Patents

Literature

43 results about "Laplace pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Laplace pressure is the pressure difference between the inside and the outside of a curved surface that forms the boundary between a gas region and a liquid region. The pressure difference is caused by the surface tension of the interface between liquid and gas. The Laplace pressure is determined from the Young–Laplace equation given as ΔP≡Pᵢₙₛᵢdₑ-Pₒᵤₜₛᵢdₑ=γ(1/R₁+1/R₂), where R₁ and R₂ are the principal radii of curvature and γ (also denoted as σ) is the surface tension.

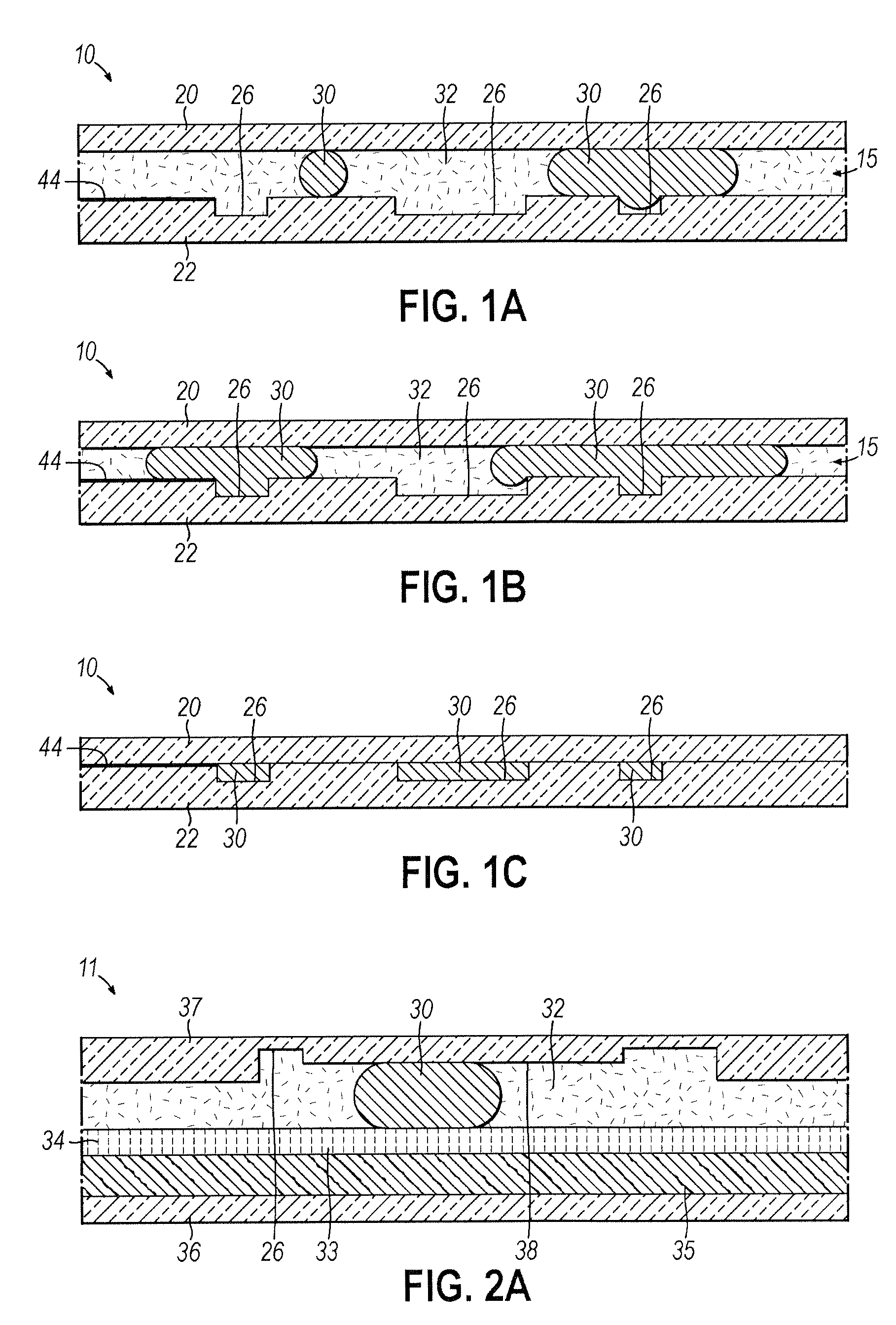

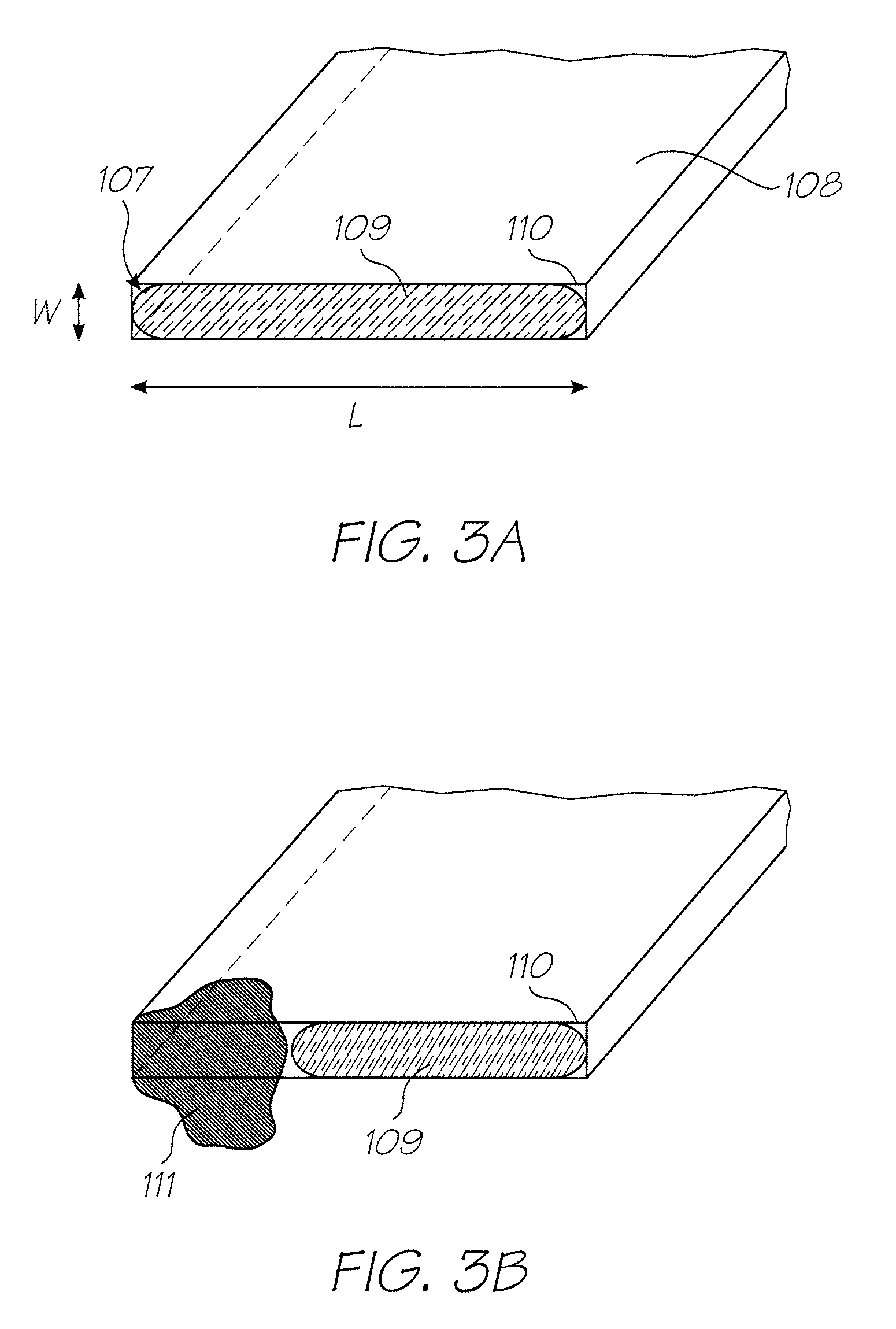

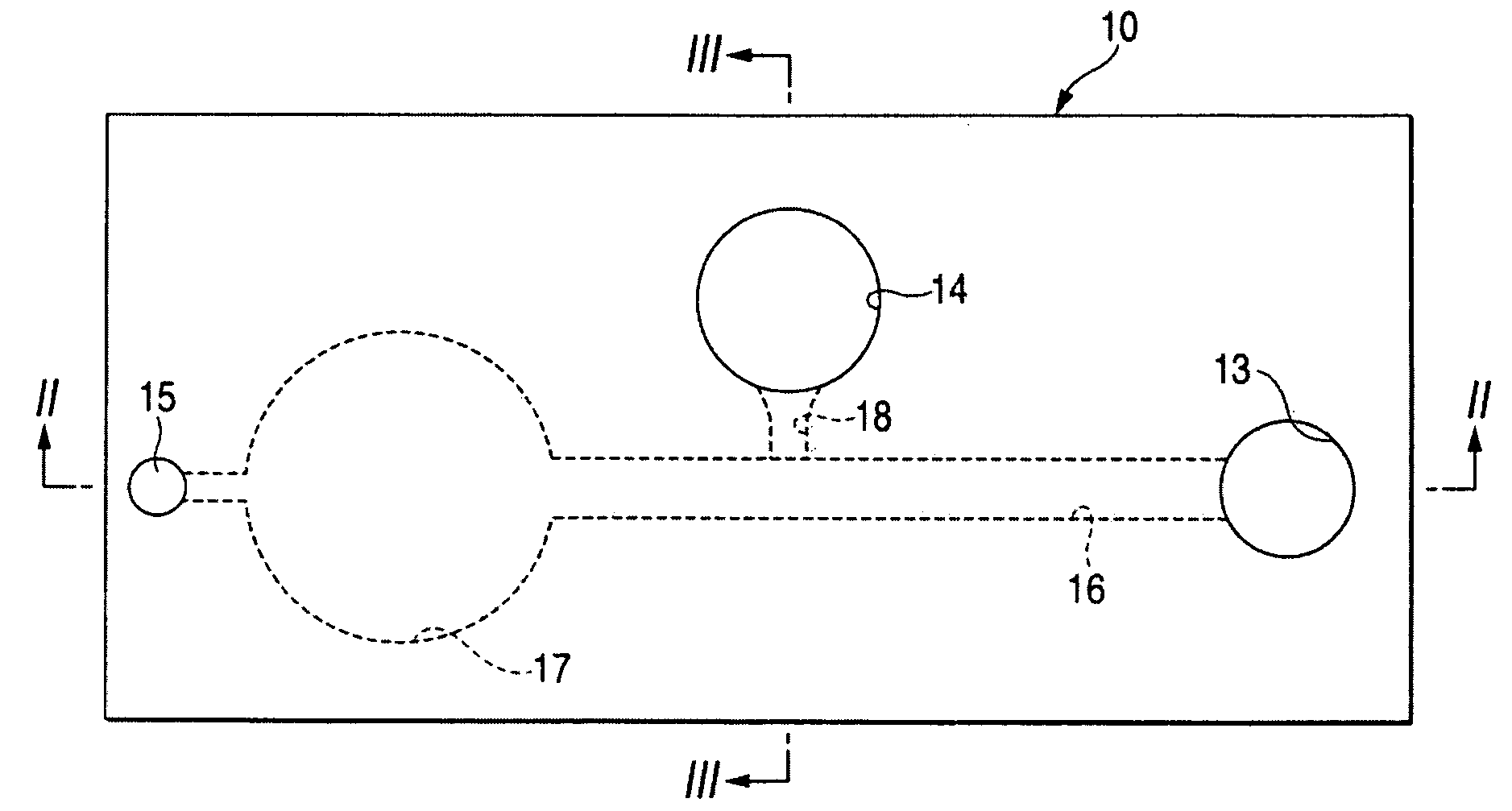

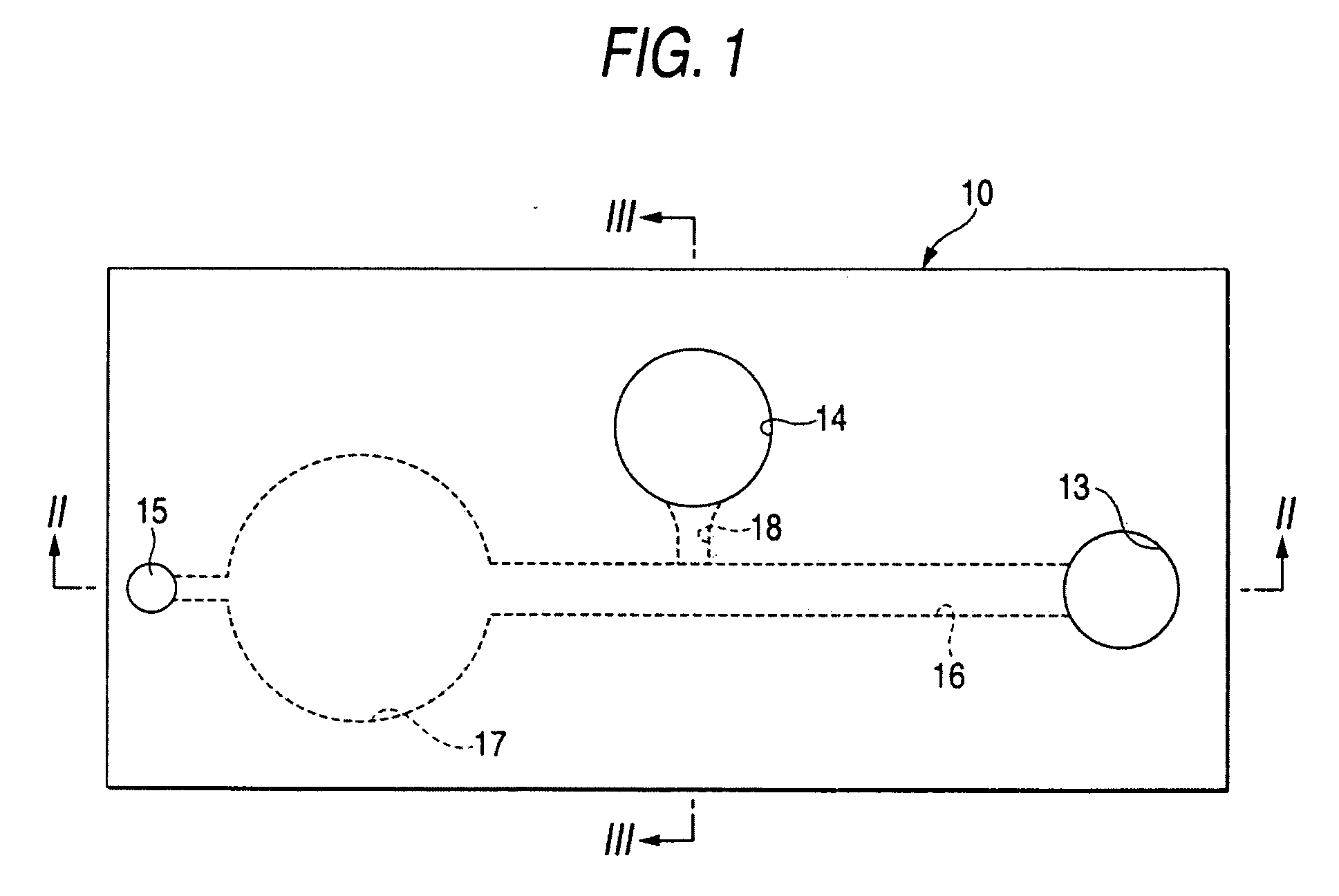

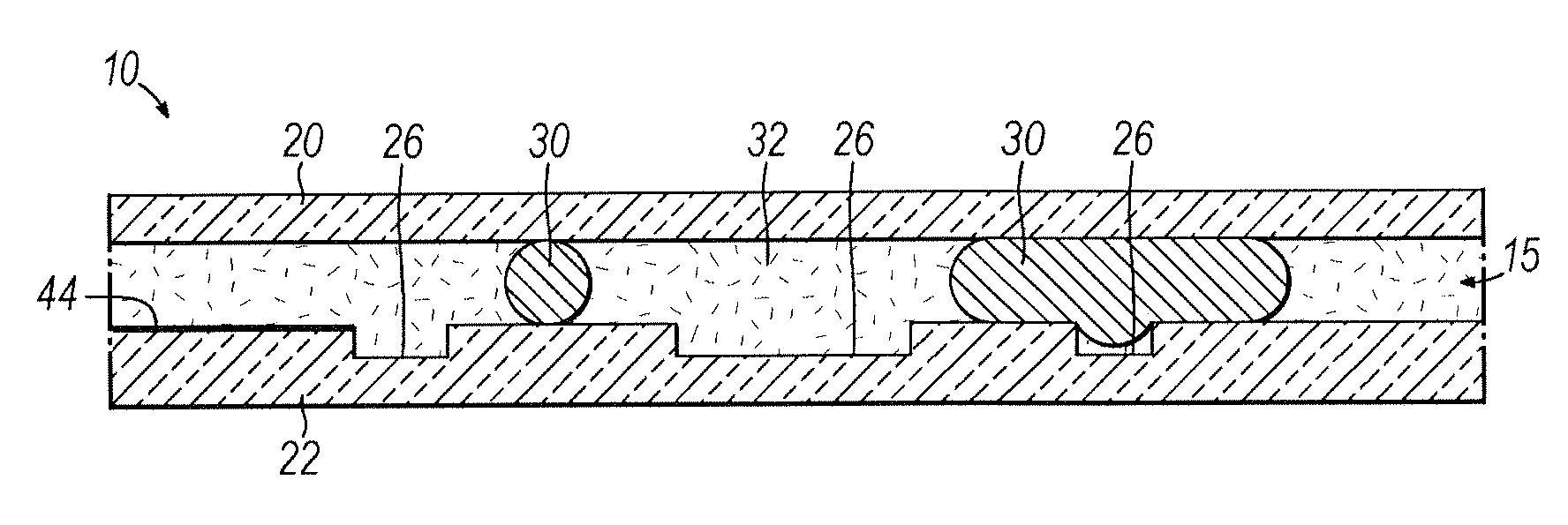

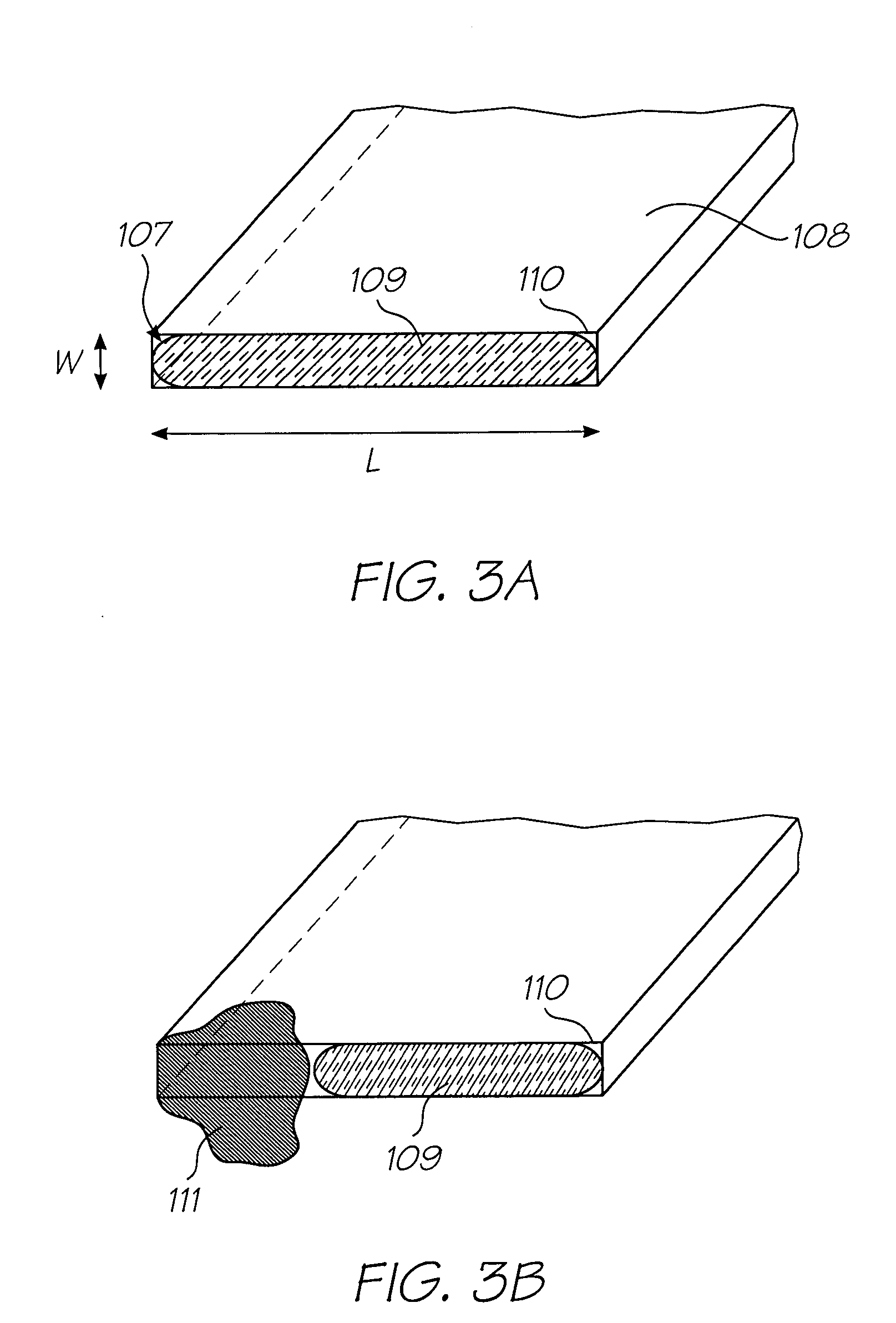

Pressure reconfigured electromagnetic devices

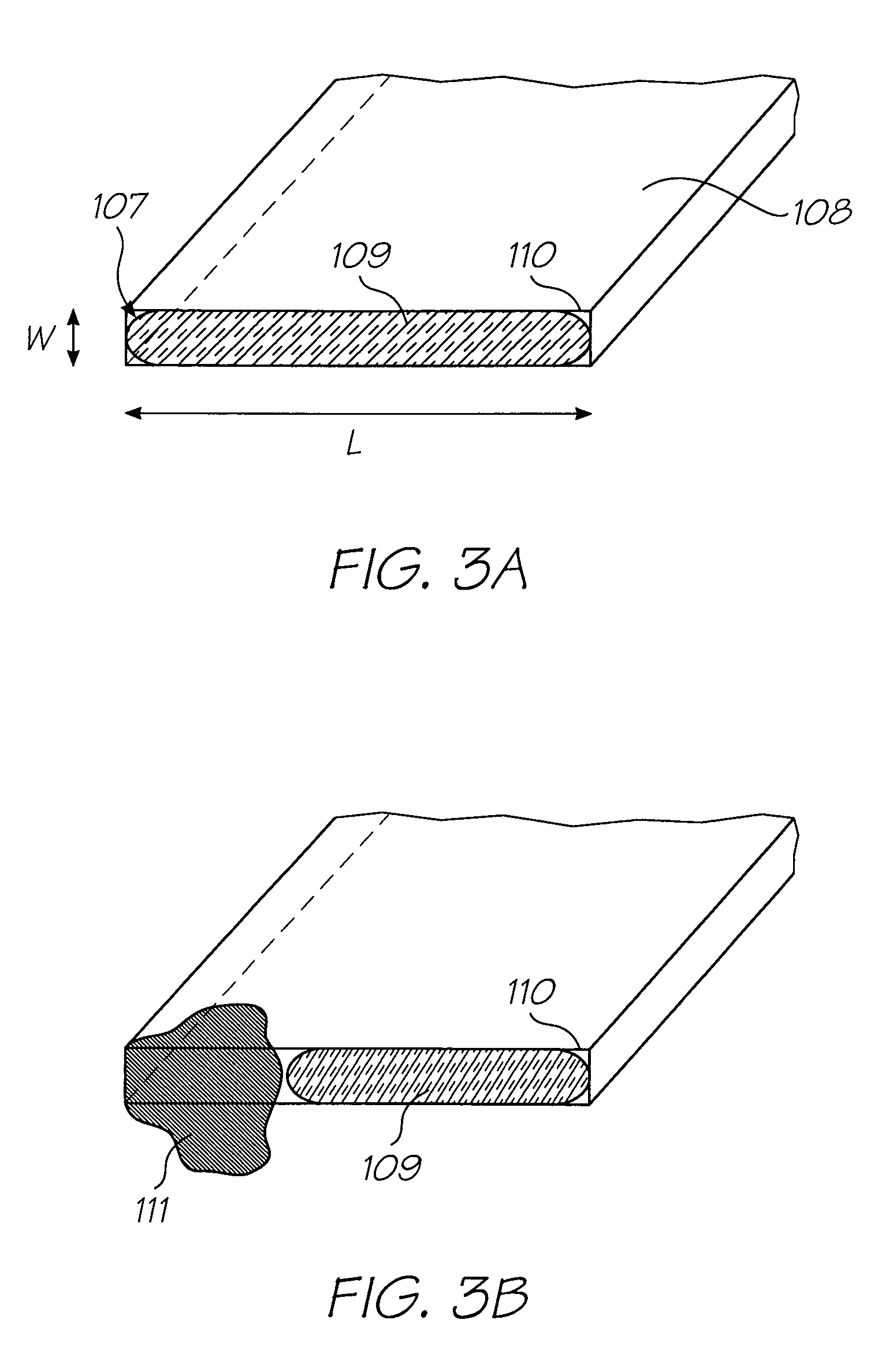

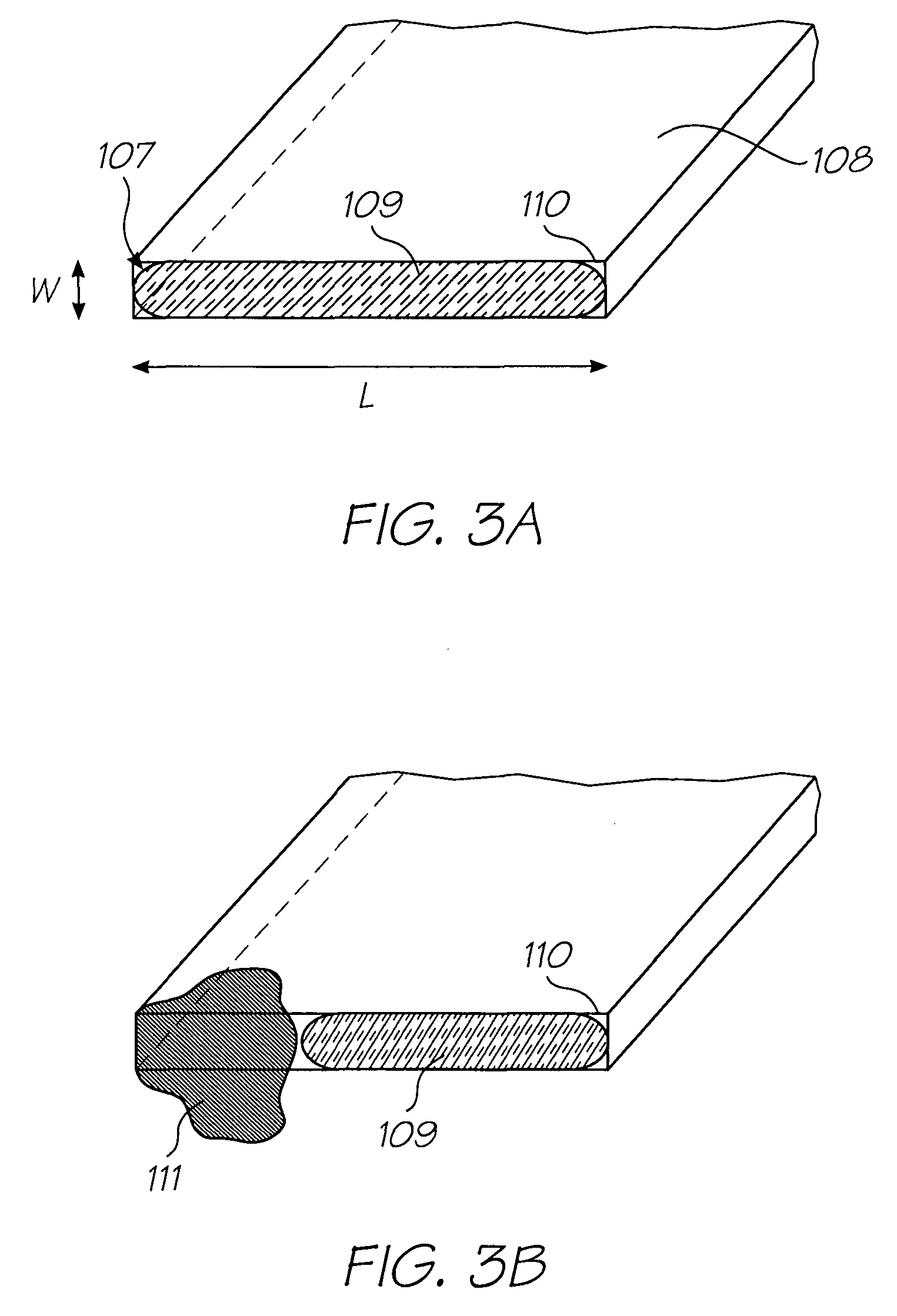

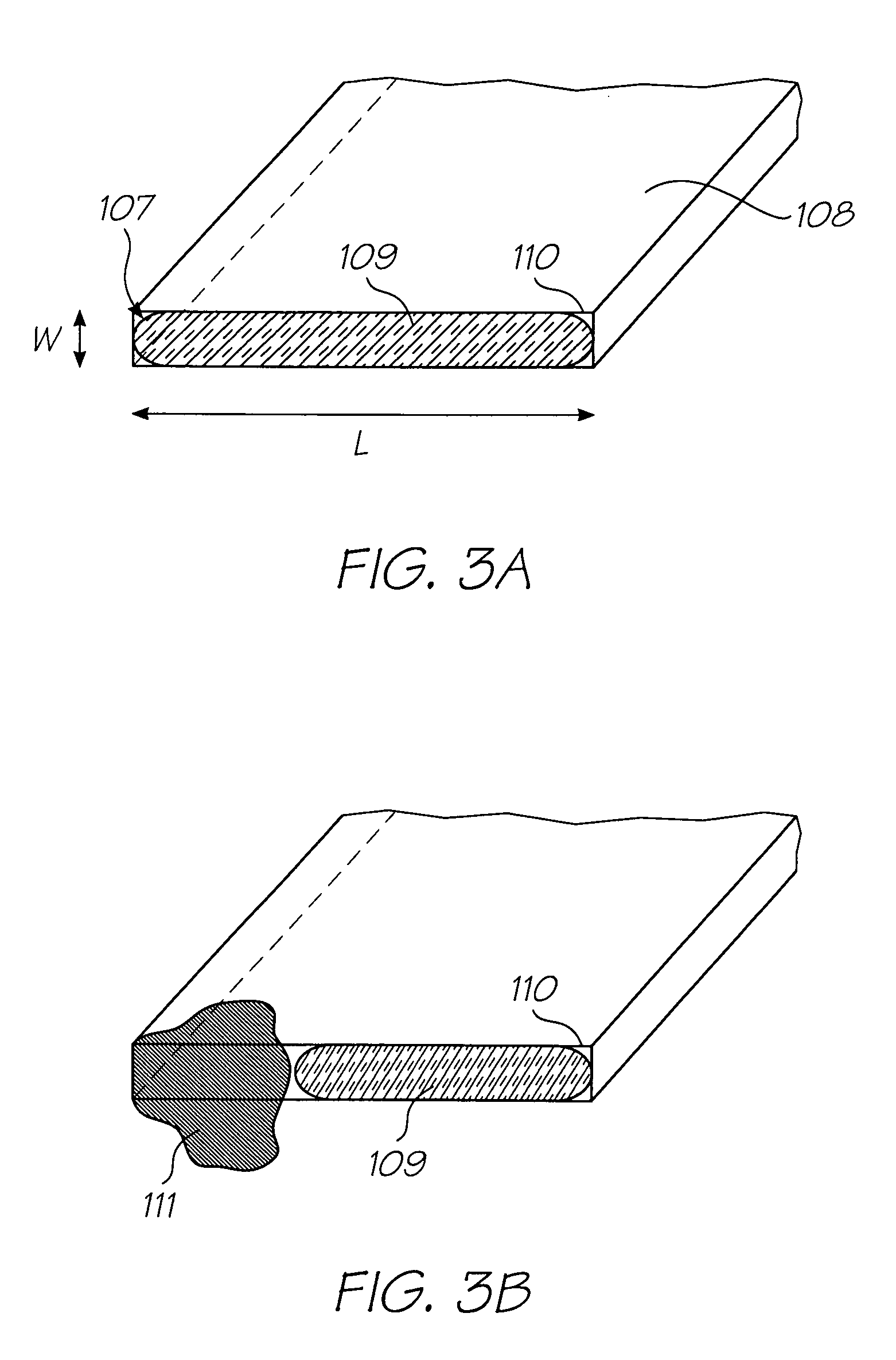

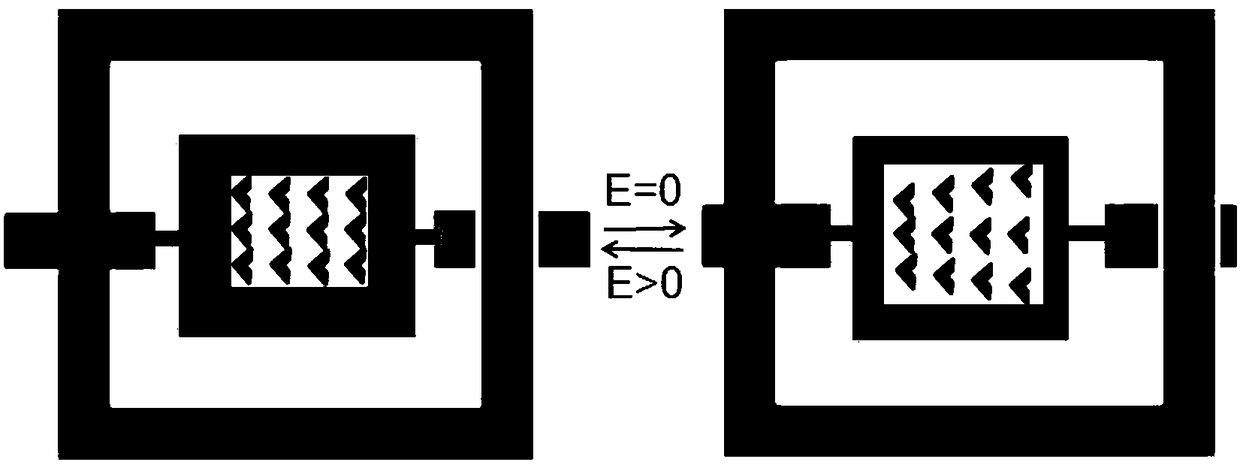

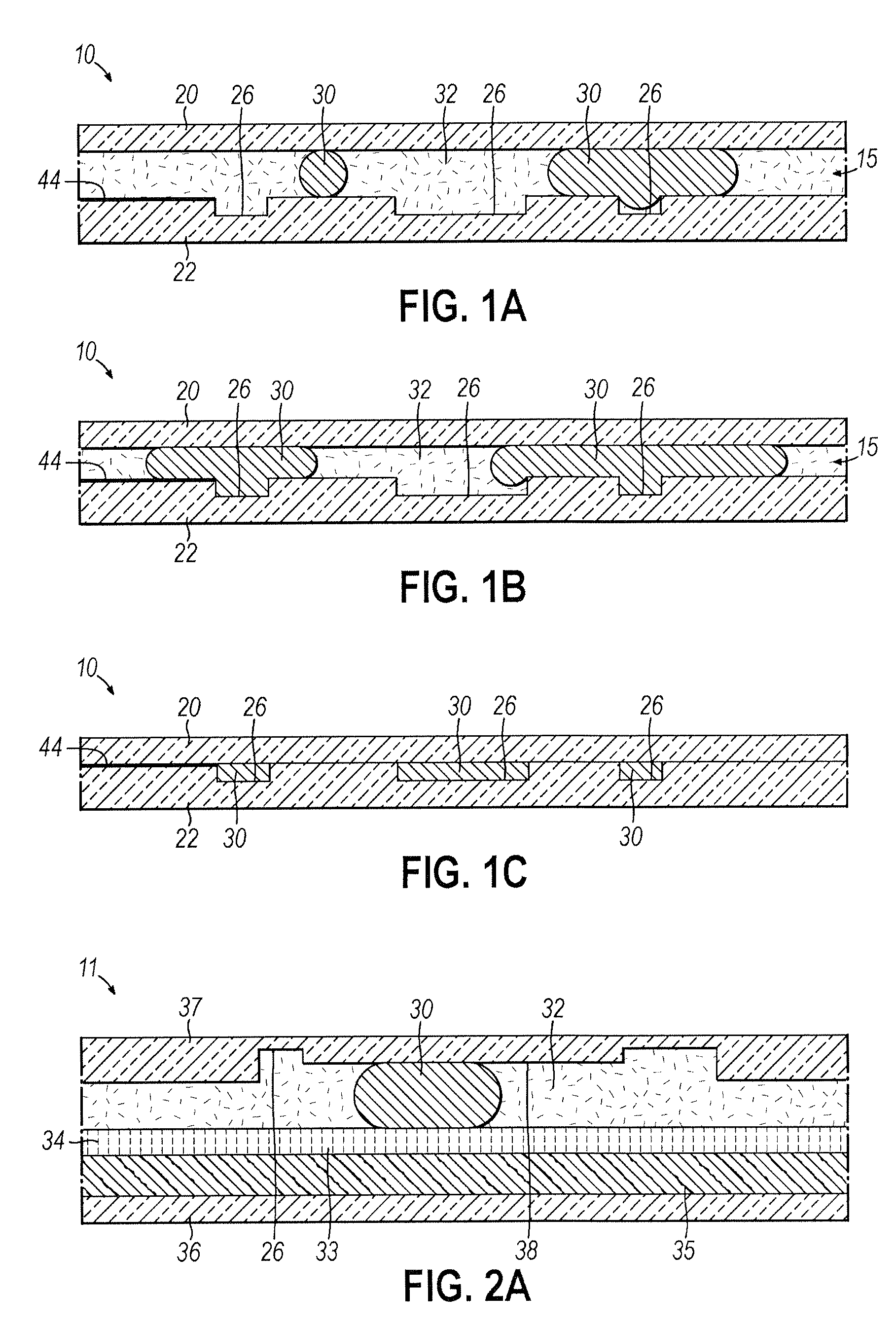

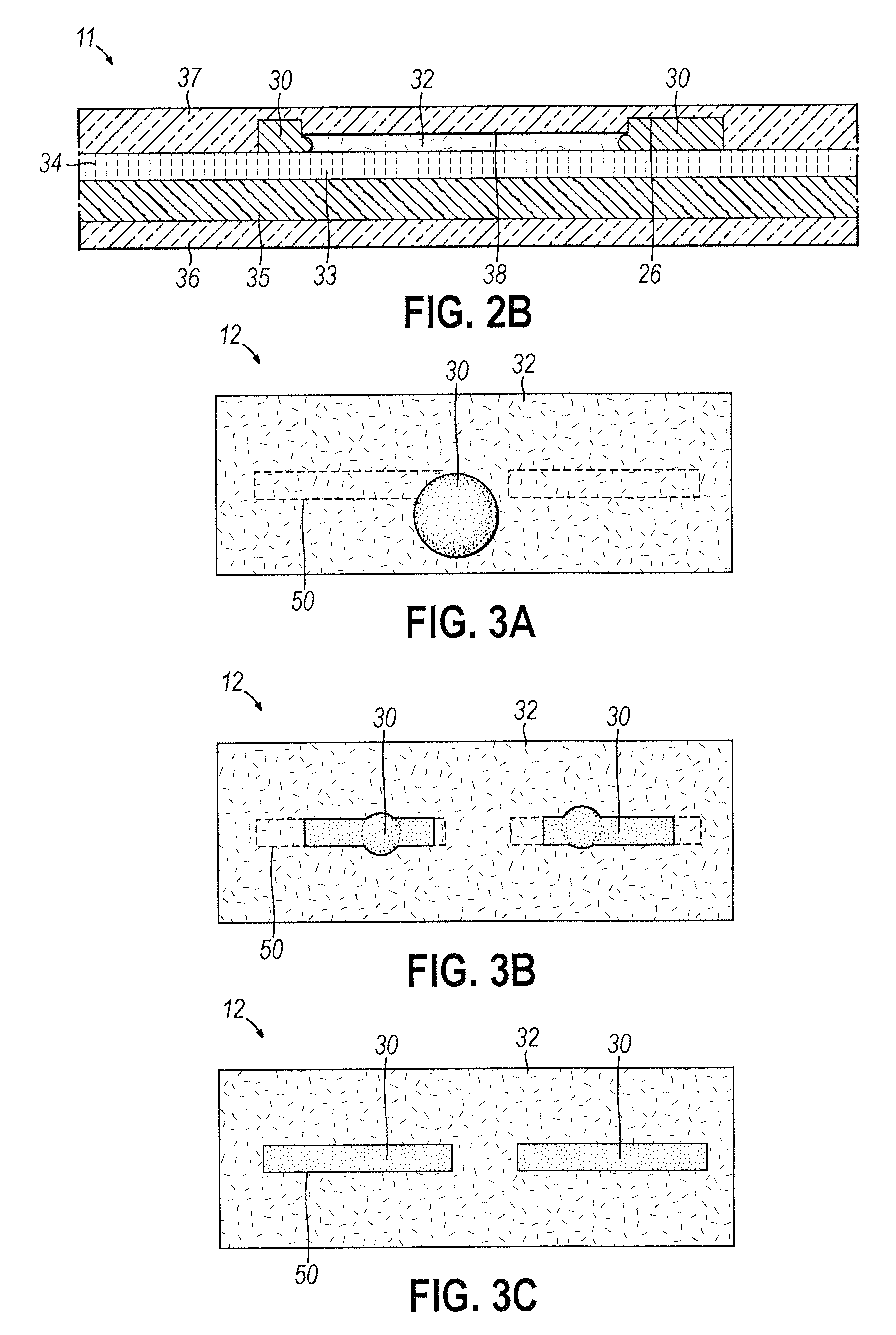

