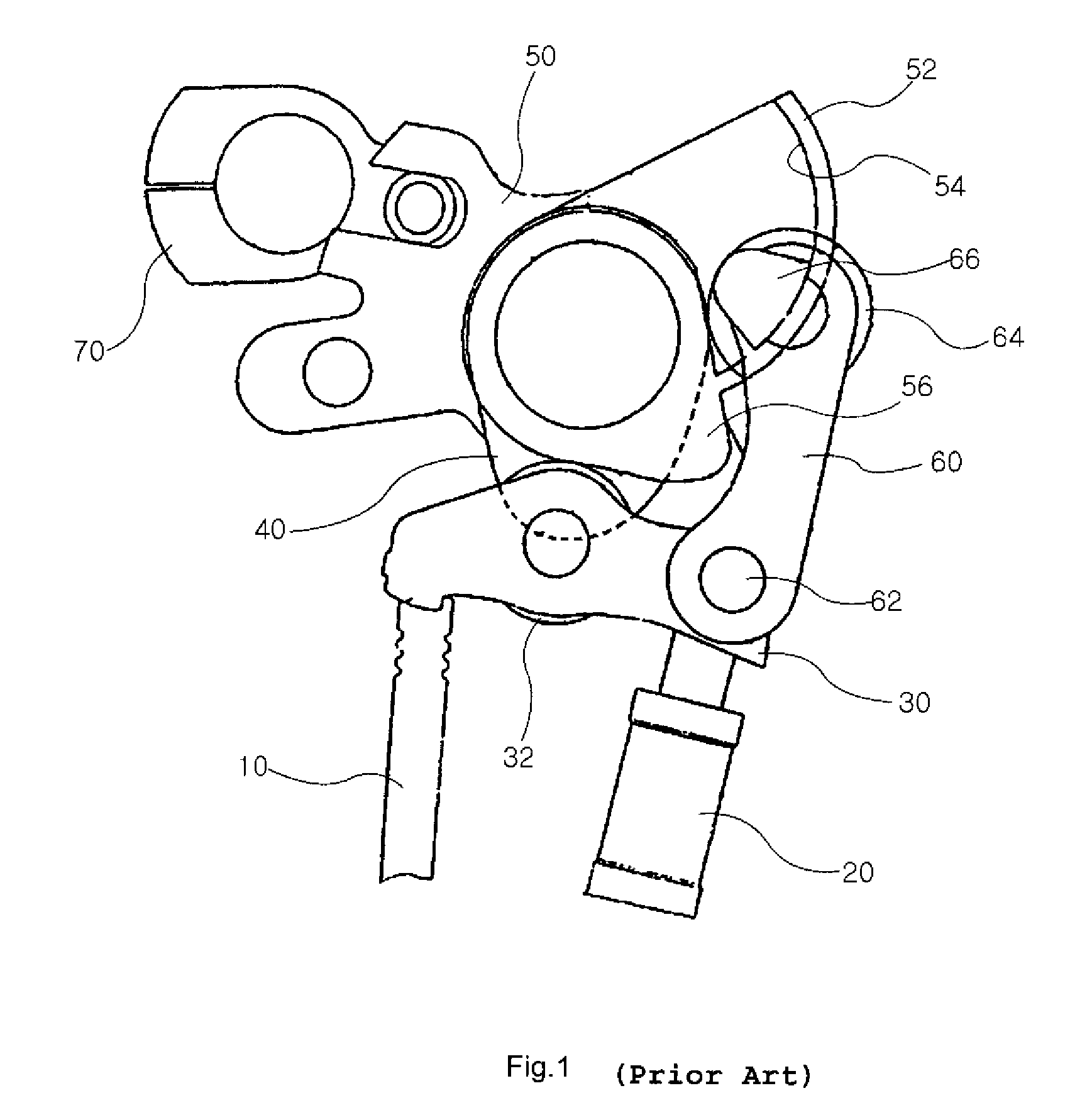

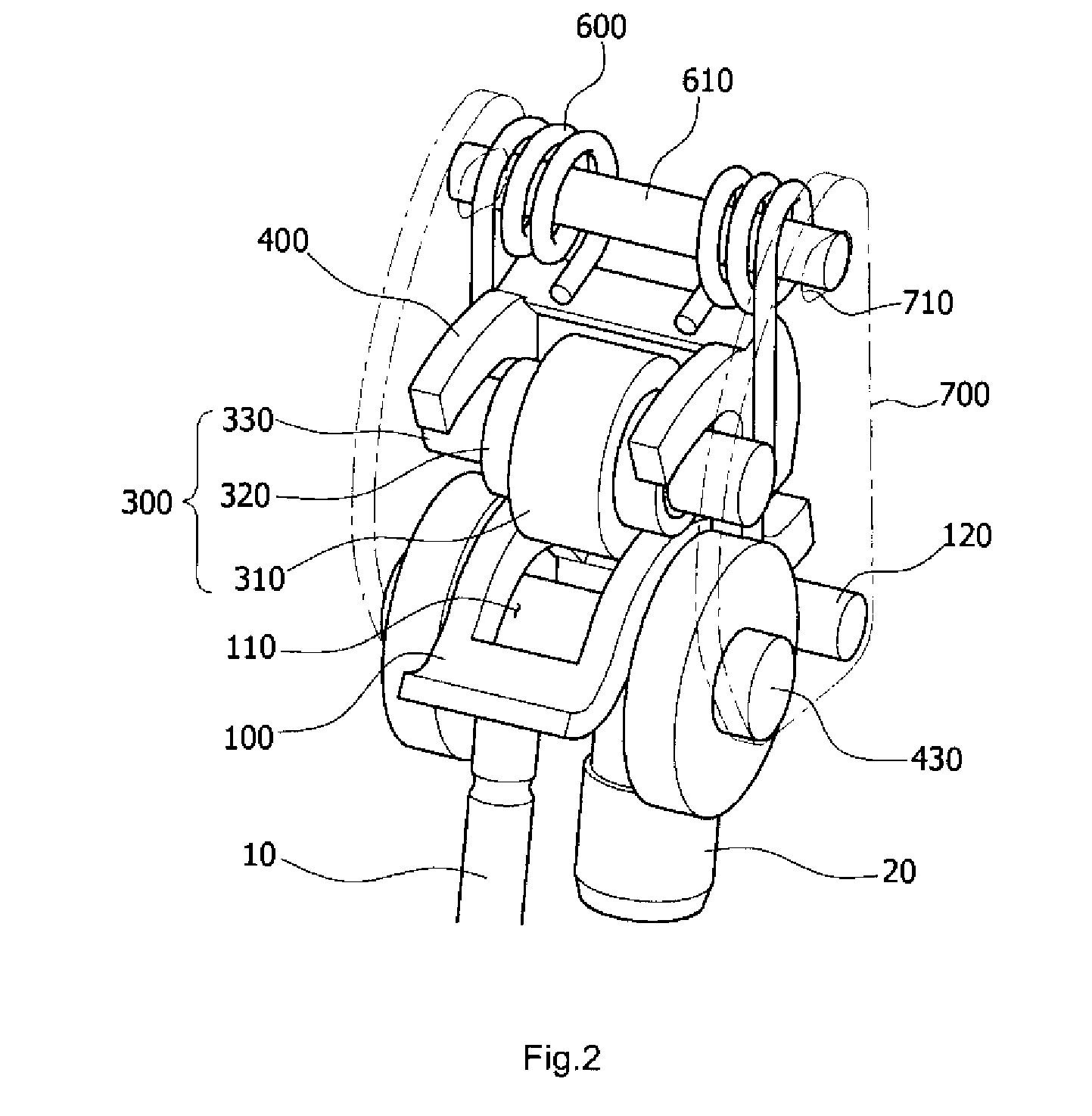

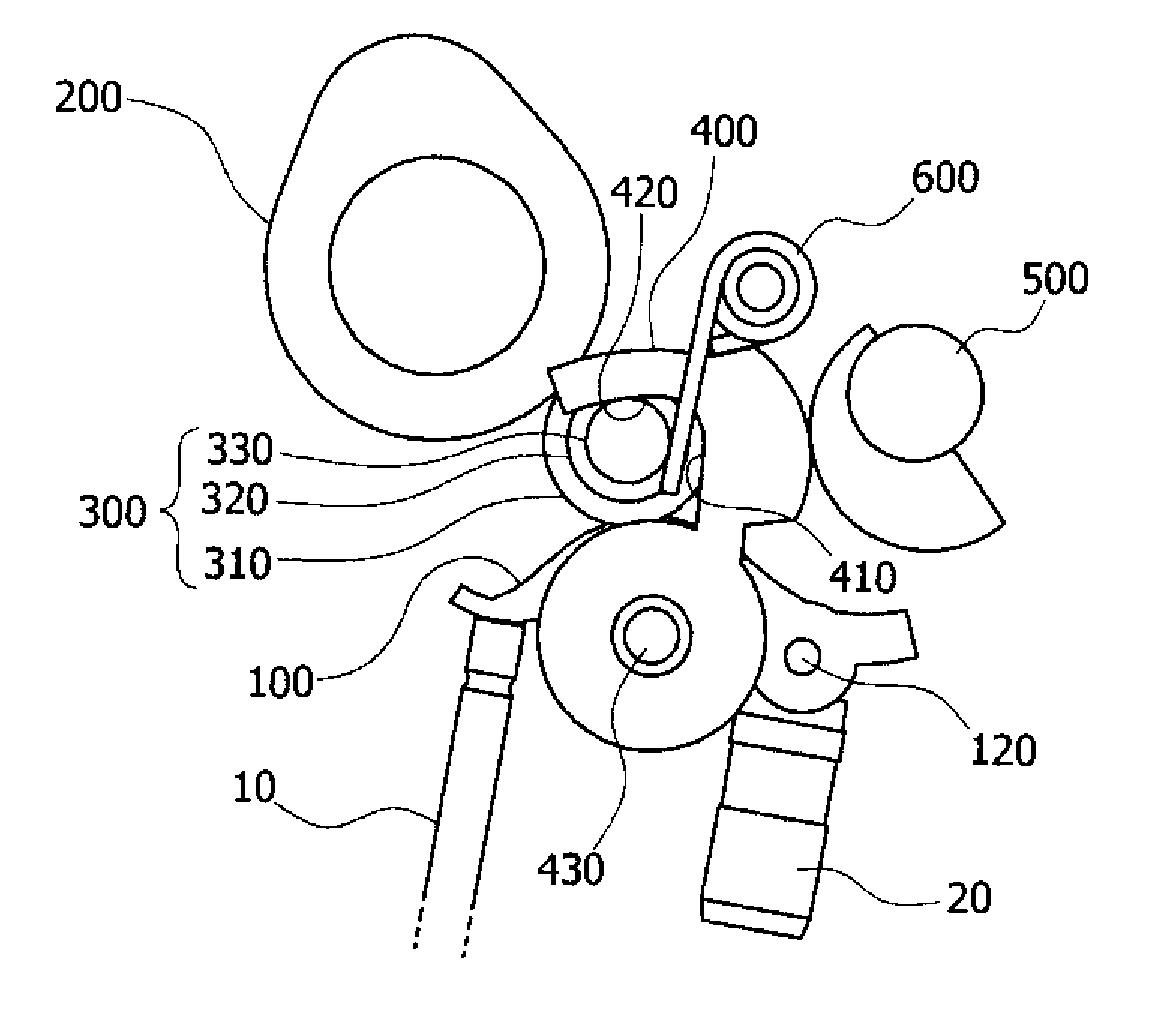

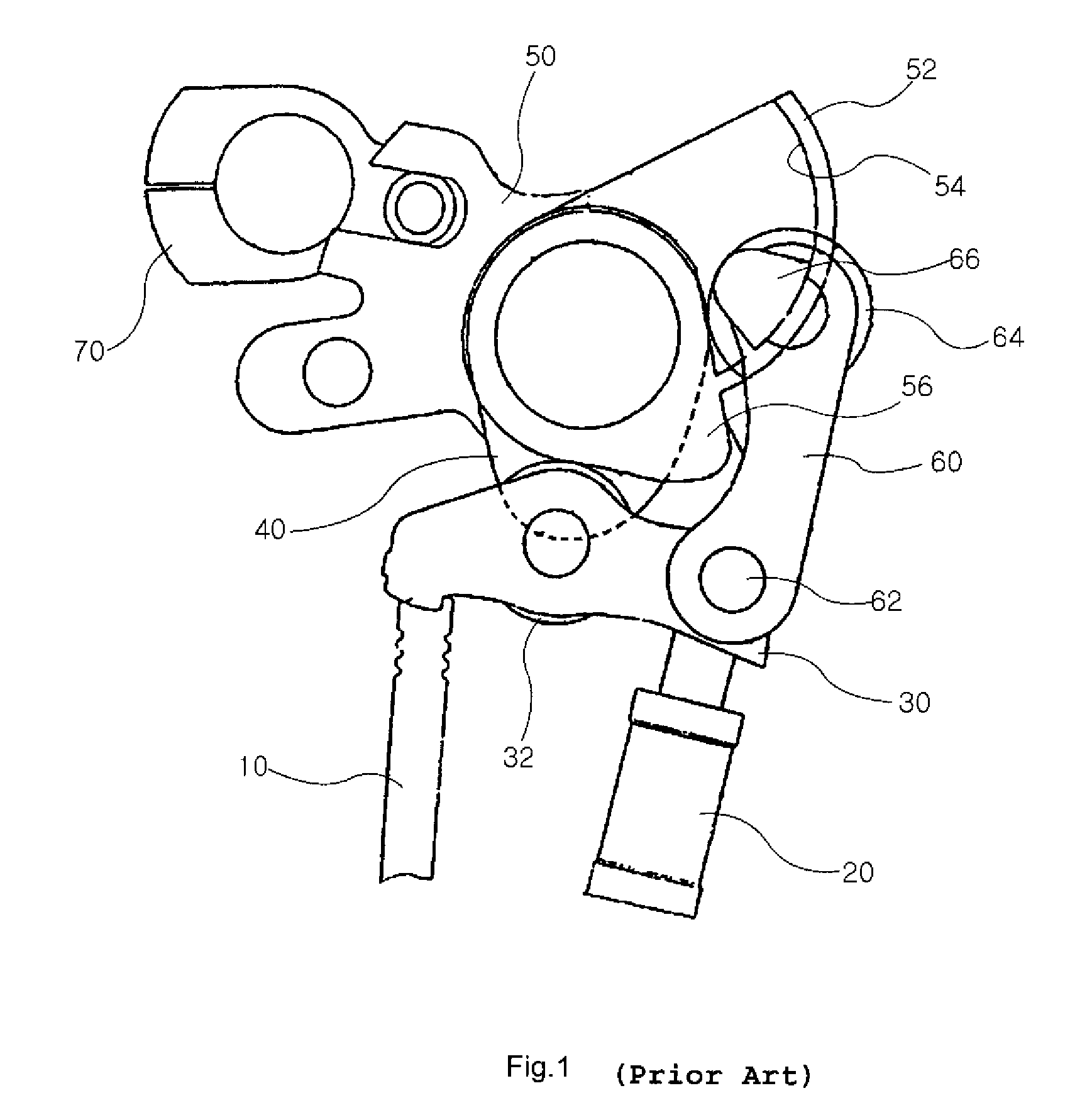

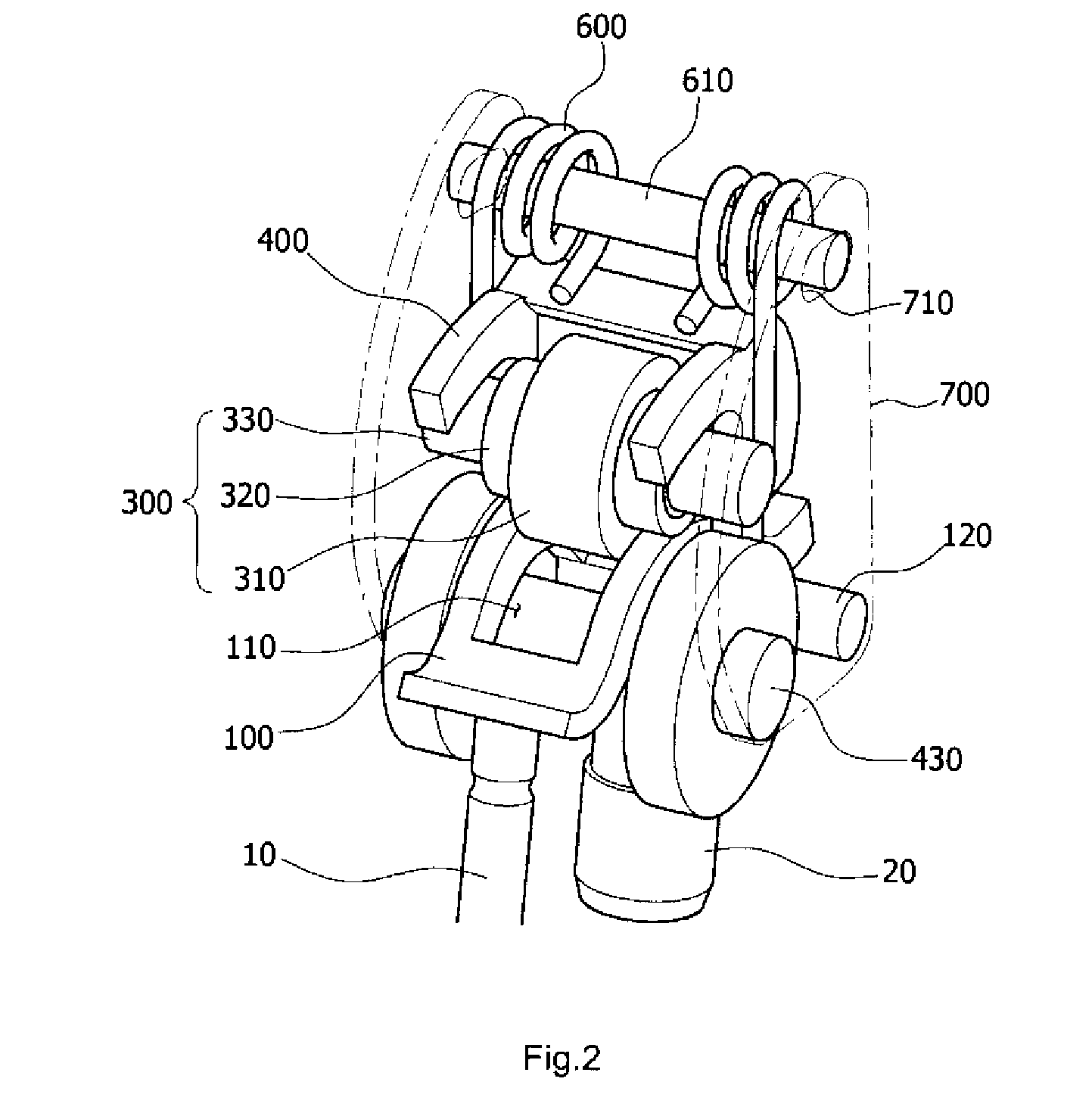

Slide Type Continuous Variable Valve Lift Device

InactiveUS20100018484A1Power Loss MinimizationPrecise operation controlValve arrangementsCam-followersFuel efficiencyEngineering

A slide type continuous variable valve lift (CVVL) device includes a swing arm rotating to press a valve; a cam lobe; a roller transmitting a driving force of the cam lobe to the swing arm; and a guide guiding the roller to move along a predetermined path. The CVVL device generally can minimize the number of places where sliding friction between respective parts may occur to minimize power loss and enable more precise operation control, reduce the number of parts to enhance the overall robustness of the device, and advance the time of maximum valve opening to improve the fuel efficiency of an engine.

Owner:HYUNDAI MOTOR CO LTD

Preparation method of two-aqueous-phase micro liquid droplets with uniform and controllable sizes

InactiveCN110227378AUniform sizeThe size is easy to controlTransportation and packagingMixersPolyelectrolyteOrganic solvent

The invention discloses a preparation method of micro liquid droplets with uniform and controllable sizes based on an ultra-low interfacial tension two-aqueous-phase system. The method specifically comprises the following steps: a glucan aqueous solution is used as an inner phase, a polyethylene glycol aqueous solution is used as a middle phase and an outer phase, the three phases are merged in amicrofluidic device to form a laminar flow, and the monodisperse two-aqueous-phase liquid droplets are generated by utilizing action of mechanical wave vibration; and in addition, the obtained two-aqueous-phase liquid droplets are used as a template, polyelectrolytes in the inner phase and the outer phase meet at the liquid droplet interface and complexed through electrostatic force, and thereforepolyelectrolyte microcapsules are prepared. According to the method provided by the invention, the two-aqueous-phase liquid droplets prepared by the method have good monodispersity, and the method can effectively control the sizes of the liquid droplets by changing flow speeds of an inner-phase fluid, a middle-phase fluid and an outer-phase fluid and frequency and amplitude of applied vibration;and compared with a traditional method for preparing capsules by using oil / water liquid droplets, the method provided by the invention uses the two-aqueous-phase liquid droplets as templates to prepare the capsules without using organic solvents, and the two-aqueous-phase liquid droplets have higher biocompatibility and have wider application in the fields of food, cosmetics, medicine, biologicalmicroreactors and sensing analysis testing.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

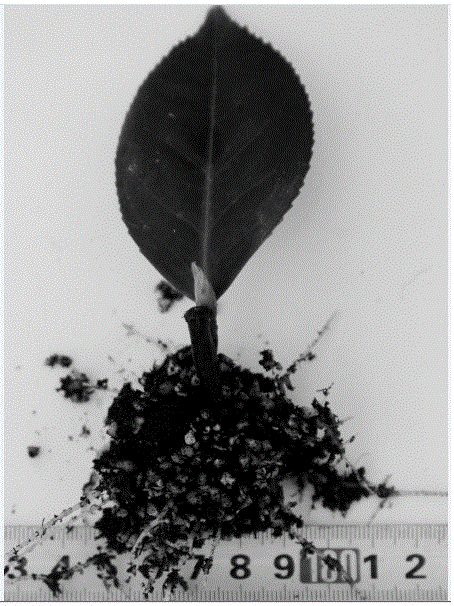

Single-bud soilless cutting propagation method of camellia

InactiveCN105684854APrecise operation controlImprove qualityAgriculture gas emission reductionCultivating equipmentsPeatBud

