Cobweb-like hollow spindle knot microfiber device with water collection characteristic and preparation method

A microfiber and microfluidic device technology, applied in the field of biomimetic materials, can solve the problems of fiber water collection efficiency to be improved, fiber capillary adsorption force is weak, etc., achieve good water collection efficiency, flexible and convenient production, and alleviate fresh water shortage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

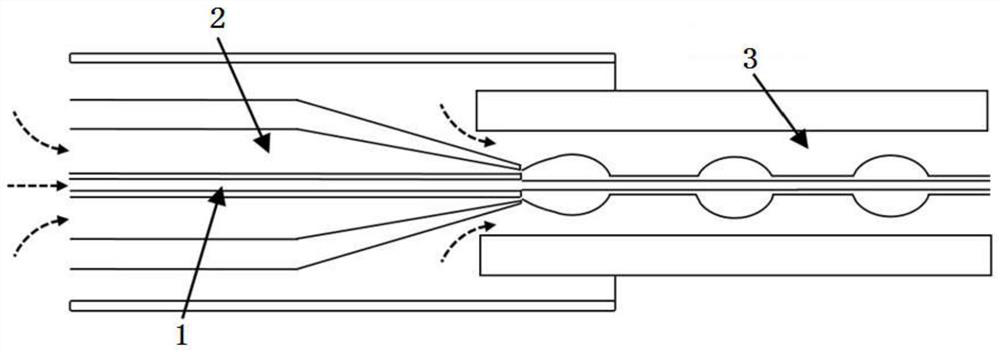

Method used

Image

Examples

preparation example Construction

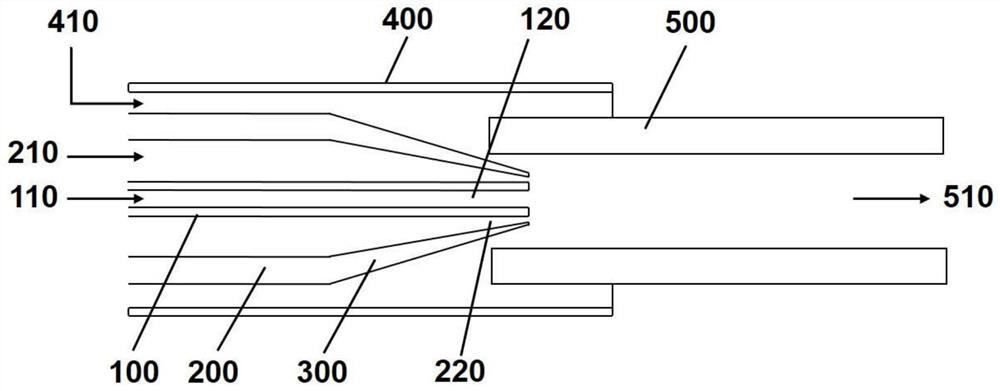

[0040] A preparation method for imitating spider silk hollow spindle knuckle microfibers, comprising the following steps:

[0041] Step 1: fully miscible equal volumes of polyethylene glycol aqueous solution with a mass fraction of 5-15% and dextran aqueous solution with a mass fraction of 5-15%, and then separate phases; the upper phase is polyethylene glycol solution, and the lower phase is The phase is a dextran solution; after fully miscible in a beaker under the condition of magnetic stirring (200 rpm), the phases can be separated after standing for 6 hours; the molecular weight of polyethylene glycol is 8kDa, and the molecular weight of dextran is 500kDa.

[0042] Step 2: Add calcium chloride to the dextran solution obtained in step 1 to form a mixed solution A, and the calcium chloride content in the mixed solution A is 1 to 5 mg·mL -1 ;

[0043] Step 3: adding sodium alginate to the polyethylene glycol solution obtained in step 1 to form a mixed solution B, the conten...

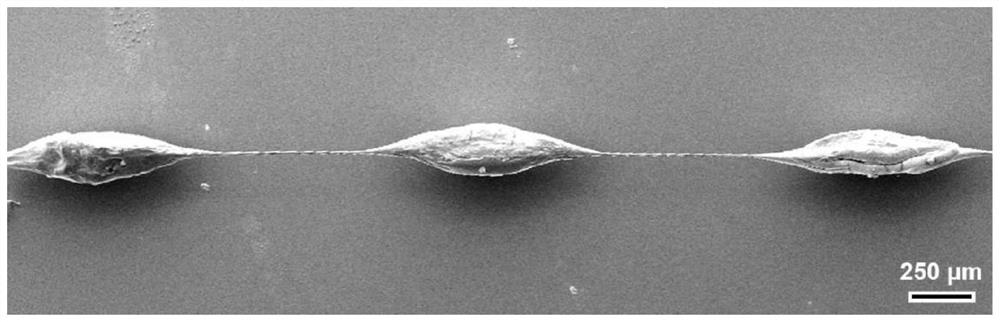

Embodiment 1

[0047] A preparation method for imitating spider silk hollow spindle knuckle microfibers, comprising the following steps:

[0048] Step 1: Prepare 50 mL of an aqueous solution of polyethylene glycol with a mass fraction of 8 wt % and 50 mL of an aqueous solution of dextran with a mass fraction of 8 wt %; after fully mixing, stand still for 6 hours and then separate phases. The upper phase is a polyethylene glycol solution, and the lower phase is a dextran solution; extract the upper and lower phases and store them in different beakers for later use.

[0049] Step 2: Add calcium chloride to the dextran solution obtained in step 1 to form a mixed solution A, and the calcium chloride content in the mixed solution A is 4 mg·mL -1 ;

[0050] Step 3: adding sodium alginate to the polyethylene glycol solution obtained in step 1 to form a mixed solution B, the content of calcium alginate in the mixed solution B is 2wt%;

[0051] Step 4: inject the mixed solution A into the plastic s...

Embodiment 2

[0055] A preparation method for imitating spider silk hollow spindle knuckle microfibers, comprising the following steps:

[0056] Step 1: Prepare 50 mL of an aqueous solution of polyethylene glycol with a mass fraction of 8 wt % and 50 mL of an aqueous solution of dextran with a mass fraction of 8 wt %; after fully mixing, stand still for 6 hours and then separate phases. The upper phase is a polyethylene glycol solution, and the lower phase is a dextran solution; extract the upper and lower phases and store them in different beakers for later use.

[0057] Step 2: Add calcium chloride to the dextran solution obtained in step 1 to form a mixed solution A, and the calcium chloride content in the mixed solution A is 4 mg·mL -1 ;

[0058] Step 3: adding sodium alginate to the polyethylene glycol solution obtained in step 1 to form a mixed solution B, the content of calcium alginate in the mixed solution B is 2wt%;

[0059] Step 4: inject the mixed solution A into the plastic s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com