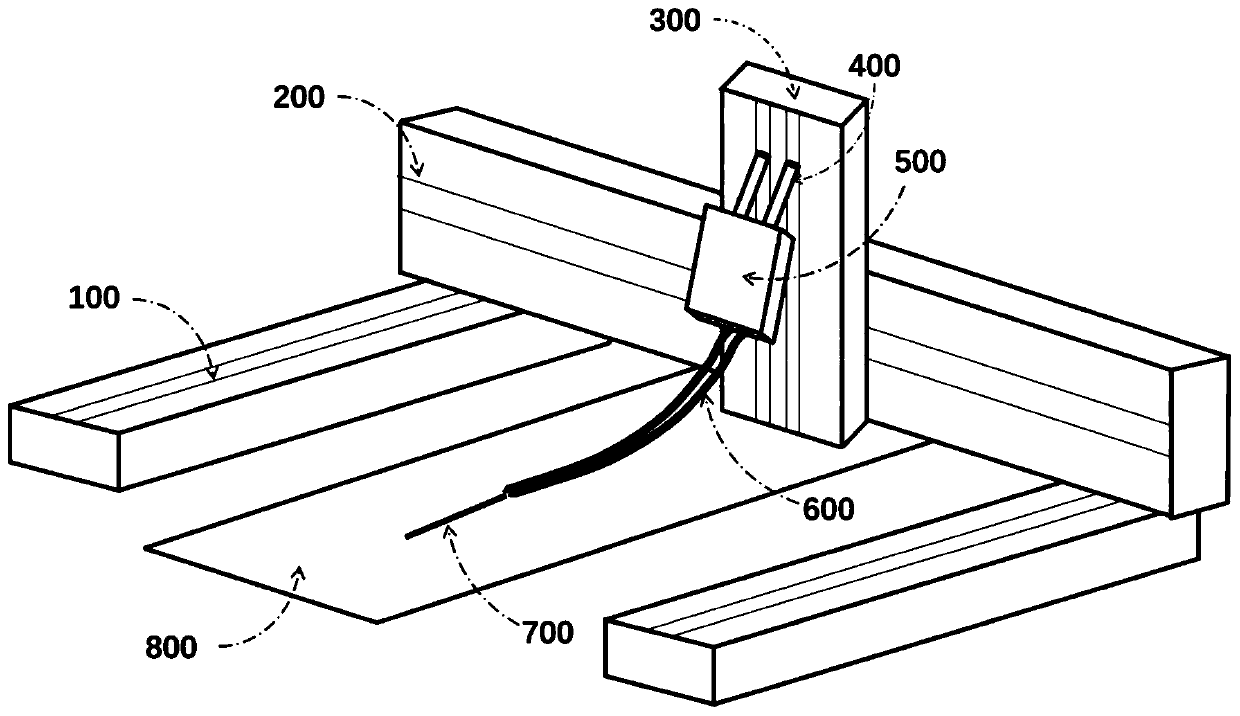

ActiveUS20140054067A1Reduce areaPrinted circuit aspectsPrinted circuit manufactureLaplace pressureLiquid metal

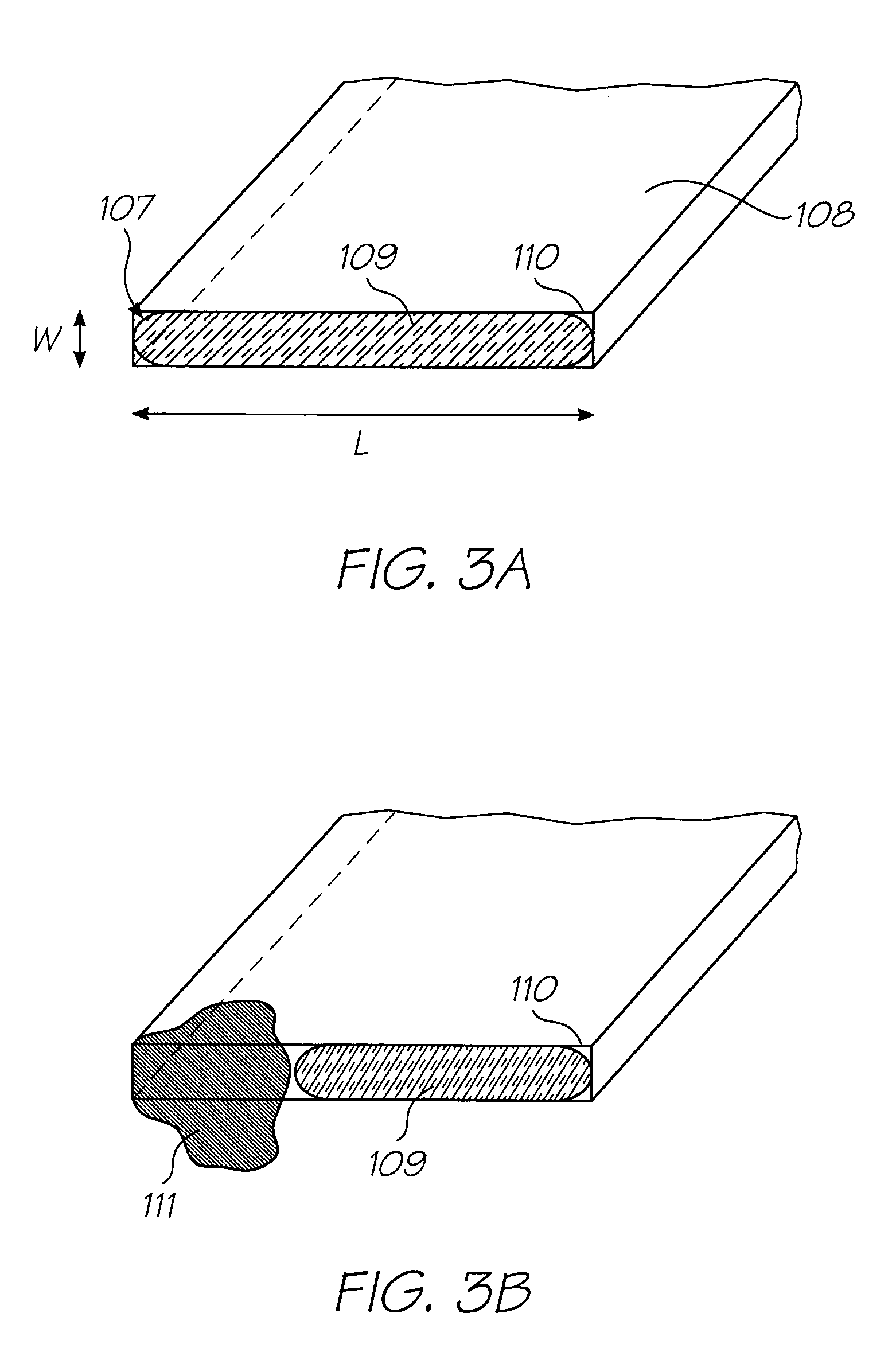

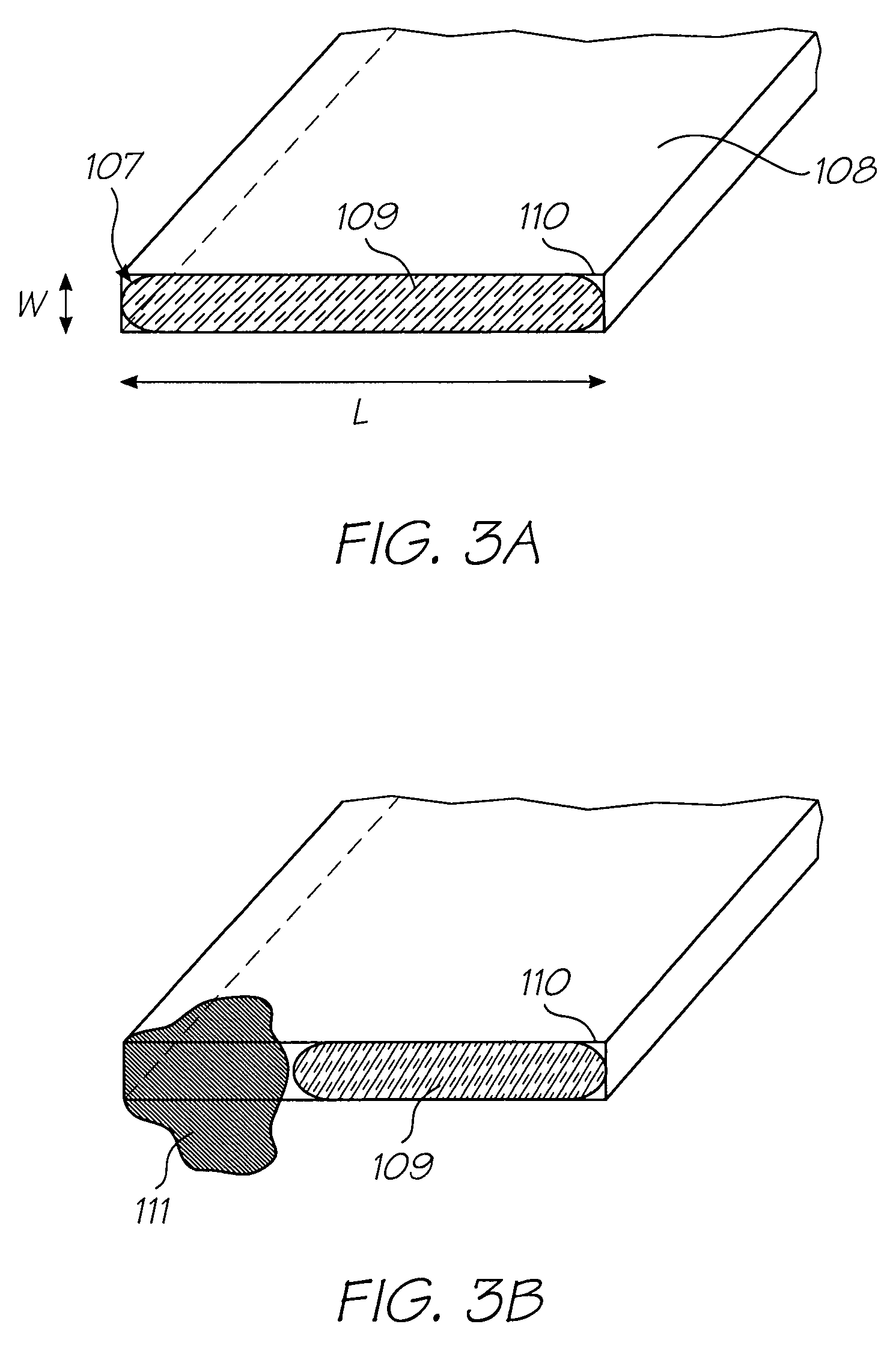

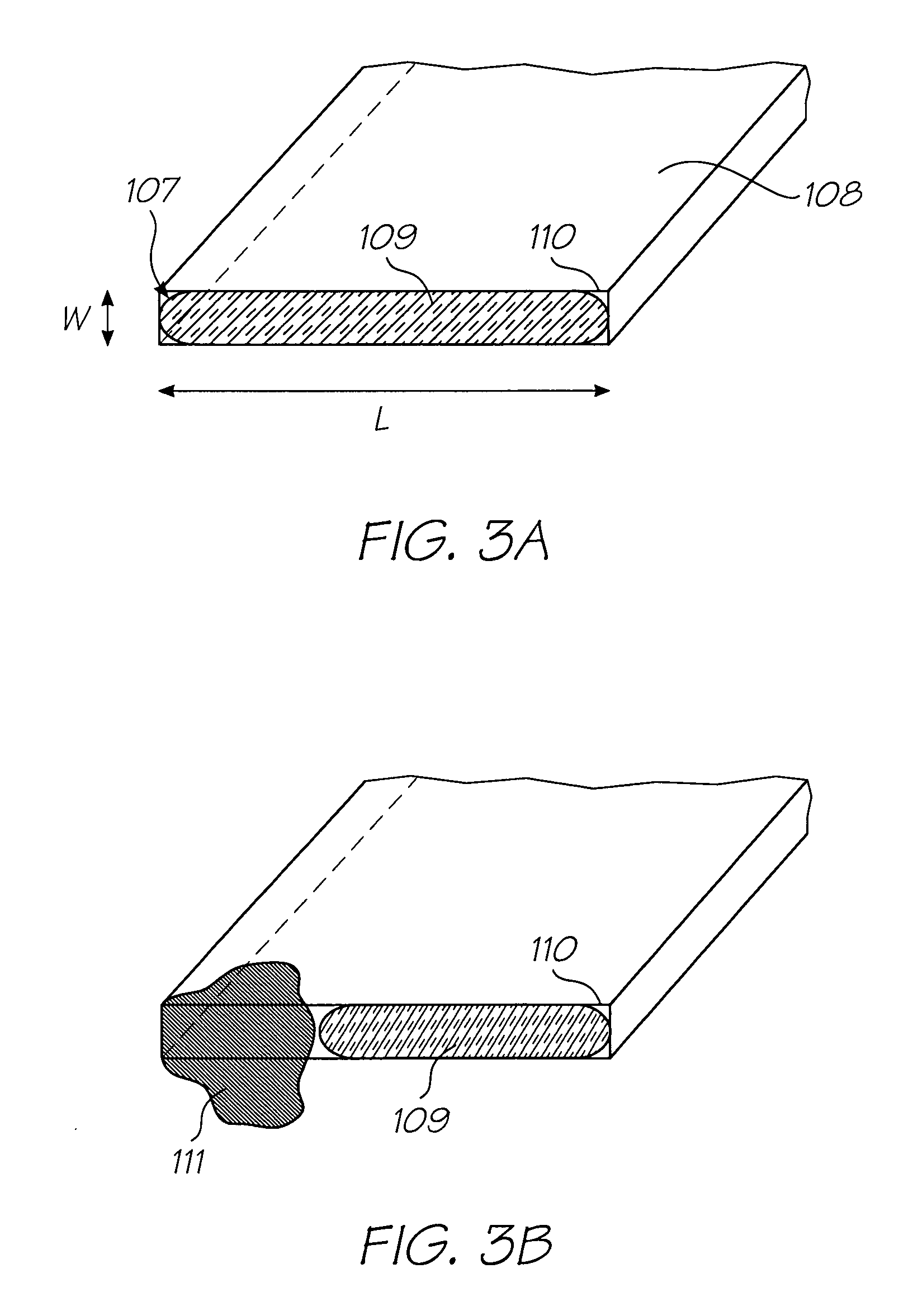

A reconfigurable electromagnetic device includes a first and second planar layer having facing surfaces. One of the surfaces includes one or more micro-trenches. The area between the two surfaces is filled with an electro-fluid, such as a liquid metal and a second immiscible fluid, such as an inert gas. When pressure is applied, forcing the two surfaces together, Laplace pressure causes the electro-fluid to flow into the trench as the inert fluid is evacuated from the area between the two surfaces, forming an electromagnetic device. The shape of the trenches defines the reconfigurable device, such as circuitry, switch, antenna or the like. When the inert fluid is reintroduced into the area between the two surfaces, the electro-fluid withdraws from the trench, which is the off position, in which the device does not function.

