Hydrophilic/hydrophobic area synergistic water-collecting patterned surface and preparation method thereof

A patterned and hydrophobic technology, applied in the direction of manufacturing tools, welding equipment, laser welding equipment, etc., can solve the problem of limited improvement of surface water collection efficiency, achieve improved water collection efficiency, high water collection efficiency, and improve collection speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Cut the copper sheet, and cut the copper sheet with a thickness of 1mm into a square copper sheet with a length of 30mm*30mm.

[0039](2) Polish the copper sheet, polish the copper sheet with 200 mesh, 500 mesh, 800 mesh, 1200 mesh, and 2000 mesh sandpaper in turn for polishing.

[0040] (3) Clean the surface, place the polished copper sheet in deionized water for 10 minutes of ultrasonic cleaning, then rinse with ethanol, isopropanol, and deionized successively, and dry the surface with cold wind to obtain a clean copper sheet.

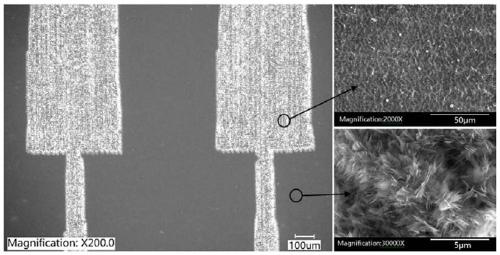

[0041] (4) chemical corrosion, preparation of NaClO 2 :NaOH:Na 3 PO 4 12H 2 O: DI water=3.75:5:10:100wt% alkaline solution, and heated to 95 ° C, the clean copper sheet was placed in the alkaline solution for 30 minutes, rinsed with deionized water and dried after taking it out, to obtain Superhydrophilic surfaces with knife-edge nanostructures.

[0042] (5) Surface modification, soak the super-hydrophilic copper surface in the n-hexa...

Embodiment 2

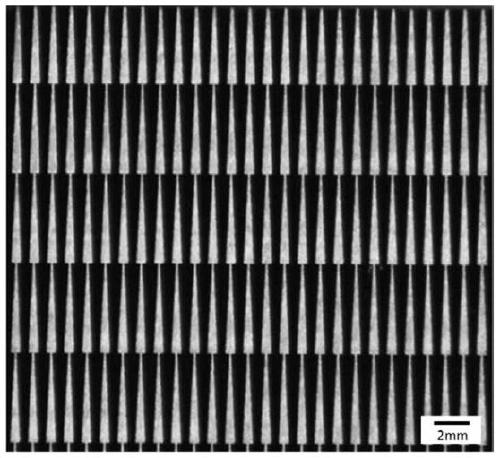

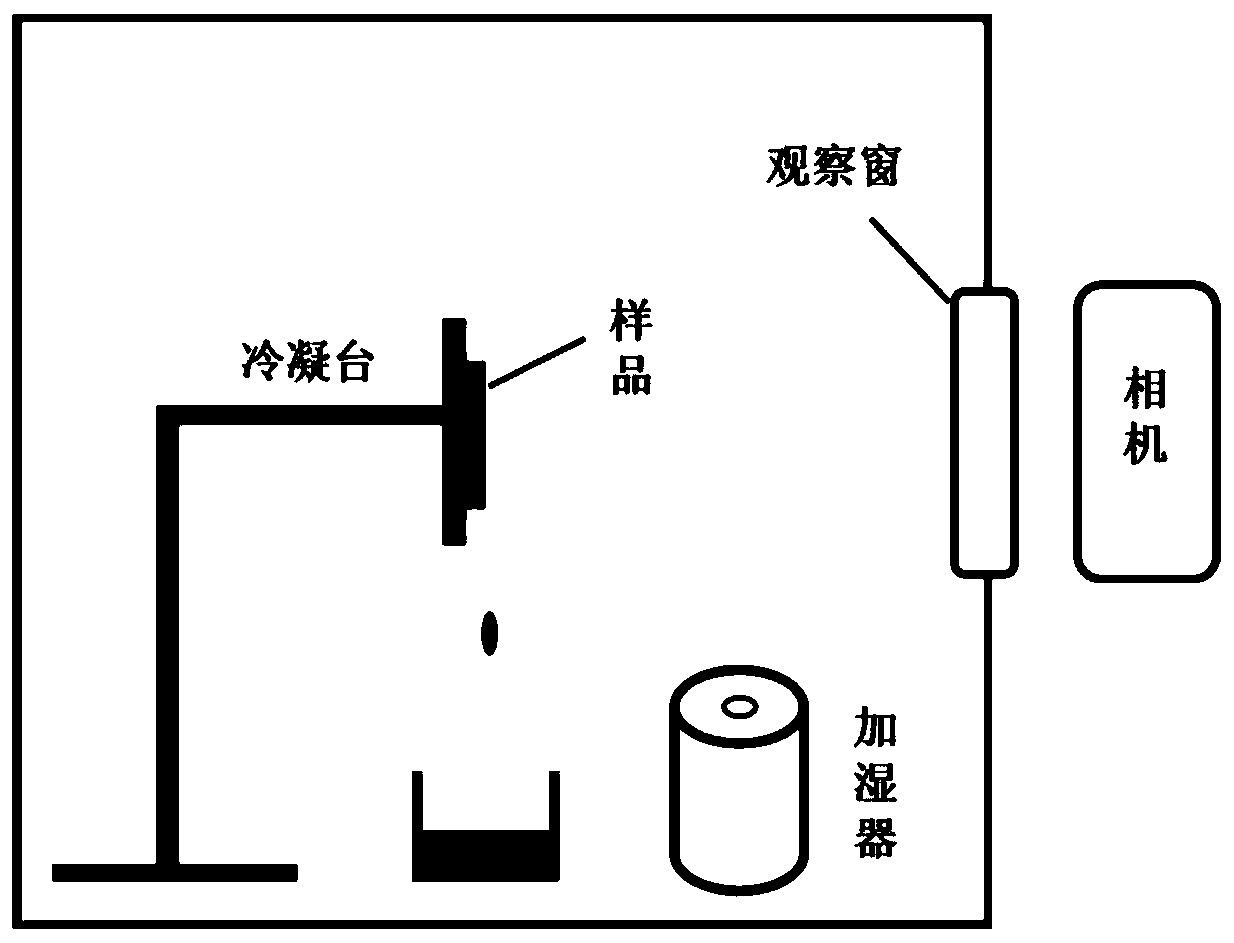

[0047] According to the method of embodiment 1, the spacing of each column pattern in step (6) is changed into 1.0mm, 2.0mm, 4.0mm, other conditions are constant, obtain superhydrophilic / superhydrophobic composite water-collecting surfaces with different spacings, And carry out condensation water collection experiment. Comparing the water collection results, the super-hydrophilic and super-hydrophobic regions of the samples made on the surface work in harmony, and the collected droplets will not spread across the entire surface, which has an efficient water collection effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com