The invention discloses a single-bud soilless cutting propagation method of camellia. The method comprises the steps that a seedbed cutting matrix in a plastic greenhouse is prepared from peat and perlite, the volume ratio of the peat to the perlite is 2:1 or 3:2, floor heating lines are laid in a seedbed, and an automatic high-pressure thick mist spraying device is installed in the greenhouse; current-year semi-lignified branches of a maternal plant serve as cuttings, and a stem node, a leaf and a resting bud are retained on each cutting; in the cutting propagation period, the air temperature in the plastic greenhouse does not exceed 30 DEG C, and the temperature of the cutting matrix keeps at 20 DEG C-25 DEG C; the light intensity is 30,000-50,000 lx, the relative air humidity in the greenhouse is 85% or above, and the relative air humidity after rooting is 70%-85%; alternating spraying is performed with a 0.1% thiophanate methyl solution and a 0.1% chlorothalonil solution every other 10 days. According to the method, precise operation is achieved, the repeatability is high, the rooting rate reaches 85% or above, the propagation period is short, and transplanting can be performed after cutting is performed for 90-100 days.

Owner:FLOWER RES INST OF YUNNAN ACAD OF AGRI SCI

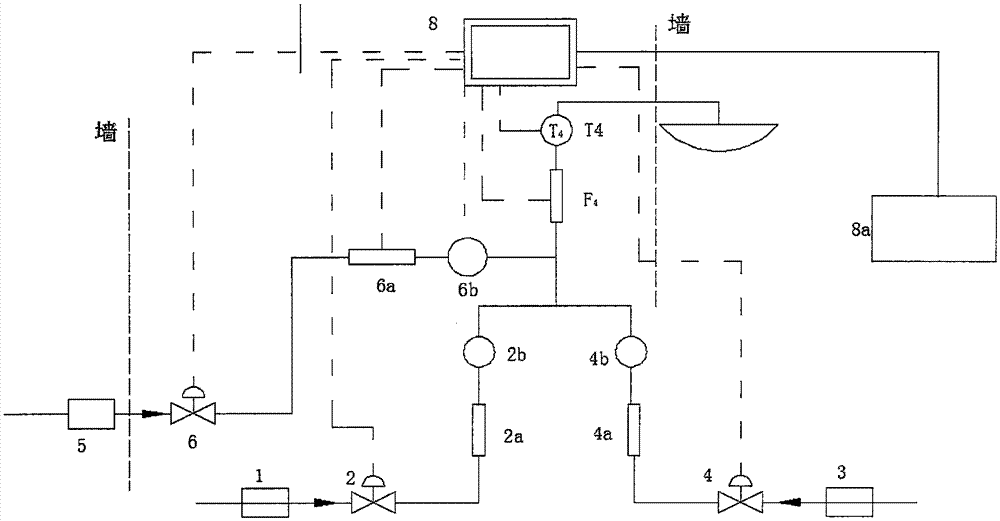

Washing shower system with ideal flow rate, temperature and distribution of sprinkled water

The present invention is suitable for shower systems in the field of showers, especially a washing shower system with ideal flow, temperature, and spray water distribution. The system includes: cold and hot water inlet devices, detergent adding devices, water spray devices, Multiple flow regulating valves, thermometers and flow meters, control center and control panel. The devices in the shower system involved in the present invention are all controlled automatically, intelligently and precisely by the control center, and the user realizes the operation through the control panel connected with the control center; the user can also add detergent from the detergent adding device according to personal preference to improve Shower experience. The present invention realizes the ideal flow rate, temperature and uniform distribution of shower spray water through the method of automatic control, without the need for users to manually adjust during the shower process. wasted water resources.

Owner:李润超

Gain monitoring method for optical amplifier and apparatus thereof

InactiveUS7308208B2Accurate detectionPrecise operation controlFibre transmissionTransmission monitoringMultiplexingAudio power amplifier

An object of the invention is to realize a gain monitoring method for an optical amplifier and an apparatus thereof, capable of detecting a gain for a signal light regardless of a noise light generated inside the optical amplifier. To this end, in the gain monitoring method according to the present invention, a part of a signal light input to an optical amplifier is branched as an input monitor light, and the input monitor light is modulated, and also a part of a light output from the optical amplifier is branched as an output monitor light, so that the modulated input monitor light and the output monitor light are multiplexed. Then, the multiplexed light is converted into an electrical signal, an interference component contained in the electrical signal is extracted, and a gain for the signal light in the optical amplifier is detected based on the interference component.