Owner:UNIVERSITY OF CINCINNATI

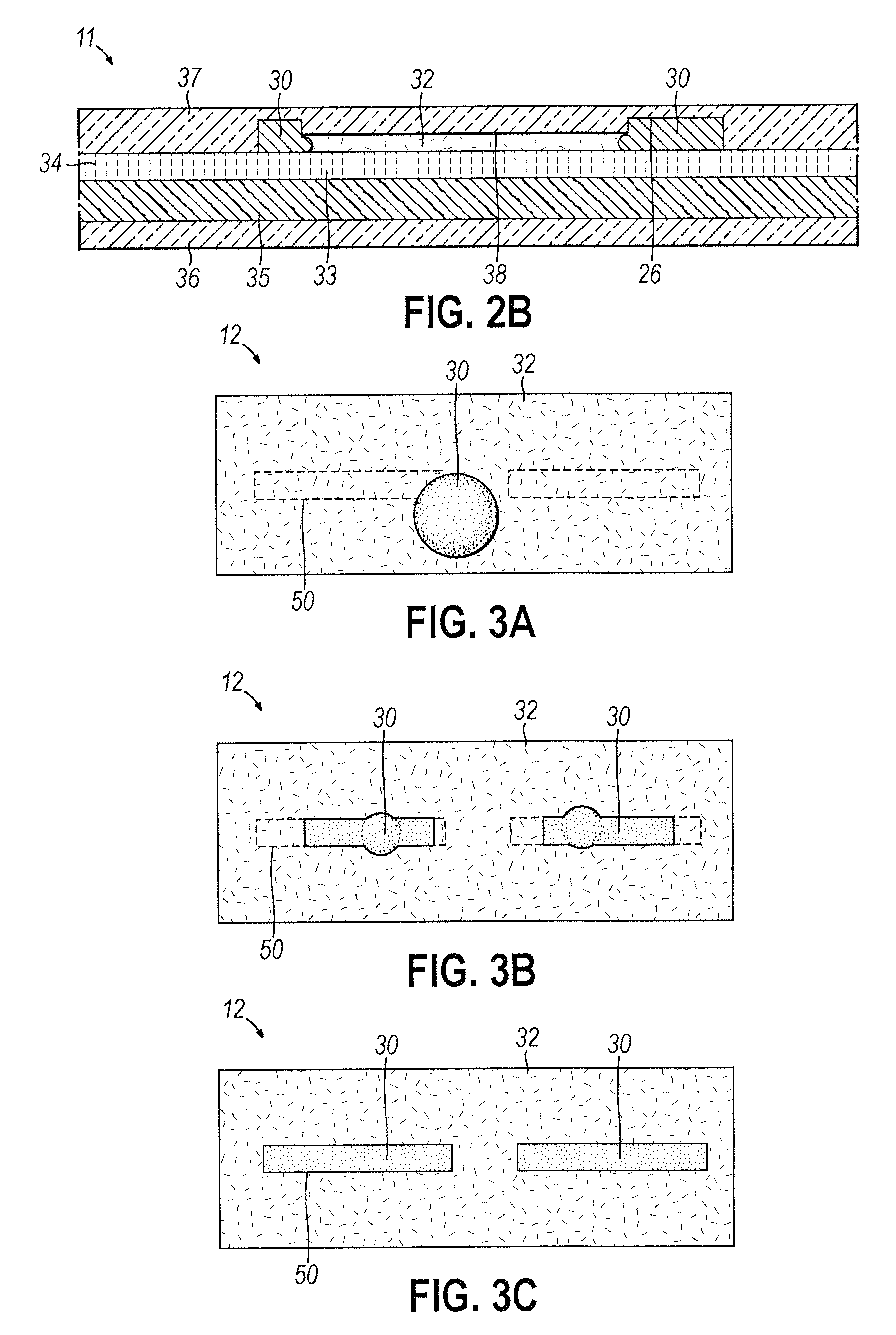

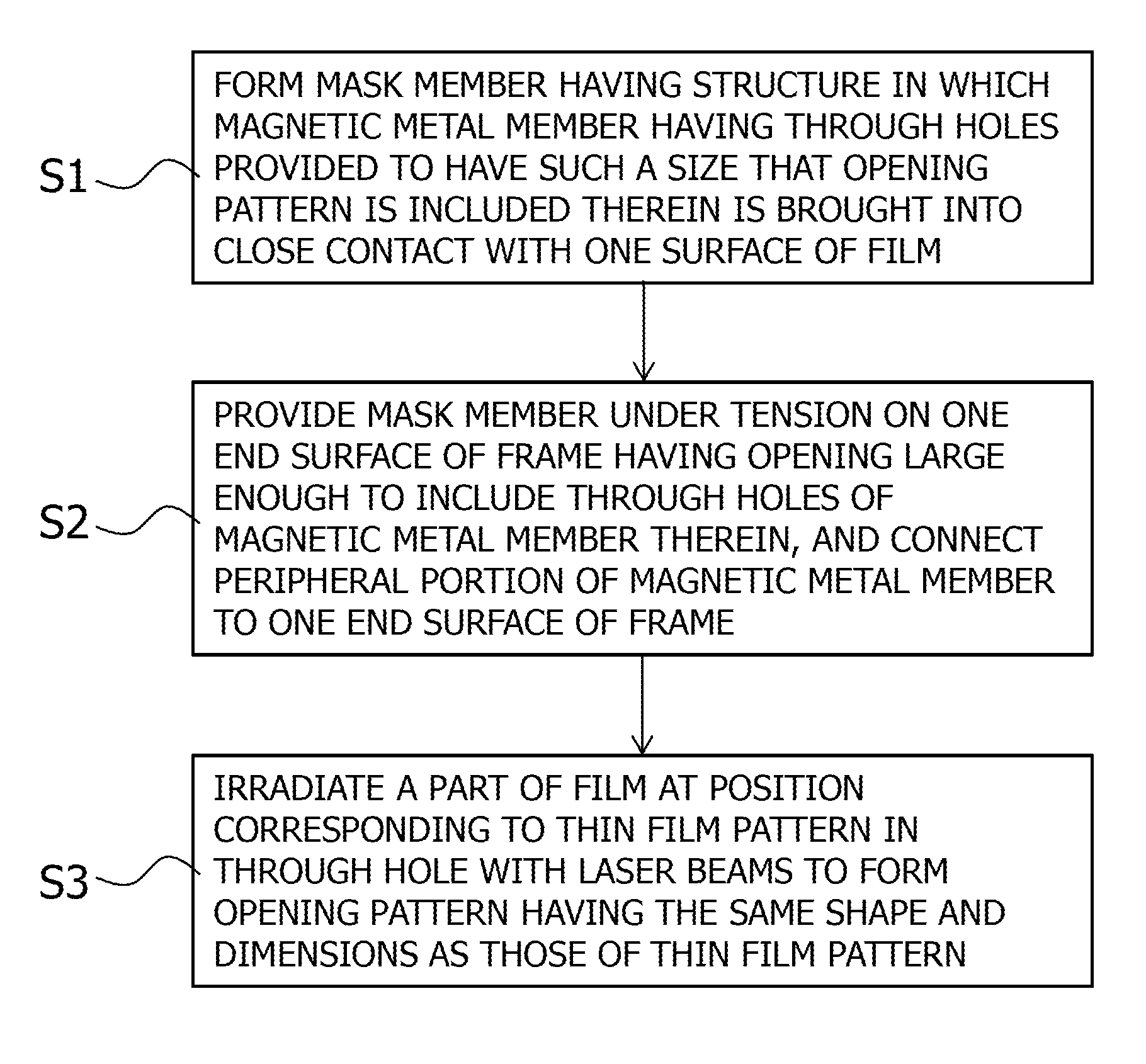

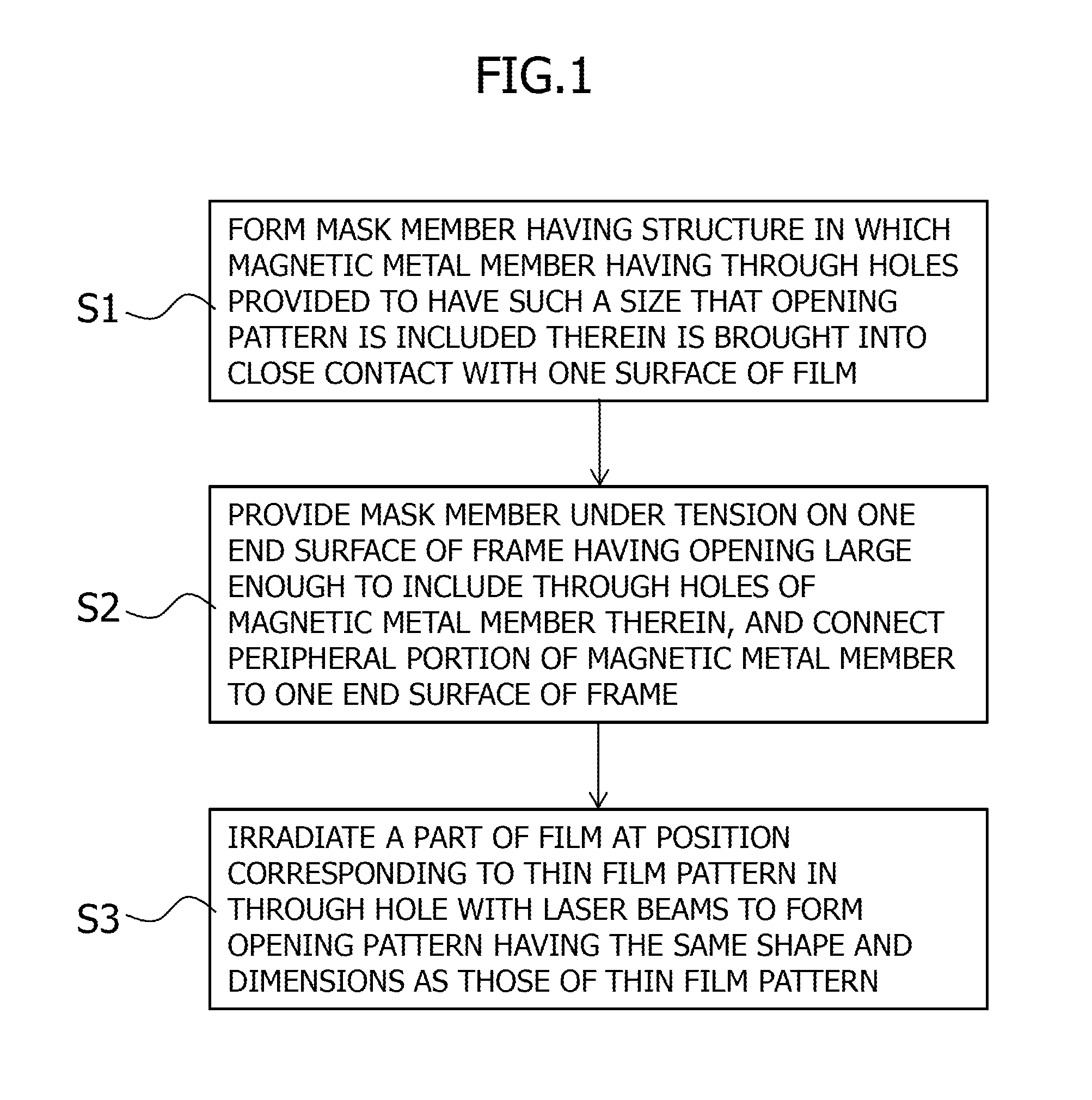

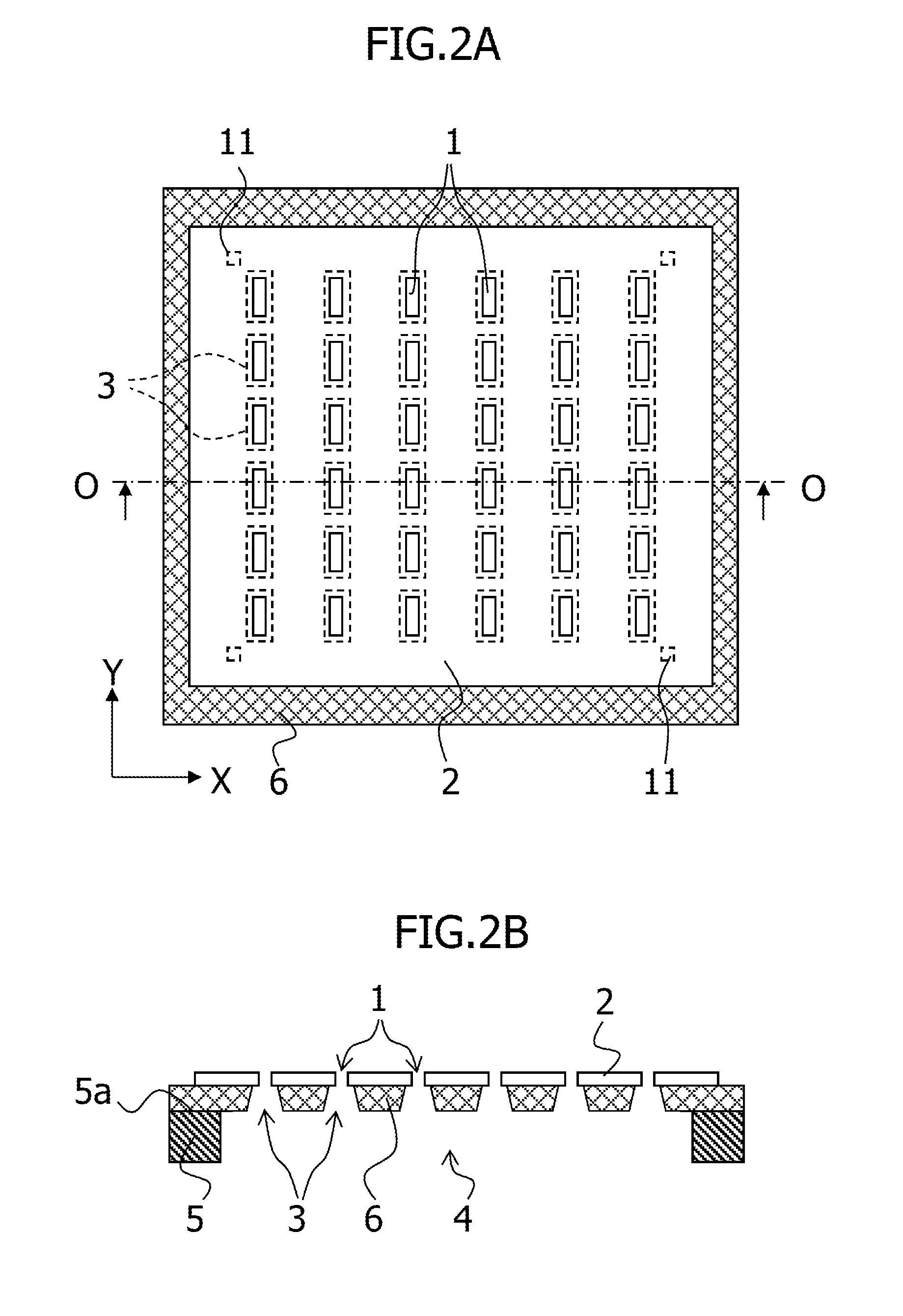

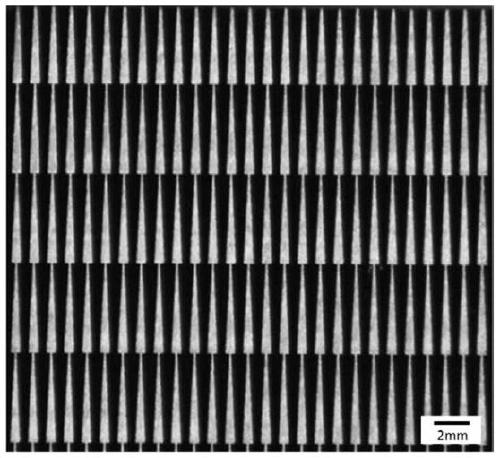

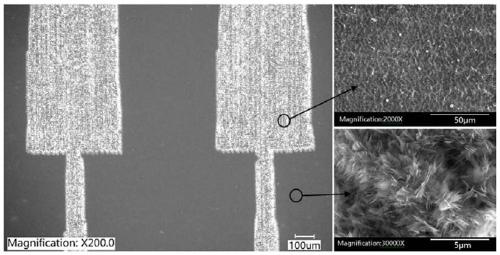

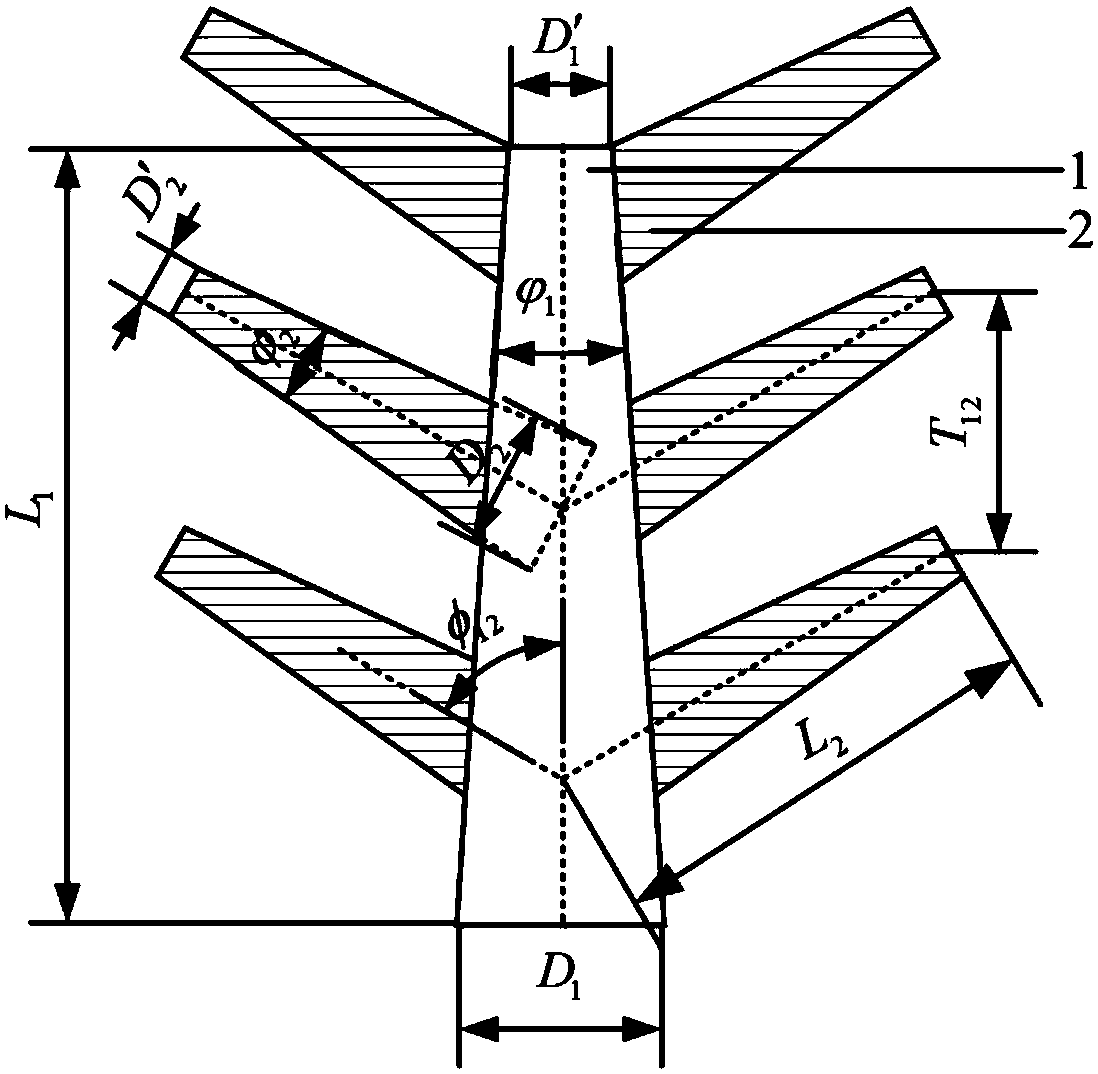

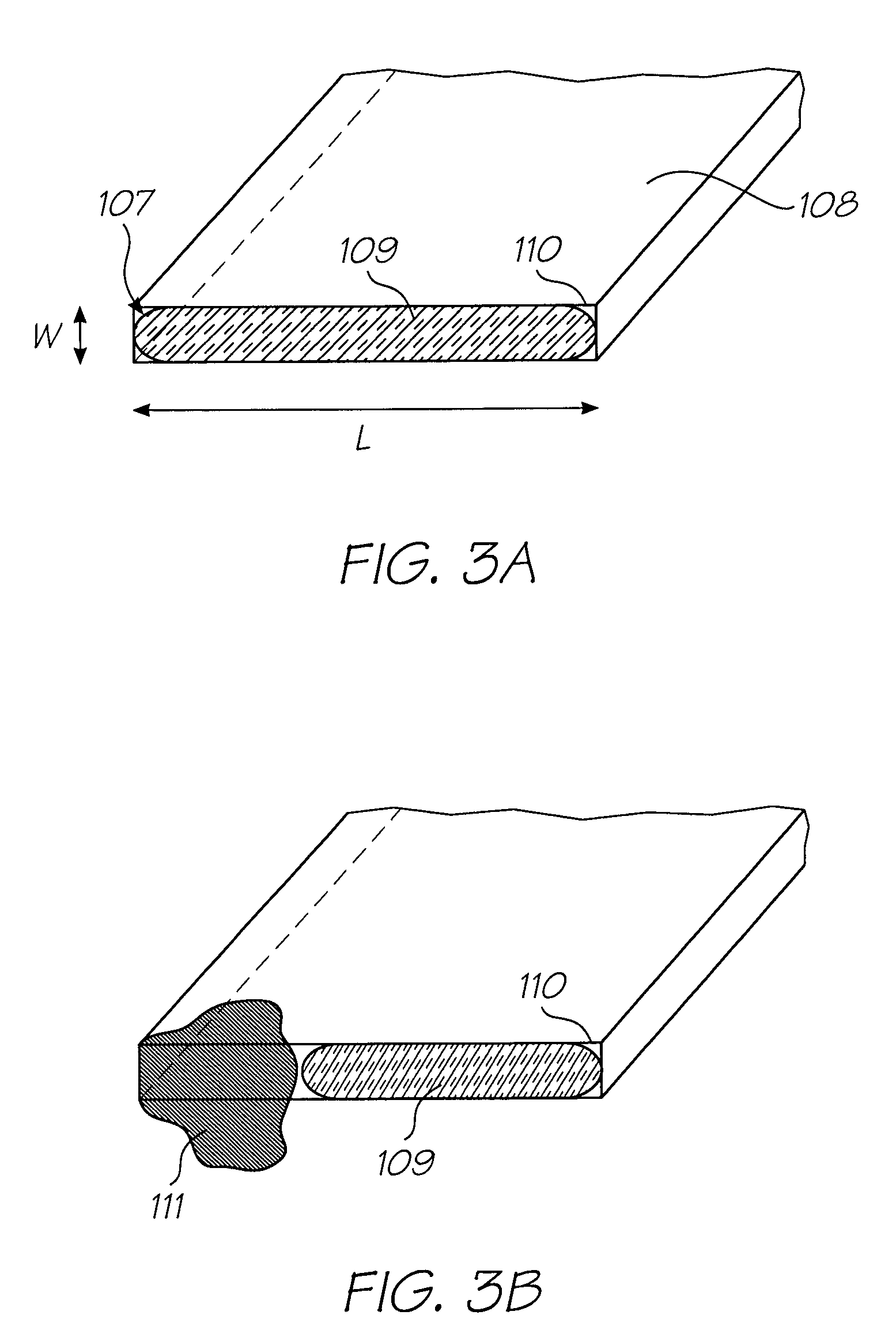

Method for producing deposition mask

InactiveUS20150283651A1Avoid it happening againImprove accuracyLiquid surface applicatorsVacuum evaporation coatingLaser processingLaplace pressure

The invention provides a method for producing a deposition mask that includes forming of an opening pattern 1 at a predetermined position in a resin film 2 by laser processing so as to penetrate therethrough. The method including the steps of: forming a meniscus of a liquid film 14 between the resin film 2 and a smooth surface 13b of a reference substrate 13 supporting the resin film 2; and after the resin film 2 and the reference substrate 13 are brought into close contact with an adsorption force generated by Laplace pressure, forming the opening pattern 1 by performing the laser processing. Accordingly, it is possible to increase the speed of the laser processing without generating a burr on an edge portion of the opening pattern.

Owner:V TECH CO LTD

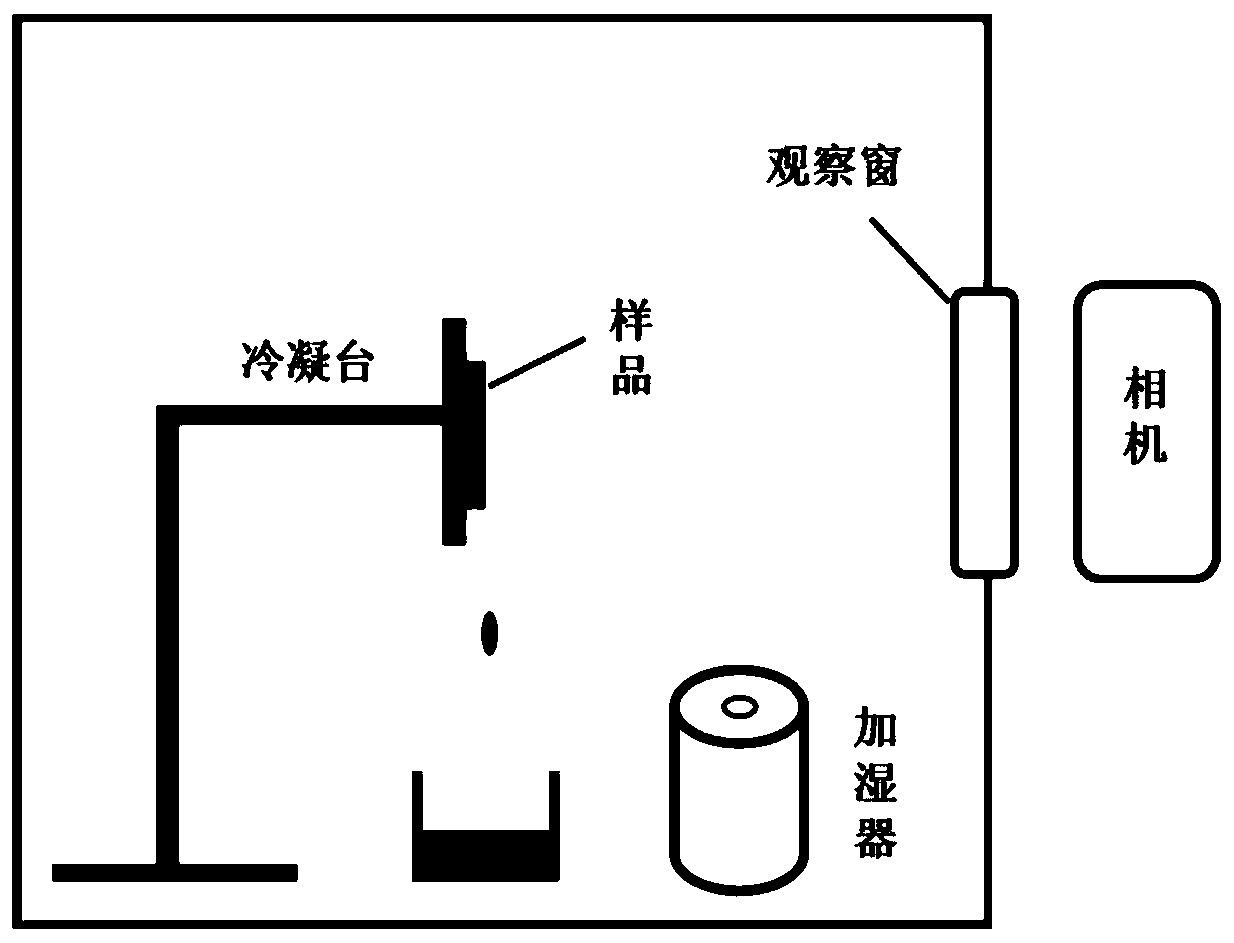

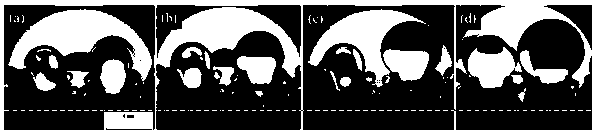

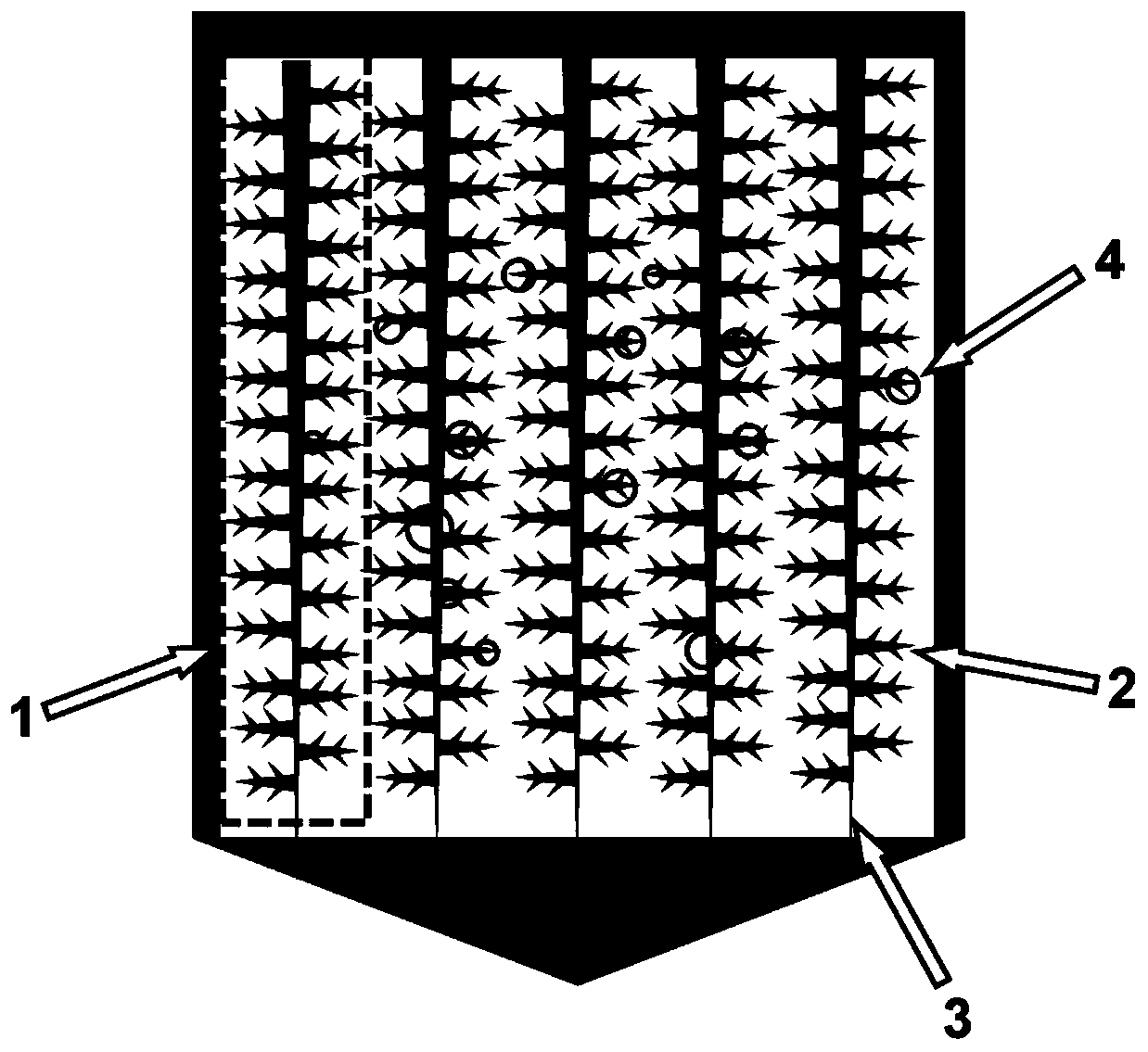

Hydrophilic/hydrophobic area synergistic water-collecting patterned surface and preparation method thereof

PendingCN110408933AOvercome areaOvercome densityCoatingsLaser beam welding apparatusVolumetric Mass DensityEngineering

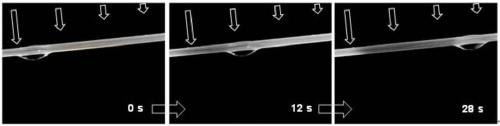

The invention belongs to the field of metal surface modification, and particularly relates to a hydrophilic / hydrophobic area synergistic water-collecting patterned surface and a preparation method thereof. The surface involves constructing a super-hydrophilic pattern of a tree-like array structure on a super-hydrophobic copper substrate, wherein the tree-like array structure is formed by the up and down connection of a plurality of patterns with shape gradient. The method comprises the following steps of cleaning the surface of a copper sample; corroding the cleaned copper surface through using alkaline solution; conducting low surface energy chemical modification on a super-hydrophilic copper surface; and using optical fiber laser to conduct ablating a pattern with the tree-like array structure on a super-hydrophobic copper surface so as to obtain the super-hydrophilic pattern, and finally the hydrophilic / hydrophobic area synergistic water-collecting patterned surface can be obtained.According to the hydrophilic / hydrophobic area synergistic water-collecting patterned surface and the preparation method thereof, the defects of large aggregation of droplets in a single hydrophilic area, low nucleating density in a single hydrophilic area and the like are solved; and in addition, the super-hydrophilic pattern has shape gradient, so when the surface is vertically placed, under thedual effects of the Laplace pressure and gravity force, the droplets in a single hydrophilic area can quickly fall off from the surface, thus achieving high efficiency in water collecting.

