Visual testing device and method for soil and structure shearing characteristic research

A test device and structure technology, which is applied in the direction of using a stable shear force to test the strength of materials, measuring devices, strength characteristics, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

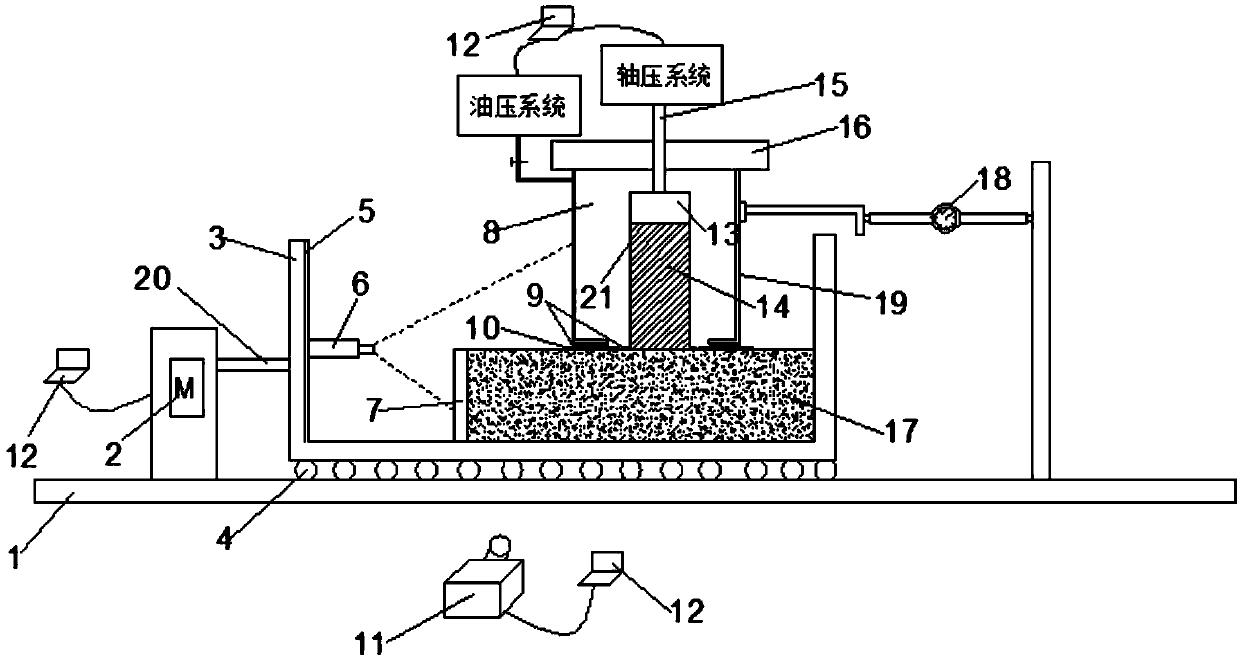

[0050] The invention provides a visual test device for the study of shear properties of soil and structures, such as figure 1 and 2 As shown, including upper shearing system, lower shearing system, horizontal force applying device, pressure control system and data acquisition system;

[0051] Downshear systems include:

[0052] The base 3 is arranged on an optical platform 1, and a liquid drop 4 is arranged between the base 3 and the optical platform 1;

[0053] The shear box 7 is arranged above the base 3 and is used to place the structure to be tested; the shear box 7 is made of plexiglass.

[0054] The upper shear system includes:

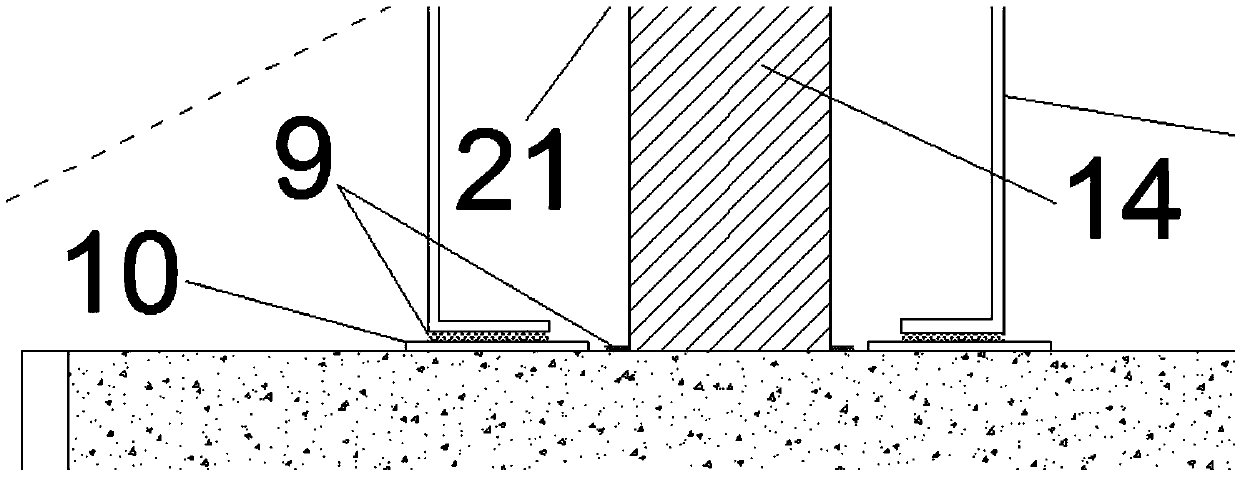

[0055] The glass cylinder 19 is open up and down, and the upper end of the glass cylinder 19 is provided with an upper cover 16 . The glass cylinder 19 is set on the structure to be tested, and the glass plate 10 is set between the glass cylinder 19 and the structure to be tested; the graphene 9 is set between the glass cylinder 19 and the gla...

Embodiment 1

[0082] What embodiment 1 adopts is to carry out the study of the shear characteristic of soil and structure contact surface under the condition of controlling rock-like or concrete-like material 17 confining pressure and axial pressure constant, for the soil-structure contact surface shearing under the change of confining pressure For the study of characteristics, on the basis of Example 1, the implementation of step 5 can be changed. The initial confining pressure of the shearing process is set to 100MPa by the oil pressure system, each increase is 50MPa, and the interval is 120s; the axial pressure is kept constant at 300MPa during the shearing process, and the change of the horizontal displacement is paid close attention to during the test. When the horizontal displacement is observed When the reading in Table 18 is 0.4mm, the test is stopped; after the test, the obtained pictures are analyzed by the computer image processing software PIV, and the changes of the stress and d...

Embodiment 3

[0084] For the research on the shear characteristics of the contact surface between soil and structure under the change of axial pressure, the implementation of step 5 can be changed on the basis of Example 1. The initial axial pressure of the shearing process is set to 100MPa by the hydraulic system, and each increase is 50MPa, with an interval of 120s; the confining pressure is kept constant at 200MPa during the shearing process, and the change of the horizontal displacement is paid close attention to during the test. When the horizontal displacement is observed When the reading in Table 18 is 0.4mm, the test is stopped; after the test, the obtained pictures are analyzed by the computer image processing software PIV, and the changes of the stress and displacement of the contact surface when the soil and the structure are sheared under the change of axial pressure are obtained process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com