Owner:FUJITSU LTD

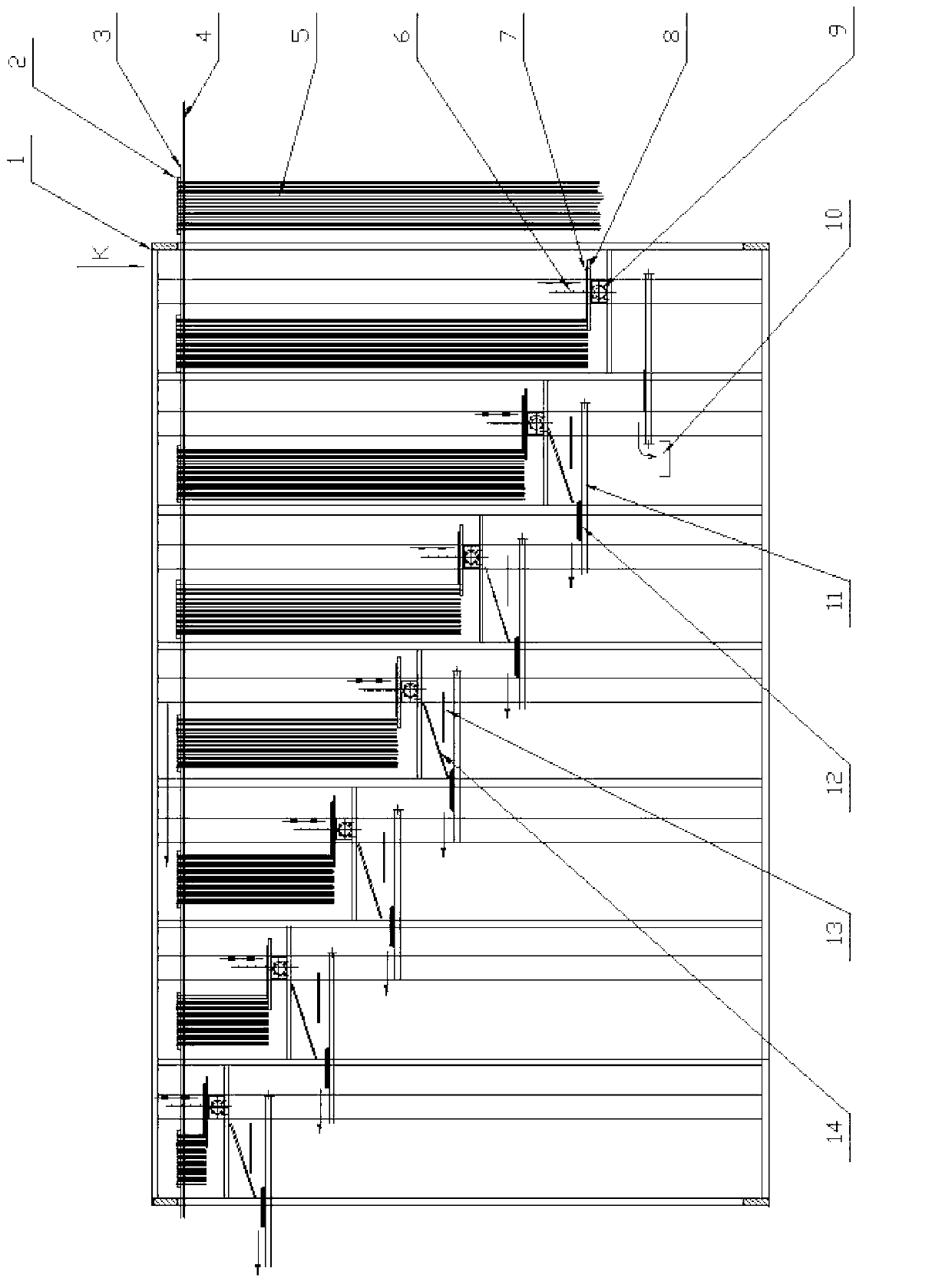

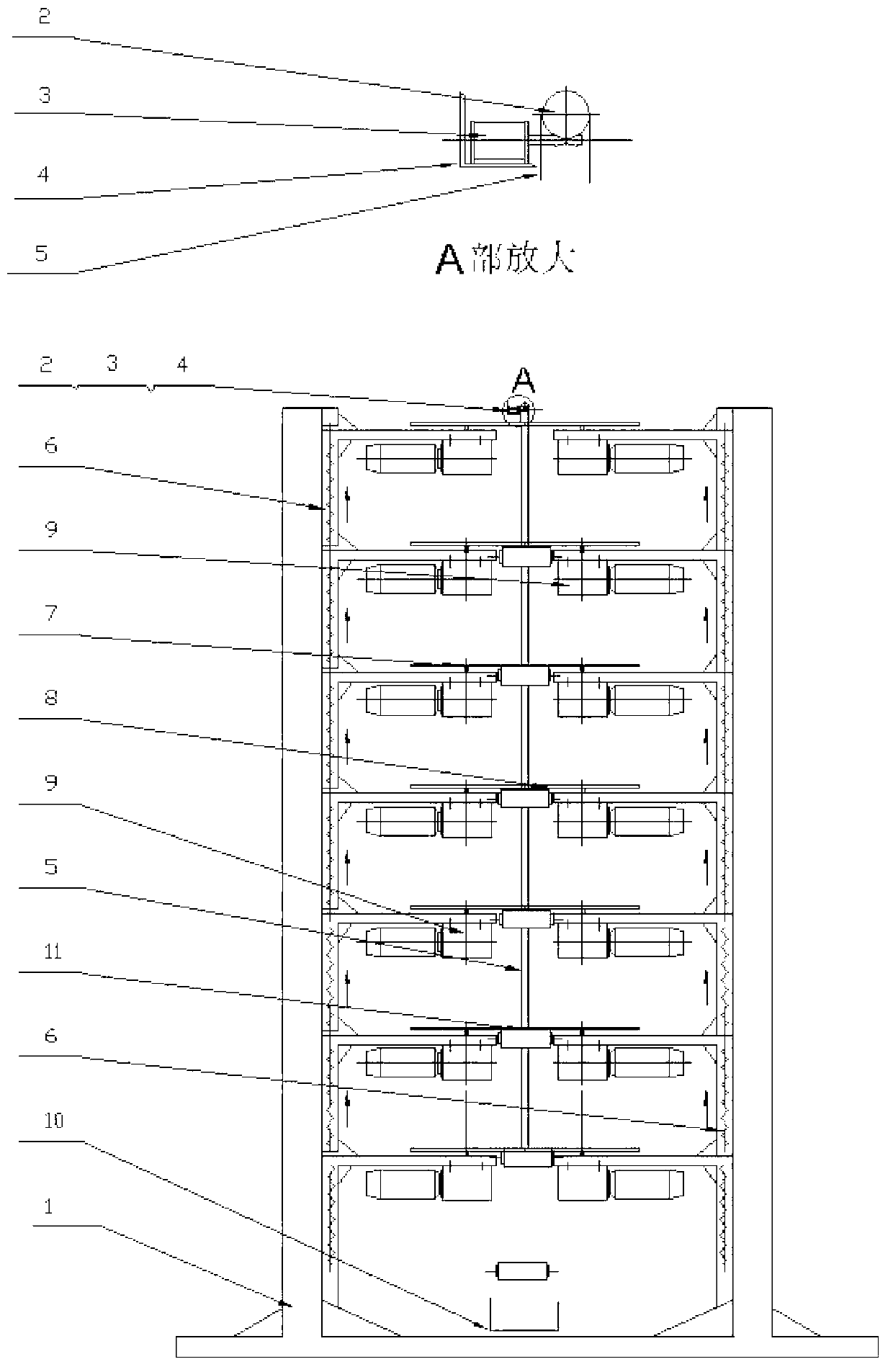

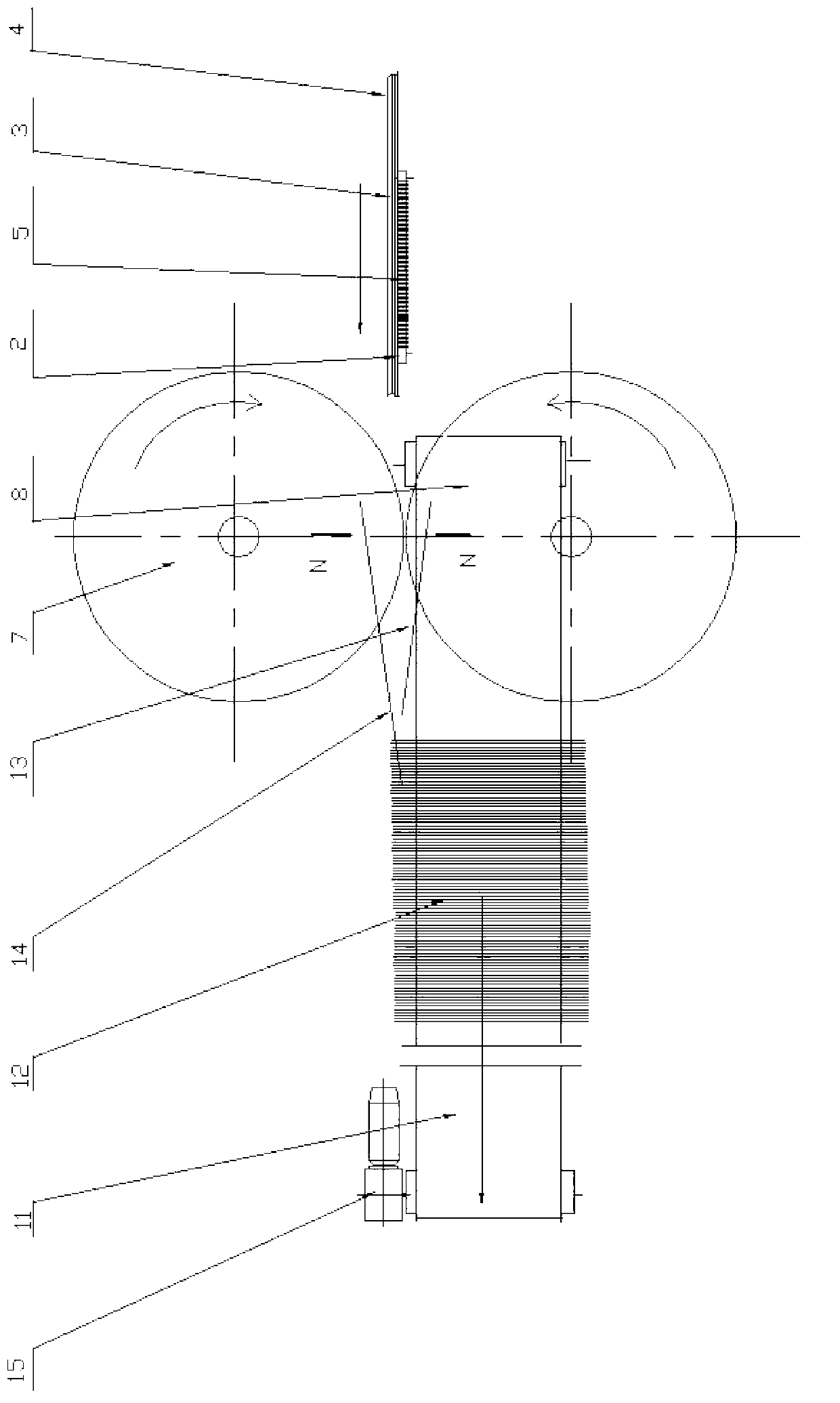

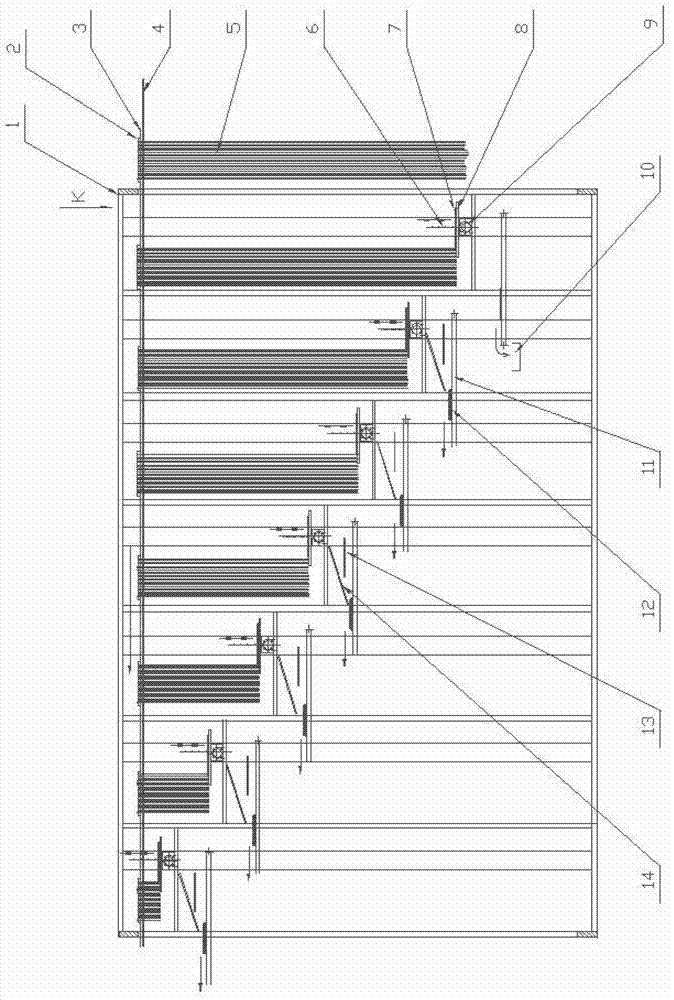

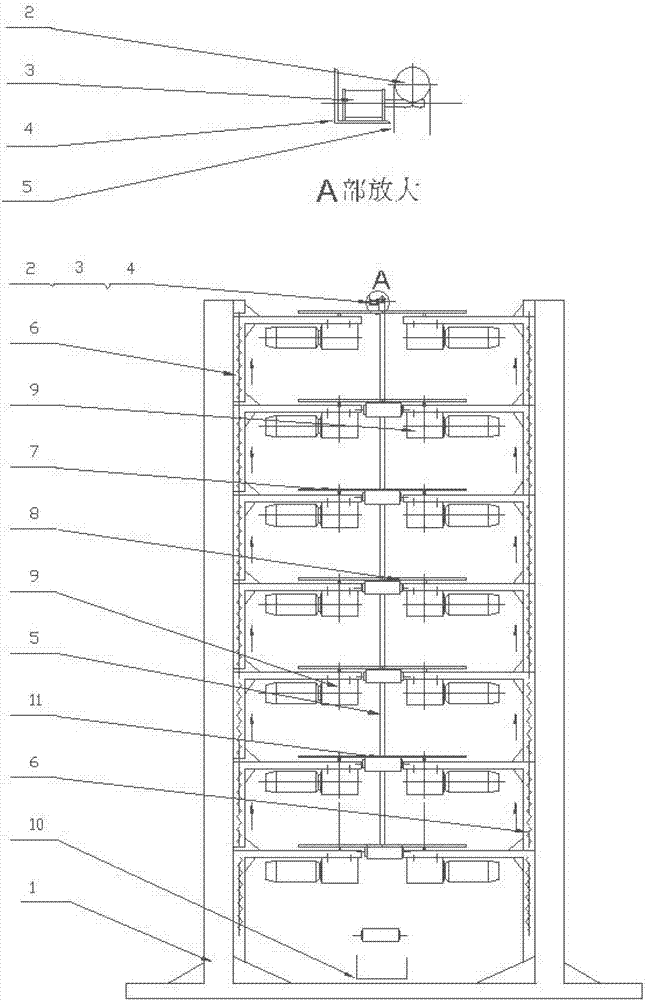

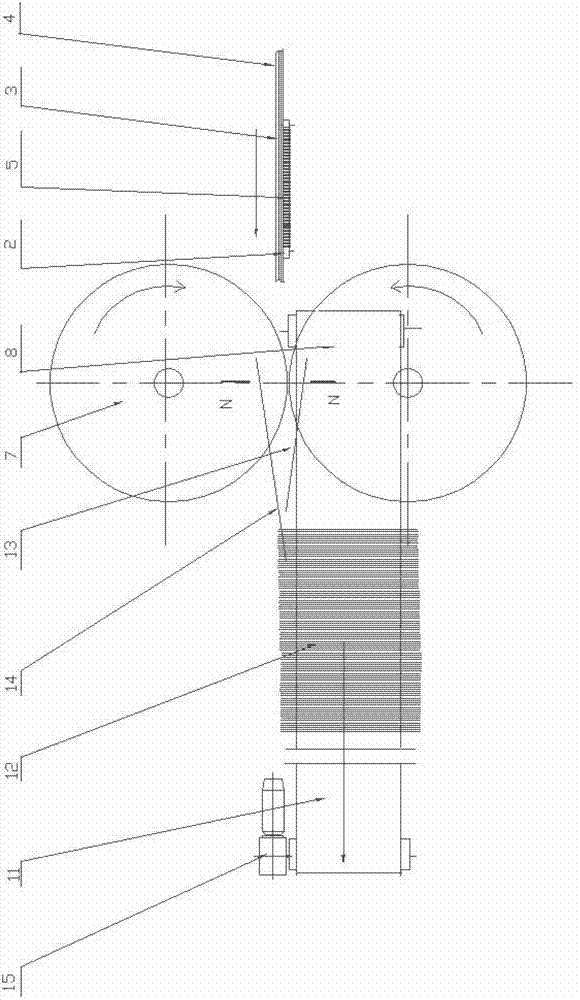

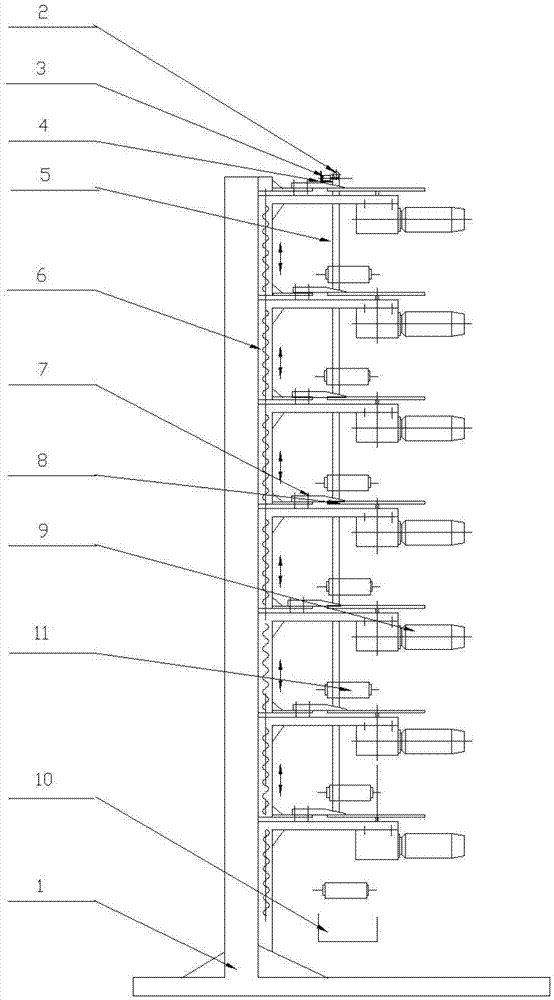

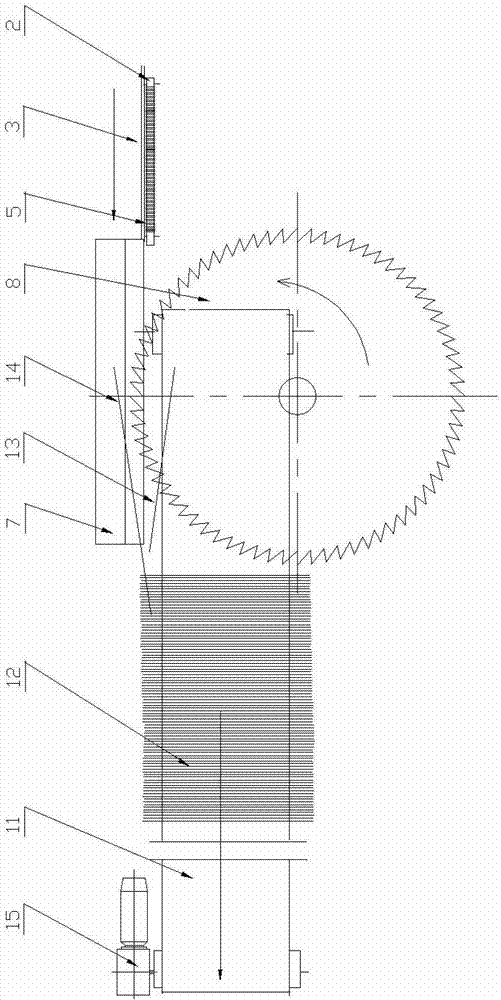

Vertical cutting-off machine of fine dried noodles

The invention discloses a vertical cutting-off machine of fine dried noodles, relating to a fine dried noodle machine, and in particular relates to a mechanical device for cutting dried fine dried noodles into fine dried noodle sections with required certain length in a production process of the fine dried noodles. The machine comprises a stand, fine dried noodle cutting-off devices arranged on the stand, cut fine dried noodle conveying belts and a fine dried noodle rod conveying mechanism guide rail, wherein more than two groups of fine dried noodle cutting-off devices comprising left rotating cutters, right rotating cutters and rotating cutter drive mechanisms are arranged on the frame-shaped stand, each group of left rotating cutter and right rotary cutter is matched to form a pair of fine dried noodle cutter consists of a left rotating cutter and a right rotary cutter which are matched with each other, all groups of fine dried noodle cutting-off devices are arranged at different heights on the stand according to the demand, the cut fine dried noodle conveying belt is arranged below each group of fine dried noodle cutting-off device, the fine dried noodle rod conveying mechanism guide rail is arranged on the top of the stand, fine dried noodles to be cut off enter the vertical cutting-off machine in