Multi-branch distribution heat pipe and manufacturing method thereof

A manufacturing method and multi-branch technology, applied in the field of electronics, can solve the problems of excessive heat dissipation space, insufficient heat dissipation capacity of heat pipes, single heat pipe structure, etc., and achieve simple manufacturing process, promote market-oriented development, and strong heat transfer capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

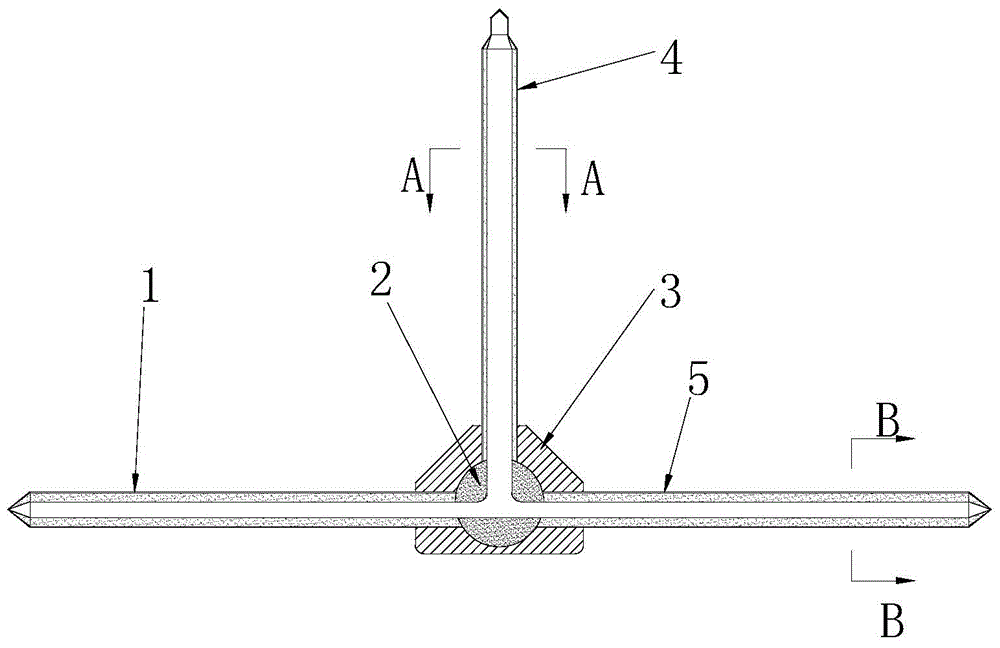

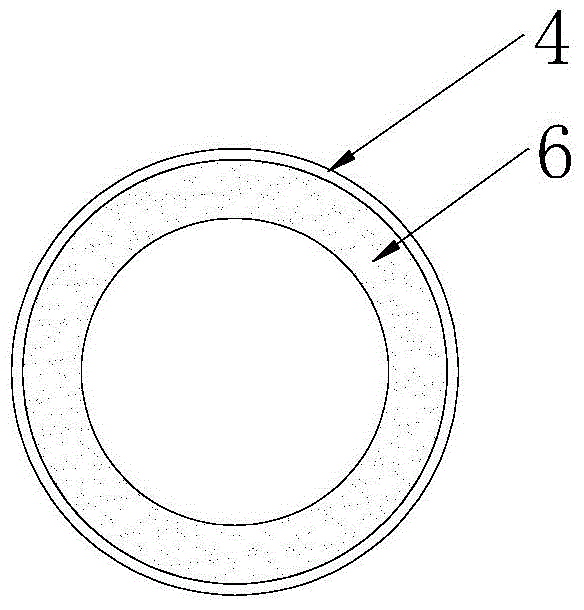

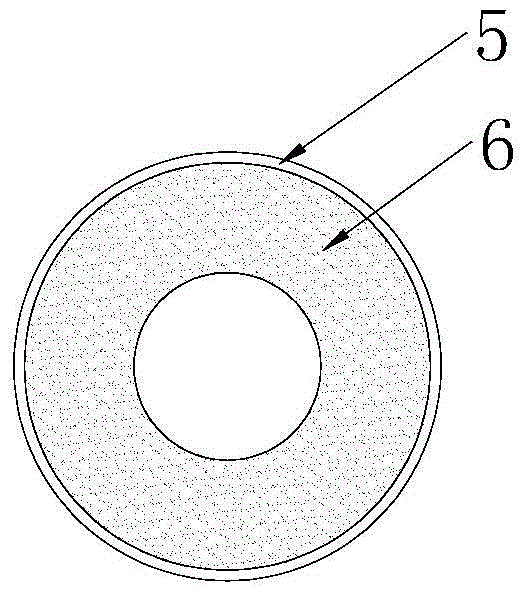

[0037] like figure 1 As shown, a multi-branch distribution heat pipe includes a multi-channel pipe joint 3, a first shell 1, a second shell 4 and a third shell 5 with one end sealed, and the multi-channel pipe joint 3 is provided with a The interface of each shell, the multi-channel pipe joint 3 is provided with a sealed cavity that communicates with each interface, and the other ends of the first shell 1, the second shell 4, and the third shell 5 are respectively plugged into the Each interface of the multi-channel pipe joint 3 forms an interconnected T-shaped structure, and the inner walls of the first shell 1, the second shell 4, and the third shell 5 are all provided with a layered porous capillary layer 6 (see figure 2 , image 3 ), the sealed inner cavity of the multi-channel pipe joint 3 is filled with a capillary connector 2 that keeps each shell connected, the first shell 1, the second shell 4, the third shell 5 The inner hole and the sealed cavity of the channel p...

Embodiment 2

[0042] A method for manufacturing a multi-branch distributed heat pipe, comprising the following steps:

[0043] (1) Use the welding process to weld and fix the first shell 1, the second shell 4 and the third shell 5 with the multi-channel shell joint 3, and then assemble and fix the sintered mandrel at one end of the third shell 5 Graphite sleeve 9 with concentric fixing effect;

[0044] (2) Prepare the first sintered mandrel 7 and the second sintered mandrel 8, the cross-sectional area of the first sintered mandrel 7 is half of the cross-sectional area of the second sintered mandrel 8, and the first sintered mandrel 7 and the diameter of the second sintered mandrel 8 are all smaller than the inner diameter of each shell, and one end of the second sintered mandrel 8 inserted into the second shell 4 is provided with a through hole with the same diameter as the first sintered mandrel 7, and then the Each shell and the two sintered mandrels are integrally derusted and degre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com