Owner:NANJING UNIV OF SCI & TECH

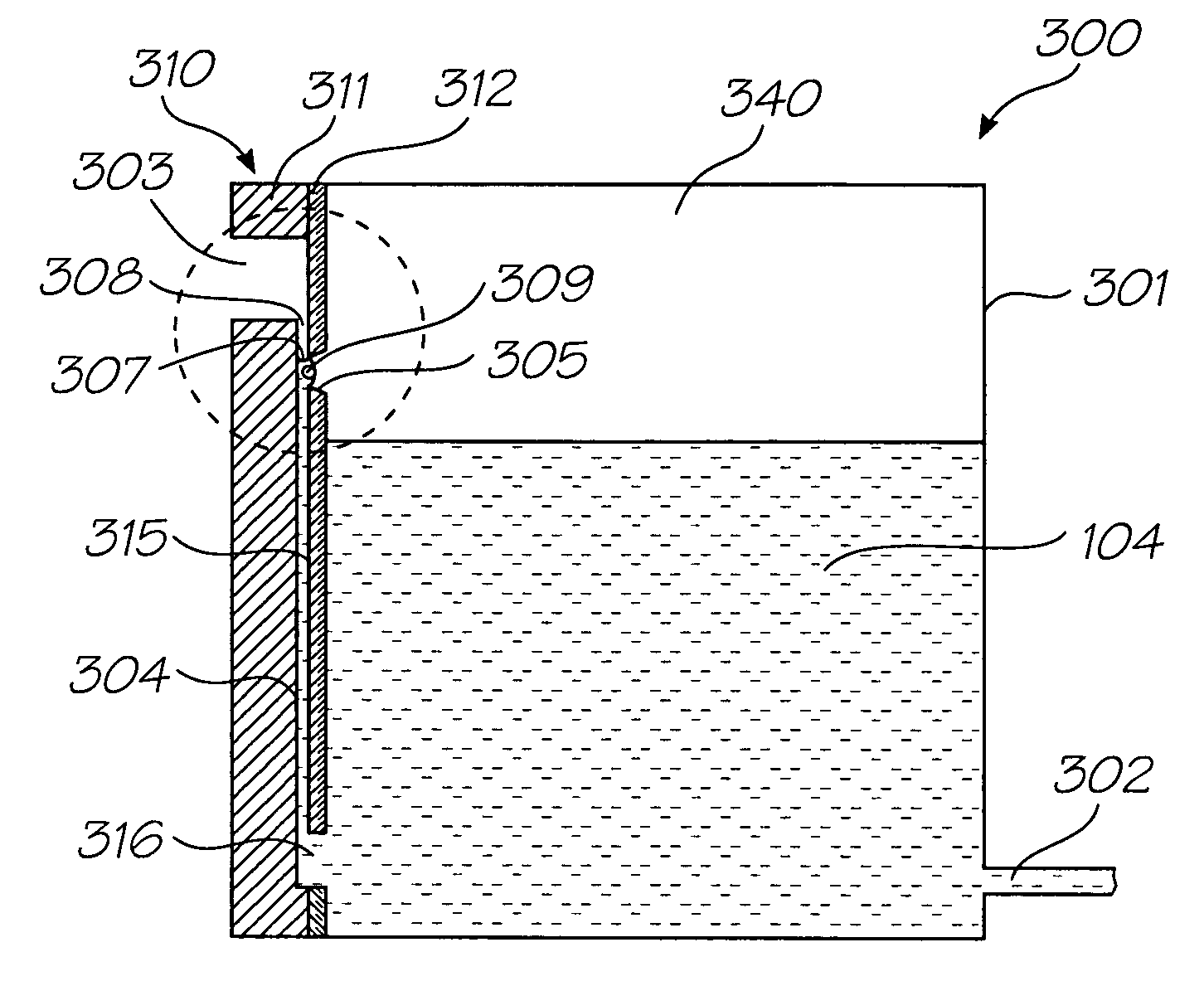

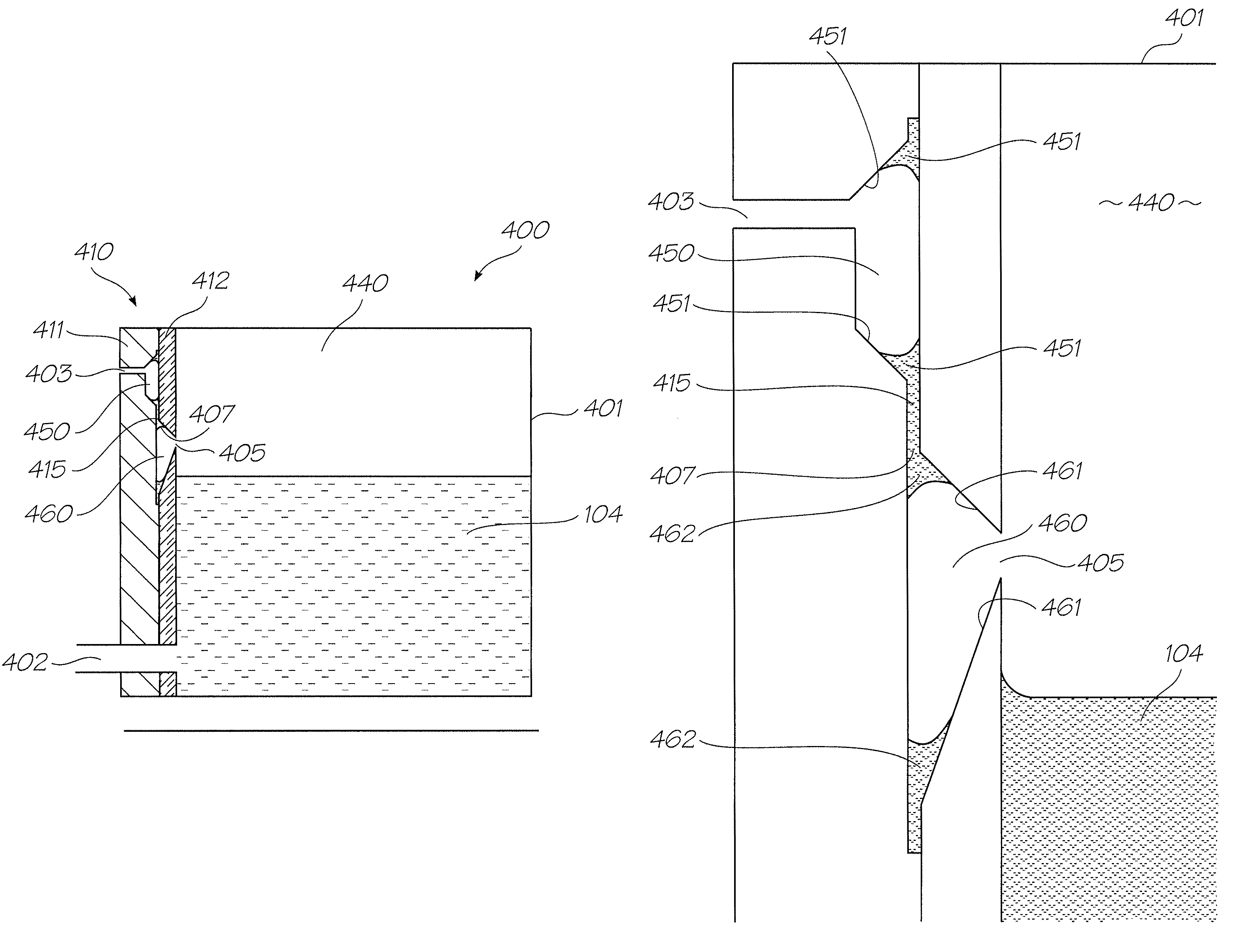

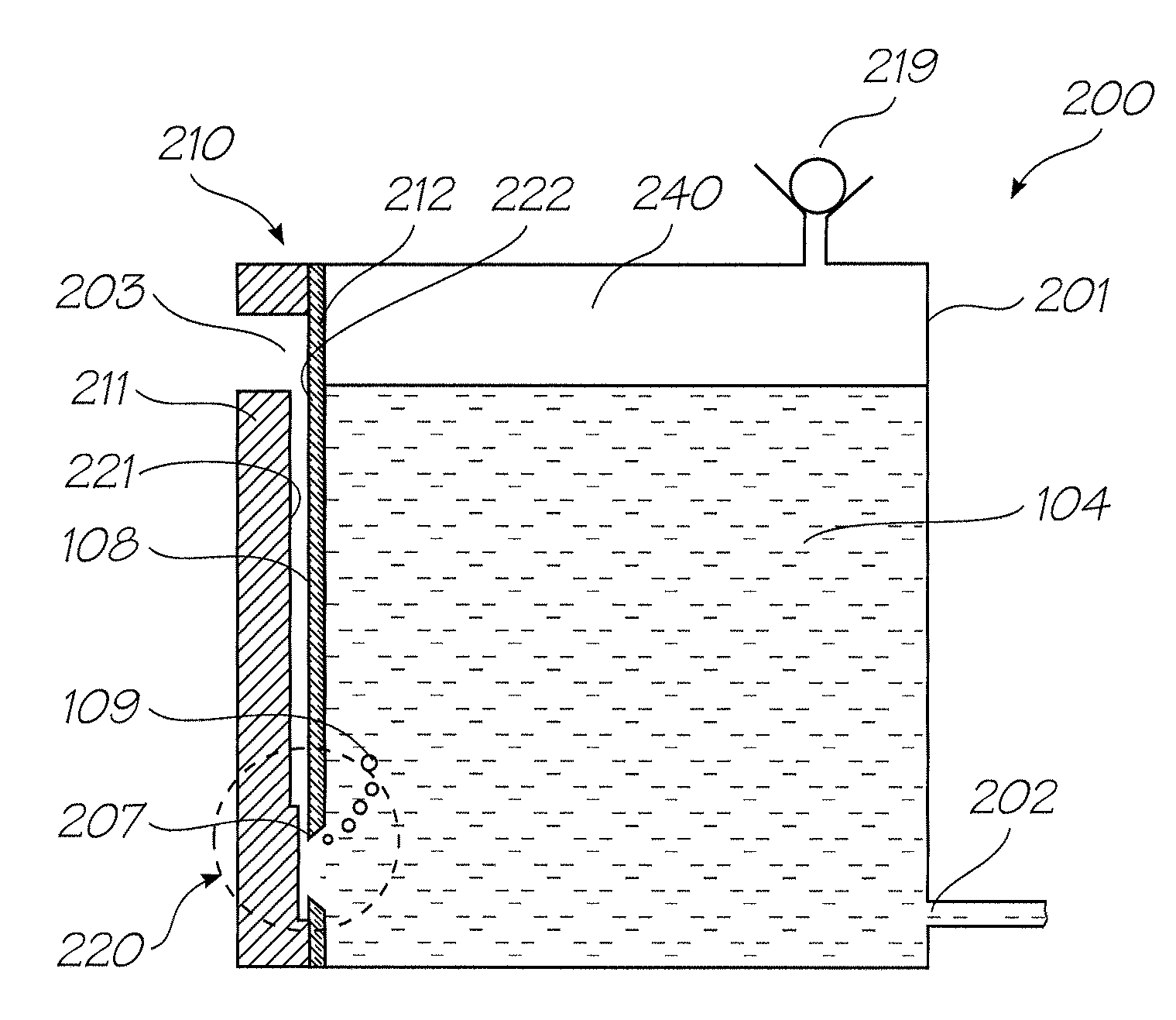

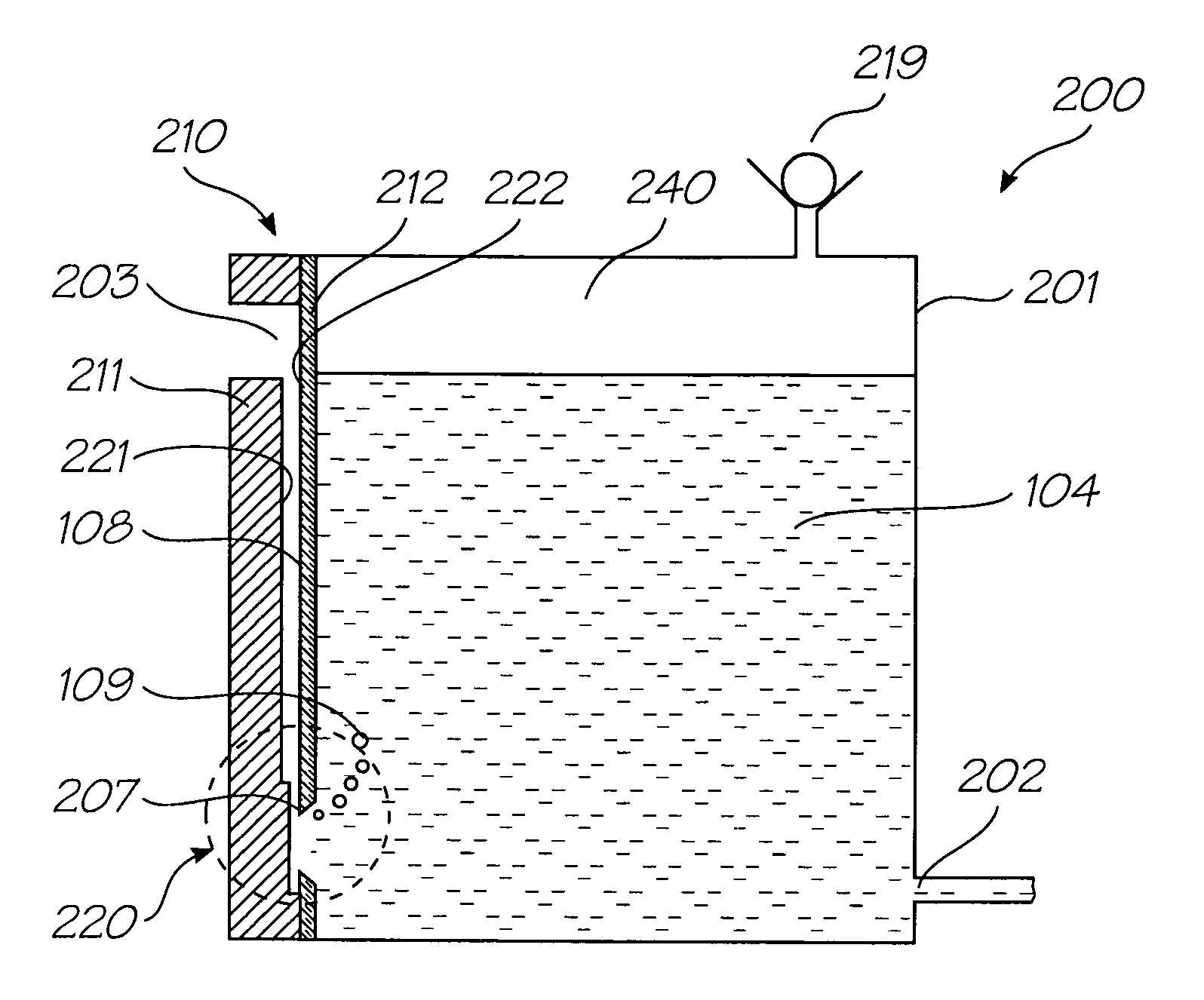

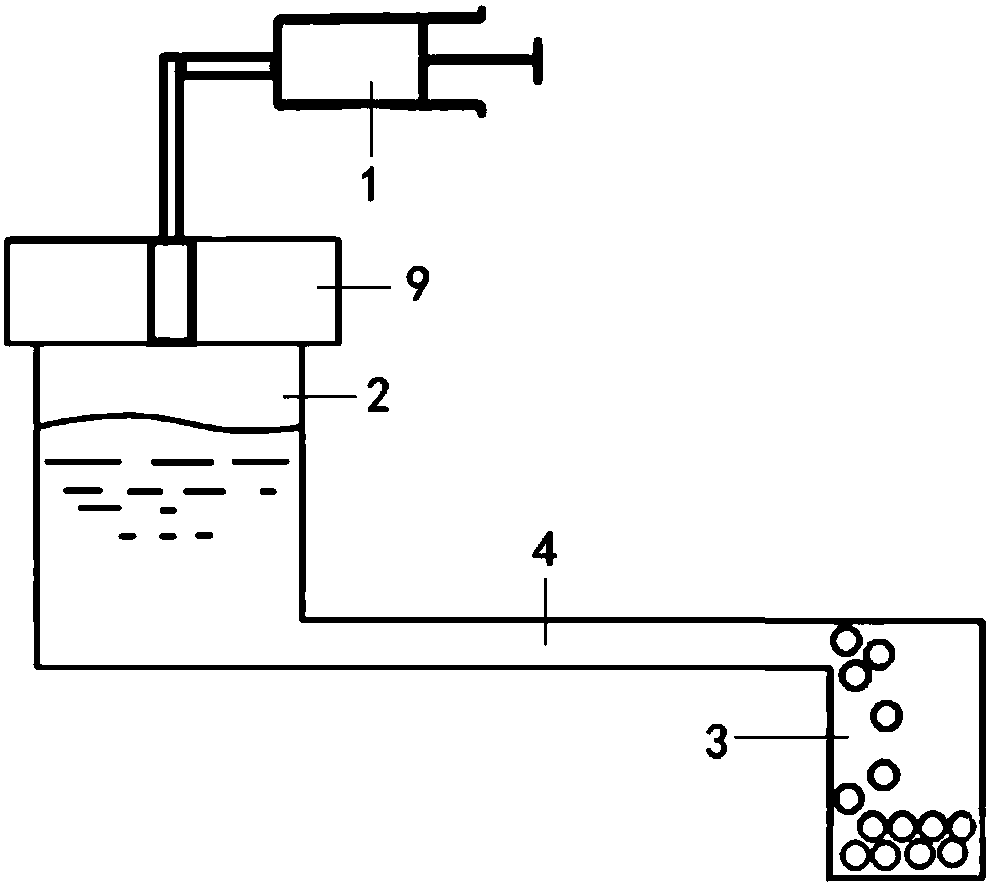

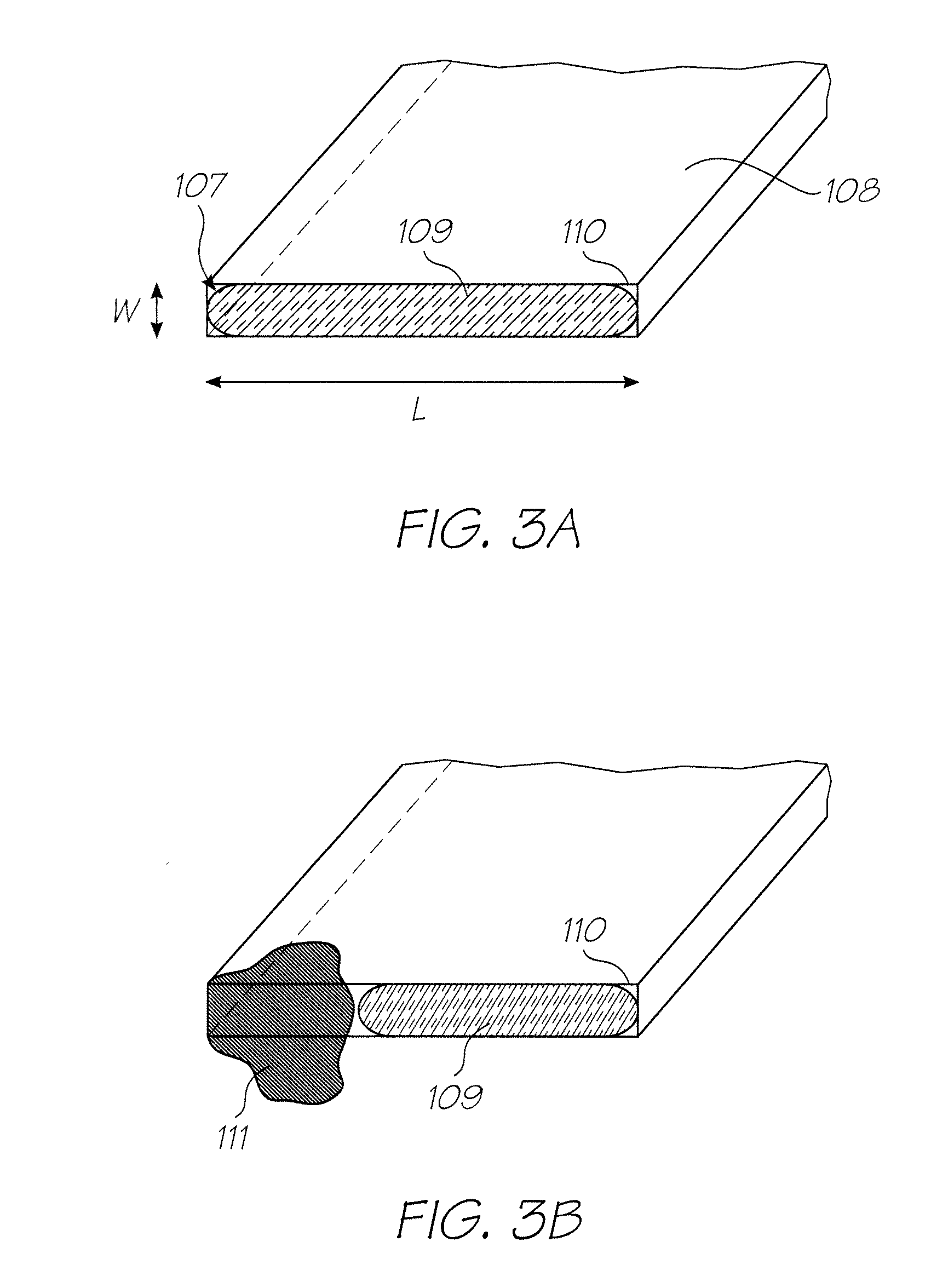

Ink pressure regulator with regulator channel fluidically isolated from ink reservoir

There is provided an ink pressure regulator for regulating a hydrostatic pressure of ink supplied to an inkjet printhead. The regulator comprises: an ink chamber having an ink outlet for fluid communication with the printhead via an ink line; an air inlet; a regulator channel having a first end communicating with the air inlet and a second end communicating with a headspace of the chamber, the second end defining a bubble outlet; and a wetting system for maintaining at least some liquid in the regulator channel, thereby ensuring that air entering the headspace first passes through the liquid. The regulator channel is dimensioned to control a Laplace pressure of air bubbles drawn from the bubble outlet as result of supplying ink to the printhead, thereby regulating a hydrostatic pressure of the ink.

Owner:SILVERBROOK RES PTY LTD +1

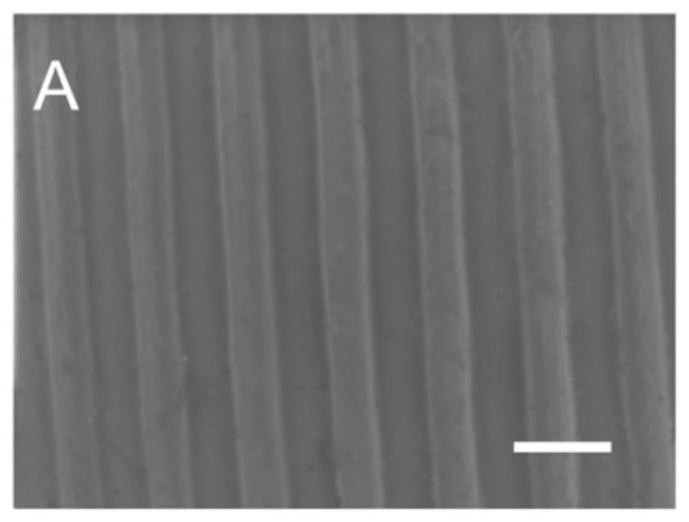

Stable superhydrophobic metal surface with three-dimensional three-stage micro-nano structure and preparation method thereof

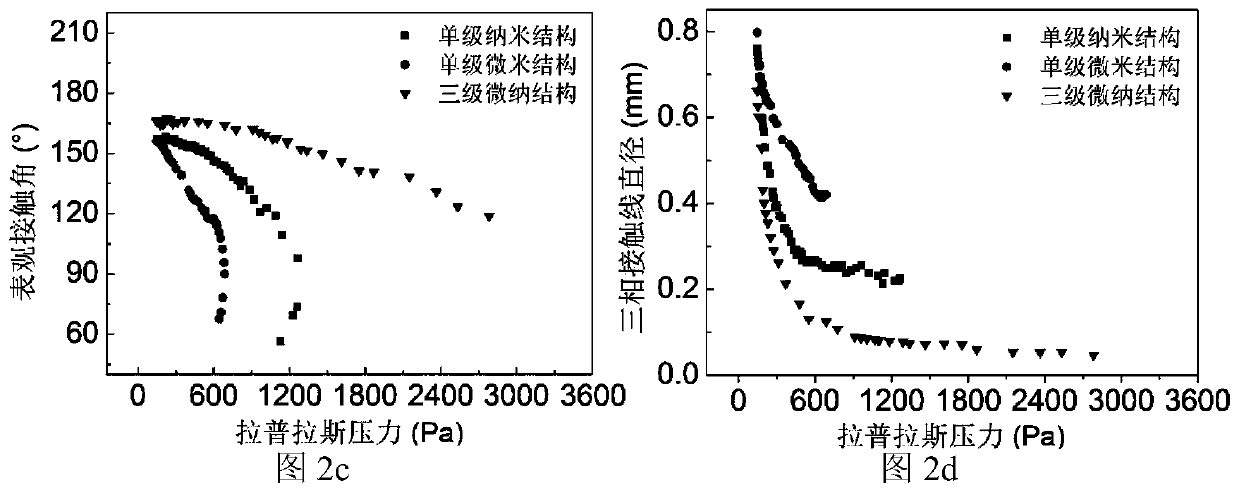

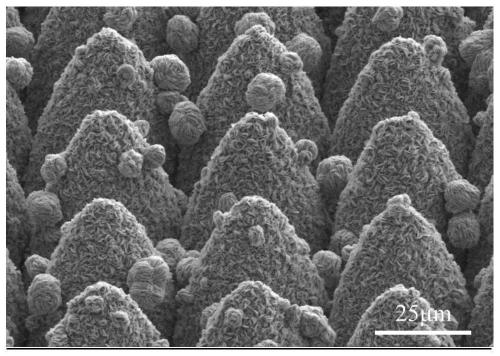

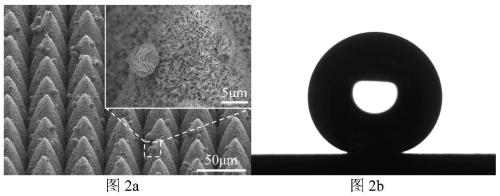

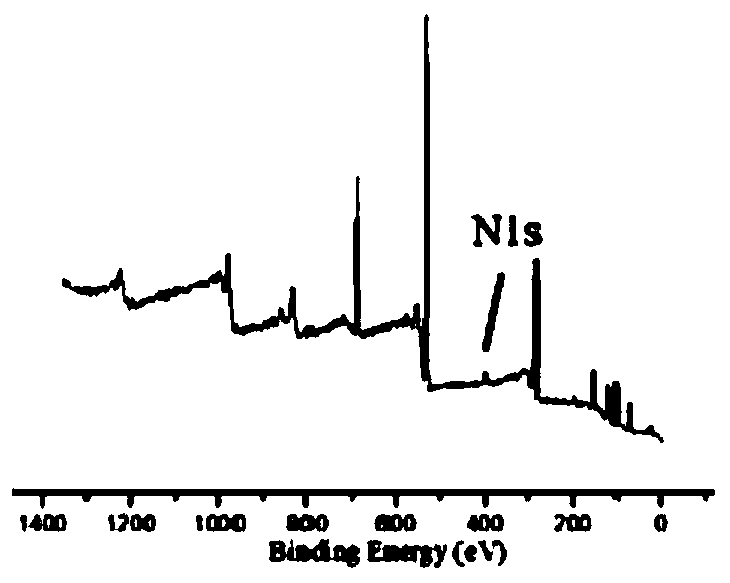

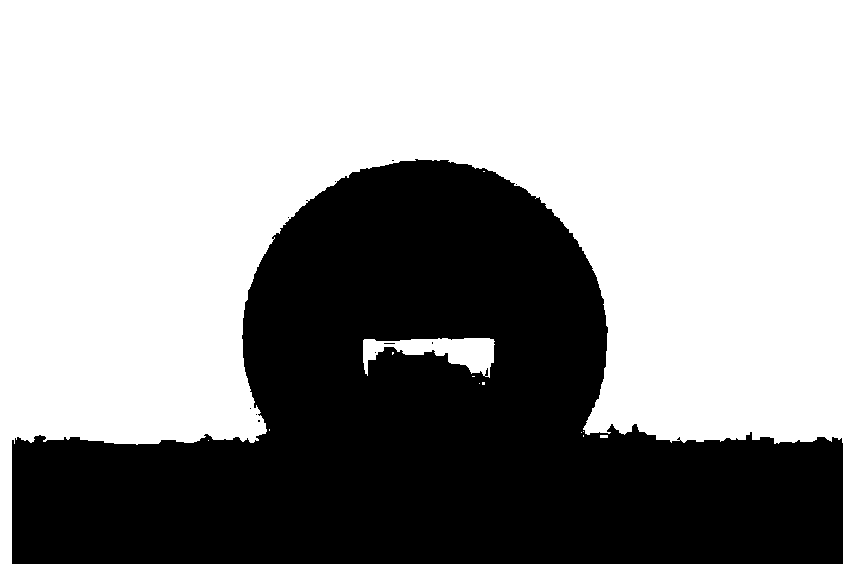

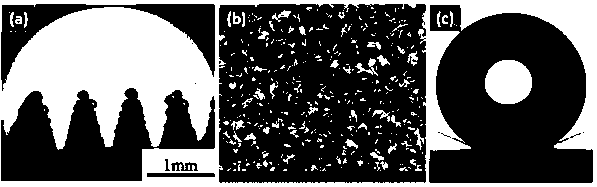

ActiveCN109881193AHigh Cassie state stabilityImprove self-cleaning functionMaterial nanotechnologyMetallic material coating processesMetallic substratePollution

The invention discloses a stable superhydrophobic metal surface with a three-dimensional three-stage micro-nano structure and a preparation method thereof, and belongs to the technical field of structuring functional surfaces. The metal surface contains the three-stage micro-nano structure, the structure is based on a three-dimensional micron cone structure distributed on the surface of a metal substrate, one-dimensional nanorods, nanotubes or two-dimensional nanosheets densely growing radially are distributed on the surfaces of the micron cones, and micron balls or micron flowers are distributed on the surfaces of the micron cones and among the micron cones. The preparation method adopts a composite method combining ultra-fast laser ablation and chemical oxidation for preparation, and then through chemical modification of the surface with low free energy, the high-stable super-hydrophobic self-cleaning function is realized, and the contact angle can be still larger than 150 degrees when bearing the Laplace pressure being up to 1400Pa. The method has the advantages of high efficiency, capable of being controlled and large-area preparation, and can be widely used in the applicationfields of superhydrophobic self cleaning, anti-icing, anti-corrosion, anti-pollution, anti-bacterial, water collection, resistance reduction, oil and water separation and the like.