a vertical state to be cut off. The rotating speed of the rotary cutters is 30-60 rpm. The machine has the advantages that the cut fine dried noodles are uniform, the length of the cut fine dried noodle sections is regulated flexibly and conveniently, and the cut fine dried noodles directly enters a fine dried noodle metering device and fine dried noodle rods completing the cutting off can be directly sent to a fine dried noodle rod bin of a fine dried noodle cutting unit of a fine dried noodle production line; after applied to the fine dried production line, the machine can improve the mechanization and automation level of the fine dried noodle production line.

Owner:山东江泷机械有限公司

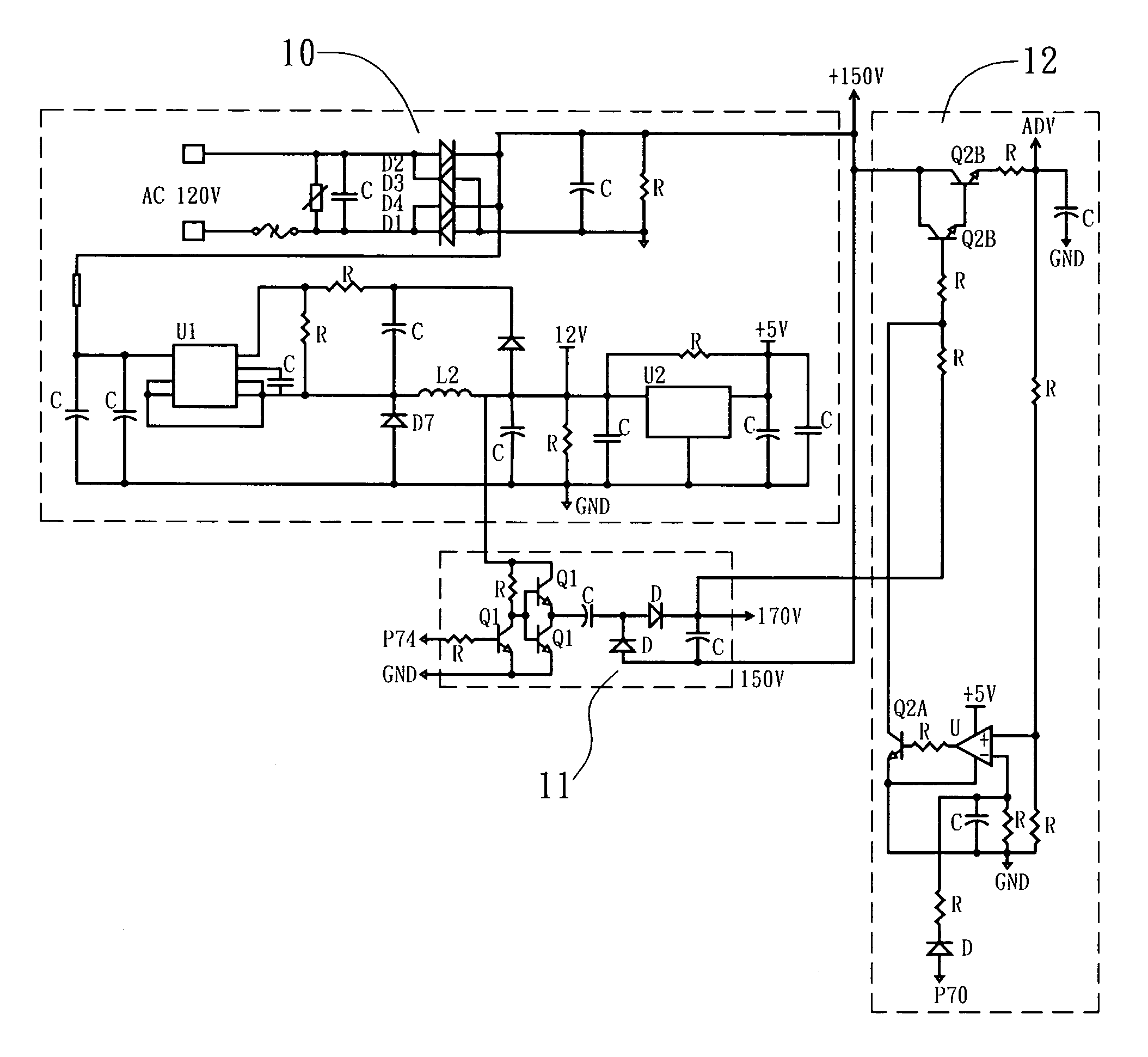

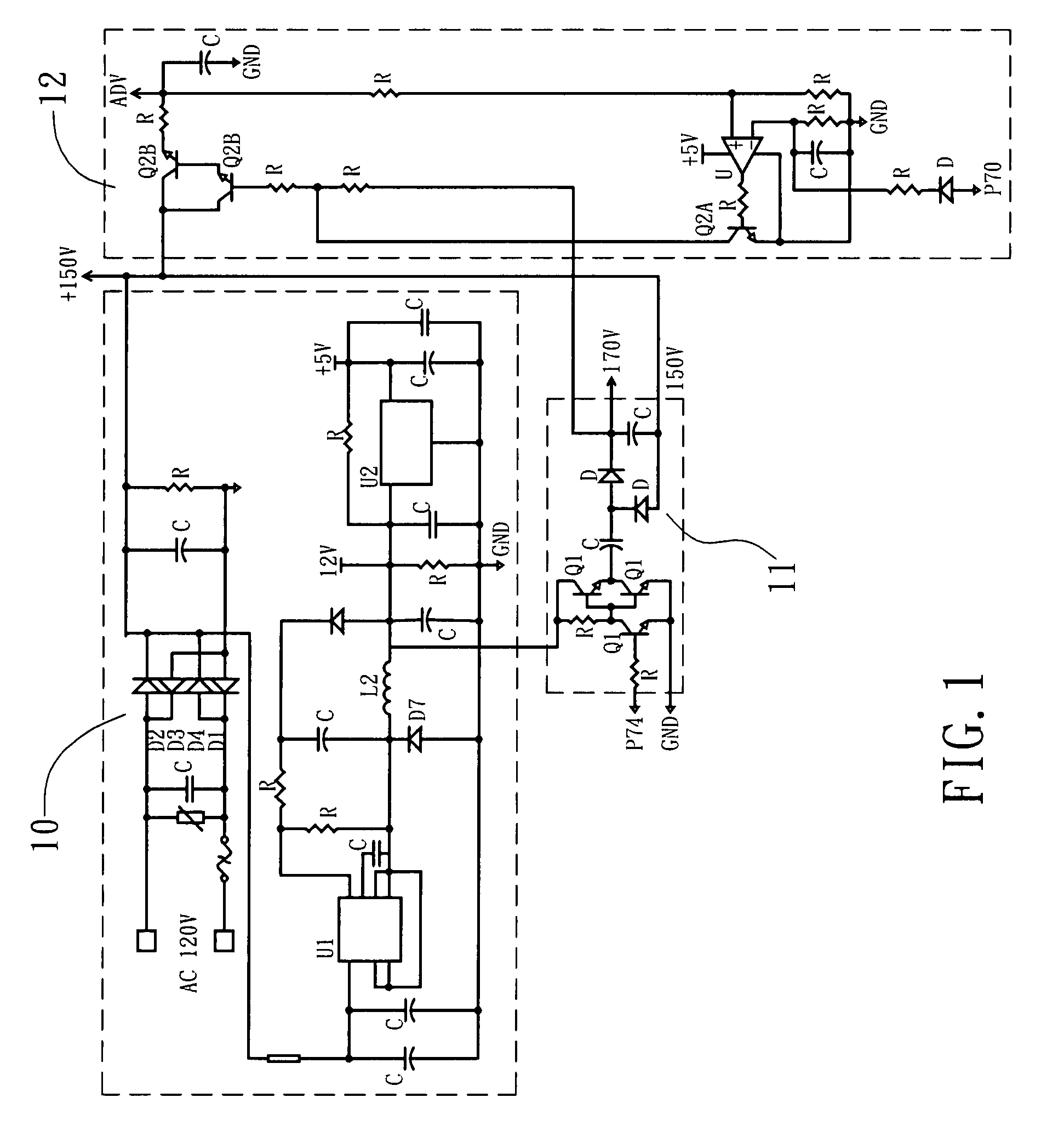

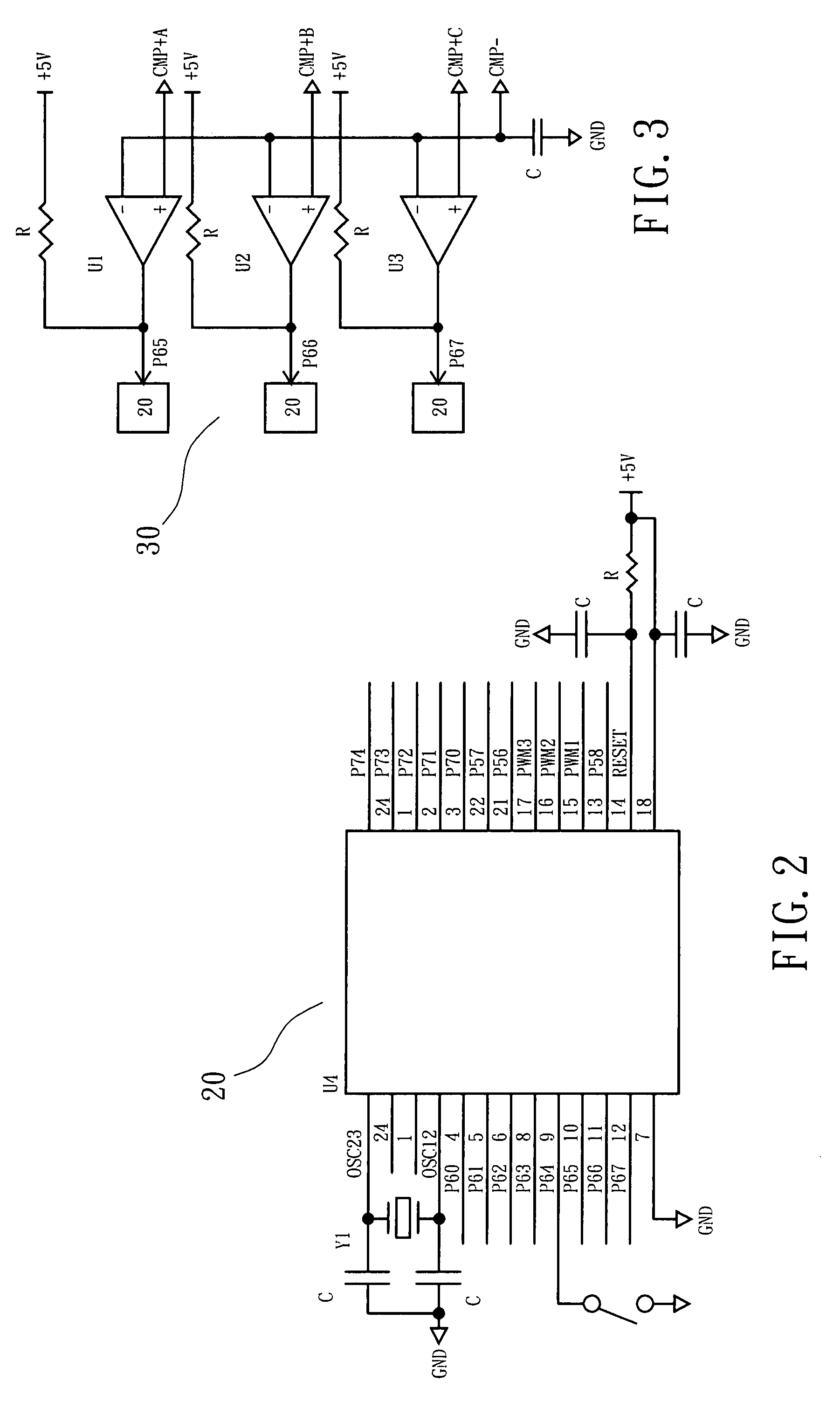

Brushless motor control circuit assembly for ceiling fan

InactiveUS7557526B2Lower temperature levelMore power consumptionSynchronous motors startersDC motor speed/torque controlCeiling fanBrushless motors

A power-saving, high-performance, low-noise brushless motor control circuit assembly is disclosed formed of a power supply circuit, a booster and compensation circuit, a voltage regulator circuit, a microprocessor, a back electromagnetic force sensor, three driver circuits, and three output circuits. By means of detecting back electromagnetic force, the magnetic pole position of the brushless motor is known accurately, ensuring accurate operation control. By means of providing a high voltage to drive the drive circuits, the field effect transistors of the output circuits are operated under full conduction, saving much power consumption and lowering the working temperature of the brushless motor.

Owner:LEE HSIEN MENG +1

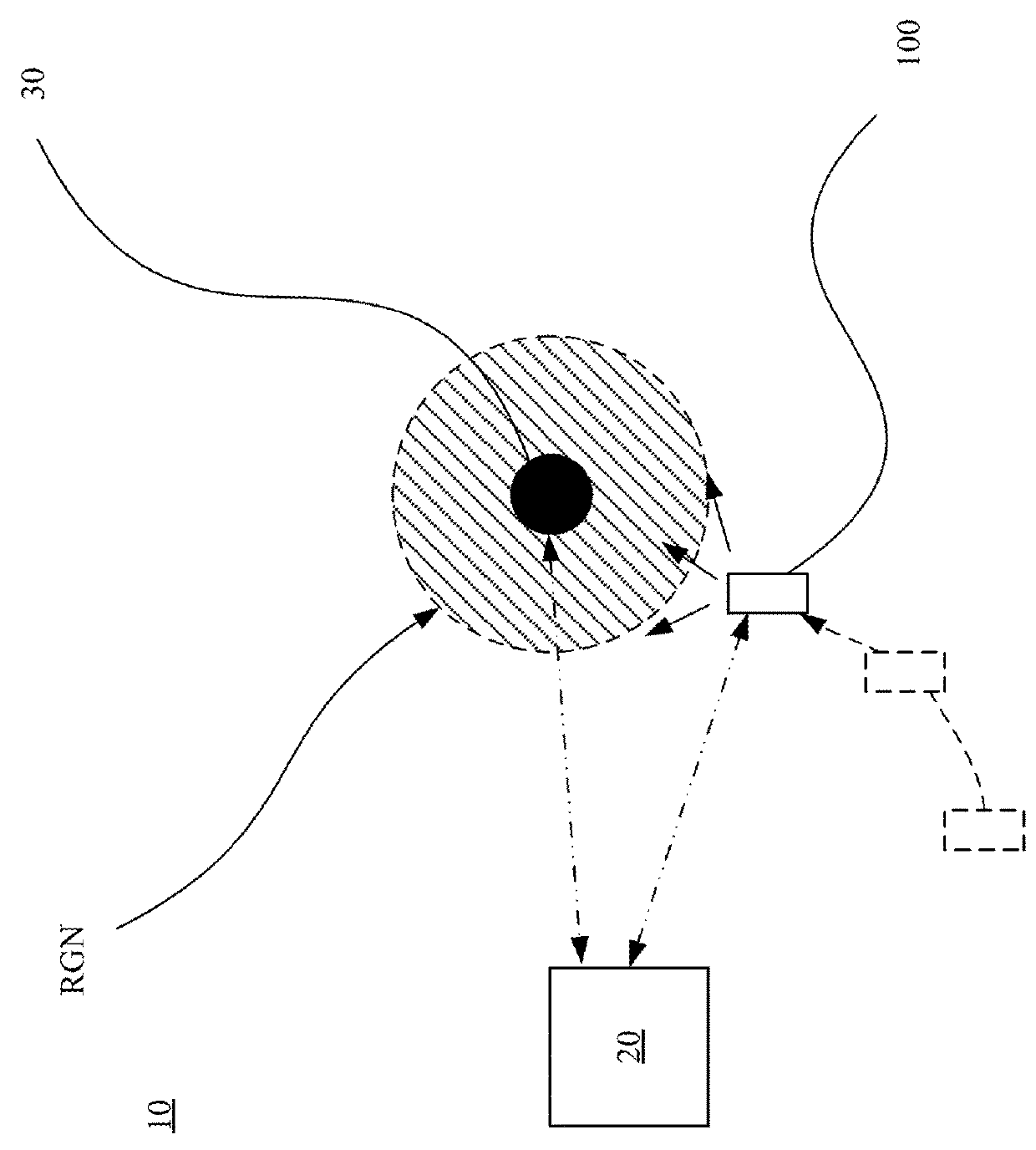

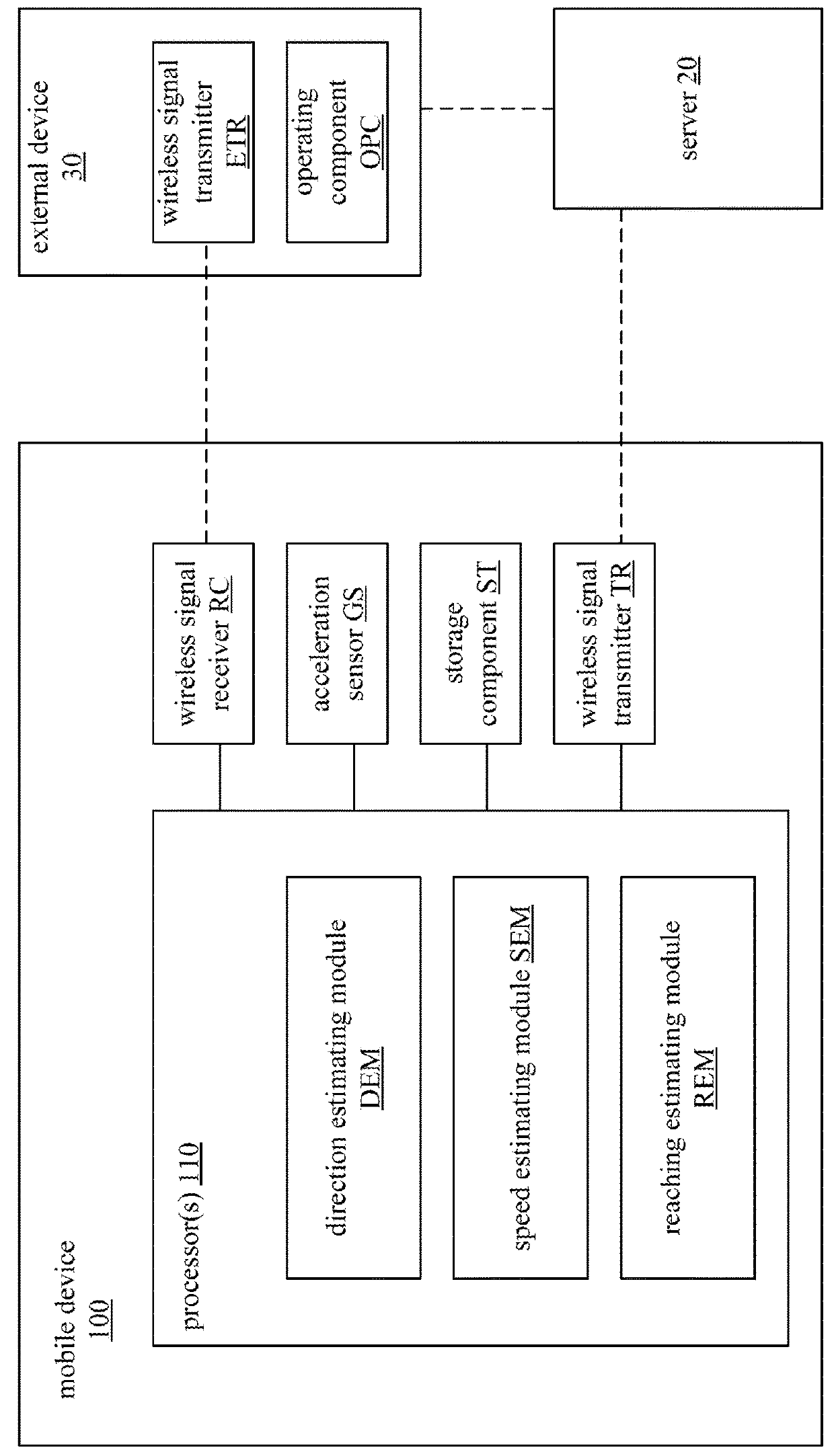

Mobile device, operating method thereof, and non-transitory computer readable storage medium for controlling an external device

ActiveUS10009872B2Precise operation controlEasy to controlProgramme controlReceivers monitoringMobile deviceComputer science

An operating method of a mobile device includes determining a plurality of moving directions of a mobile device corresponding to a plurality of time points according to an acceleration sensing signal; determining a plurality of distances between the mobile device and an external wireless signal transmitter corresponding to the time points according to a wireless signal from the external wireless signal transmitter; calculating an average moving speed of the mobile device according to the moving directions and the distances between the mobile device and the external wireless signal transmitter; estimating an estimating moving direction of the mobile device according to the moving directions; and selectively outputting an operating requirement according to the average moving speed and the estimating moving direction of the mobile device, to make an external device operates an instruction corresponding to the operating requirement.

Owner:INSTITUTE FOR INFORMATION INDUSTRY

A portable apparatus and an input method of a portable apparatus

ActiveCN102968206AImprove conveniencePrecise operation controlTransmissionDigital output to display deviceElectricityTerminal equipment

Owner:SAMSUNG ELECTRONICS CO LTD

Magnetic pressure water purifier

ActiveCN105565402ADense materialImprove the purification and filtration effectWater/sewage treatment by magnetic/electric fieldsImpellerWater pipe

The invention relates to a magnetic pressure water purifier, comprising a domestic water pipe and a purifying device; a driving chamber is serially connected to the domestic water pipe; a driving blade wheel is fitted inside the driving chamber; the domestic water pipe is bypassed with a purified water pipe, with the other end of the purified water communicated with the inside of a purifying chamber of the purifying device; a permanent magnet column in a strip shape is mounted inside the purifying chamber and is connected with a driving spindle through an energy storage disc spring, and the driving spindle is perpendicular to a magnetizing direction of the permanent magnet pole; two piston plates are symmetrically mounted inside the purifying chamber and are made with two permanent magnet plates having opposite unlike poles; the piston plates can shift along the lateral wall of the purifying chamber in the magnetizing direction of the permanent magnet pole; the bottom of the purifying chamber is fitted with a purifying filter element; the magnetic pressure water purifier can provide cleaner purified water and also discharge purified water at higher speed.