Owner:TSINGHUA UNIV

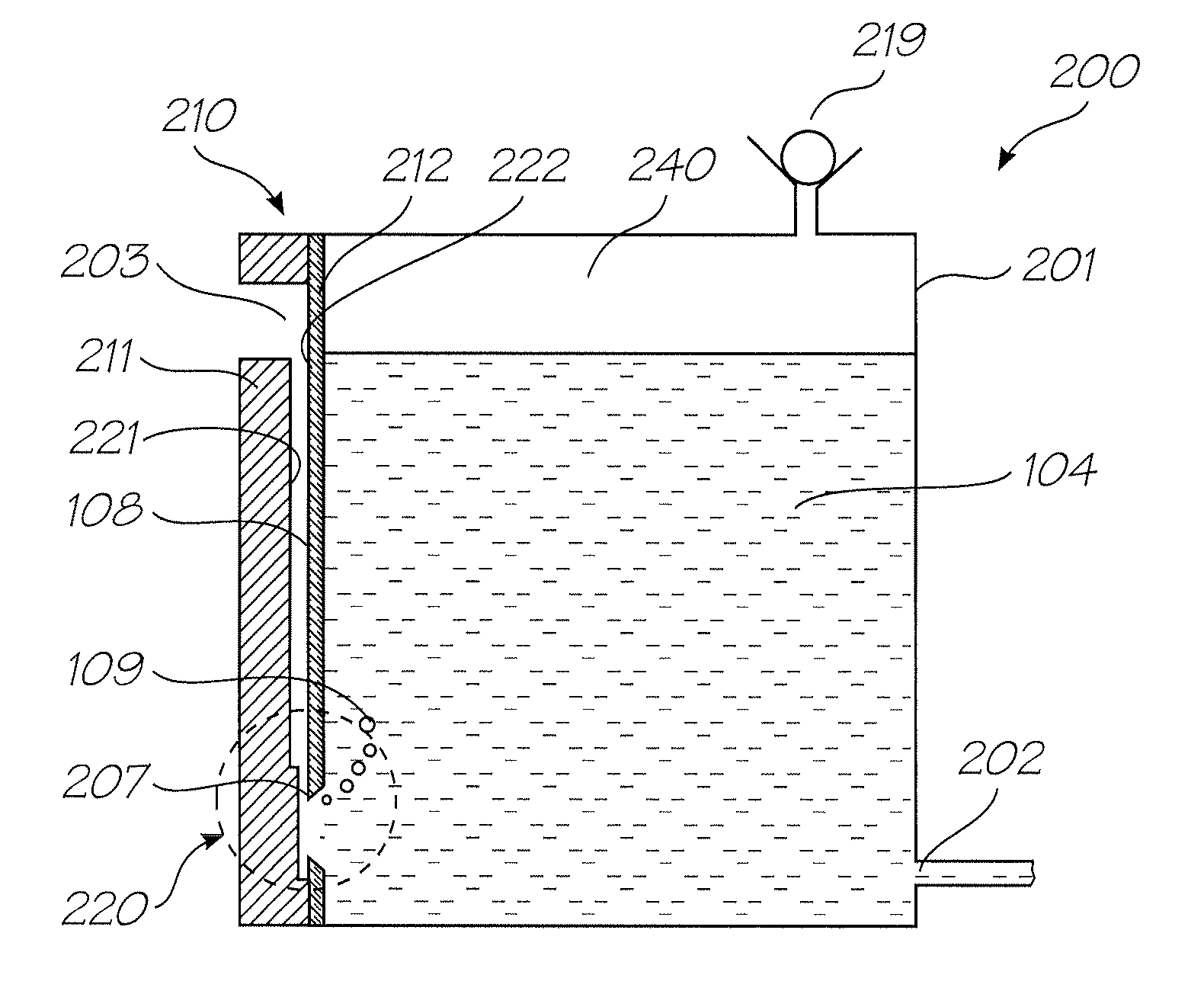

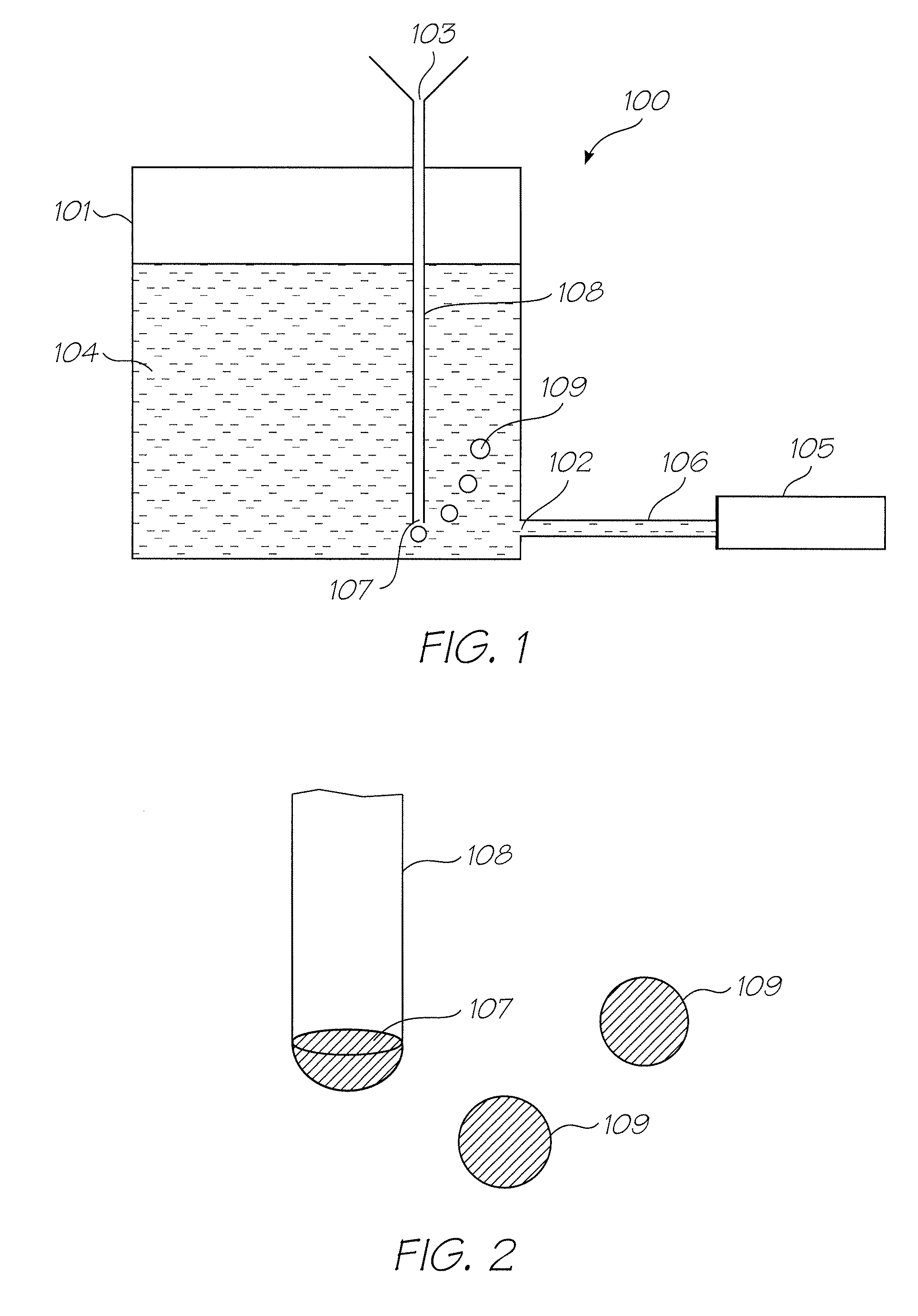

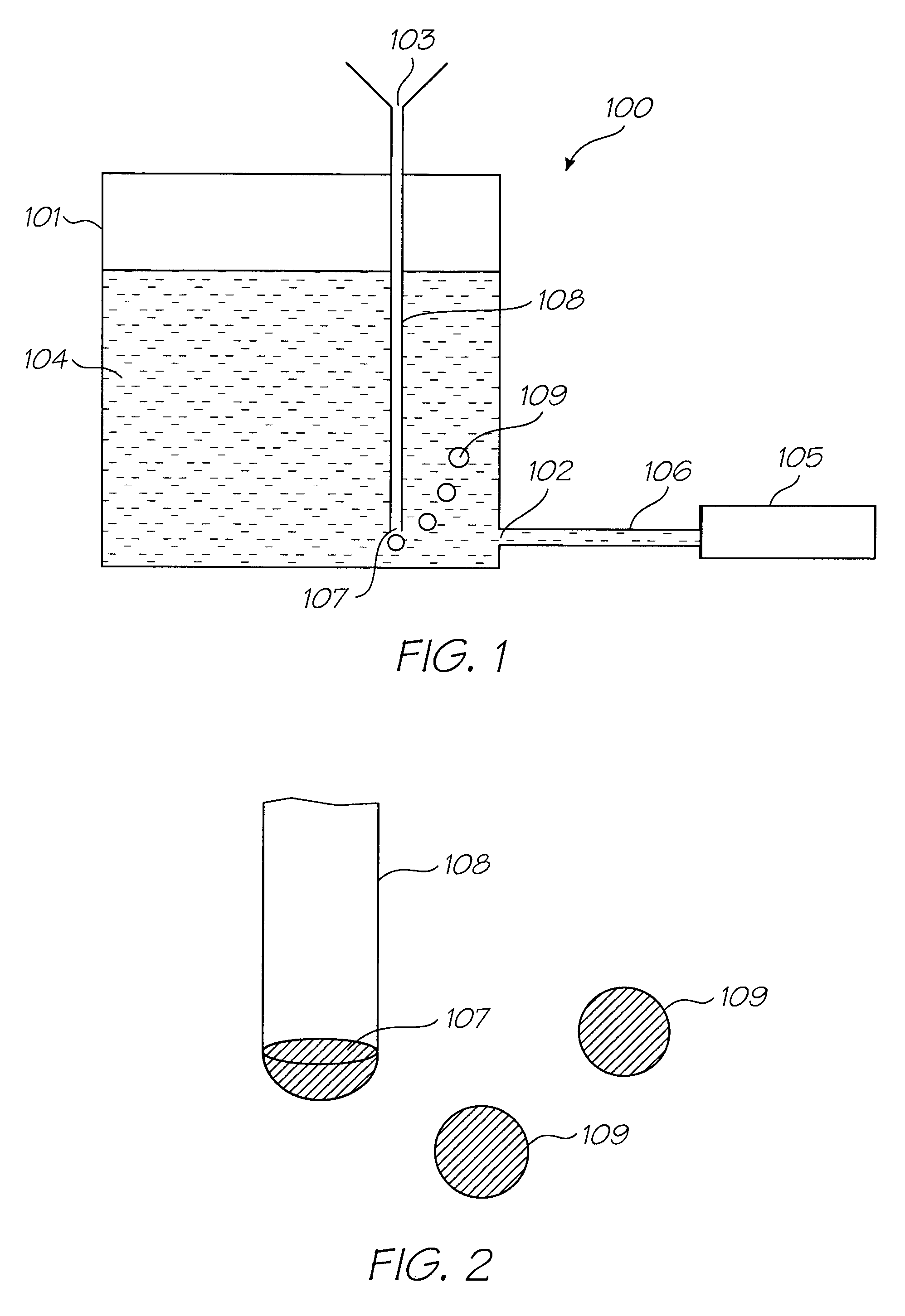

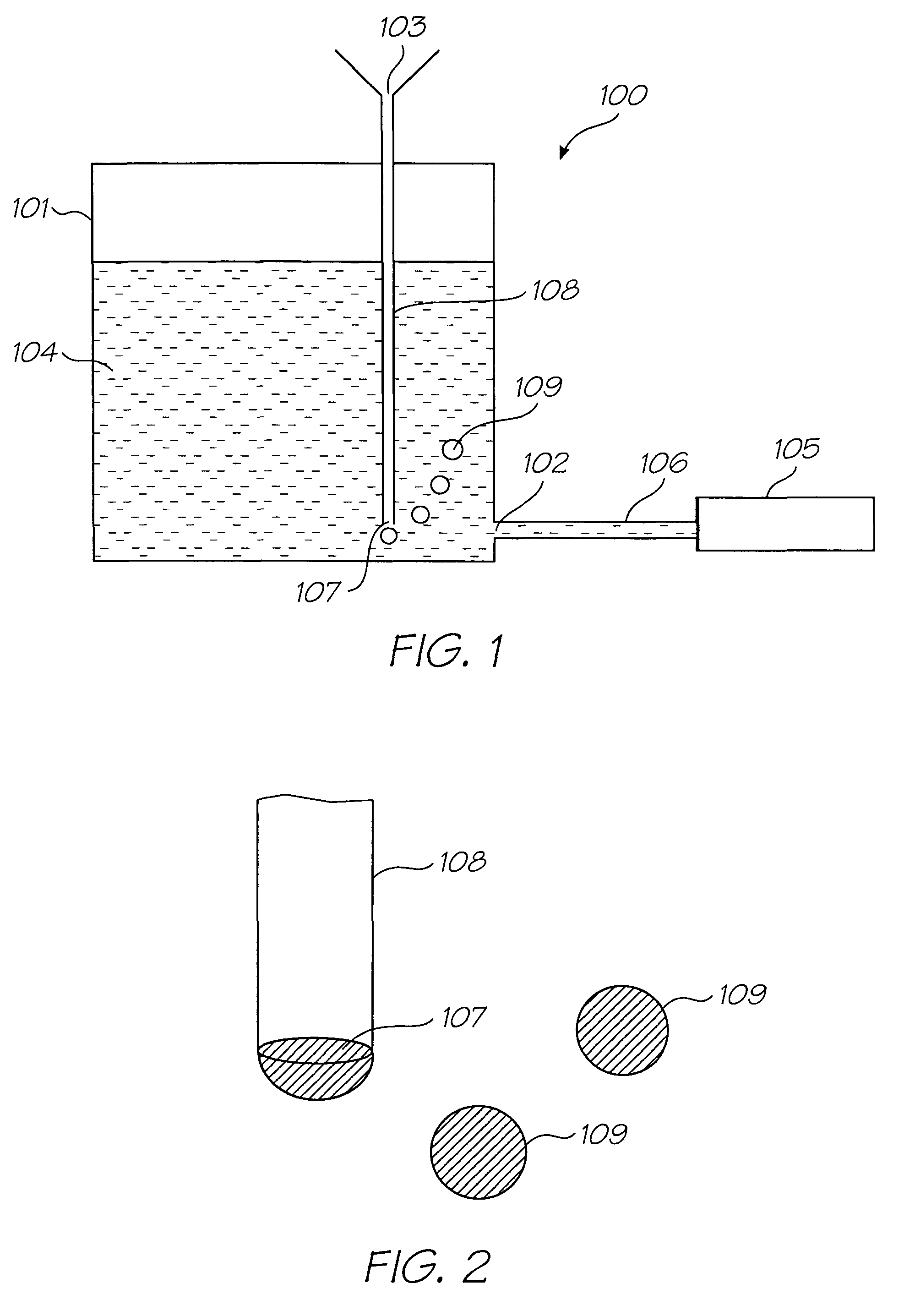

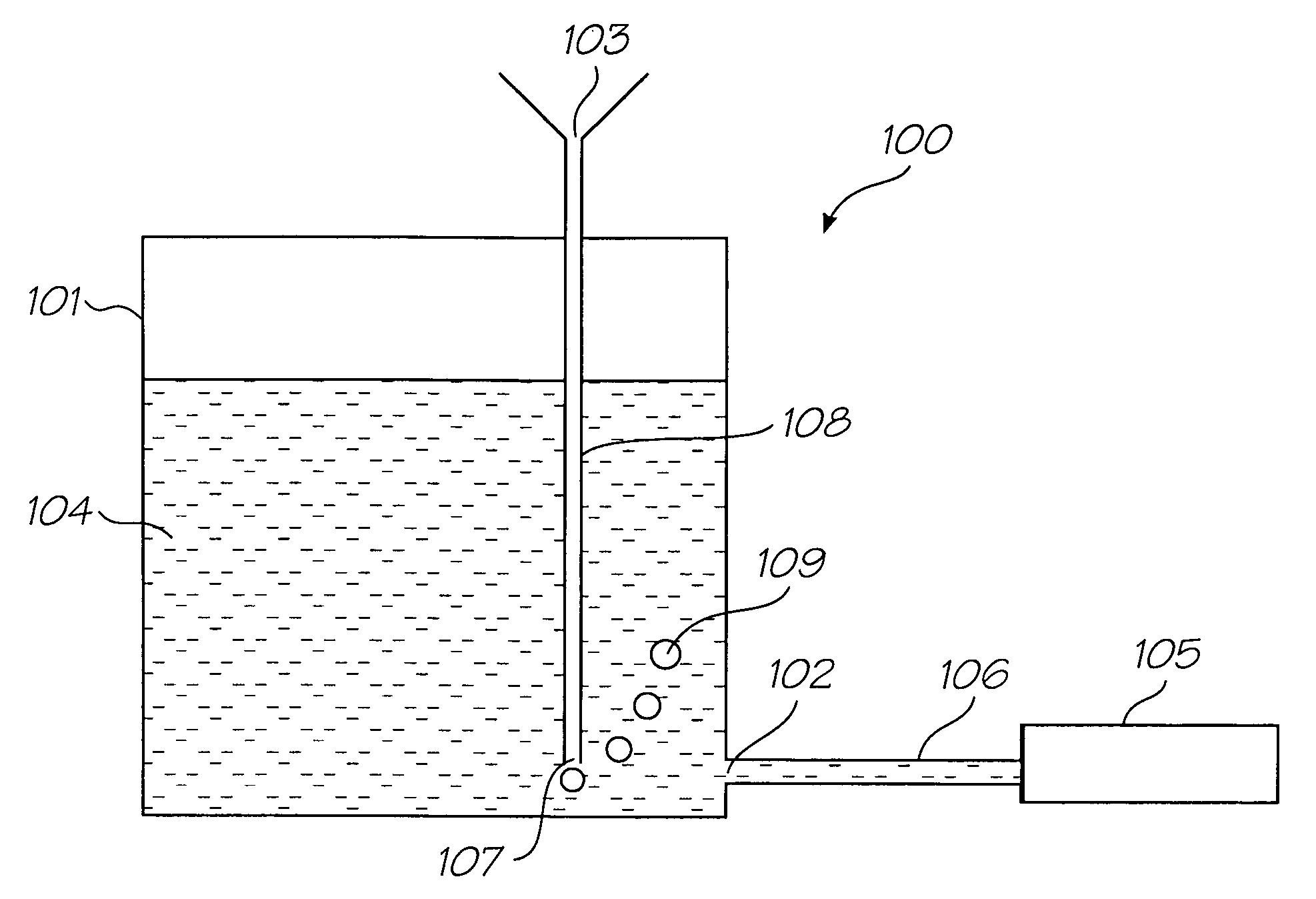

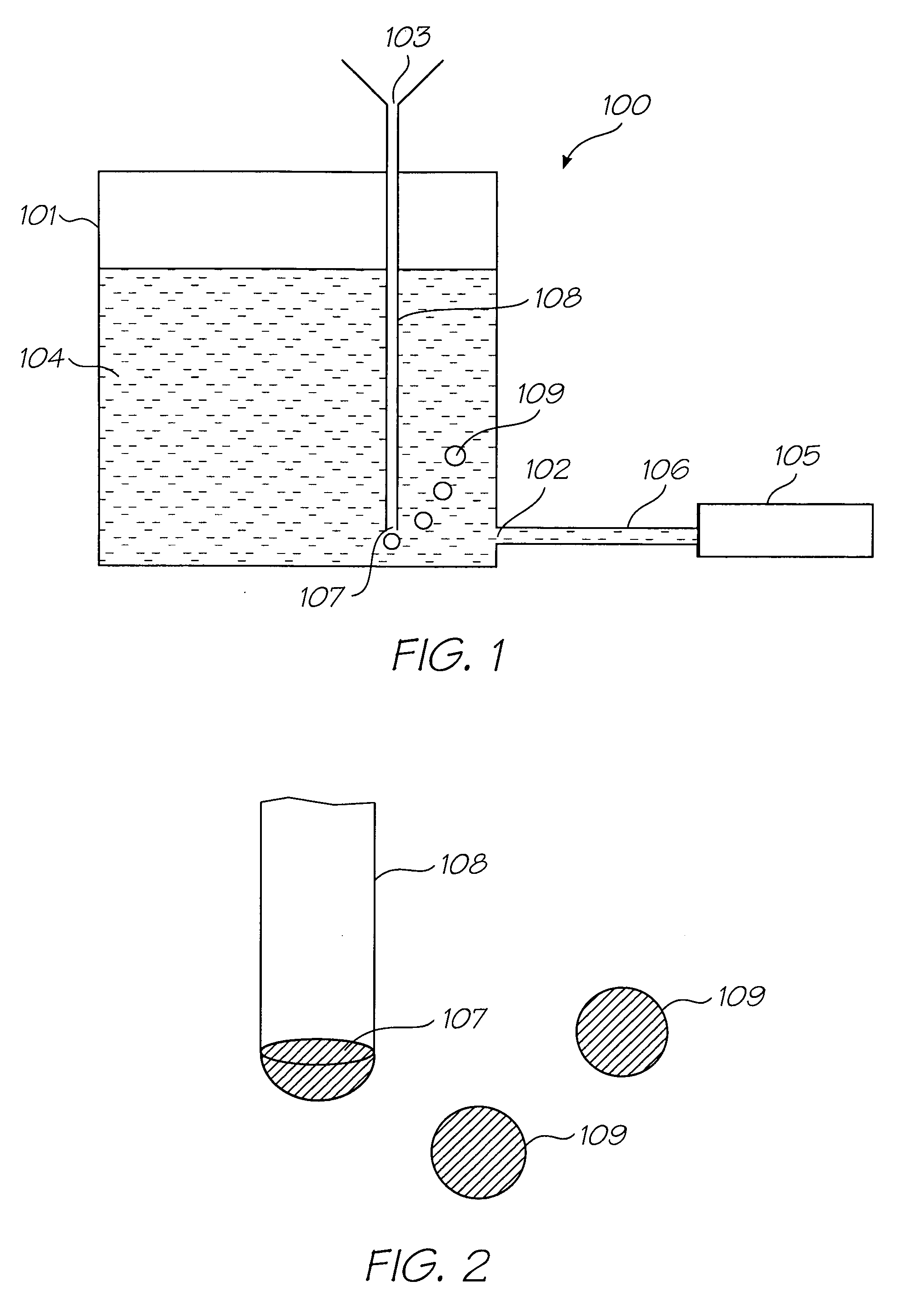

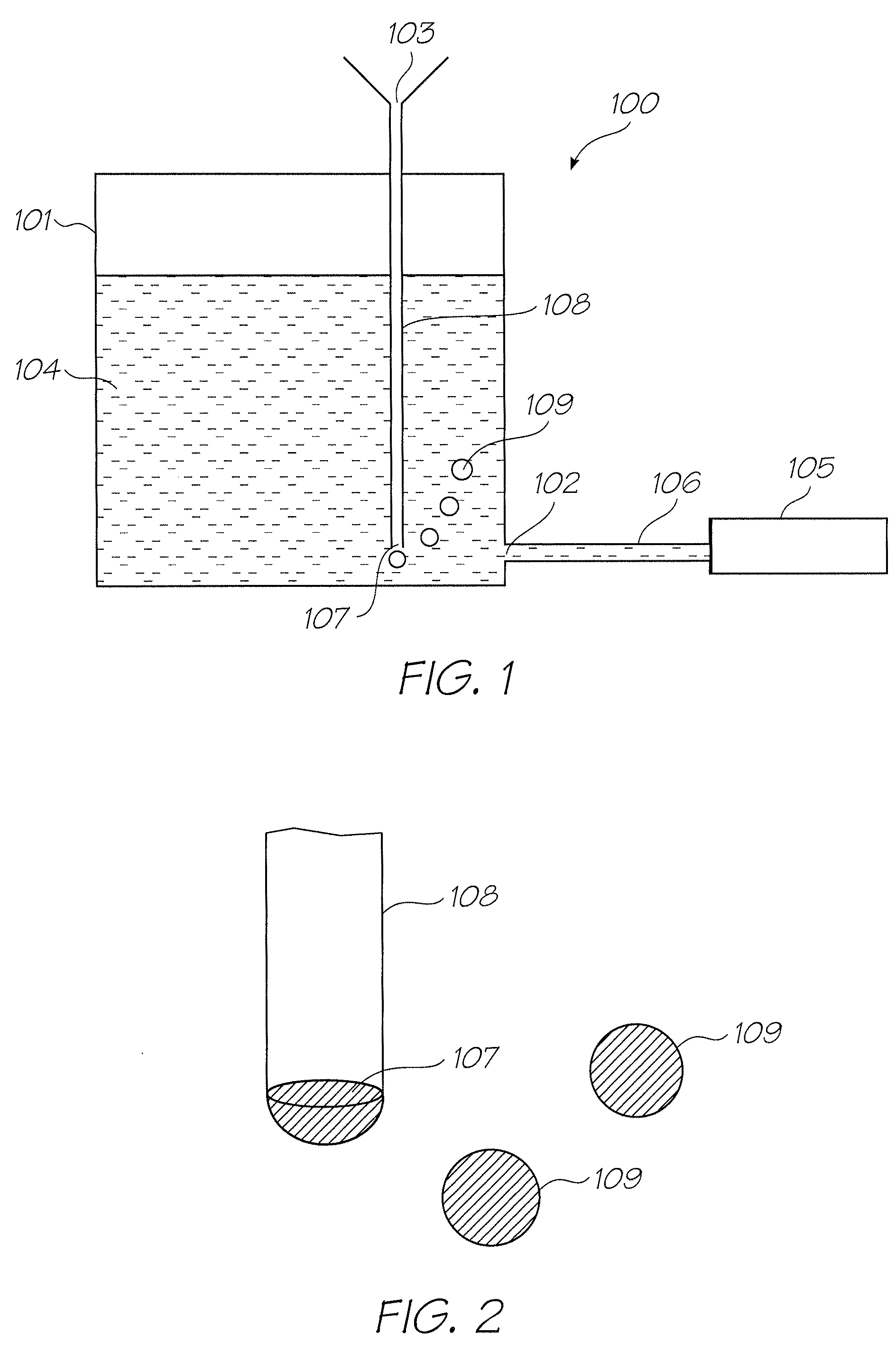

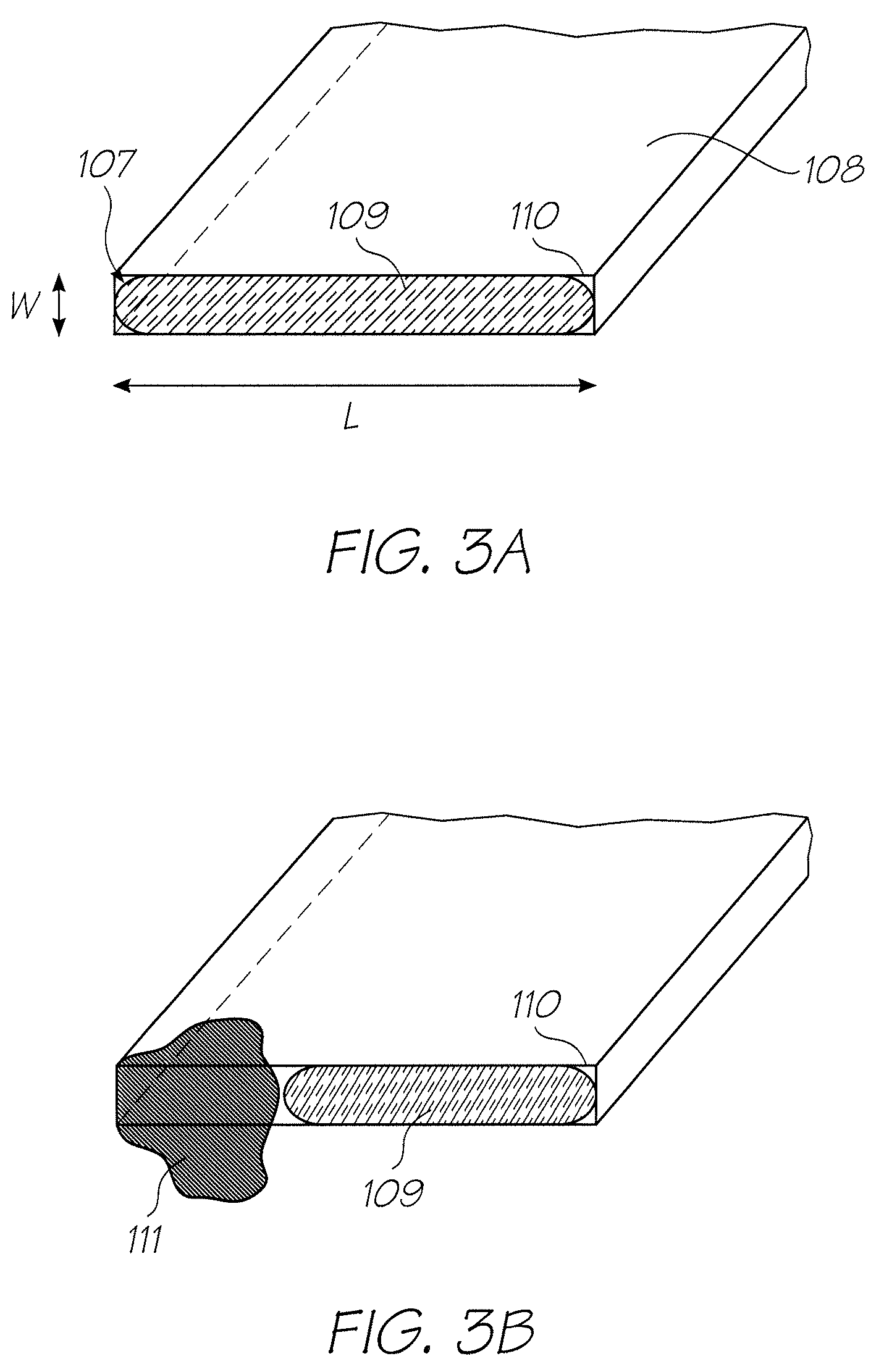

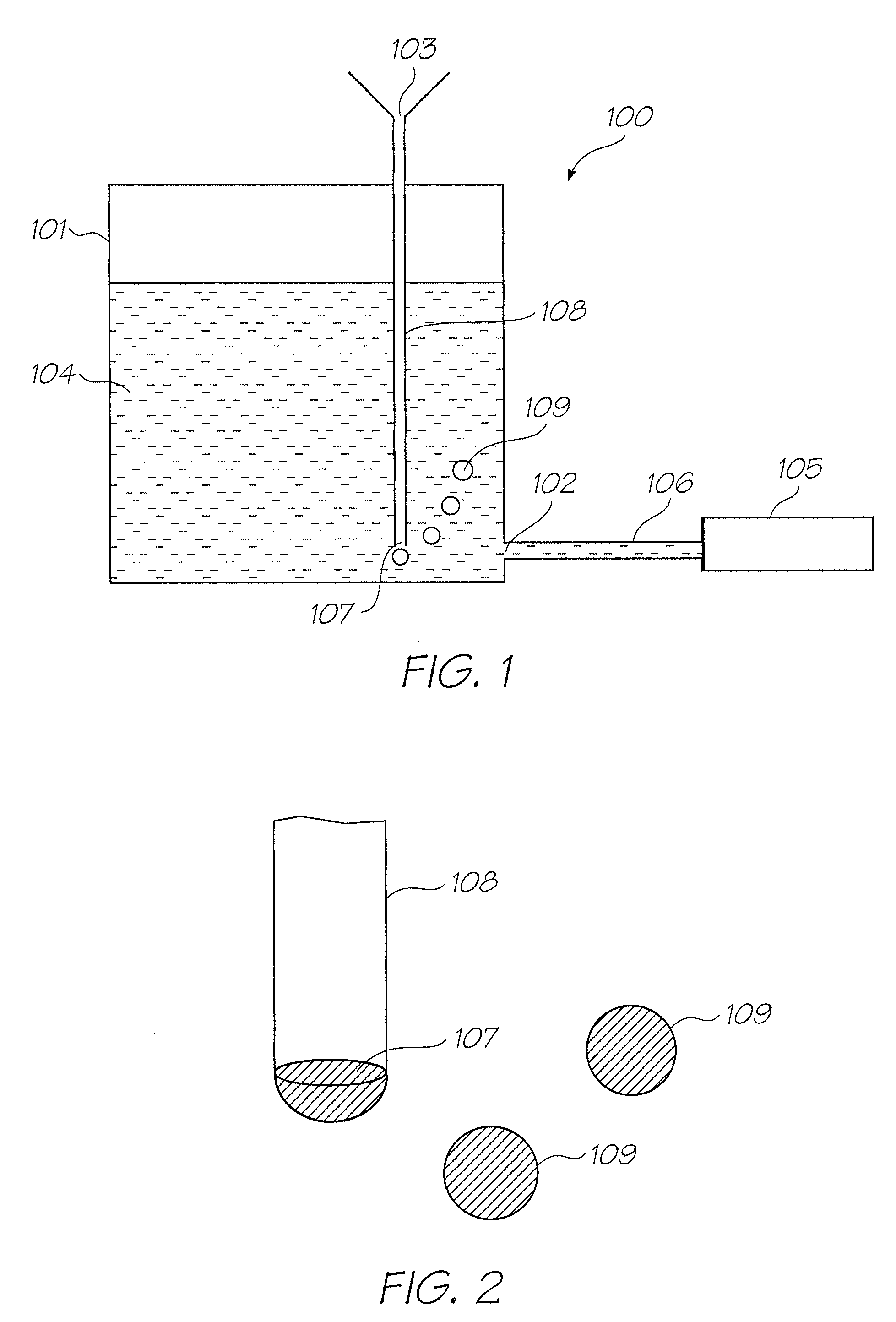

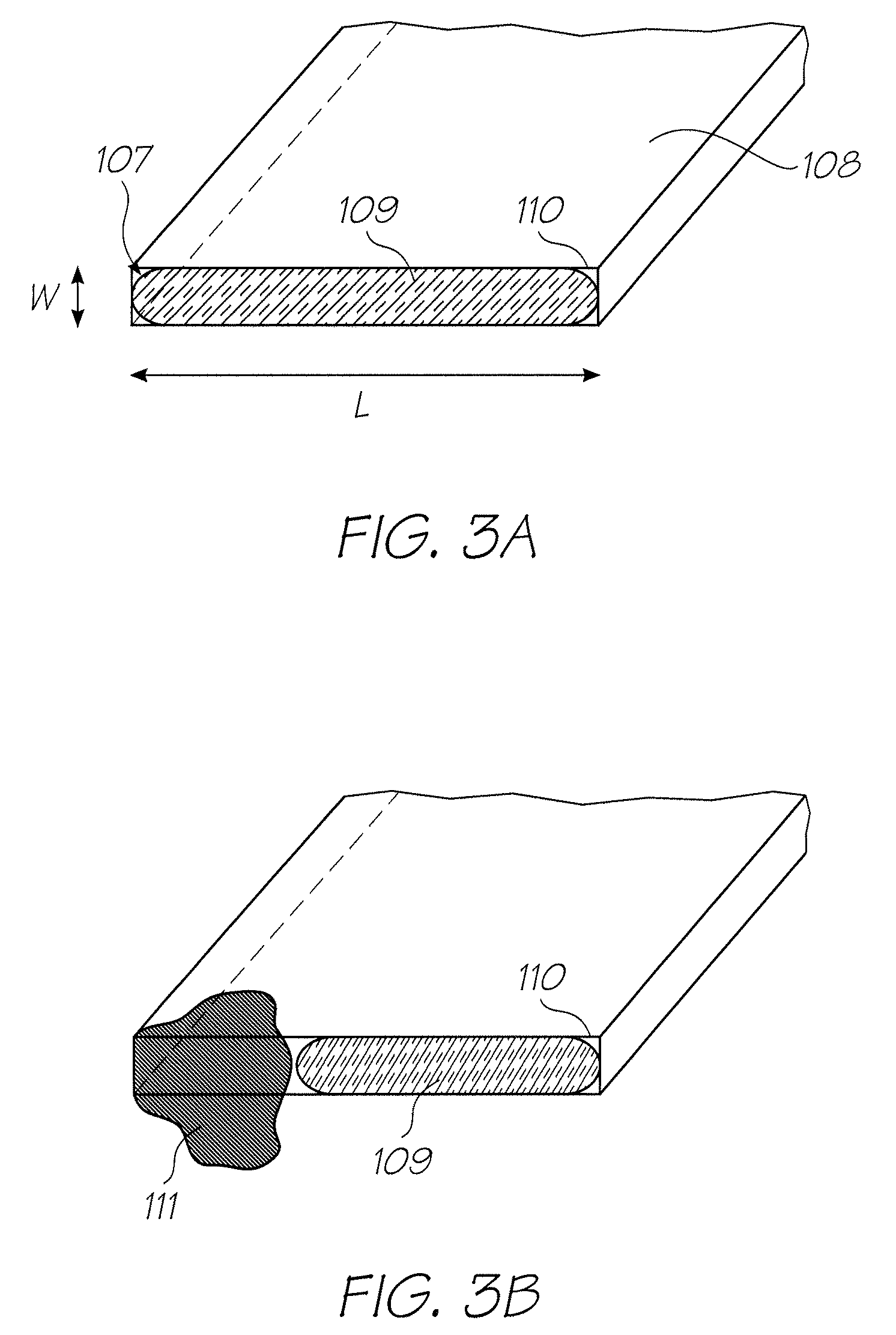

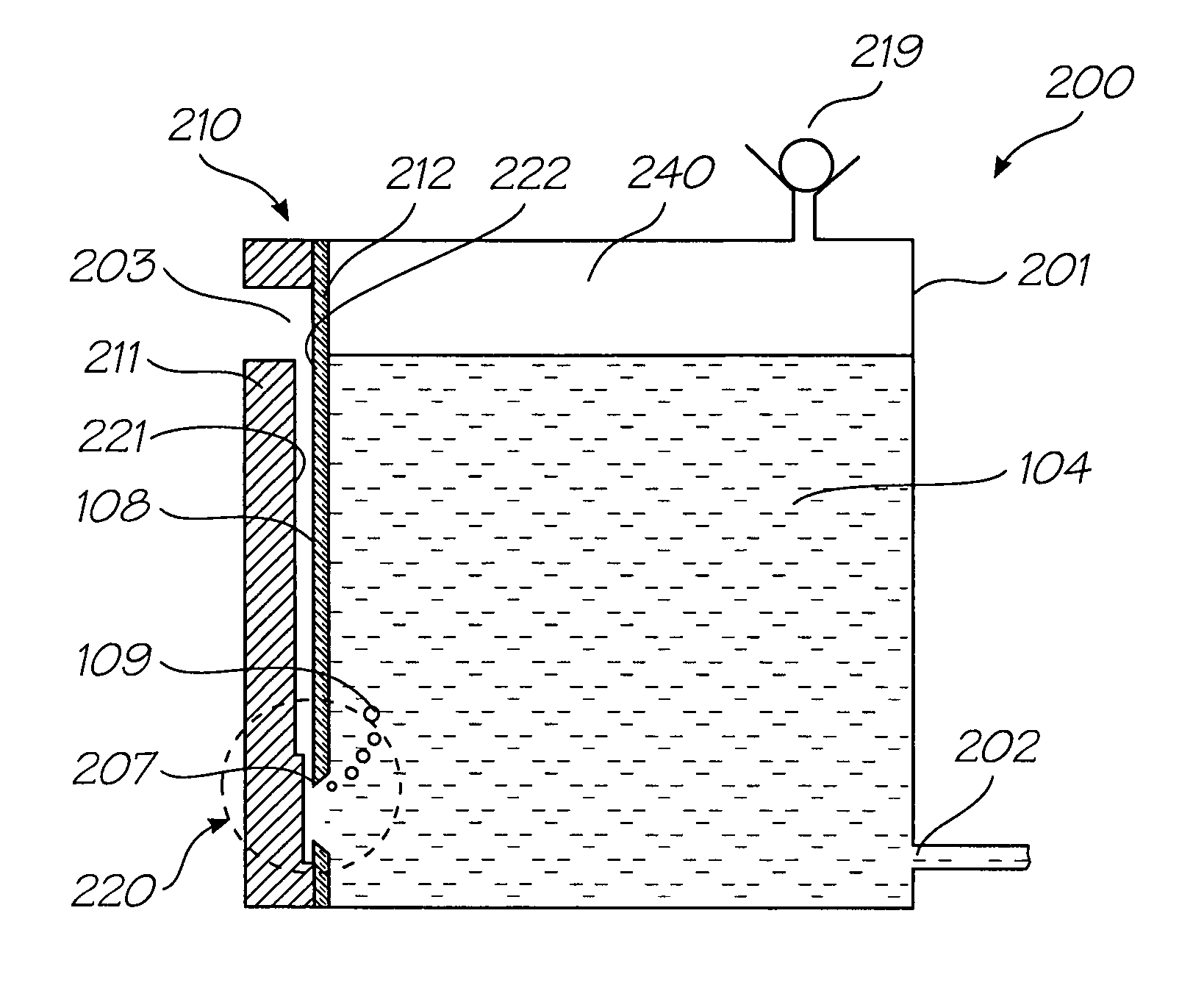

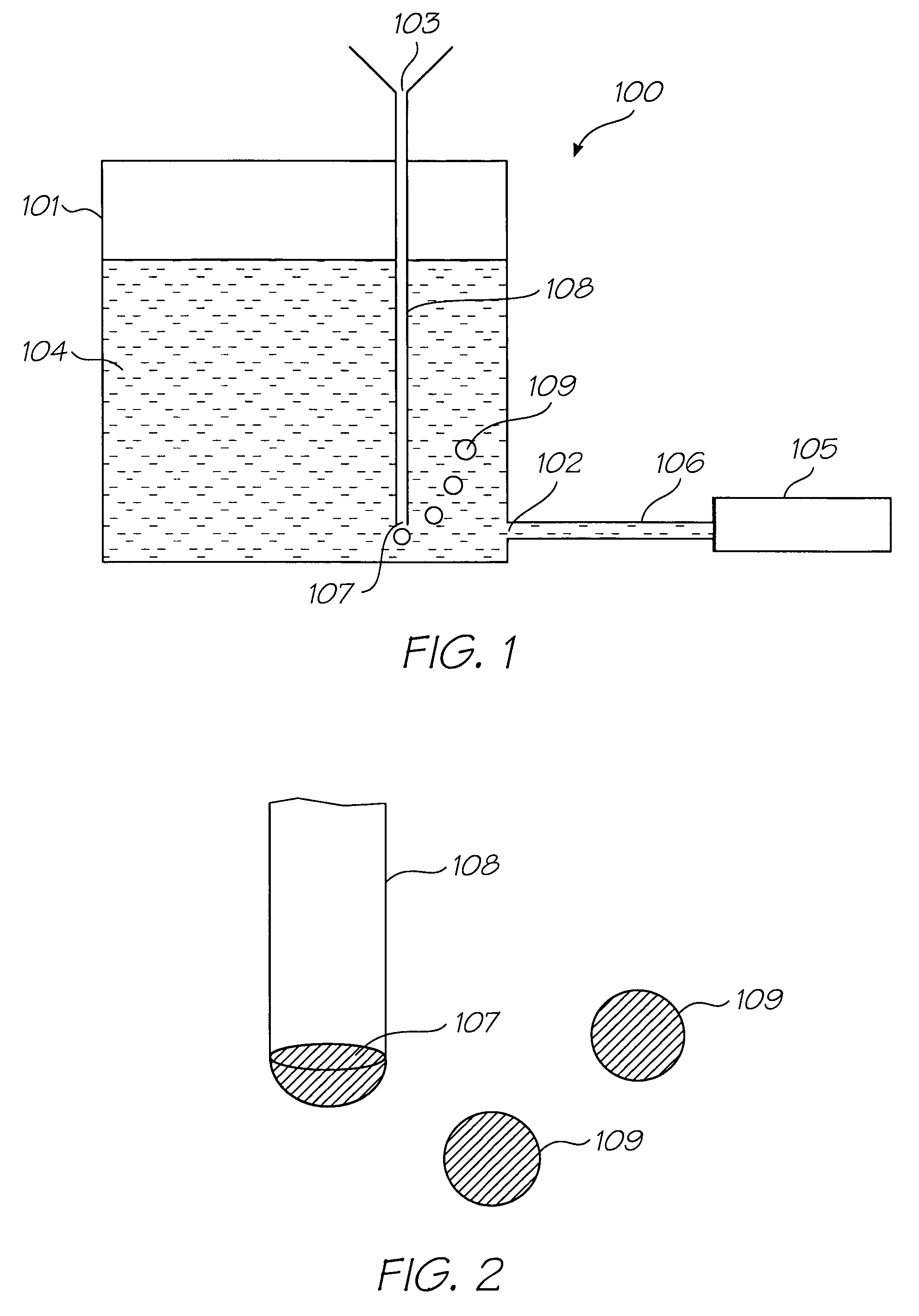

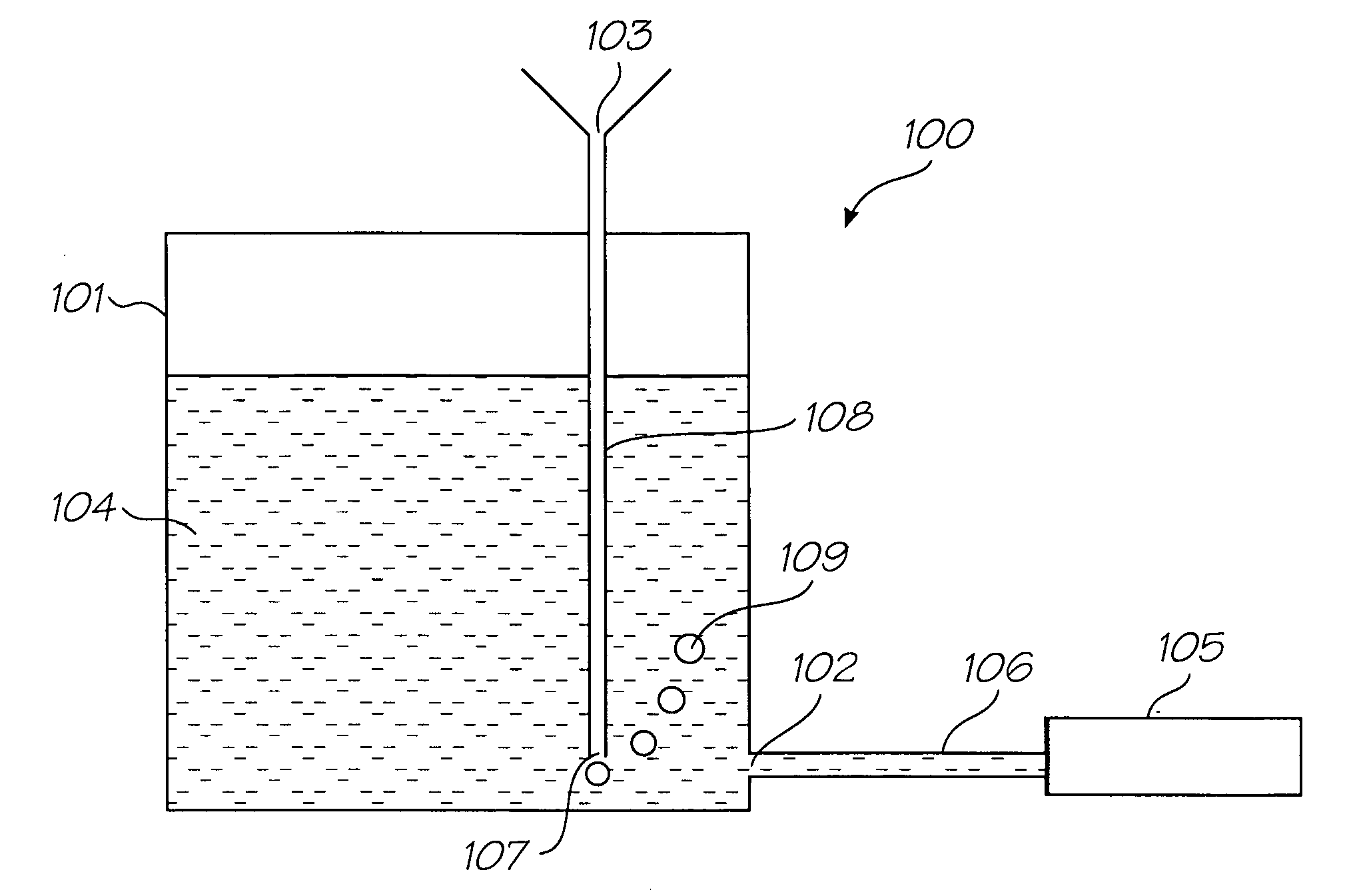

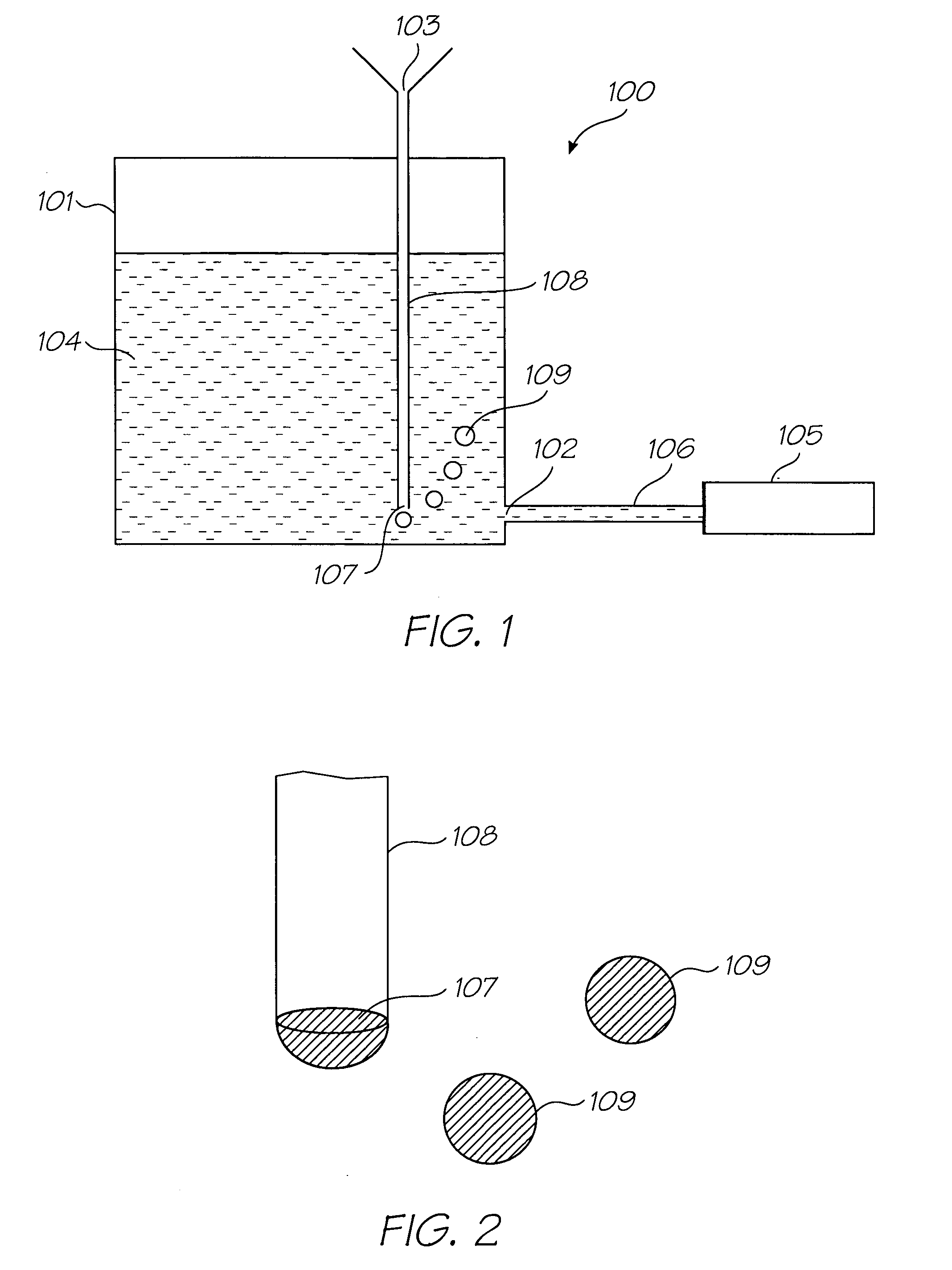

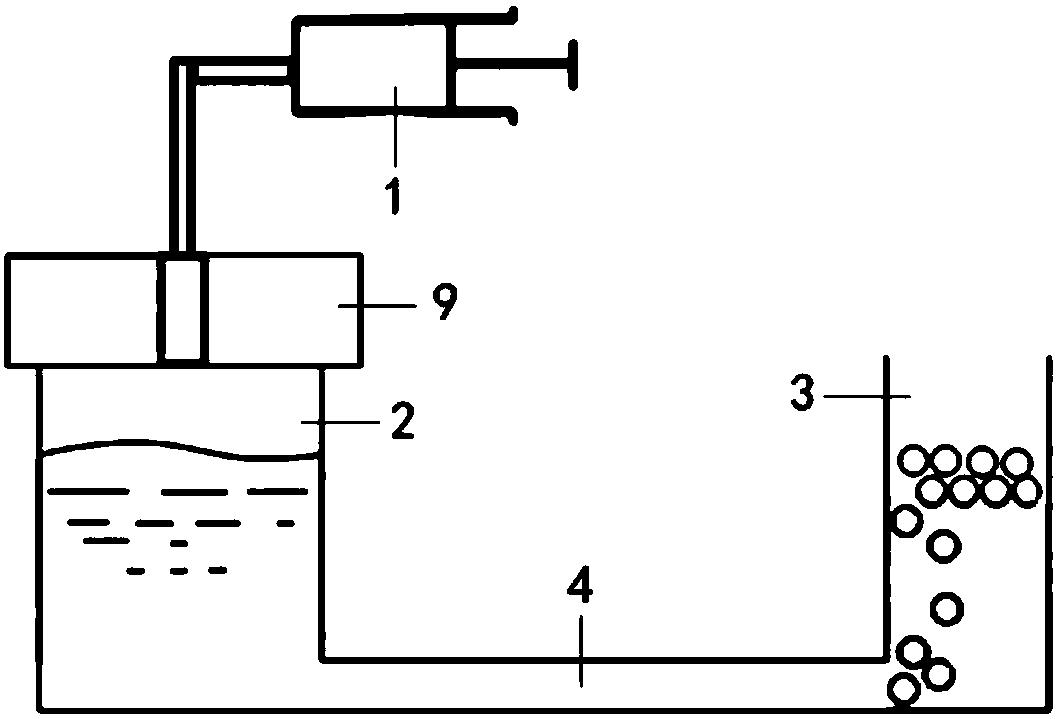

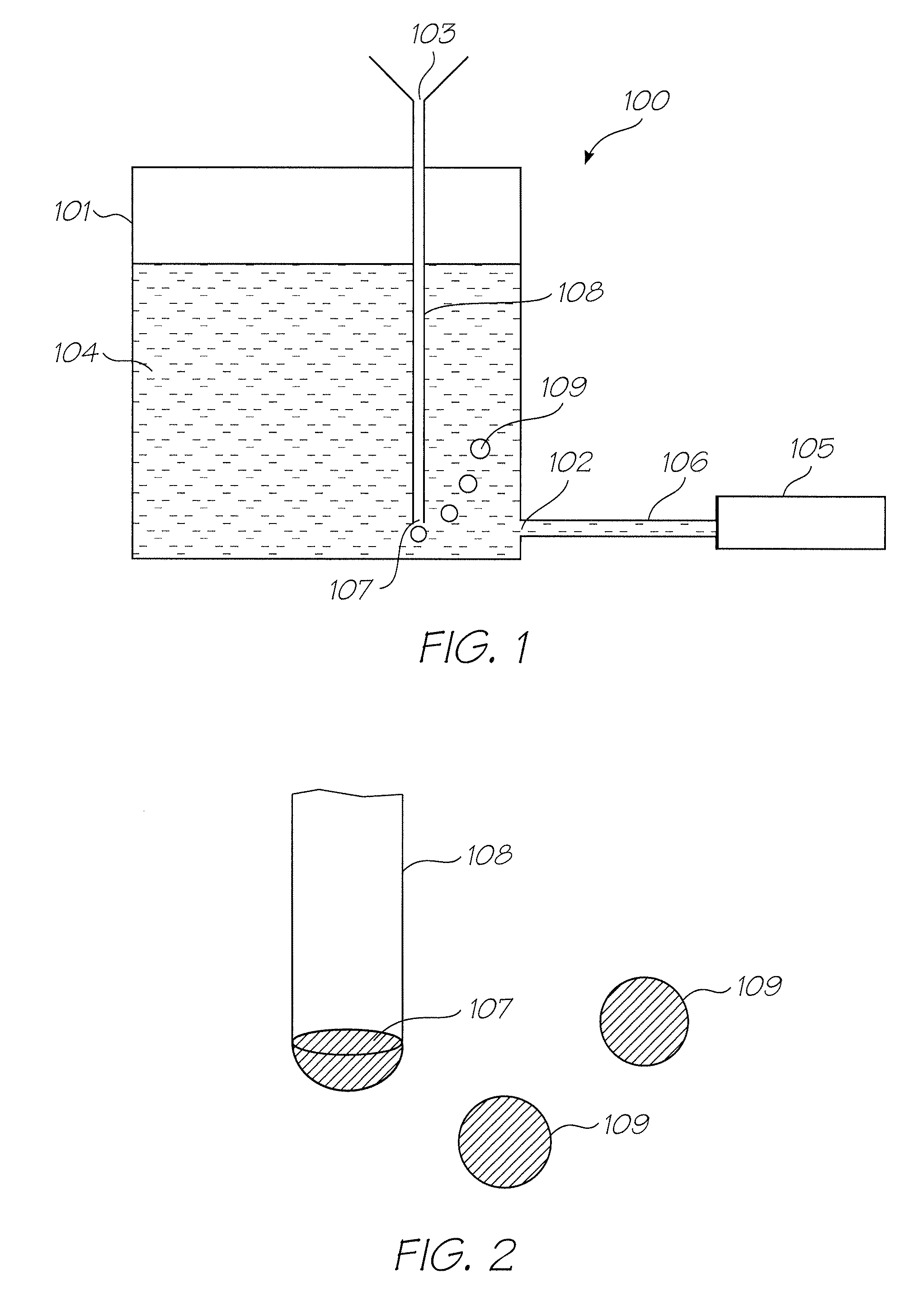

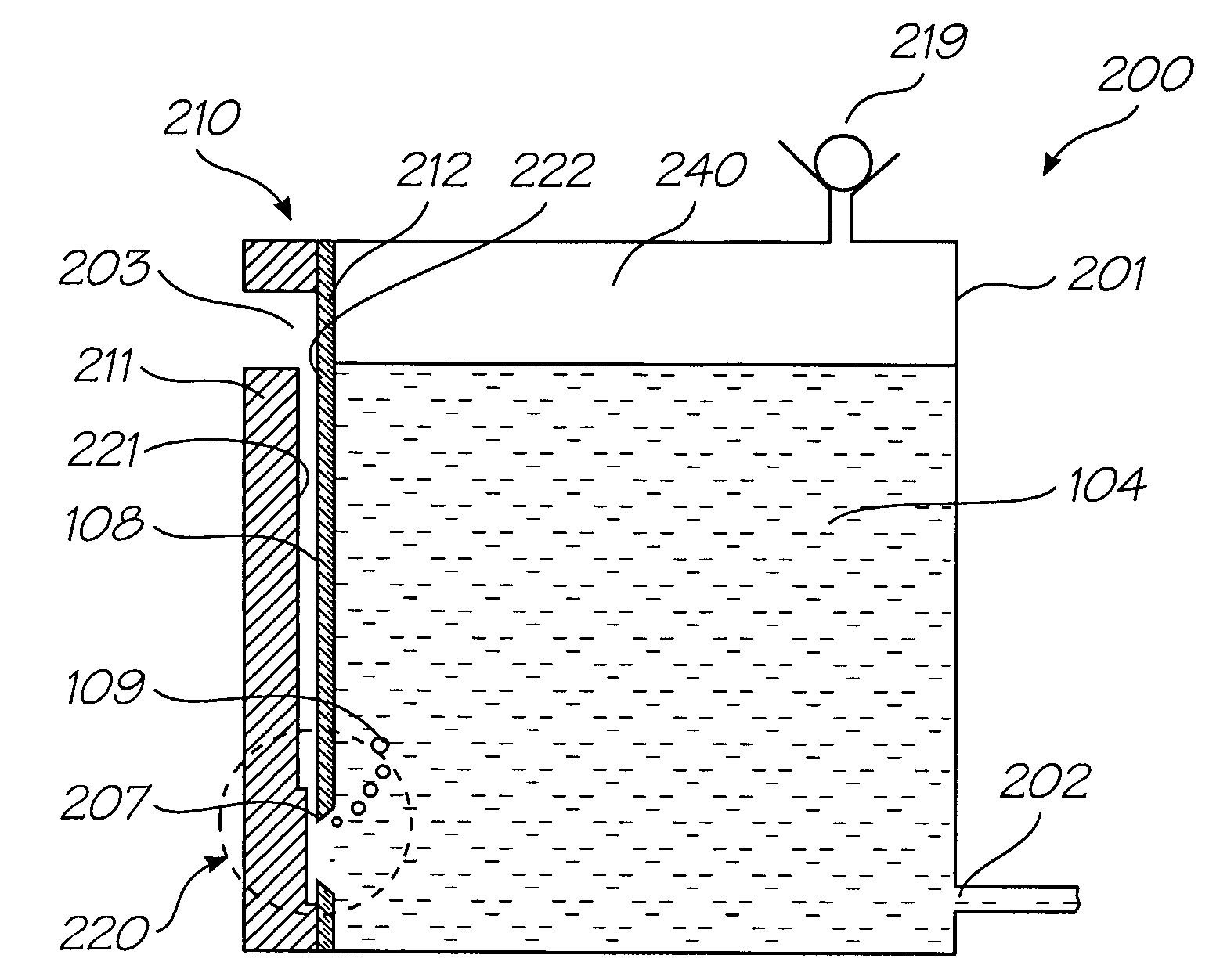

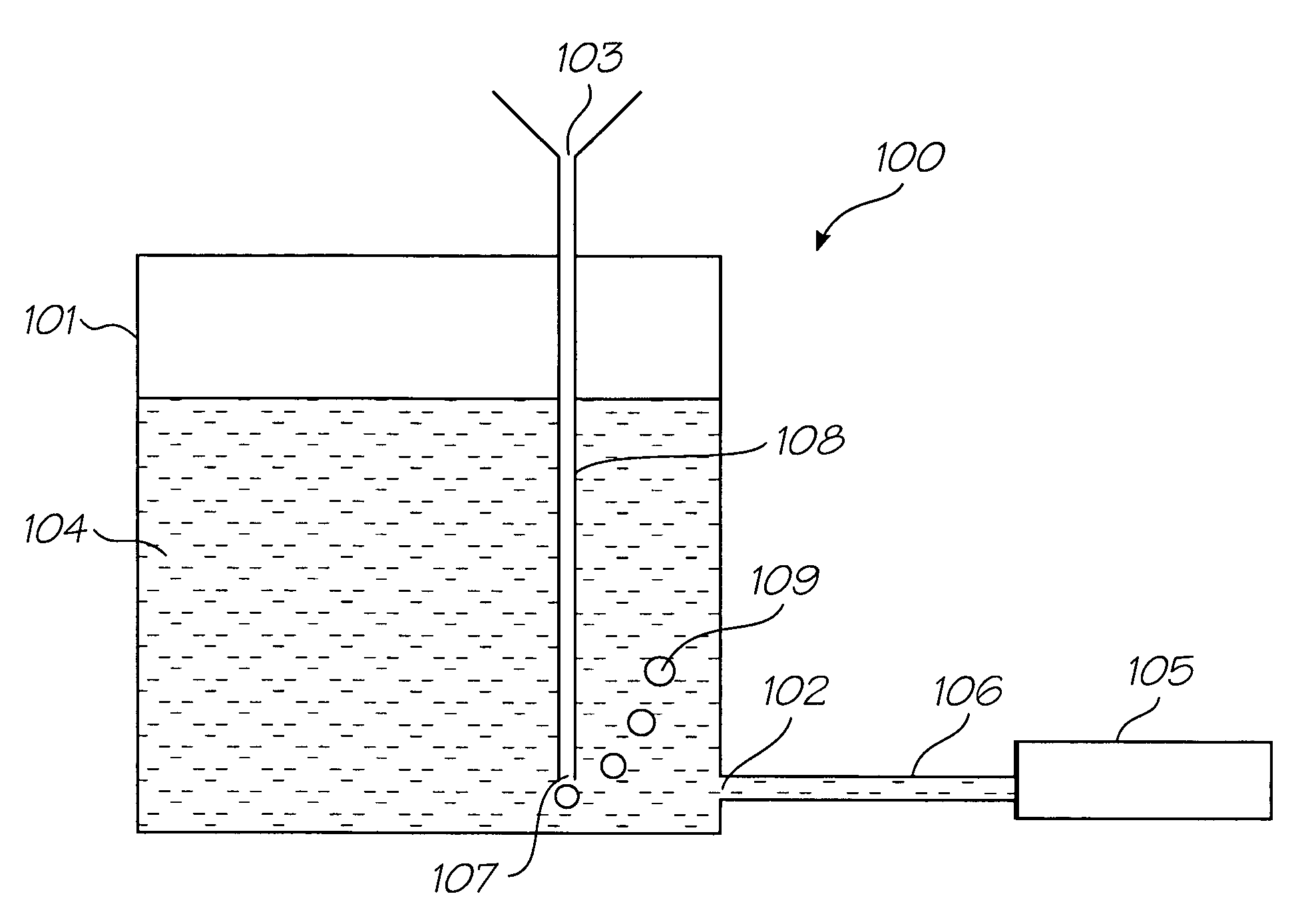

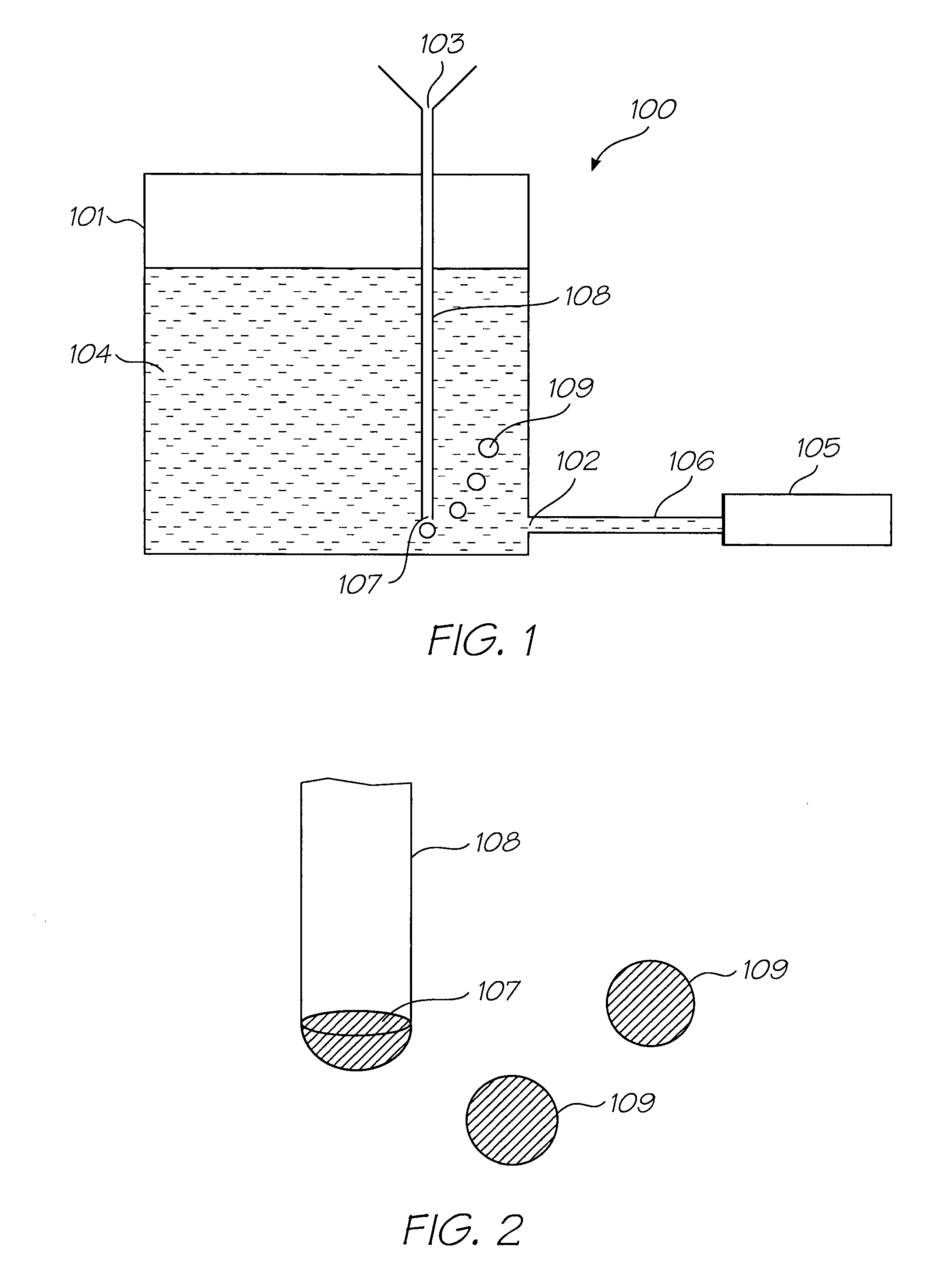

Ink pressure regulator using air bubbles drawn into ink

There is provided an ink pressure regulator for regulating a hydrostatic pressure of ink supplied to an inkjet printhead. The regulator comprises: an ink chamber having an ink outlet for fluid communication with the printhead via an ink line; an air inlet open to atmosphere; a bubble outlet positioned for bubbling air into ink contained in the chamber; and an air channel connecting the air inlet and the bubble outlet. The bubble outlet is dimensioned to control a Laplace pressure of air bubbles drawn into the ink as result of supplying ink to the printhead. Hence, the hydrostatic pressure of the ink is regulated.

Owner:MEMJET TECH LTD +1

Ink pressure regulator

There is provided an ink pressure regulator for regulating a hydrostatic pressure of ink supplied to an inkjet printhead. The regulator comprises: an ink chamber having an ink outlet for fluid communication with the printhead via an ink line; an air inlet open to atmosphere; a bubble outlet for bubbling air bubbles into the chamber, each air bubble comprising an air cavity trapped inside a film or a body of ink; and an air channel connecting the air inlet and the bubble outlet. The bubble outlet is dimensioned to control a Laplace pressure of air bubbles drawn into the chamber as result of supplying ink to the printhead, thereby regulating a hydrostatic pressure of the ink.

Owner:MEMJET TECH LTD +1

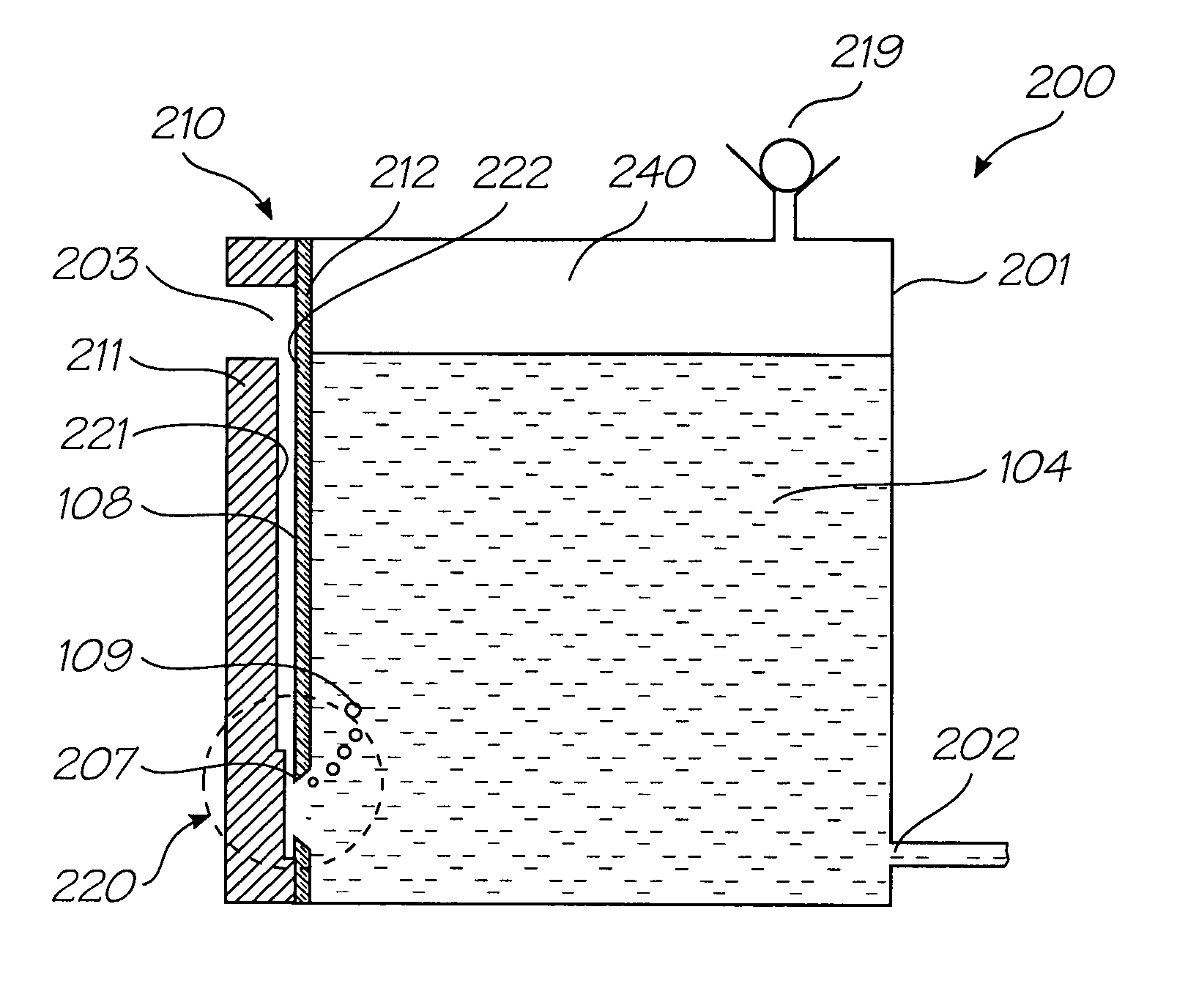

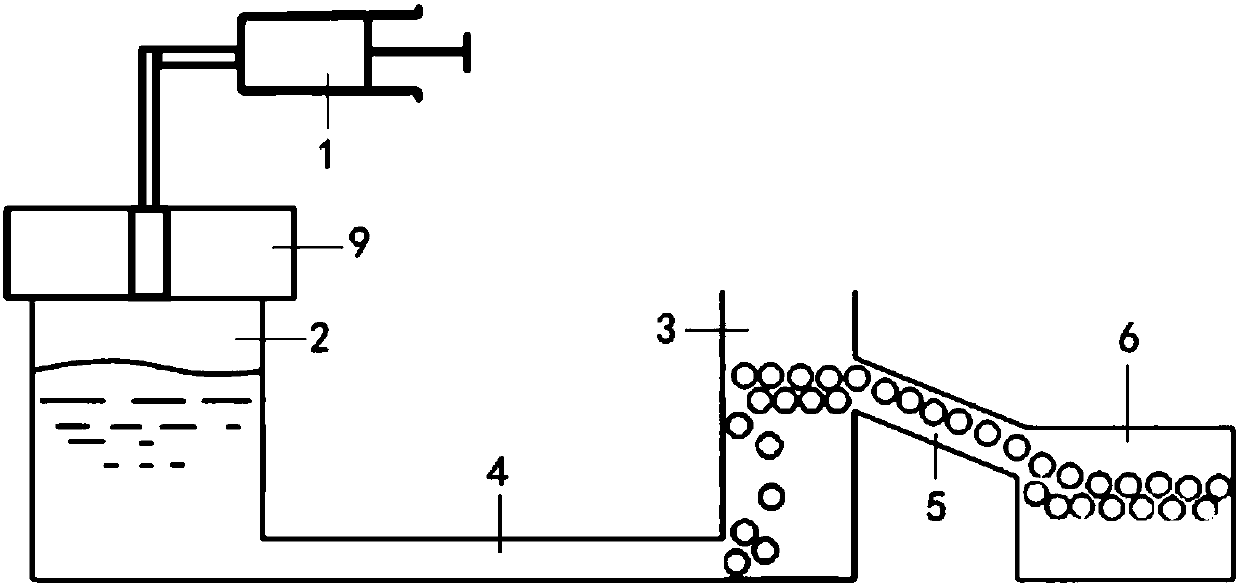

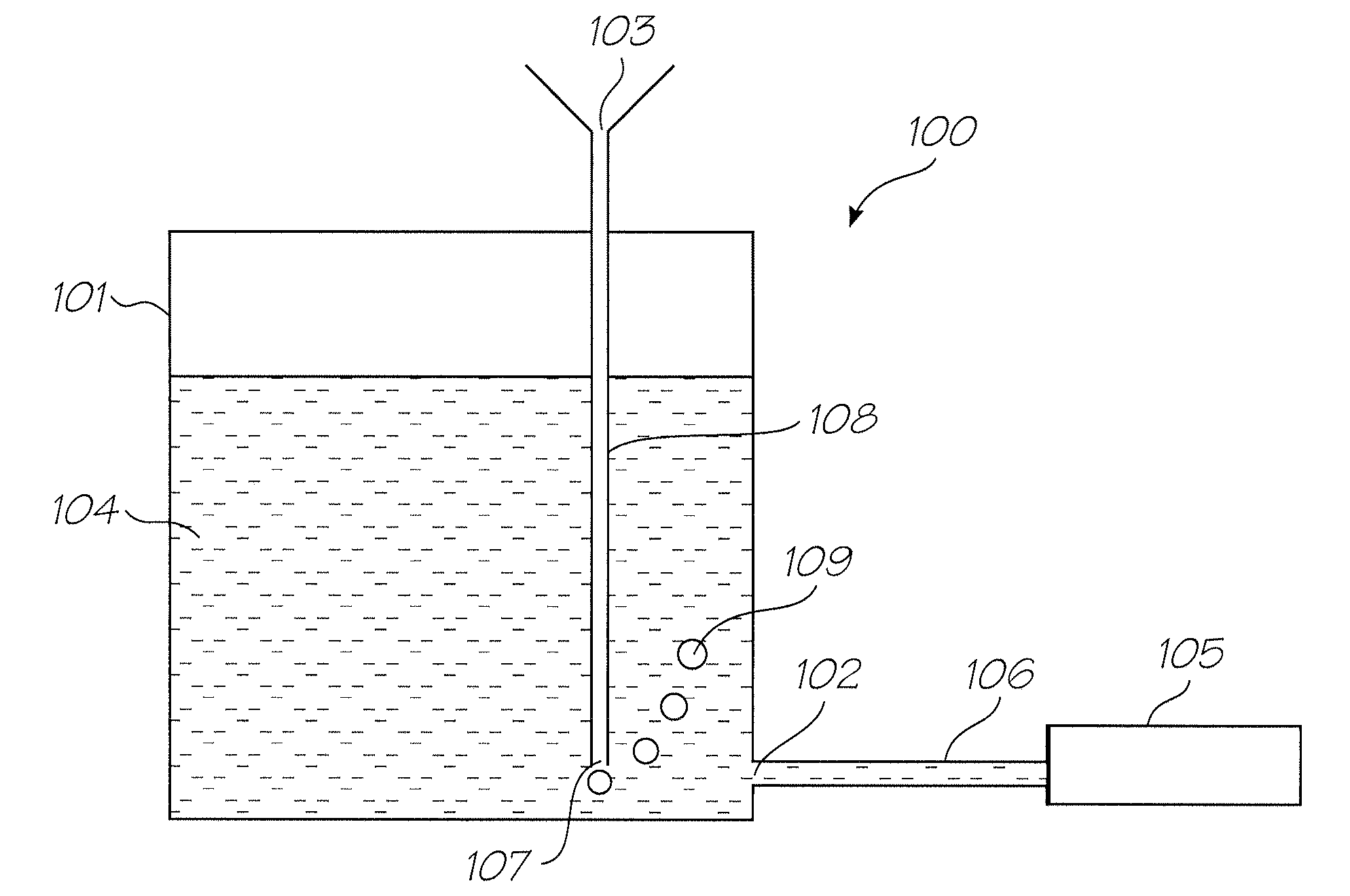

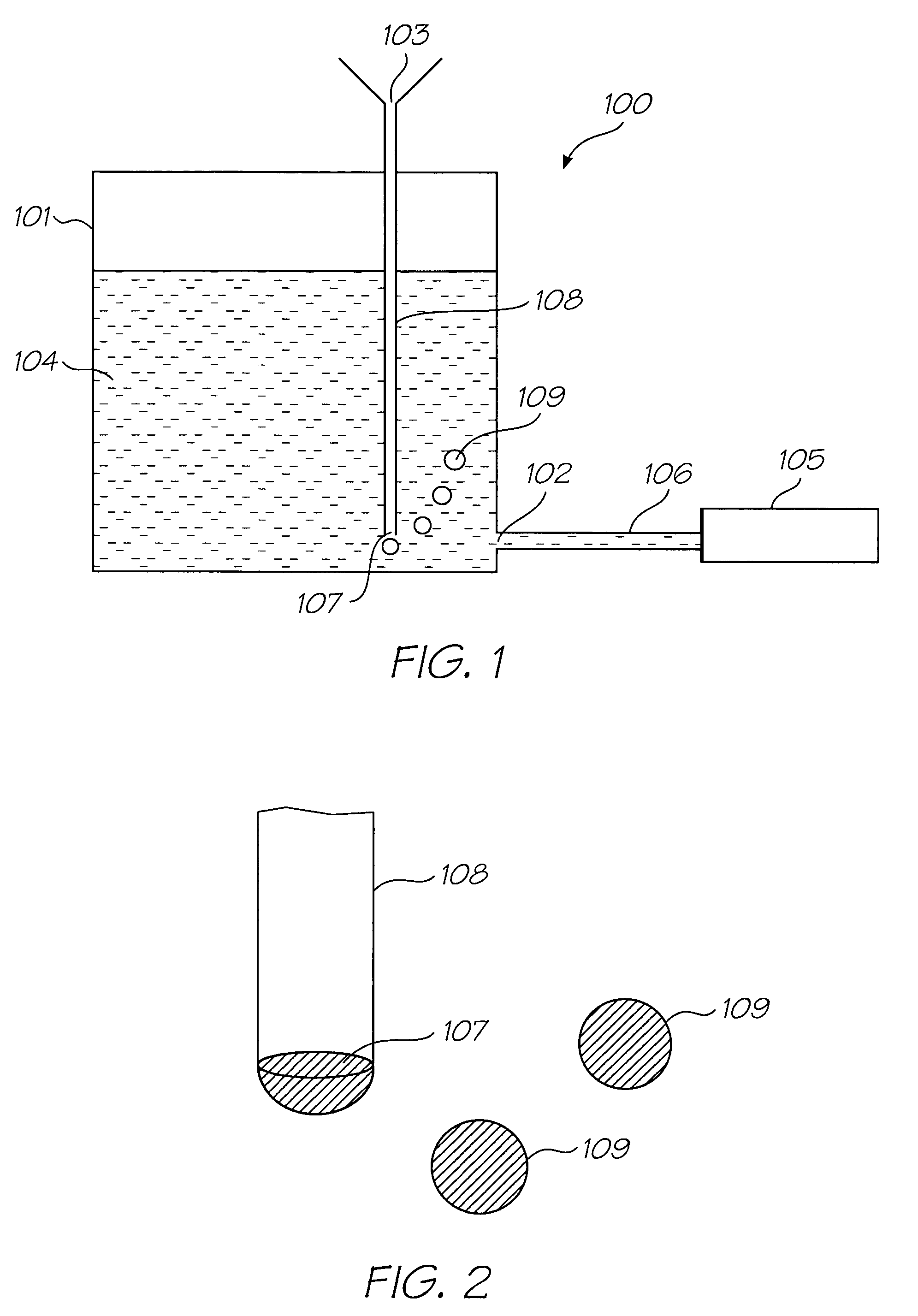

Printhead ink supply system comprising ink pressure regulator

InactiveUS20080143802A1Minimizing ink losses through the air inletFlow resistance is minimizedOther printing apparatusHydrostatic pressureLaplace pressure

A printhead ink supply system is provided. The system comprises an inkjet printhead; an ink reservoir; an ink pressure regulator and an ink line connecting the printhead and the regulator. The ink pressure regulator regulates a hydrostatic pressure of ink supplied to the printhead and comprises an ink chamber having an ink outlet; an air inlet open to atmosphere; a bubble outlet for bubbling air bubbles into the chamber and an air channel connecting the air inlet and the bubble outlet. Each air bubble comprises an air cavity trapped inside a film or a body of ink and the bubble outlet is dimensioned to control a Laplace pressure of air bubbles drawn into the chamber as result of supplying ink to the printhead.

Owner:SILVERBROOK RES PTY LTD +1

Ink pressure regulator with improved liquid retention in regulator channel