Owner:嘉兴传盛机械设备有限公司

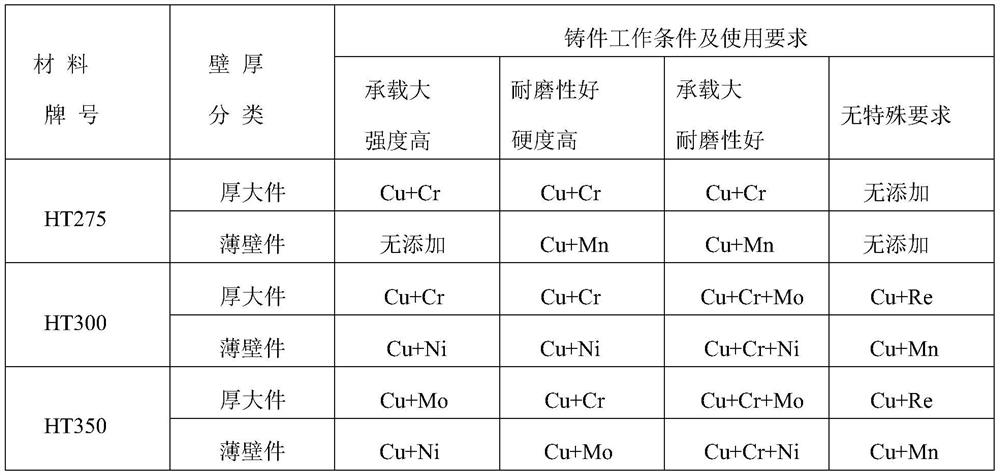

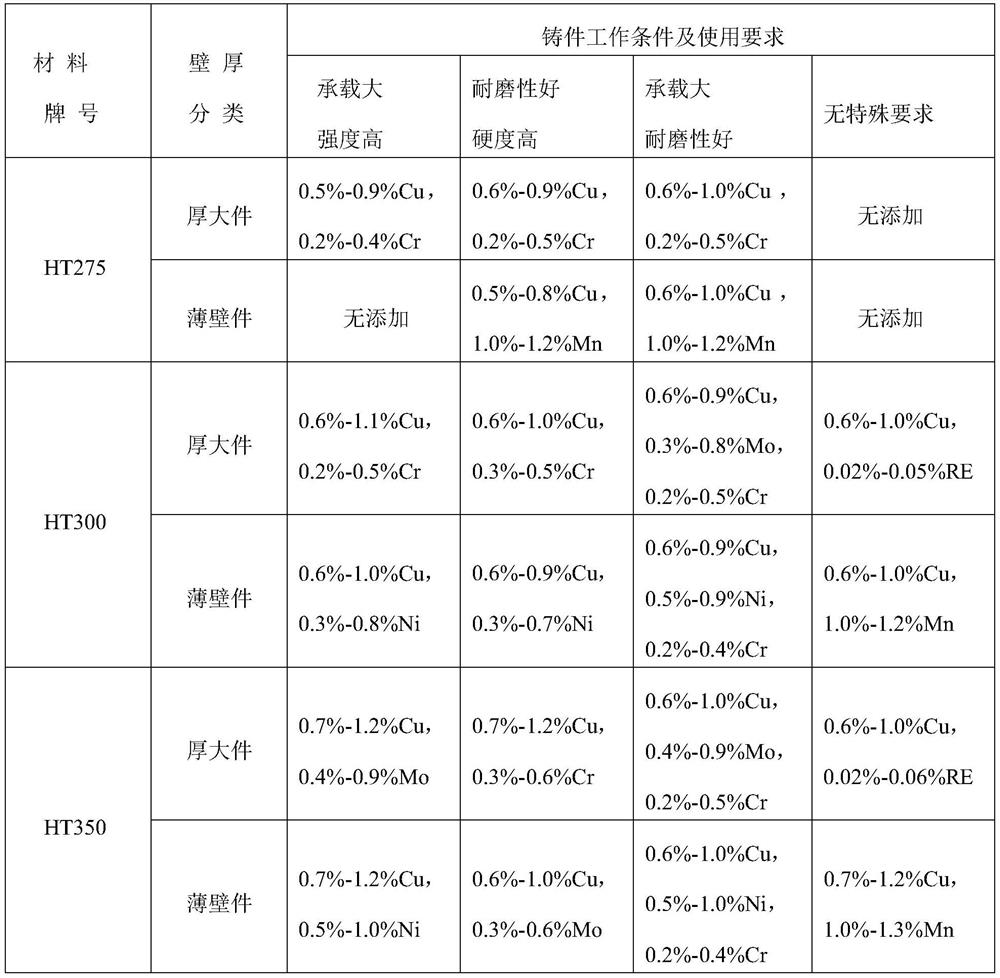

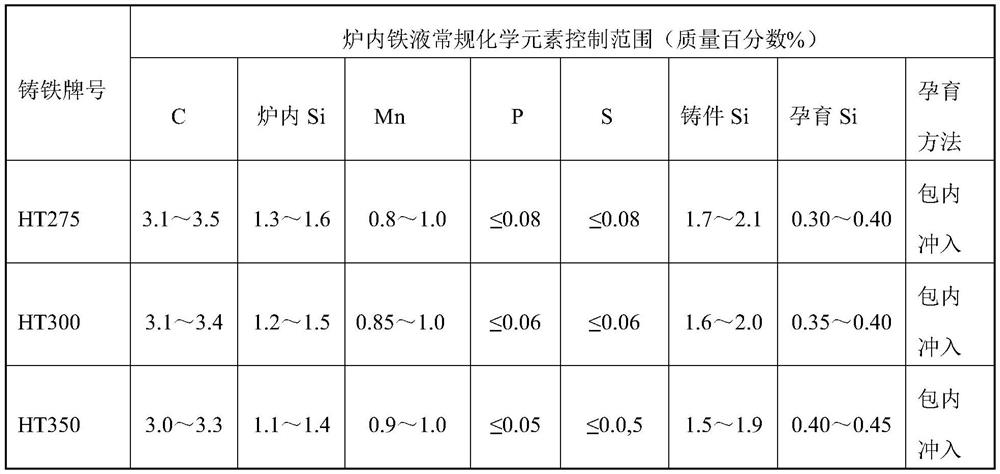

Multi-element low-alloying treatment method for high-strength gray cast iron

PendingCN113403443AStable melting qualityStable control of melting qualityProcess efficiency improvementChemical compositionBloomery

The invention discloses a multi-element low-alloying treatment technical method for high-strength gray cast iron, and belongs to the technical field of casting. The method comprises the following steps of A, determining the components and proportion of furnace charge in a high-strength gray iron casting, a matching method and content range of various alloy elements and a content range of conventional chemical elements according to the requirements of a to-be-produced casting; B, determining a melting process procedure of the high-strength gray iron casting; C, preparing materials, charging, heating and melting according to the requirements of "cast iron melting burdening process sheet"; D, sampling and analyzing the chemical components of an iron liquid in a furnace, and adjusting the chemical components of the iron liquid in the furnace; E, carrying out molten iron treatment and tapping pouring; and F, detecting the material performance of the high-strength gray iron casting. The method provides a simple and feasible chemical component determination, melting burdening and alloy liquid treatment method, so that alloy element matching, cast iron melting burdening and alloying treatment of the high-strength gray cast iron are more accurate and convenient, and cast iron melting operation control is more reasonable and feasible.

Owner:HEBEI HUABEI DIESEL ENGINE

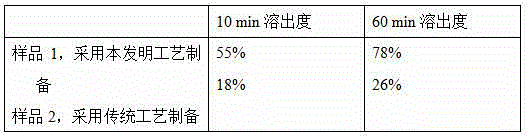

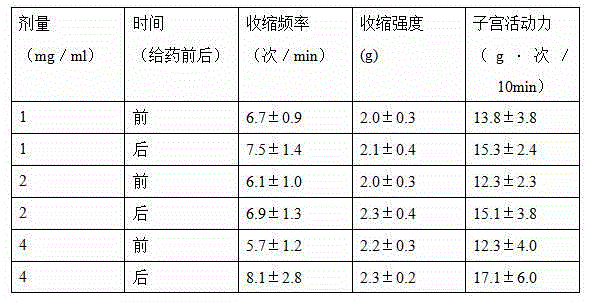

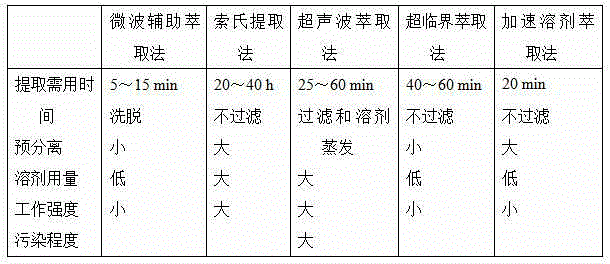

Compound motherwort herb mixture as well as preparation method and application thereof in treatment of gynecological diseases

InactiveCN104547021AIn line with the theory of traditional Chinese medicineExact therapeutic effectAntibacterial agentsDispersion deliveryMotherwortMedicine

The invention relates to a compound motherwort herb preparation as well as a preparation method and application thereof in treatment of gynecological diseases. The traditional Chinese medicine compound preparation contains active ingredients of motherwort herb and astragalus that are extracted by atmospheric pressure microwave-assisted extraction, wherein active substances of motherwort herb and astragalus are extracted by an atmospheric pressure microwave-assisted extraction method. According to the invention, the compound motherwort herb preparation has good effect on the treatment of gynecological diseases; the preparation method has the advantages of high extraction efficiency, full extraction, good reproducibility and less solvent consumption.

Owner:HENAN JIUSHI BIOLOGICAL PHARMA

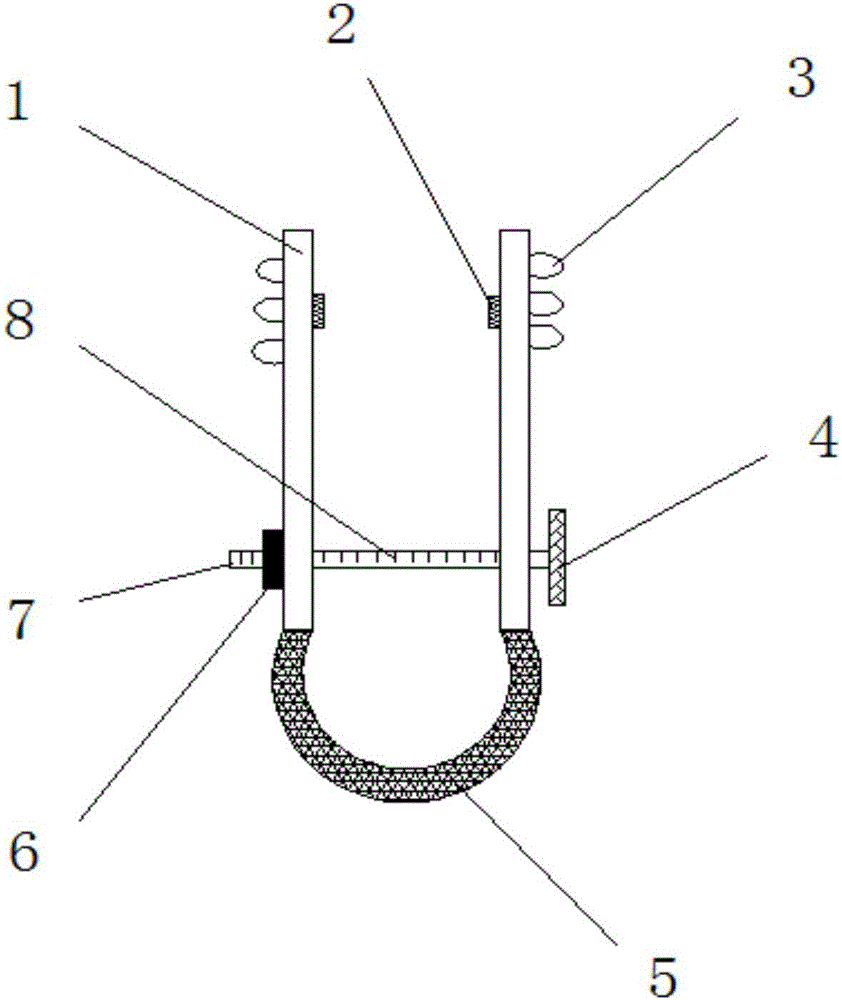

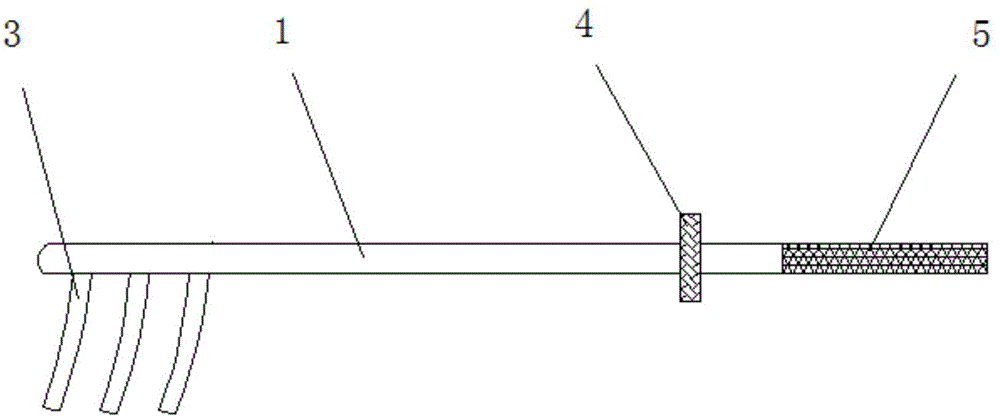

Retractor for neurosurgeries

InactiveCN106344085AReasonable designSimple designSurgical field illuminationEngineeringNeurosurgical Procedure

The invention discloses a retractor for neurosurgery, which comprises a retractor arm and an arc-shaped support plate, the front end of the retractor arm is equipped with an arc-shaped support plate, and the retractor arm is smoothly connected with the handle of the retractor. The inner side of the front end of the retracting arm is provided with an empty slot, and a miniature lighting lamp is installed inside the empty slot, the top of the empty slot is provided with a vertically downward connecting rod, and the bottom end of the connecting rod is provided with a rotating ball , the miniature illuminating lamp is provided with a ball groove, the rotating ball is stuck inside the ball groove, the miniature illuminating lamp is provided with a control rod passing through the empty groove, and the retracting arm is close to one end of the handle of the retractor There is a threaded rod passing through the two retracting arms, one end of the threaded rod is fixedly connected with the adjusting knob, and the other end of the threaded rod is provided with a nut, and the nut is close to the outside of the retracting arm. The retractor for neurosurgery is reasonable in design, simple in structure, easy to operate, small in size, well exposed in the operation field, convenient for observation, and precise in control, and can be widely used.

Owner:GUANGZHOU DANJUE COMM TECH CO LTD

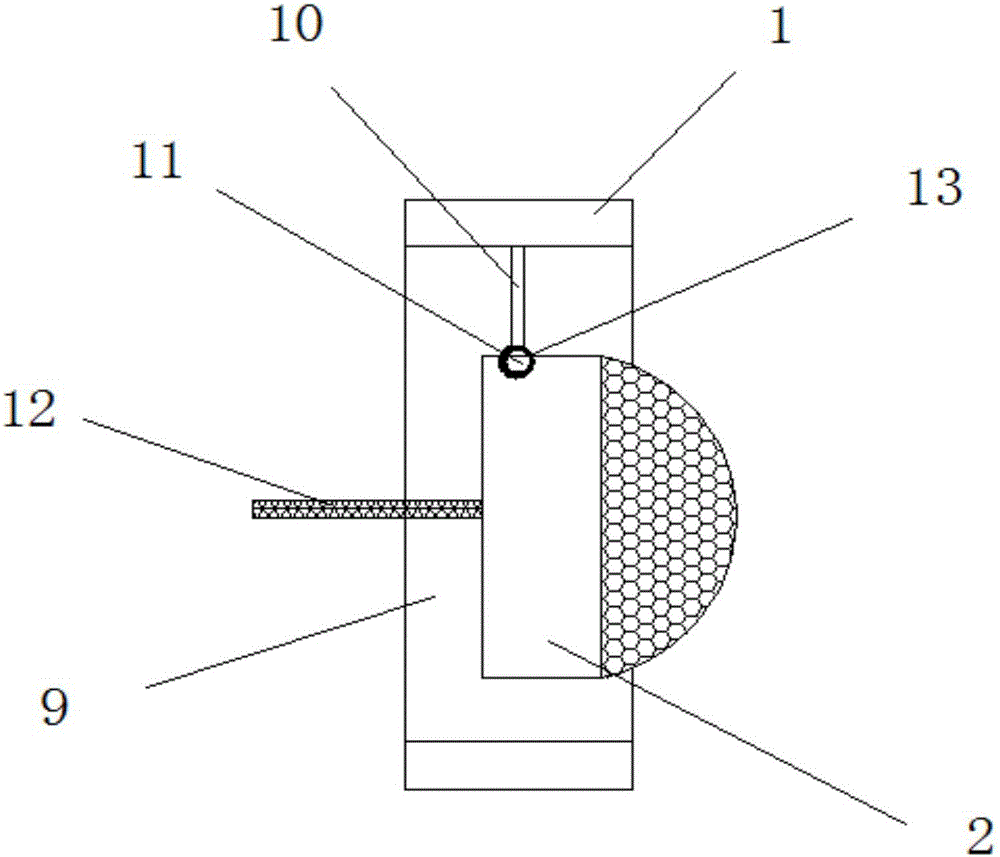

Bathroom control panel structure

InactiveCN107483040AReasonable structureClear tactile perceptionElectronic switchingInput/output processes for data processingTouch PerceptionHaptic sensing

The invention discloses a bathroom control panel structure. A control button and a linkage device are separately arranged on two sides of an installation wall body, after rotating or toggling the control button with a built-in magnetic coupler, the linkage device that is also provided with the built-in magnetic coupler follows to generate a synchronous motion, a location identification module on the linkage device transfers motion information or location information to a location sensor on a control circuit board, a control action is obtained and converted to an electric signal after signal processing, and the accurate operation control is achieved. The clear touch perception can be obtained by directly rotating or toggling the control button, the process of obtaining a control action by virtue of eyesight is not required, and thus the bathroom control panel structure is suitable for persons with any eyesight level to operate; as the control button is not in contact with the circuit board, the control button does not need any waterproof structure, the problem of electric leakage or electric appliance failures caused by aged waterproof structures can be avoided, and the control button can be arranged at any height according to the actual needs to meet the use of operators with different heights; and the overall bathroom control panel structure is reasonably arranged and can meet the use requirements.

Owner:佛山市海科知识产权交易有限公司 +1

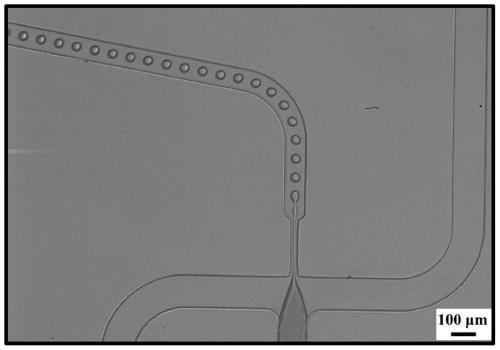

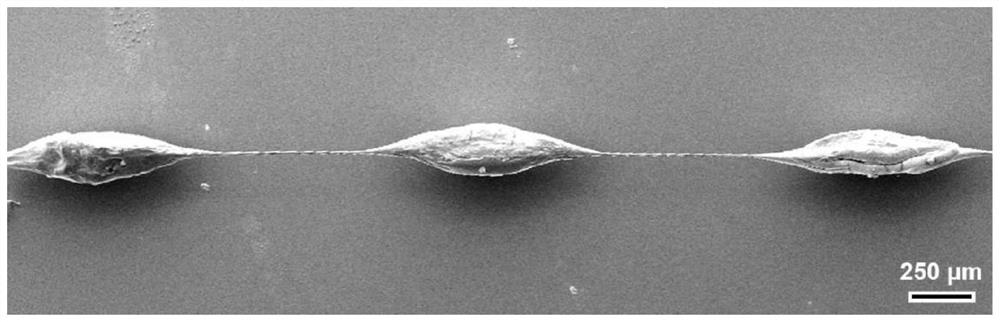

Cobweb-like hollow spindle knot microfiber device with water collection characteristic and preparation method

ActiveCN114457442AIncrease capillary forcePromote aggregationHollow filament manufactureFilament/thread formingCalcium alginateChloride

The invention relates to a cobweb-imitated hollow spindle section microfiber device with a water collection characteristic and a preparation method, the cobweb-imitated hollow spindle section microfiber device with the water collection characteristic is composed of an inner phase feeding pipe, a middle phase feeding pipe and an outer phase feeding pipe which are coaxial and a discharging pipe, and a dextran solution containing calcium chloride, a dextran solution containing calcium alginate and liquid paraffin are respectively pumped into the inner phase feeding pipe, the intermediate phase feeding pipe and the outer phase feeding pipe. On the basis of hydrodynamics, alginic acid and a calcium chloride solution are mixed in a pipeline to be subjected to gelation reaction by utilizing a chemical principle that sodium alginate and calcium chloride react to generate calcium alginate hydrogel; a periodic spindle joint structure is formed by utilizing the shearing force of an oil-water interface, and water collection is performed by virtue of a Laplace pressure difference and a surface energy level gradient; and the water collection effect of the fiber is enhanced by utilizing the capillary water absorption effect. The preparation method disclosed by the invention is simple, low in cost, high in experimental repeatability, beneficial to batch production, safe in preparation process and high in material biocompatibility.

Owner:SOUTHWEST JIAOTONG UNIV

Slide type continuous variable valve lift device

InactiveUS8079333B2Reduce in quantityImprove robustnessValve arrangementsCam-followersFuel efficiencyEngineering

A slide type continuous variable valve lift (CVVL) device includes a swing arm rotating to press a valve; a cam lobe; a roller transmitting a driving force of the cam lobe to the swing arm; and a guide guiding the roller to move along a predetermined path. The CVVL device generally can minimize the number of places where sliding friction between respective parts may occur to minimize power loss and enable more precise operation control, reduce the number of parts to enhance the overall robustness of the device, and advance the time of maximum valve opening to improve the fuel efficiency of an engine.

Owner:HYUNDAI MOTOR CO LTD

Vertical cutting-off machine of fine dried noodles

InactiveCN102986764BEasy to adjustHigh degree of automationDough shapingProduction lineMechanization

The invention discloses a vertical cutting-off machine of fine dried noodles, relating to a fine dried noodle machine, and in particular relates to a mechanical device for cutting dried fine dried noodles into fine dried noodle sections with required certain length in a production process of the fine dried noodles. The machine comprises a stand, fine dried noodle cutting-off devices arranged on the stand, cut fine dried noodle conveying belts and a fine dried noodle rod conveying mechanism guide rail, wherein more than two groups of fine dried noodle cutting-off devices comprising left rotating cutters, right rotating cutters and rotating cutter drive mechanisms are arranged on the frame-shaped stand, each group of left rotating cutter and right rotary cutter is matched to form a pair of fine dried noodle cutter consists of a left rotating cutter and a right rotary cutter which are matched with each other, all groups of fine dried noodle cutting-off devices are arranged at different heights on the stand according to the demand, the cut fine dried noodle conveying belt is arranged below each group of fine dried noodle cutting-off device, the fine dried noodle rod conveying mechanism guide rail is arranged on the top of the stand, fine dried noodles to be cut off enter the vertical cutting-off machine in a vertical state to be cut off. The rotating speed of the rotary cutters is 30-60 rpm. The machine has the advantages that the cut fine dried noodles are uniform, the length of the cut fine dried noodle sections is regulated flexibly and conveniently, and the cut fine dried noodles directly enters a fine dried noodle metering device and fine dried noodle rods completing the cutting off can be directly sent to a fine dried noodle rod bin of a fine dried noodle cutting unit of a fine dried noodle production line; after applied to the fine dried production line, the machine can improve the mechanization and automation level of the fine dried noodle production line.

Owner:山东江泷机械有限公司

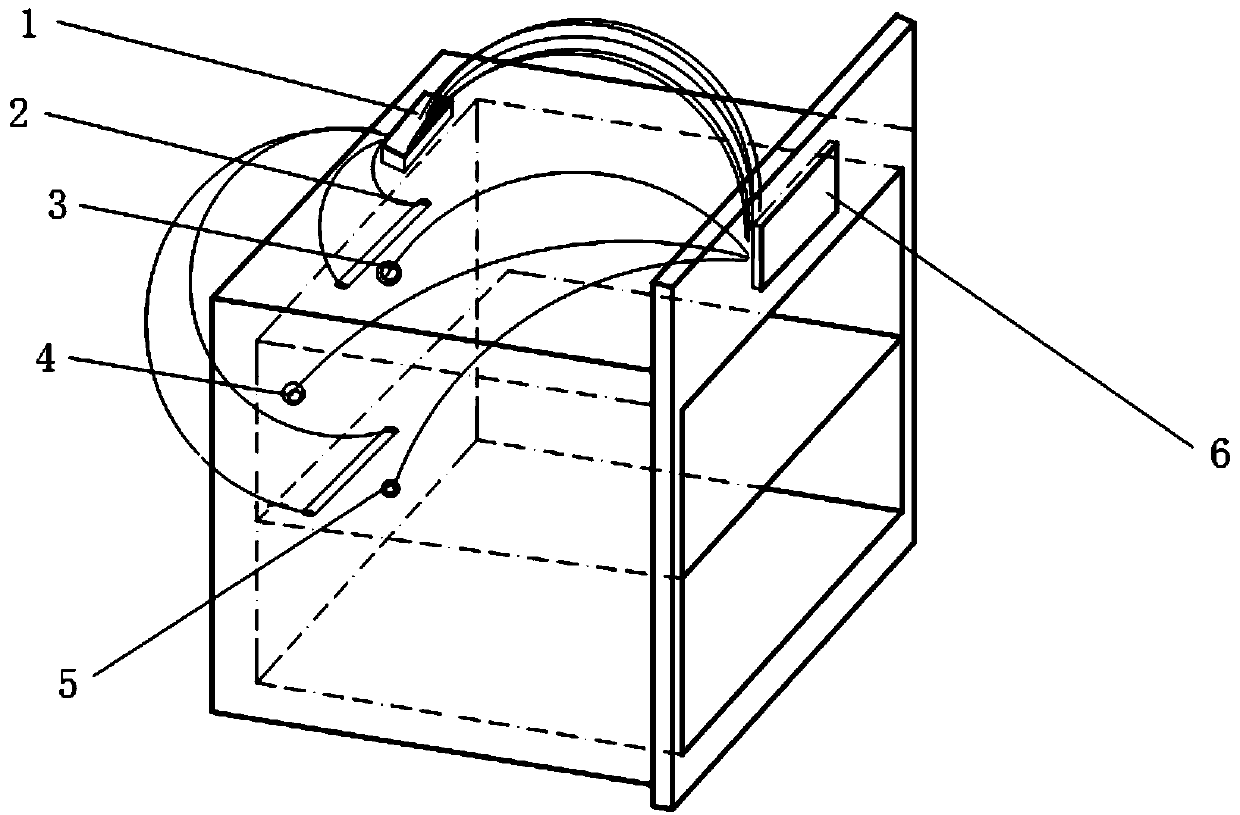

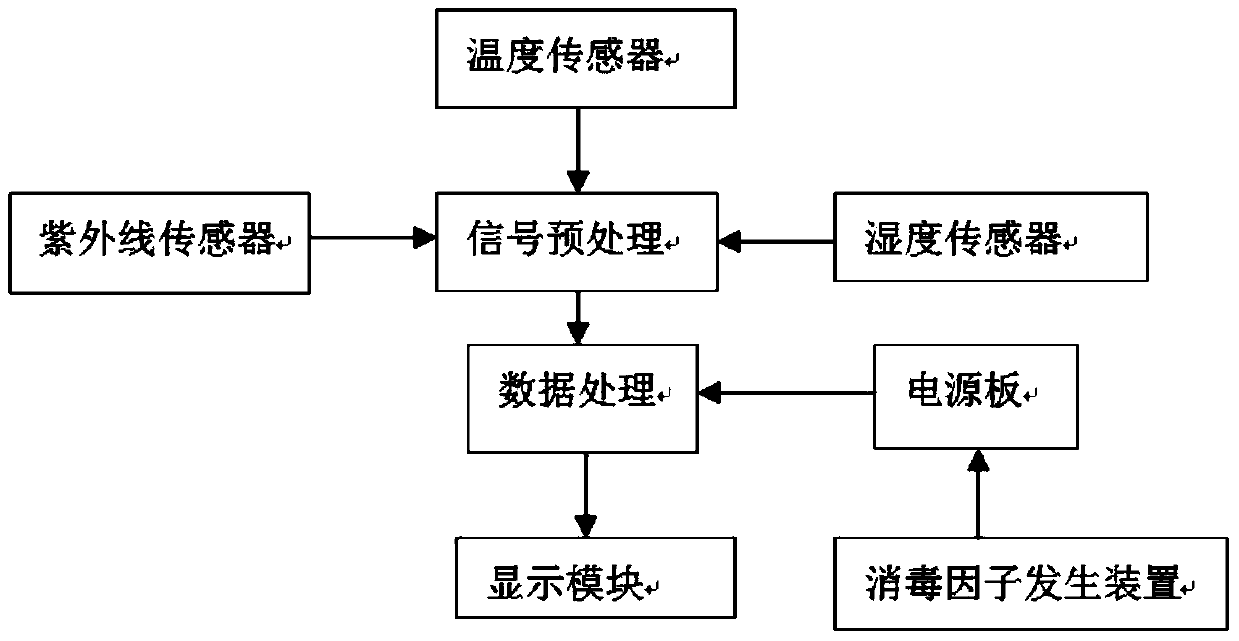

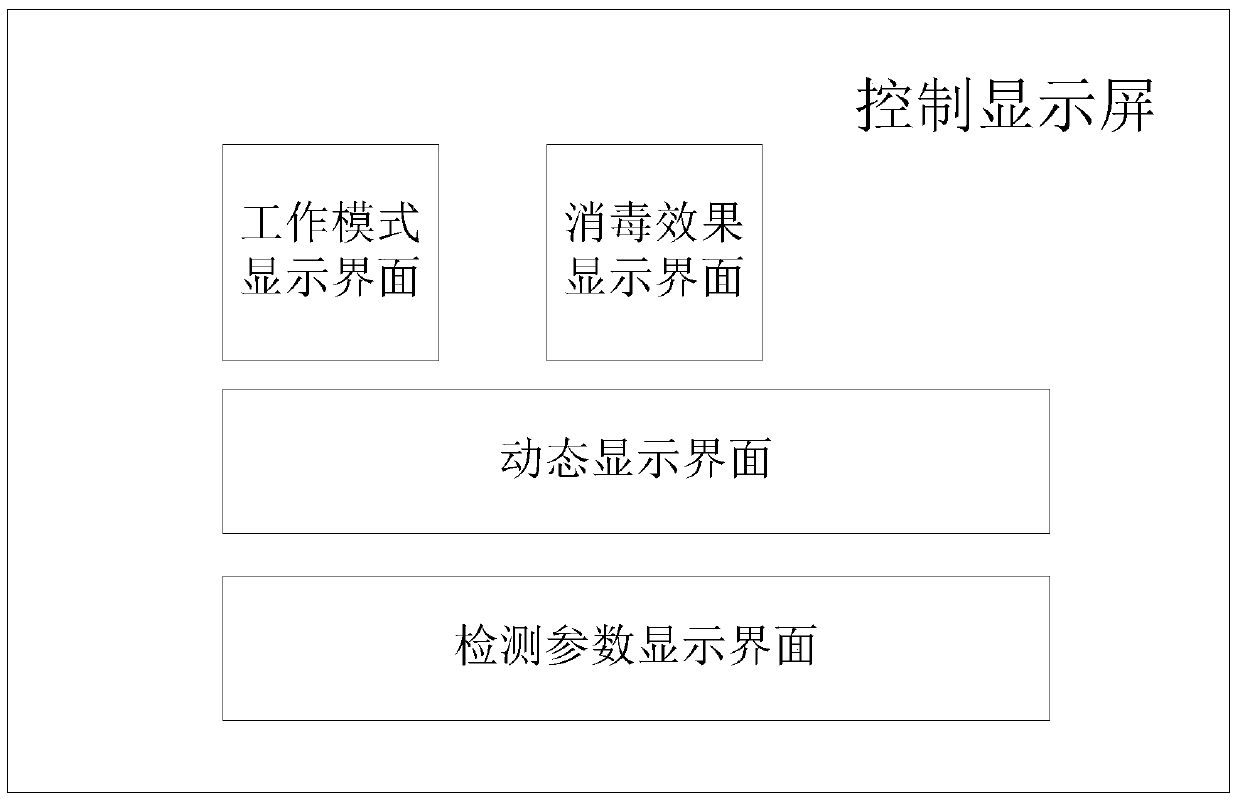

Disinfection cabinet and display method for displaying disinfection effect

ActiveCN107198786BPrecise operation controlImprove information interactivityLavatory sanitoryDisinfectionEngineering

The invention discloses a disinfection cabinet with display of disinfecting effect and a display method. The disinfection cabinet comprises a cabinet body and a control panel arranged on a panel of the cabinet body; a generation device with disinfecting factors and a disinfecting factor detecting unit are arranged in the cabinet body; the disinfecting cabinet is further provided with an intelligent display system, and the intelligent display system comprises a display module connected with the control panel; the disinfecting factor detecting unit is connected with an input end of the control panel, wherein the control panel receives the data of the disinfecting factor sent by the disinfecting factor detecting unit and acquires the disinfecting effect parameter, and controls the display module to display the data of the disinfecting factor and the disinfecting effect parameter in real time, so that the disinfecting effectiveness and disinfecting effect of the disinfecting cabinet are improved. The disinfecting cabinet is simple in both of structure and disinfection display method, and suitable for production and popularization.