There is provided an ink pressure regulator for regulating a hydrostatic pressure of ink supplied to an inkjet printhead. The regulator comprises: an ink chamber having an ink outlet for fluid communication with the printhead via an ink line; an air inlet; a regulator channel having a first end communicating with the air inlet and a second end communicating with a headspace of the chamber, the second end defining a bubble outlet; and a wetting system for maintaining at least some liquid in the regulator channel, thereby ensuring that air entering the headspace first passes through the liquid. The wetting system comprises a first wetting chamber connected to the first end, a second wetting chamber connected to the second end, and a liquid-retaining structure positioned in the second wetting chamber. The regulator channel, the first wetting chamber, the second wetting chamber and the liquid-retaining structure are all in fluid communication with each other. The regulator channel is dimensioned to control a Laplace pressure of air bubbles drawn from the bubble outlet as result of supplying ink to the printhead, thereby regulating a hydrostatic pressure of the ink.

Owner:SILVERBROOK RES PTY LTD +1

Ink pressure regulator with improved liquid retention in regulator channel

There is provided an ink pressure regulator for regulating a hydrostatic pressure of ink supplied to an inkjet printhead. The regulator comprises: an ink chamber having an ink outlet for fluid communication with the printhead via an ink line; an air inlet; a regulator channel having a first end communicating with the air inlet and a second end communicating with a headspace of the chamber, the second end defining a bubble outlet; and a wetting system for maintaining at least some liquid in the regulator channel, thereby ensuring that air entering the headspace first passes through the liquid. The wetting system comprises a first wetting chamber connected to the first end, a second wetting chamber connected to the second end, and a liquid-retaining structure positioned in the second wetting chamber. The regulator channel, the first wetting chamber, the second wetting chamber and the liquid-retaining structure are all in fluid communication with each other. The regulator channel is dimensioned to control a Laplace pressure of air bubbles drawn from the bubble outlet as result of supplying ink to the printhead, thereby regulating a hydrostatic pressure of the ink.

Owner:SILVERBROOK RES PTY LTD +1

Printhead ink supply system comprising ink pressure regulator

InactiveUS7703901B2Minimizing ink losses through the air inletFlow resistance is minimizedOther printing apparatusHydrostatic pressureLaplace pressure

A printhead ink supply system is provided. The system comprises an inkjet printhead; an ink reservoir; an ink pressure regulator and an ink line connecting the printhead and the regulator. The ink pressure regulator regulates a hydrostatic pressure of ink supplied to the printhead and comprises an ink chamber having an ink outlet; an air inlet open to atmosphere; a bubble outlet for bubbling air bubbles into the chamber and an air channel connecting the air inlet and the bubble outlet. Each air bubble comprises an air cavity trapped inside a film or a body of ink and the bubble outlet is dimensioned to control a Laplace pressure of air bubbles drawn into the chamber as result of supplying ink to the printhead.

Owner:SILVERBROOK RES PTY LTD +1

Ink cartridge with pressure regulation

An ink cartridge suitable for regulating a hydrostatic pressure of ink supplied to an inkjet printhead is provided. The cartridge comprises an ink chamber having an ink outlet for fluid communication with the printhead via an ink line; an air inlet open to atmosphere; a bubble outlet for bubbling air bubbles into the chamber, each air bubble comprising an air cavity trapped inside a film or a body of ink; and an air channel connecting the air inlet and the bubble outlet. The bubble outlet is dimensioned to control a Laplace pressure of air bubbles drawn into the chamber as result of supplying ink to the printhead, thereby regulating a hydrostatic pressure of the ink.