Owner:QINGDAO HAIER WISDOM KITCHEN APPLIANCE CO LTD

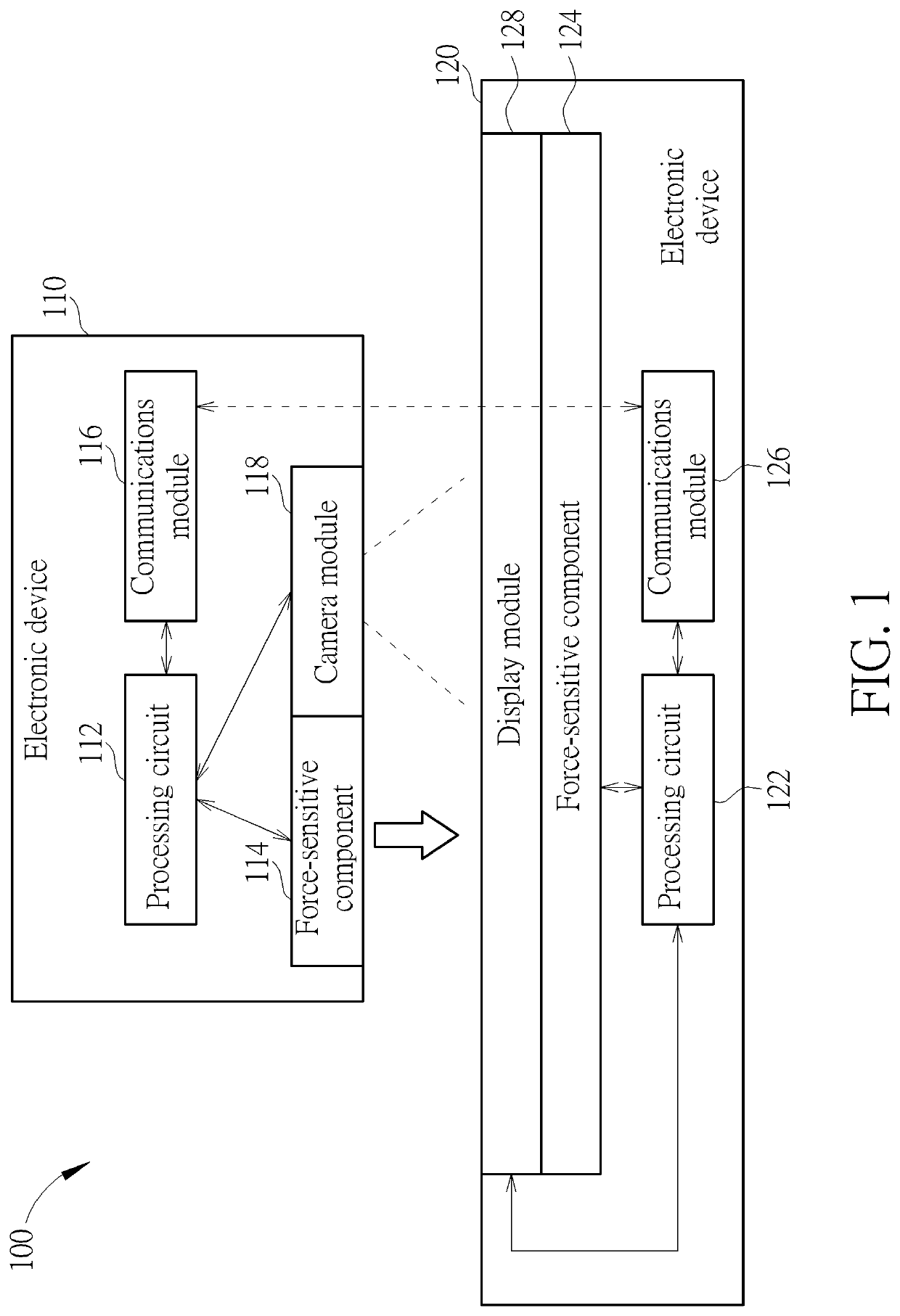

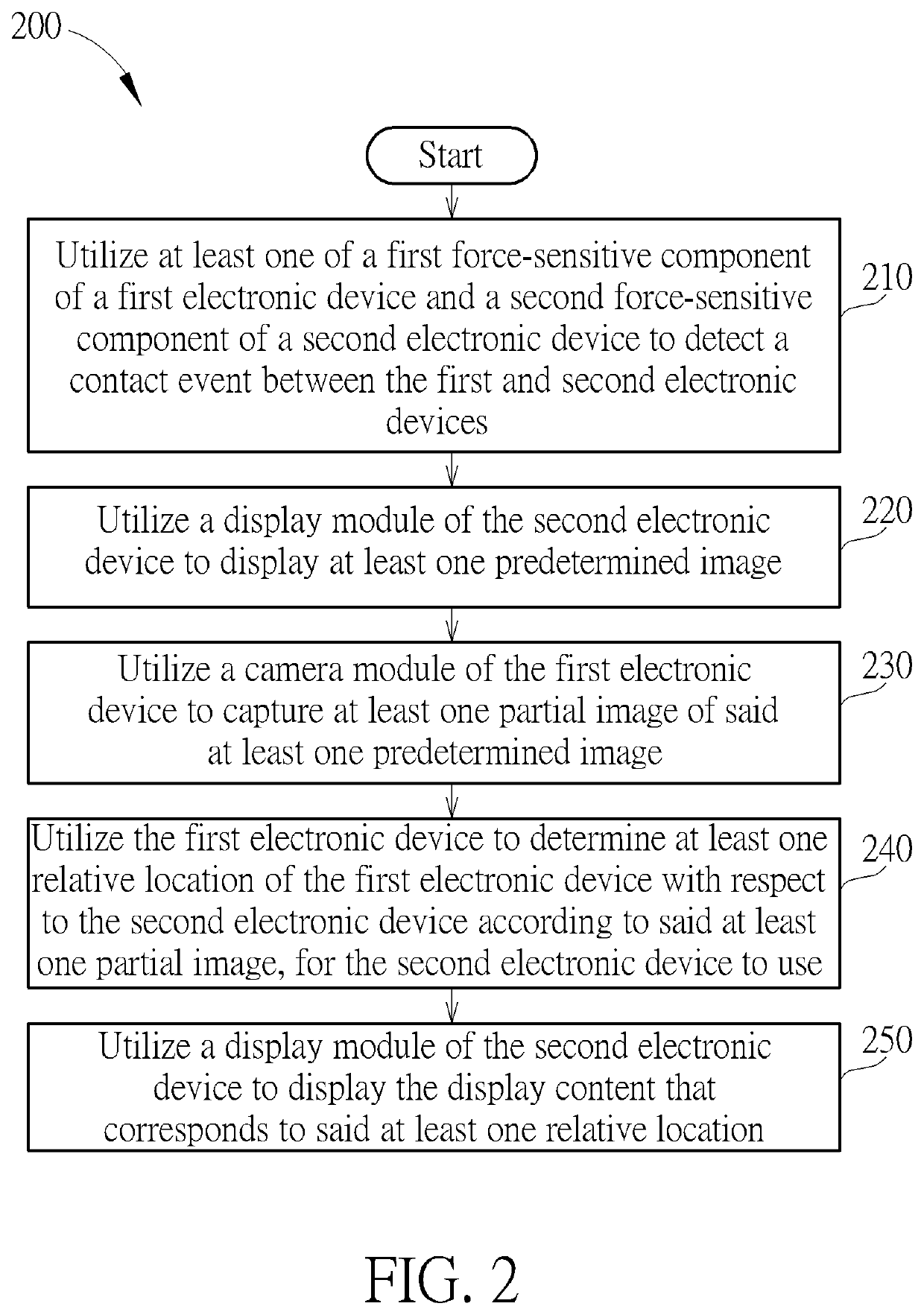

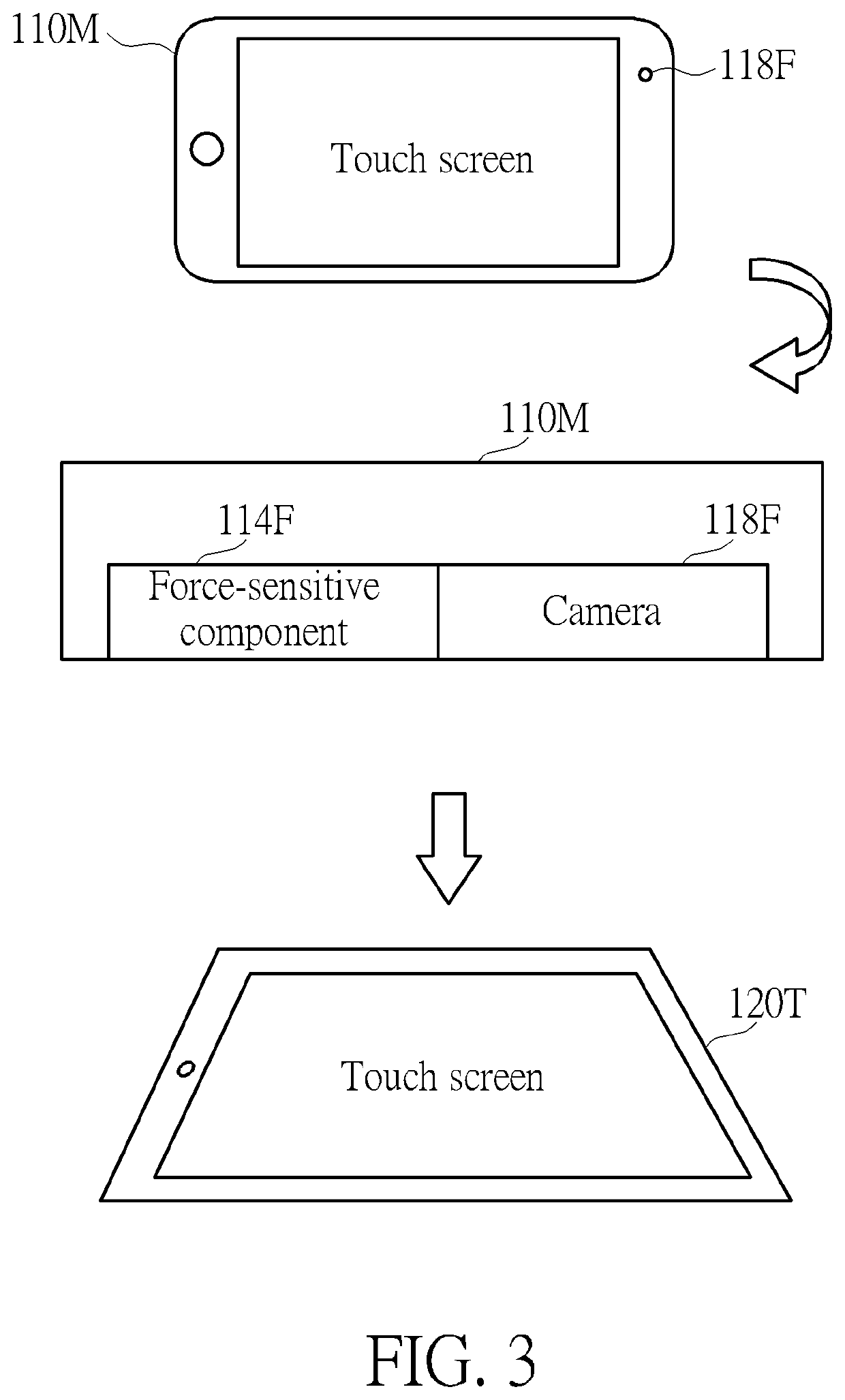

Electronic device applicable to interaction control

ActiveUS10664086B2Precise operation controlLimited spaceDigital data processing detailsInput/output processes for data processingInteraction controlHemt circuits

Electronic devices applicable to interaction control are provided. A first electronic device includes a first force-sensitive component, a camera module, and a processing circuit, and a second electronic device includes a second force-sensitive component, a display module, and a processing circuit. At least one component within the first force-sensitive component and the second force-sensitive component is arranged to detect a contact event between the first electronic device and the second electronic device. The display module displays at least one predetermined image, and the camera module captures at least one partial image of the aforementioned at least one predetermined image, to allow the first electronic device to determine at least one relative location of the first electronic device with respect to the second electronic device, for use of the second electronic device, and more particularly, the display module displays a display content corresponding to the aforementioned at least one relative location.

Owner:ACER INC

Vertical cutting off machine for fine dried noodles

InactiveCN102960385BEasy to adjustHigh degree of automationDough shapingProduction lineMechanization

The invention provides a vertical cutting off machine for fine dried noodles, relates to a fine dried noodle machine, and particularly relates to a mechanical device used for cutting dried fine dried noodles into fine dried noodle sections with a certain required length in a process of producing the fine dried noodles. The machine comprises a frame, fine dried noodle cutting devices, cut fine dried noodle conveying belts and noodle rod conveying mechanism guide rails, wherein the fine dried noodle cutting devices, the cut fine dried noodle conveying belts and the noodle rod conveying mechanism guide rails are arranged on the frame. The machine is characterized in that more than two groups of fine dried noodle cutting off devices consisting of stationary cutters, rotary cutters and rotary cutter drive mechanisms are arranged on the frame-shaped frame, each group of stationary cutters and rotary cutters are matched to form a fine dried noodle cutter, each groups of fine dried noodle devices is arranged in different heights of the frame according to the demands, the cut fine dried noodle conveying belts are arranged below the fine dried noodle cutting off devices, the noodle rod conveying mechanism guide rails are arranged on the top of the frame, and fine dried noodles to be cut off enter the vertical cutting off machine vertically so as to be cut off. The rotary cutters have rotating speeds of 30-60 turns per minute. The machine has the advantages that the cut fine dried noodles are good in uniformity, are flexibly and conveniently regulated in length, and can directly enter a fine dried noodle metering facility, and noodle rods completing the cutting off can be directly sent to a noodle rod bin of a noodle band rolling and cutting unit of a fine dried noodle production line. The vertical cutting off machine is used in the fine dried noodle production line so as to improve mechanization and automation levels of the fine dried noodle production line.

Owner:山东江泷机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com