Owner:SILVERBROOK RES PTY LTD +1

Microchannel chip and converging device

InactiveUS20080130402A1Stable mixTransportation and packagingLaboratory glasswaresLaplace pressureEngineering

A microchannel chip, includes: a first channel where a first liquid is transported from one end side to an opposite end side; a port section to which a second liquid is supplied from outside for accumulating the second liquid; and a second channel connecting the first channel and the port section through a first opening provided in a side of the first channel and a second opening provided in the port section, wherein the second channel checks flowing out of the second liquid accumulated in the port section to the first channel by a Laplace pressure valve until the first liquid arrives at the first opening, and the second channel converges the second liquid into the first liquid after the first liquid reaches the first opening, and a converging device using the same.

Owner:FUJIFILM CORP

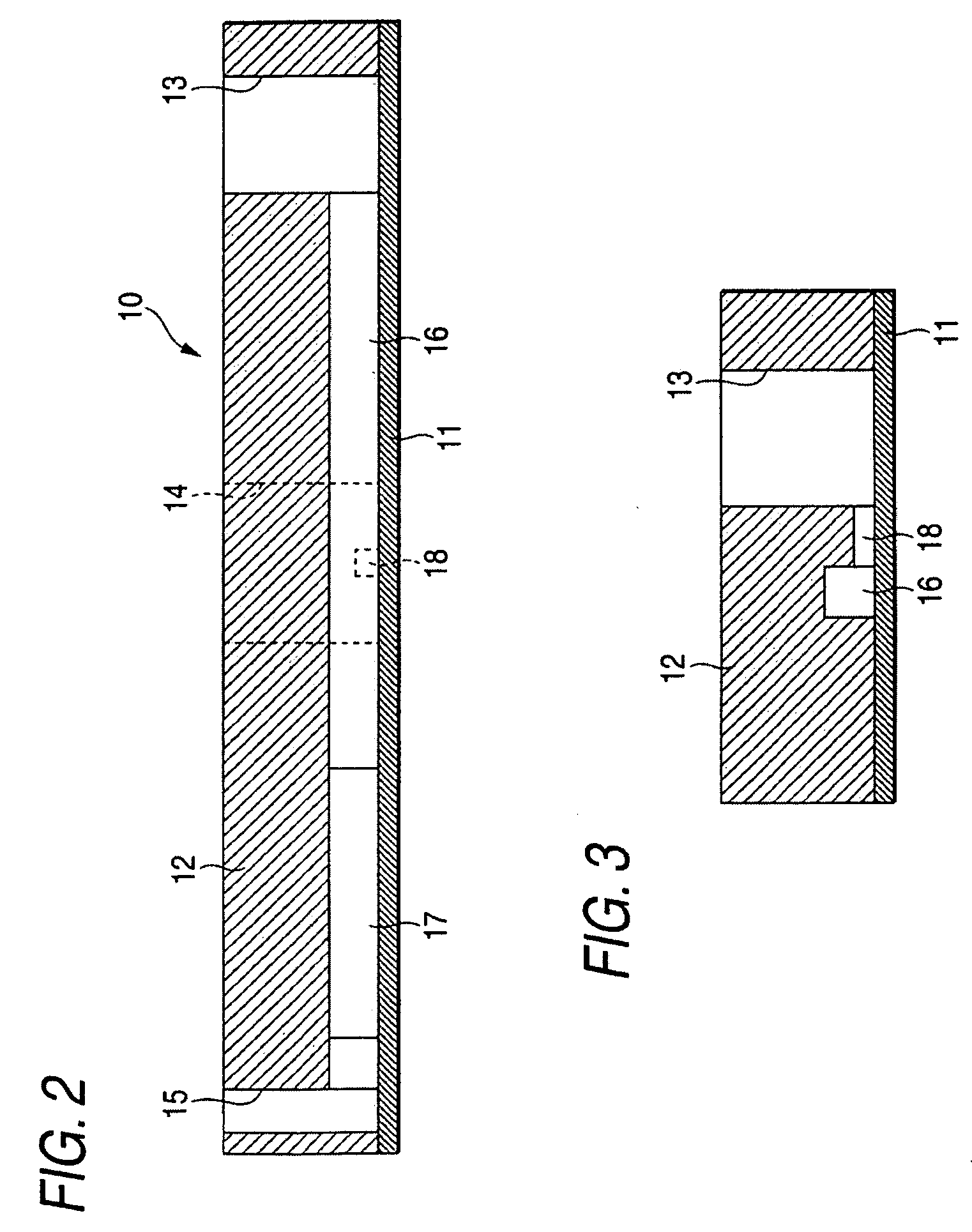

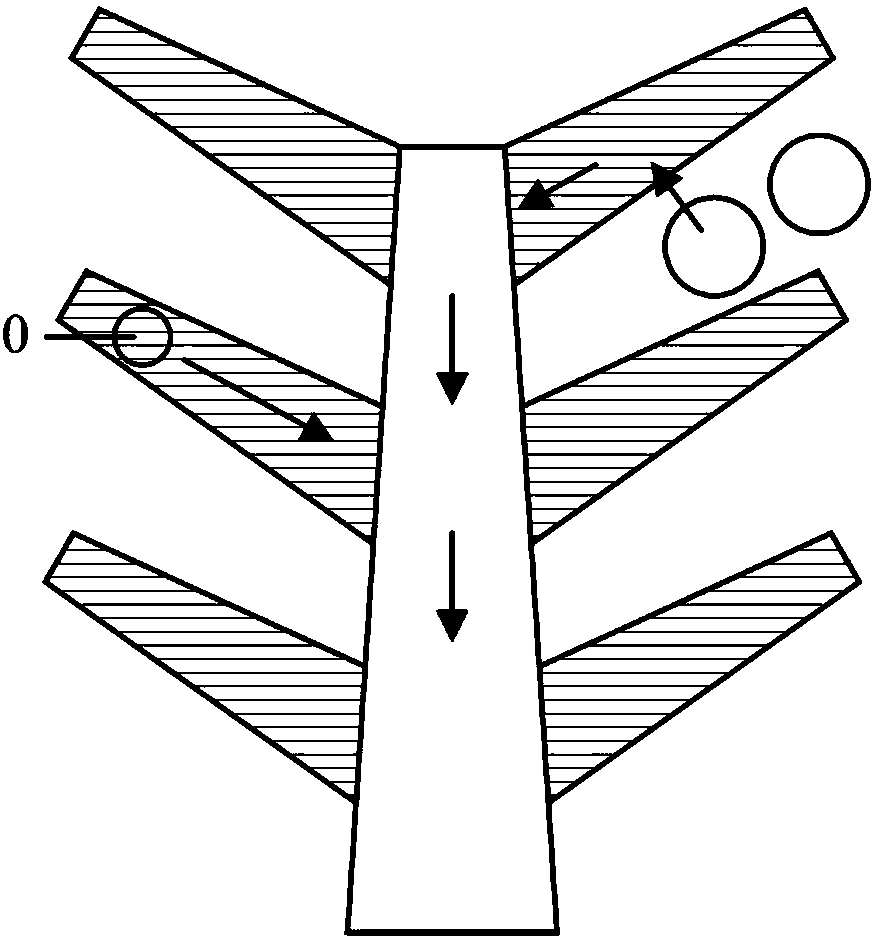

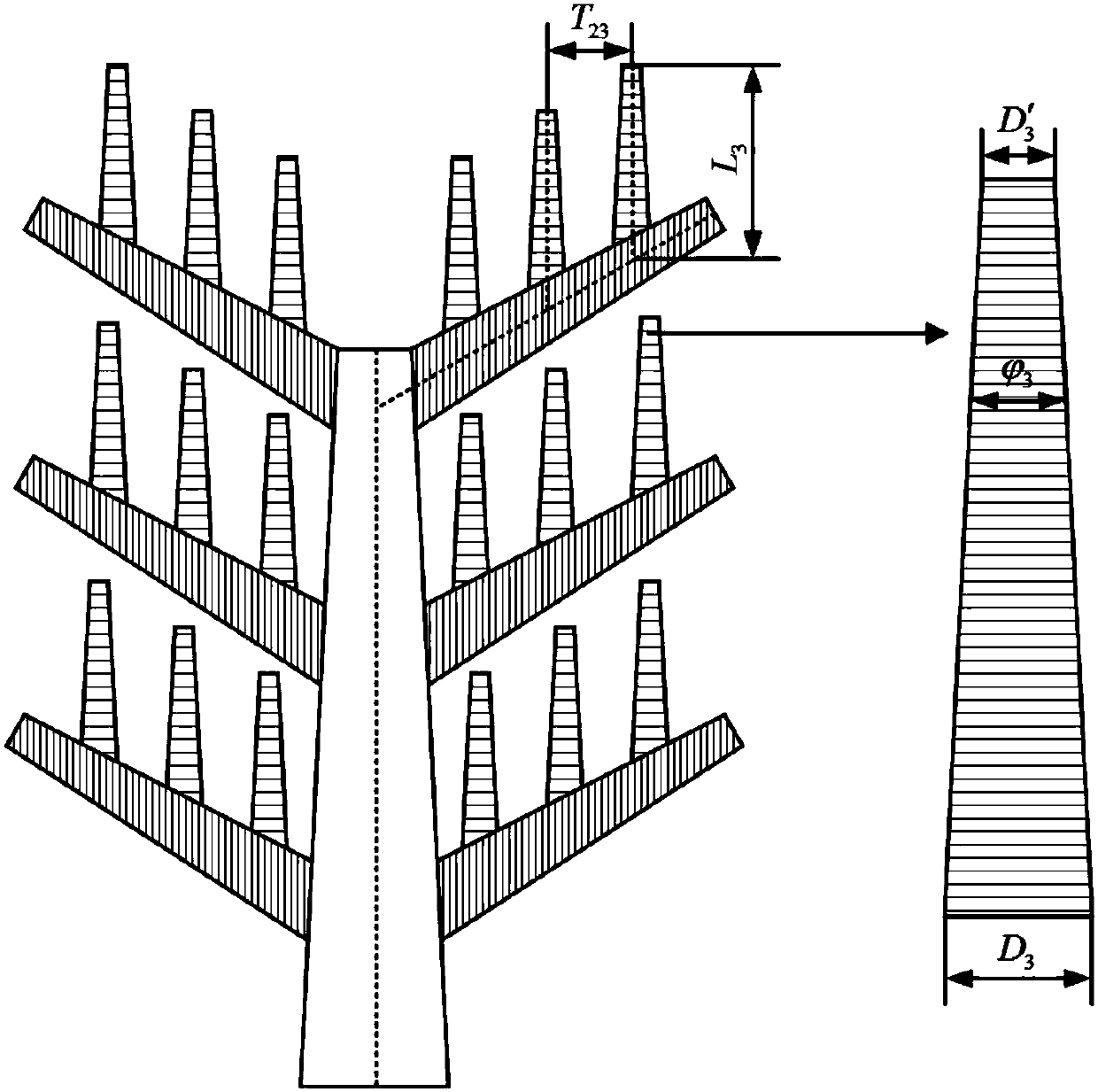

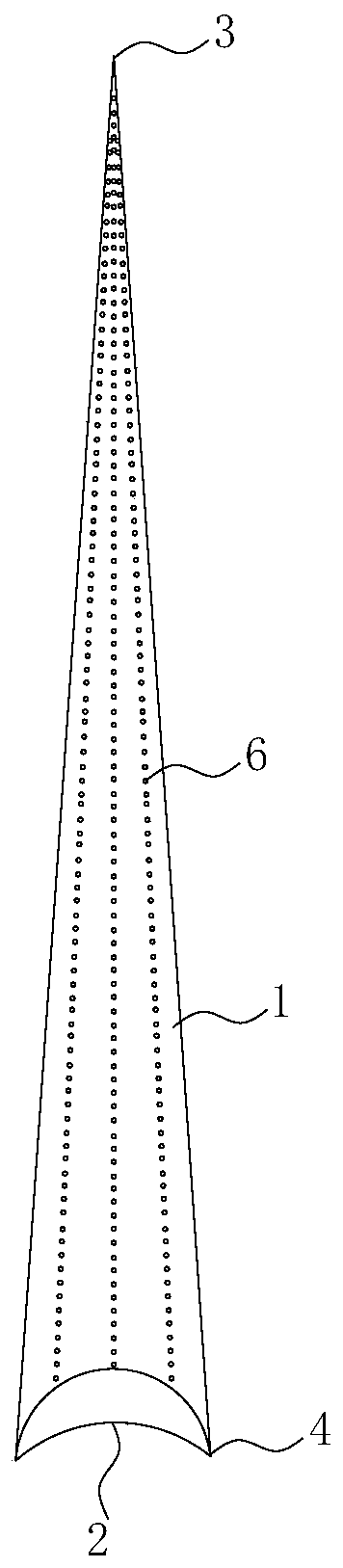

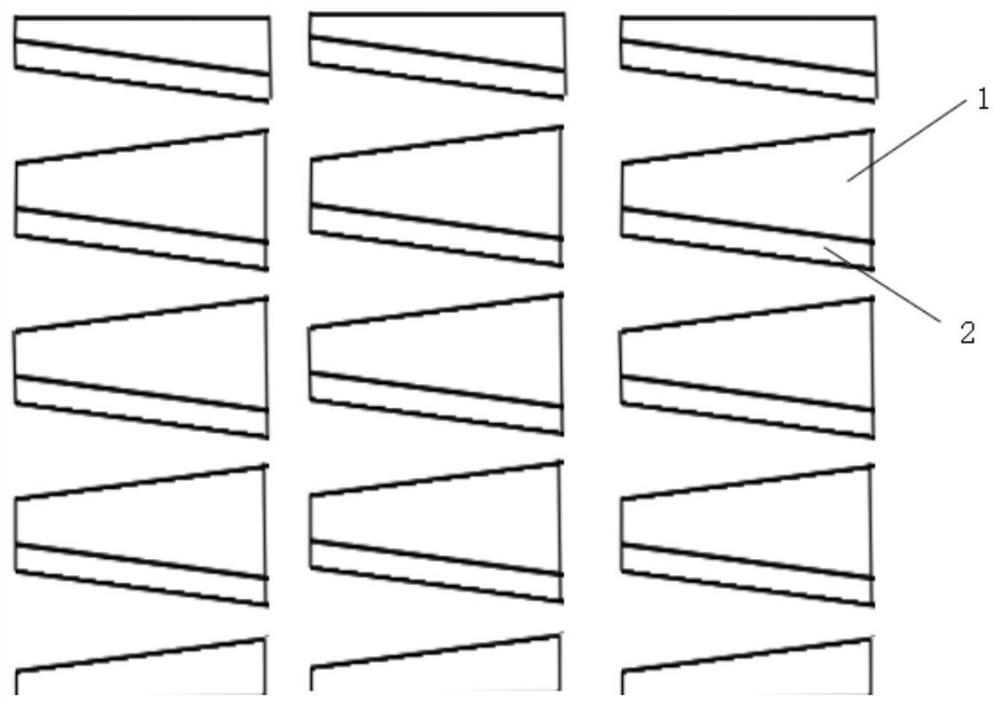

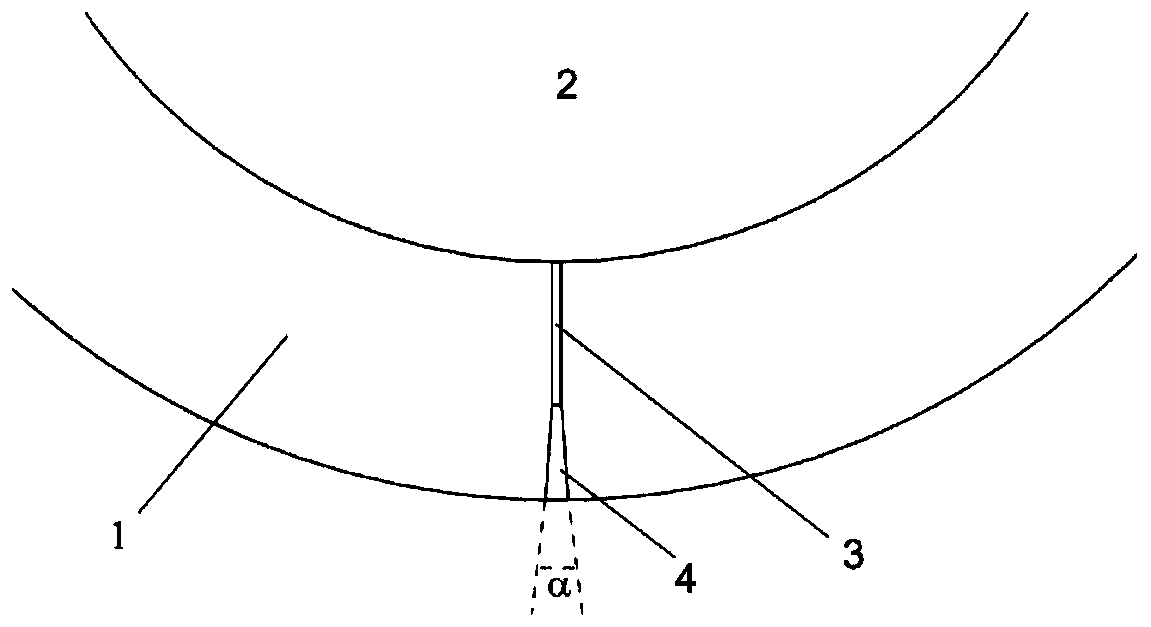

Wedge-shaped fractal based tree-from spontaneous orienting, transporting and collecting runner structure

ActiveCN108104078AHigh speedPrecise control of maximum droplet sizeConstructionsIrrigation ditchesLaplace pressureEngineering

The invention belongs to the field of planar fluid runner design, and discloses a wedge-shaped fractal based tree-from spontaneous orienting, transporting and collecting runner structure. The wedge-shaped fractal based tree-from spontaneous orienting, transporting and collecting runner structure is provided with multi-stage wedge-shaped branches, wherein the lower-bottom equivalent length of a longitudinal section of a i-stage wedge-shaped branch is Di, a gradient angle of the longitudinal section of the i-stage wedge-shaped branch is phi 1, the integral height of the longitudinal section of the i-stage wedge-shaped branch is Li, and the upper-bottom length of the longitudinal section of the i-stage wedge-shaped branch is Di', the upper-bottom length is smaller than the lower-bottom equivalent length, and the gradient angle phi 1 is an included angle between two bevel edges connected with the upper bottom; the lower bottom of the j-stage wedge-shaped branch is adhered on the bevel edges of the (j-1)-stage wedge-shaped branch, and a relationship between the lower-bottom equivalent length of the j-stage wedge-shaped branch and the upper-bottom length of the (j-1)-stage wedge-shaped branch is as follows: Dj is smaller than or equal to D(j-1)', and an included angle between the j-stage wedge-shaped branch and the central line of the (5-1)-stage wedge-shaped branch is phi j. We edge-shaped basic unit has a gradient structure, so that fluid generates Laplace pressure difference on the rubber, the fluid is spontaneously driven to transport in an orientated mode on the runner, andthe fluid is transported and collected along a continuous fractal structure, so that orientated transporting and collecting efficiency of the fluid can be realized, and large-area manufacturing is realized.

Owner:HUAZHONG UNIV OF SCI & TECH

Ink cartridge with pressure regulation

An ink cartridge suitable for regulating a hydrostatic pressure of ink supplied to an inkjet printhead is provided. The cartridge comprises an ink chamber having an ink outlet for fluid communication with the printhead via an ink line; an air inlet open to atmosphere; a bubble outlet for bubbling air bubbles into the chamber, each air bubble comprising an air cavity trapped inside a film or a body of ink; and an air channel connecting the air inlet and the bubble outlet. The bubble outlet is dimensioned to control a Laplace pressure of air bubbles drawn into the chamber as result of supplying ink to the printhead, thereby regulating a hydrostatic pressure of the ink.

Owner:SILVERBROOK RES PTY LTD +1

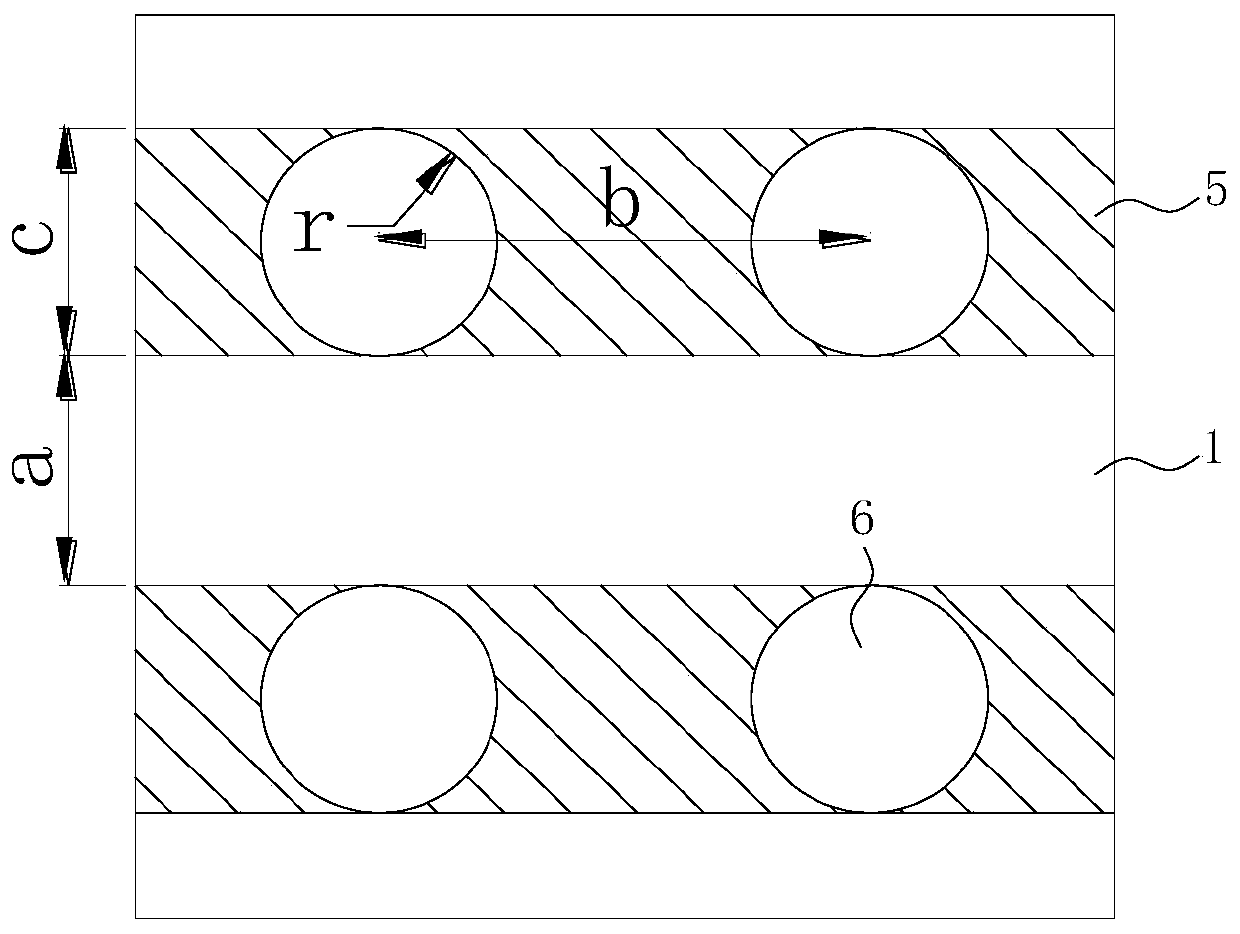

Bionic structure with fog collection capability

ActiveCN109707004AMove quicklyFacilitate directed collectionDrinking water installationStructure of the EarthLaplace pressure

The invention relates to a bionic structure with fog collection capability, and belongs to the technical field of fog collection. The bionic structure with the fog collection capability aims at solving the problem of shortage of fresh water resources existing in the prior art. The bionic structure with the fog collection capability is of a semi-conical structure; and a plurality of grooves which are dispersed in the axial direction are formed in the outer surface of the semi-conical structure from the tip to the root, and a plurality of pits are formed in the bottom of each groove from the tipto the root. According to the bionic structure with the fog collection capability, the semi-conical structure shape forms a shape gradient, so that water droplets condensed on the surface of the semi-conical can move from the tip to the root under the action of laplace pressure; and dispersed groove structures form roughness gradients on the surface of the semi-conical structure, the surface energy of the root is enabled to be larger than that of the tip, and the movement of the water droplets from the tip to the root is promoted. In addition, the pits in the grooves form a "pinning effect",and the directional collection of the water droplets is promoted.

Owner:CHANGCHUN UNIV OF SCI & TECH

Method for improving stability of super-hydrophobic surface underwater air layer

ActiveCN110697649AImprove controllabilityWide base selectivityVessel cleaningDecorative surface effectsLaplace pressureDopamine

Owner:DALIAN MARITIME UNIVERSITY

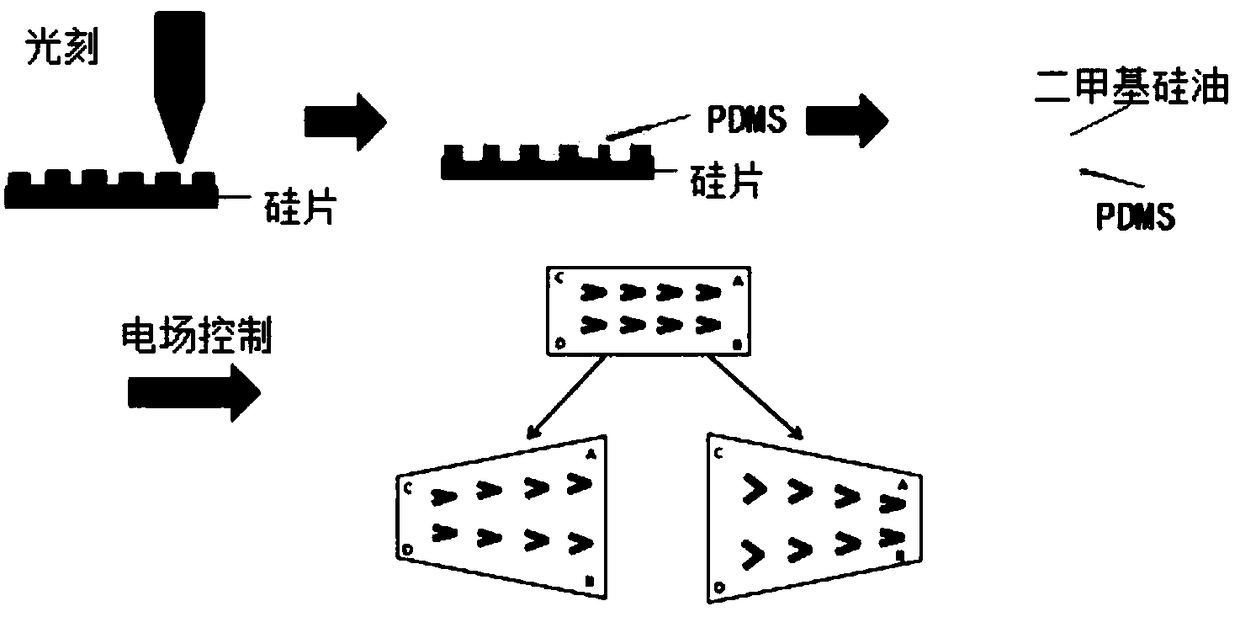

Microstructure surface liquid transport device for elastomer with electric field response performance and preparation method thereof

The invention discloses a microstructure surface liquid transport device for elastomer with electric field response performance, and further discloses a liquid transportation method. The microstructure surface liquid transport device comprises a substrate and micro-nanometer materials, wherein the substrate is the elastomer with electric response performance and is selected from any one of Dow Corning 184 polydimethylsiloxane, acrylate elastomer and polyurethane elastomer. A V-shaped prism with a V-shaped structure on the surface of the elastomer substrate is obtained through a conformal coating method; the elastomer substrate with the V-shaped structure is asymmetrically stretched by using an electric field; a driving force is generated by using an asymmetric Laplace pressure difference;and continuous and rapid transportation of liquid drops is realized by continuously repeating the process.

Owner:BEIHANG UNIV

Liquid drop generation device and liquid drop generation system

The invention discloses a liquid drop generation device, and belongs to the technical field of micro drop generation. The liquid drop generation device comprises an injection mechanism, a dispersion phase liquid storage pool, a continuous phase liquid storage pool and micro passages, wherein the output end of the injection mechanism communicates with the dispersion phase liquid storage pool; one end of the micro passages communicates with the dispersion phase liquid storage pool; the other end of the micro passages communicates with the continuous phase liquid storage pool; the widths of the micro passages and the depths of the micro passages are different. The dimension of the micro passages is smaller than the dimension of the connected continuous phase liquid storage pool; when a dispersion phase enters the flowing phase liquid storage pool from the micro passage outlets, the Laplace pressure difference of the fluid in the micro passages and at the micro passage outlet positions canbe increased, so that the liquid drop is formed. The liquid drop made by the device is only influenced by the dimension of the micro passage; the influence on the size and the stability of the liquiddrop caused by the flowing speed of the dispersion phase and the continuous phase is very small, so that the generation of the liquid drop is more stable, simpler, more convenient, faster and more reliable.

Owner:SHENZHEN BIORAIN BIOTECHNOLOGY CO LTD

Ink pressure regulator with regulator channel fluidically isolated from ink reservoir

There is provided an ink pressure regulator for regulating a hydrostatic pressure of ink supplied to an inkjet printhead. The regulator comprises: an ink chamber having an ink outlet for fluid communication with the printhead via an ink line; an air inlet; a regulator channel having a first end communicating with the air inlet and a second end communicating with a headspace of the chamber, the second end defining a bubble outlet; and a wetting system for maintaining at least some liquid in the regulator channel, thereby ensuring that air entering the headspace first passes through the liquid. The regulator channel is dimensioned to control a Laplace pressure of air bubbles drawn from the bubble outlet as result of supplying ink to the printhead, thereby regulating a hydrostatic pressure of the ink.

Owner:SILVERBROOK RES PTY LTD +1

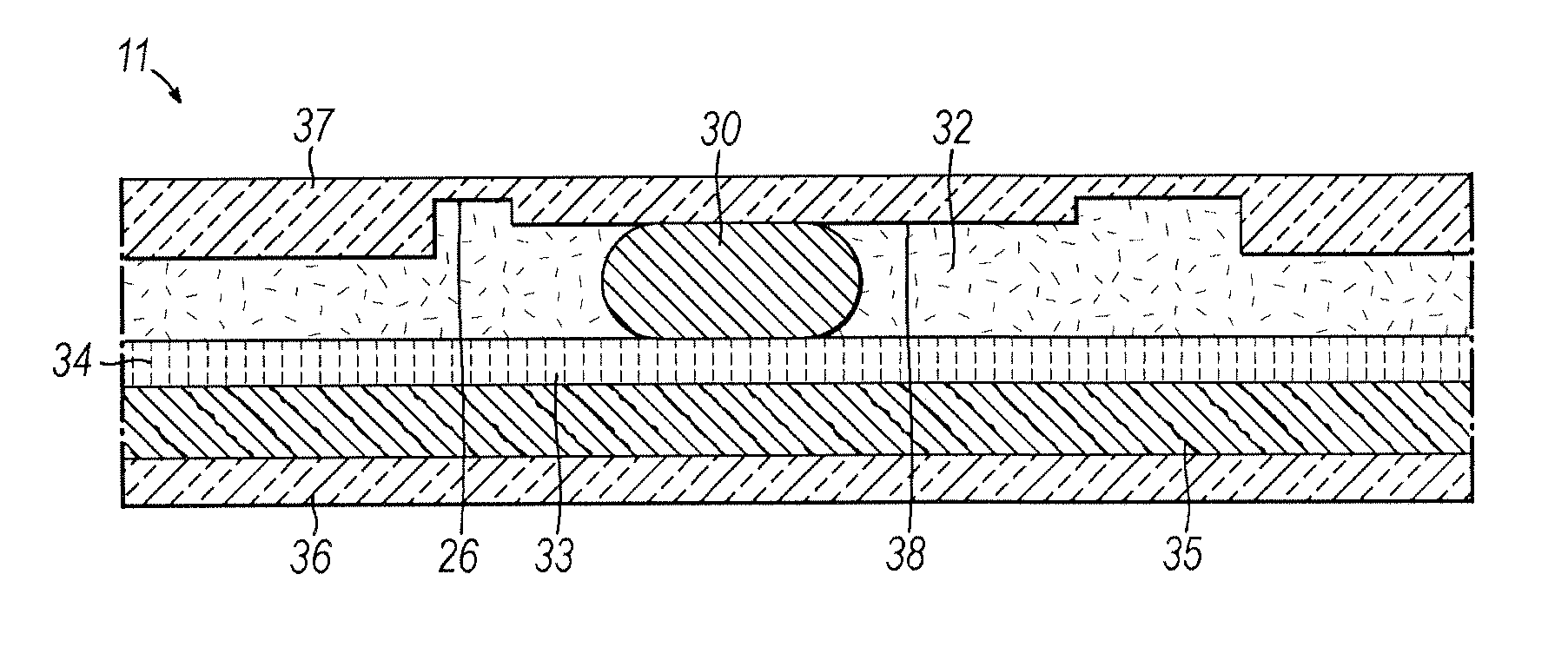

Pressure reconfigured electromagnetic devices

ActiveUS9113559B2Printed circuit aspectsRadiating elements structural formsLaplace pressureLiquid metal

A reconfigurable electromagnetic device includes a first and second planar layer having facing surfaces. One of the surfaces includes one or more micro-trenches. The area between the two surfaces is filled with an electro-fluid, such as a liquid metal and a second immiscible fluid, such as an inert gas. When pressure is applied, forcing the two surfaces together, Laplace pressure causes the electro-fluid to flow into the trench as the inert fluid is evacuated from the area between the two surfaces, forming an electromagnetic device. The shape of the trenches defines the reconfigurable device, such as circuitry, switch, antenna or the like. When the inert fluid is reintroduced into the area between the two surfaces, the electro-fluid withdraws from the trench, which is the off position, in which the device does not function.

Owner:UNIVERSITY OF CINCINNATI

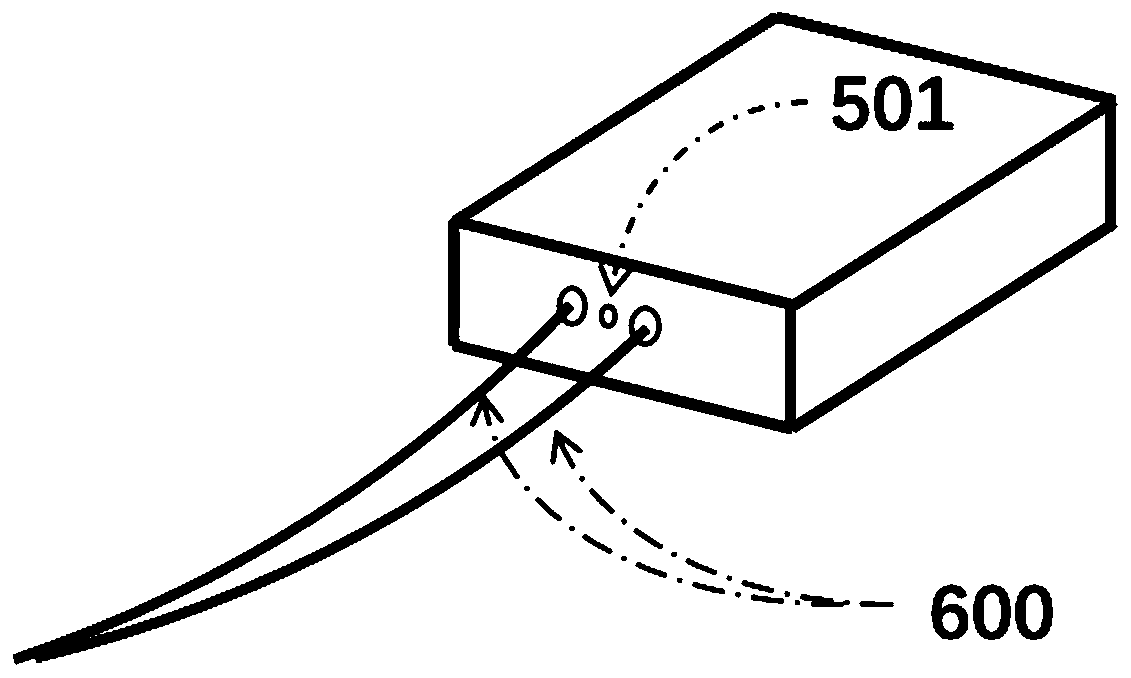

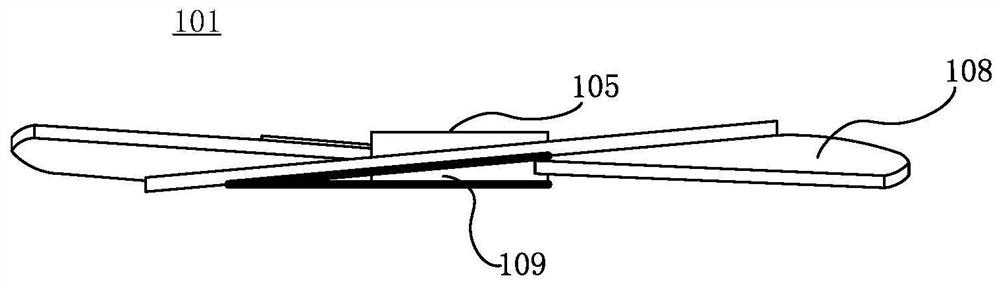

Micro-nano wire manufacturing device and micro-nano structure

PendingCN109807907AFast preparationPrecise Width ControlProgramme-controlled manipulatorLiquid conductorsMicro structureMicro nano

The invention provides a micro-nano wire manufacturing device and a micro-nano structure and belongs to the technical field of micro-electronics. The micro-nano wire manufacturing device comprises a liquid-phase nanometer material storing device and micro-nano wire arranging mechanisms; the liquid-phase nanometer material storing device is provided with at least one liquid discharging hole; the micro-nano wire arranging mechanisms and the liquid discharging holes are arranged in a one-to-one correspondence manner; each micro-nano wire arranging mechanism comprises at least two flexible wires;the surface of each flexible wire comprises regularly distributed micro-structures; the root part of each flexible wire is fixed to the liquid-phase nanometer material storing device; every two flexible wires form a group, and the end parts droop and fall on a substrate and lean against each other; and the included angle range of the two flexible wires of which the end parts lean against each other after the flexible wires are projected on the substrate is 1 to 5 degrees. The micro-nano wire manufacturing device provided by the invention can realize quick manufacturing of micro-nano wires based on the gravity of liquid-phase nanometer materials and the Lapras pressure difference and asymmetric retaining force of the flexible wires.

Owner:XIAN JIAOTONG LIVERPOOL UNIV

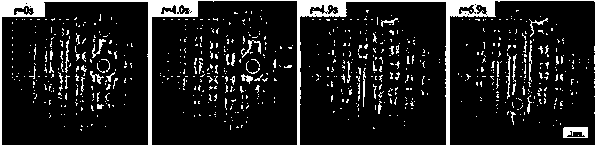

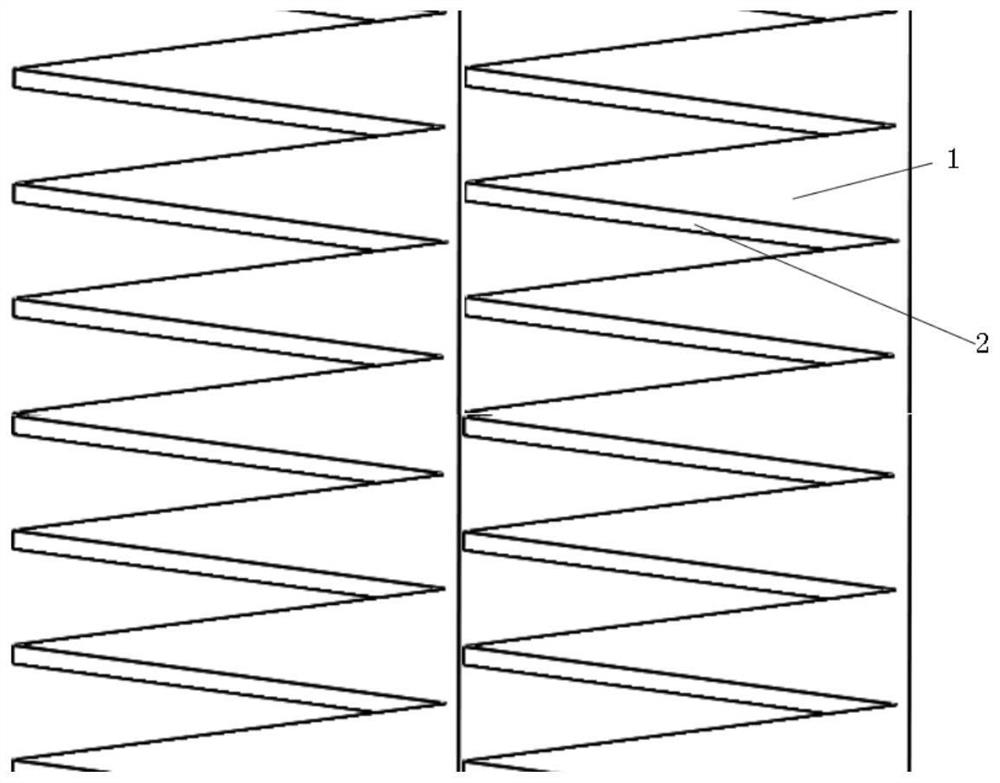

Mixed steam condensation heat transfer reinforcement surface, preparation method and application thereof

ActiveCN108097553AReduce adhesionEnhance heat and mass transferLiquid surface applicatorsCoatingsCondensation processSteam condensation

The invention belongs to technical field of reinforcement heat transfer and energy conservation, and in particular, relates to a V-shaped groove super-hydrophobic surface and application thereof to mixed steam condensation heat transfer reinforcement. A condensation surface is of a two-grade structure, and consists of a sub-millimetric V-shaped groove structure and a nanometer rough structure. Inthe condensation process of mixed steam, based on the characteristics of non-condensable gas accumulated in the sub-millimetric V-shaped groove, under high supercool degree, condensation liquid dropsat the top of the V-shaped groove are in a Wenzel wet mode, quick condensation of the liquid drops can be realized; condensation liquid drops at the bottom of the V-shaped groove are in a Cassie wet mode; and growth is slow. Along with growth of the Wenzel liquid drops, under the effect of Laplace pressure, the liquid drops perform a self-driven motion out of the V-shaped groove; and the solid-liquid contact area is reduced, that is, the adhesive force between the liquid drops and the surface is reduced. When the liquid drops grow to enable the radius to be equal to the top width of the V-shaped groove, the liquid drops fall in a scouring form, so that the condensation wall surface is updated, disturbance on a non-condensable gas layer can be realized, and mixed steam condensation heat transfer can be reinforced.

Owner:DALIAN UNIV OF TECH

Method of regulating ink pressure

InactiveUS7794068B2Minimizing ink lossesOther printing apparatusHydrostatic pressureLaplace pressure

A method of regulating a hydrostatic pressure of ink supplied to an inkjet printhead is provided. The method comprises withdrawing a volume of ink from an ink chamber and simultaneously bubbling air bubbles into the chamber via a bubble outlet to balance the withdrawn volume of ink. Each air bubble is defined by an air cavity trapped inside a film or a body of ink. The bubble outlet is dimensioned to control a Laplace pressure of the air bubbles, thereby regulating a hydrostatic pressure of the ink.

Owner:MEMJET TECH LTD +1

Film for triggering directional self-bounce of liquid drops and preparation method and application thereof

ActiveCN111604018ARealize directional long-distance bounce transportationChemical/physical/physico-chemical microreactorsLaboratory glasswaresThin membraneEngineering

The invention discloses a film for triggering directional self-bounce of liquid drops and a preparation method and application thereof. The film for triggering directional self-bounce of liquid dropscomprises a plurality of three-dimensional structure units arranged in an array, wherein the surface contour shape of each three-dimensional structure unit is a preset pattern, the preset pattern is asymmetric about a straight line perpendicular to a preset liquid drop bouncing direction, and the surface of each three-dimensional structure unit is a hydrophobic surface. The shape of the surface contour of each three-dimensional structural unit is a pattern which is asymmetric about a straight line perpendicular to a preset liquid drop bouncing direction, asymmetric Laplace pressure is generated on dripped liquid drops, so that the speed of the liquid drops moving in a preset direction is formed, and meanwhile, directional long-distance bounce transportation of the liquid drops is realizedin combination with the hydrophobic surfaces of the three-dimensional structure units.

Owner:SHENZHEN TECH UNIV

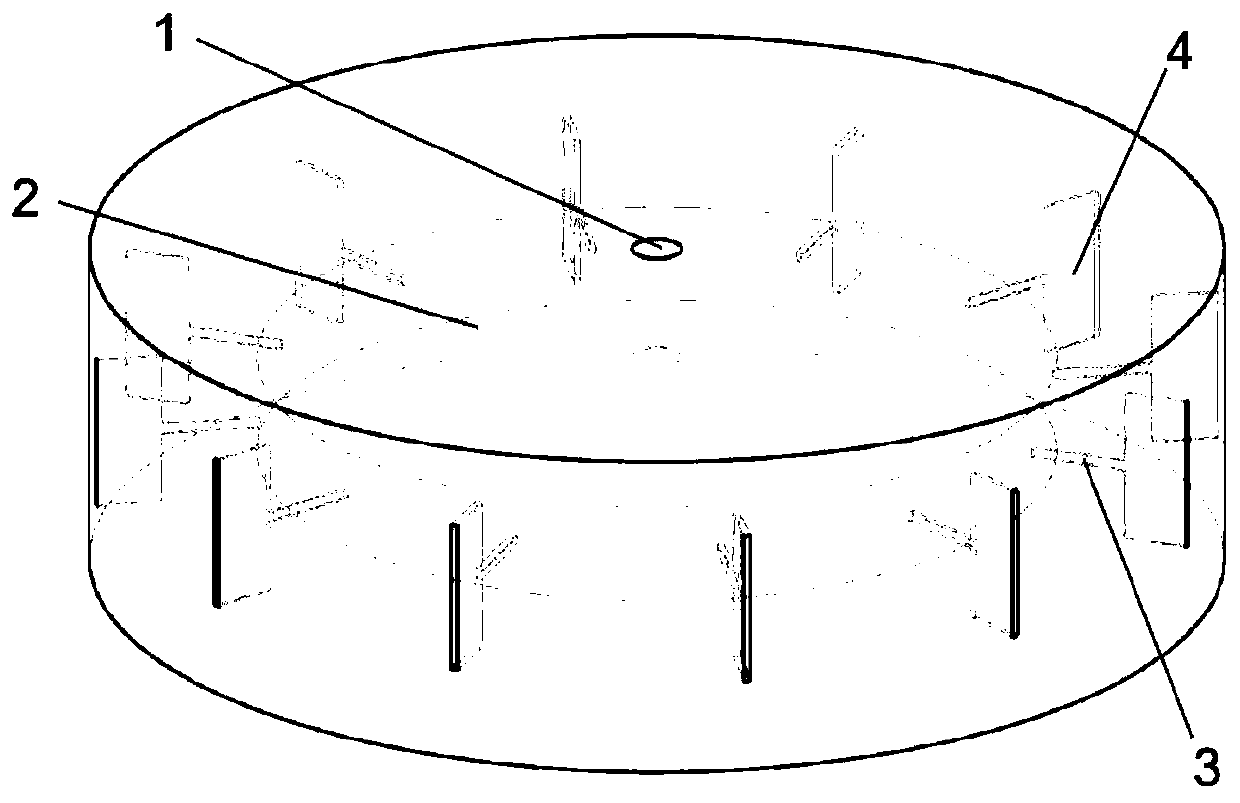

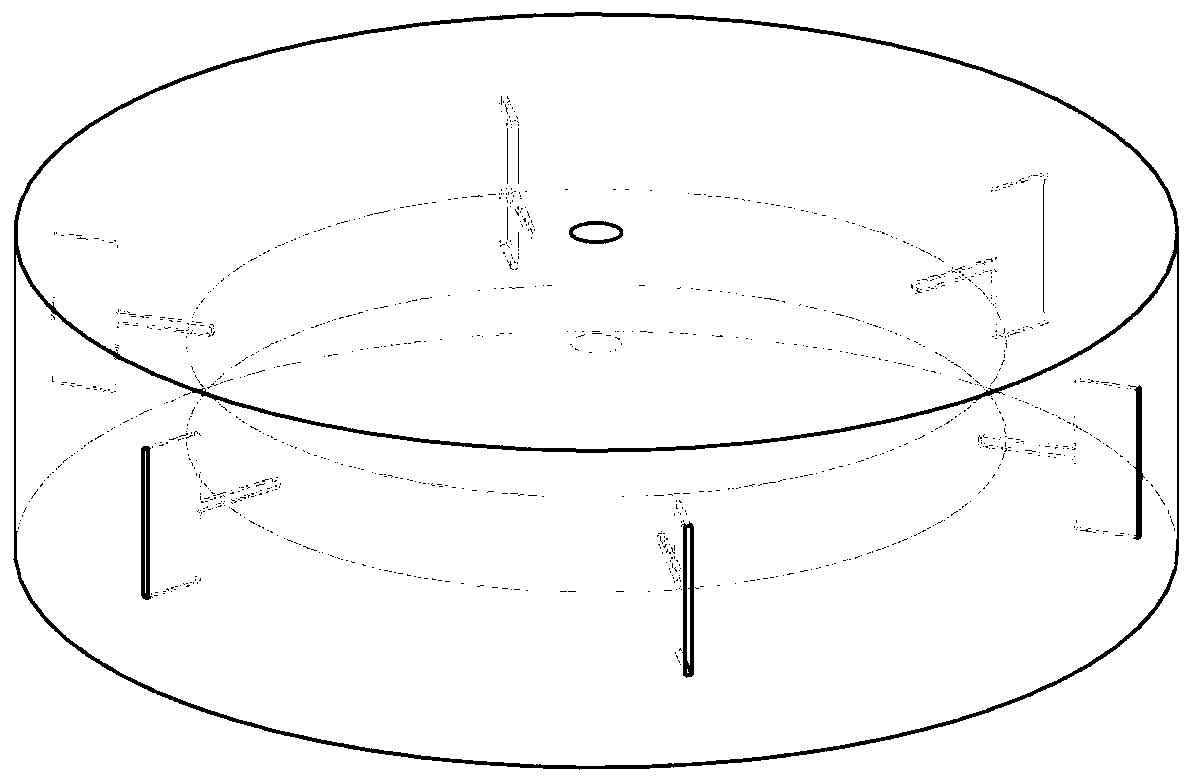

3D printing microfluidic device and large-flux monodisperse emulsion preparation method based on same

ActiveCN110075934AHigh volume fraction of dispersed phaseGood monodispersityLaboratory glasswaresCylindrical channelEmulsion

The invention provides a 3D printing microfluidic device and a large-flux monodisperse emulsion preparation method based on the same. The microfluidic device is produced by 3D printing, the device iscylindrical, the center is a cylindrical channel, the central channel is connected with multiple radially distributed micro-channels, and outlets of the radial micro-channels are of flat wedge structures. A disperse phase is injected from the cylinder center to enter the central channel and flows into the radially distributed micro-channels from the central channel. When a fluid enters flat narrowareas from the micro-channels, the Laplace pressure is higher under extrusion of flat outlets, and meanwhile, the wedge structures cause inner and outside Laplace pressure difference to extrude droplets into a collecting tank. The sizes of generated droplets can be controlled by changing structural parameters of the channels, and prepared droplets have uniform sizes, so that large-scale preparation of monodisperse emulsion with uniform and controllable sizes is realized. The method has the advantages of production simplicity and low cost and can realize industrial production.

Owner:绍兴钠钇光电有限公司

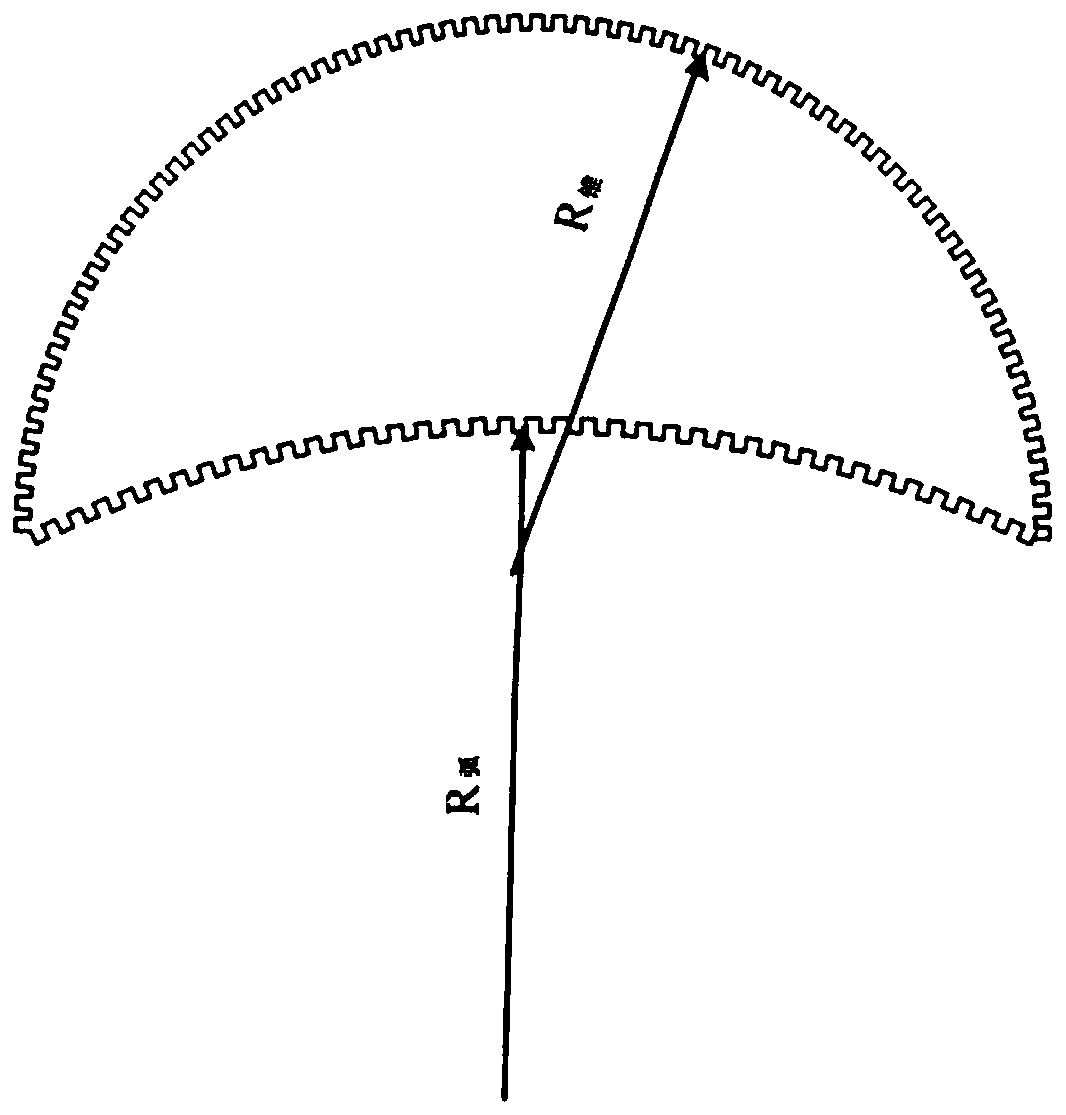

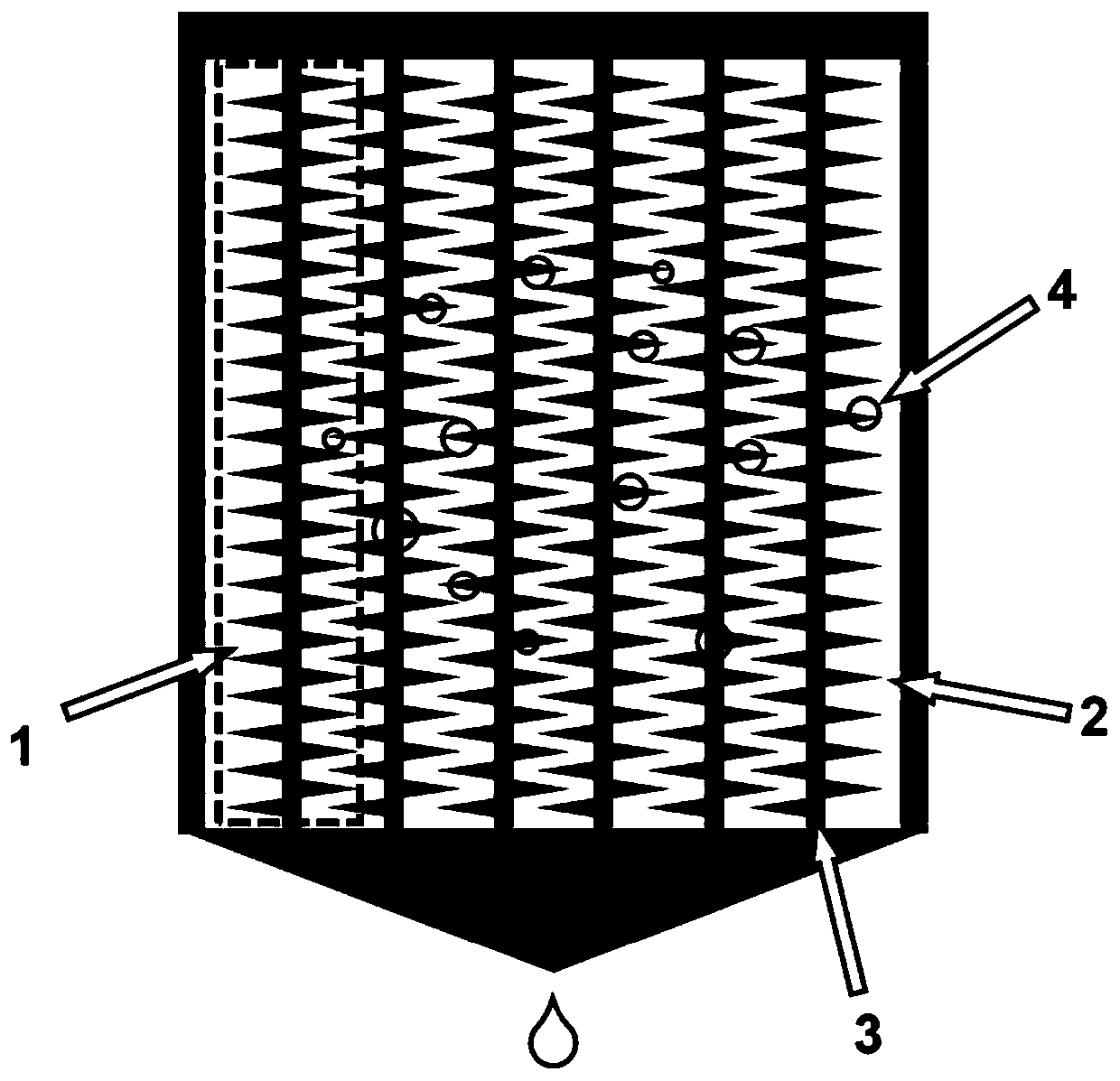

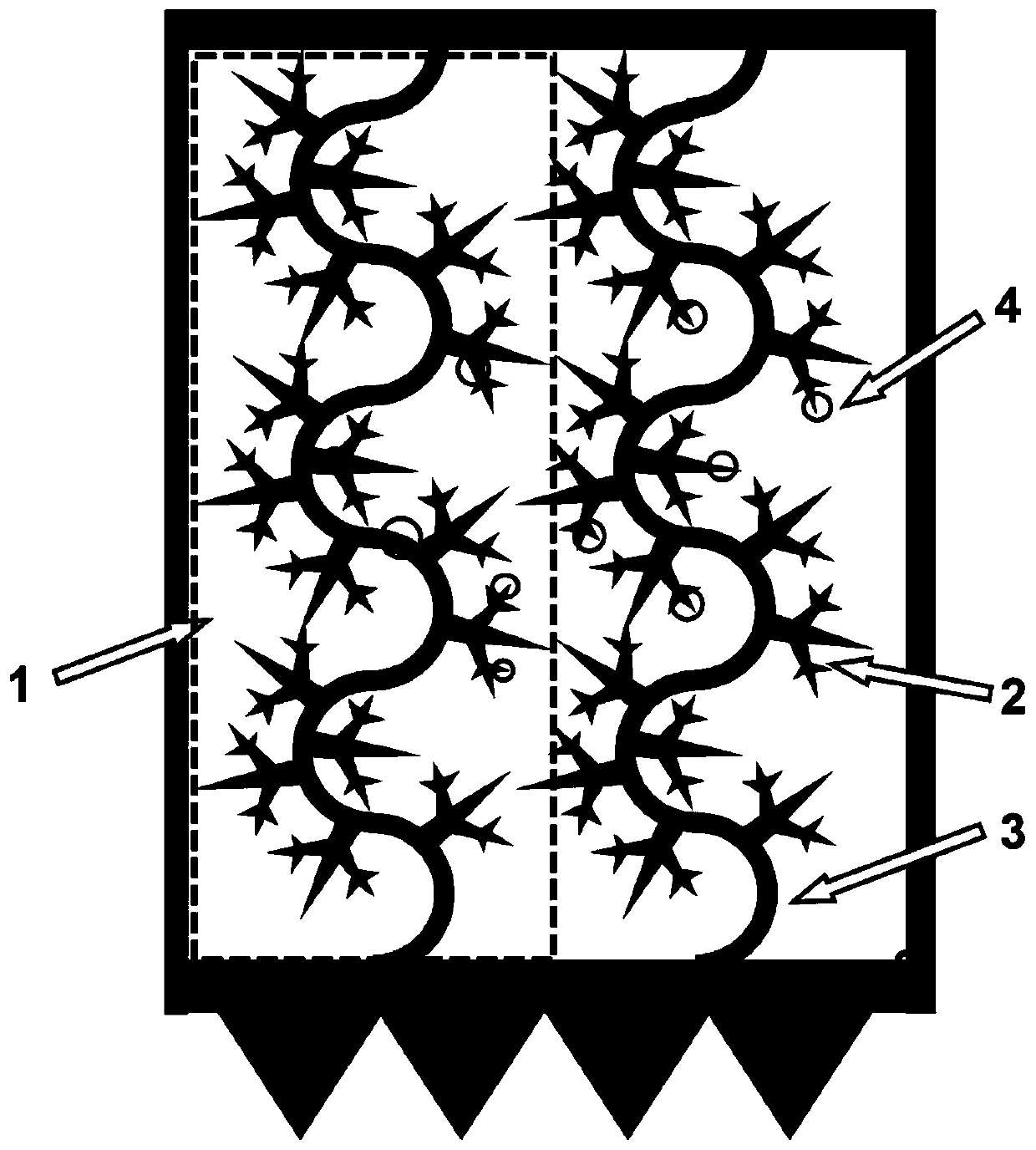

Self-driven planar fog droplet directional collecting structure

InactiveCN111549856AEfficient collectionLow costDrinking water installationLaplace pressureMechanical engineering

The invention belongs to the technical field of fog droplet collection, and discloses a self-driven planar fog droplet directional collecting structure. At least one fog collecting unit with hydrophobic or super-hydrophobic surfaces is arranged. The fog collecting units comprise ridge parts and fog collecting sheets which are arranged on the same plane. The multiple fog collecting sheets are connected to the ridge parts and further extend outwards to the two sides from the ridge parts. Each fog collecting sheet comprises at least one outer side tip end and can achieve even transition to the outer side tip end from a corresponding inner side root part. The fog collecting sheets are used for collecting droplets and further directionally conveying the droplets to the ridge parts under the driving action of Laplace pressure. The ridge parts are used for making the droplets move directionally in the length direction under the gravity driving action. According to the self-driven planar fog droplet directional collecting structure, the planar structure mode is adopted, the asymmetrical Laplace pressure and gravity are used for driving, the spontaneous capturing and spontaneous driving directional fog collecting process is completed , and thus the purposes of autonomous fog collection and self-directional conveyance are achieved; and the structure is simple, manufacturing is easy, costis low and the self-driven planar fog droplet directional collecting structure is expected to be put into use on a large scale.

Owner:TIANJIN UNIV

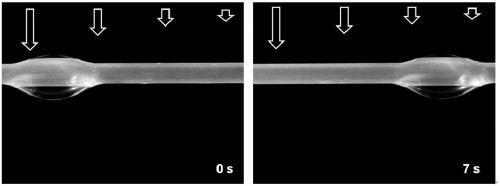

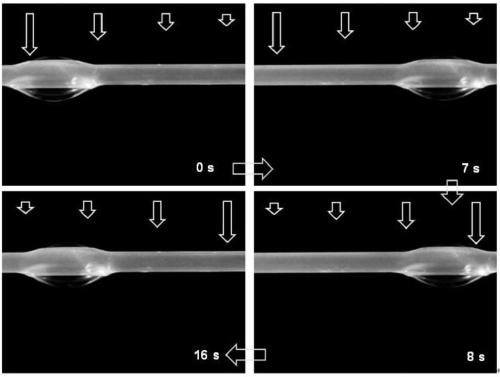

Light-controlled liquid drop movement method, light-controlled liquid drop movement micropipe and manufacturing method of light-operated liquid drop movement micropipe

ActiveCN111255778ARich varietyImprove practicalityValve arrangementsFluid dynamicsMicroreactorChemical reaction

The invention relates to a light-controlled liquid drop movement method, a light-controlled liquid drop movement micropipe and a manufacturing method of the light-operated liquid drop movement micropipe. The technology utilizes the gradient change of the curvature of the outer wall caused by the asymmetrical deformation of the light-controlled liquid drop movement micropipe to induce laplace pressure difference to be generated so as to drive a liquid drop to move. By the adoption of the light-controlled liquid drop movement method, the light-controlled liquid drop movement micropipe and the manufacturing method of the light-operated liquid drop movement micropipe, liquid drops of various polarities and components can be driven, it can also be achieved that the liquid drops are driven to conduct stirring, mixing, transmitting tiny objects and other liquid drop operations, even the liquid drops can be driven to conduct multi-grade chemical reactions, and the light-controlled liquid dropmovement method has great application potential in the fields of microreactors, micromechanical systems, chip laboratories, trace liquid conveyance, biomedical devices, water collecting devices and the like.

Owner:WESTLAKE UNIV

Method of regulating ink pressure

InactiveUS20080143761A1Minimizing ink lossesOther printing apparatusHydrostatic pressureLaplace pressure

A method of regulating a hydrostatic pressure of ink supplied to an inkjet printhead is provided. The method comprises withdrawing a volume of ink from an ink chamber and simultaneously bubbling air bubbles into the chamber via a bubble outlet to balance the withdrawn volume of ink. Each air bubble is defined by an air cavity trapped inside a film or a body of ink. The bubble outlet is dimensioned to control a Laplace pressure of the air bubbles, thereby regulating a hydrostatic pressure of the ink.

Owner:MEMJET TECH LTD +1

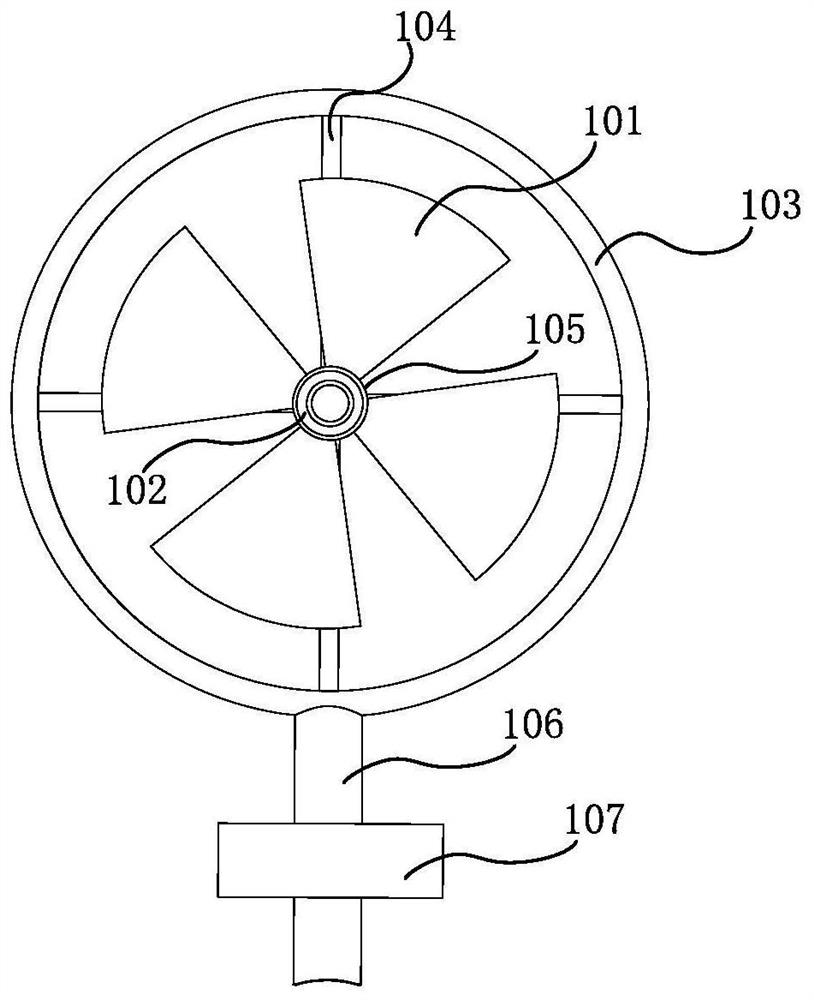

Mist water collecting device and preparation method of mist water collecting blade

ActiveCN109797807BEfficient collectionDrinking water installationStructural engineeringLaplace pressure

The invention provides a fog water collecting device and a production method of fog water collecting blades and relates to the technical field of fog water collection. The fog water collecting devicecomprises blades, a first bearing, a support and a collecting cover, wherein the blades sleeve the first bearing, the first bearing is arranged on the support, the collecting cover covers the outer edges of the blades in a surrounding manner and is connected to the support, and at least one side of every blade is provided with a groove structure. The fog water collecting device has the advantagesthat the groove structures formed in the blades enable fog water in air to condense in projecting areas in the groove structures of the blades, the condensed fog water deposits in grooves of the groove structures to form liquid drop under the action of Laplace Pressure, and the liquid drop can transfer to the collecting cover along the groove structures when the blades rotate in the presence of wind, so that fog water can be efficiently collected in the presence of natural wind.

Owner:THE CHINESE UNIV OF HONG KONG SHENZHEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com