Method for treating wastewater containing nitrogen and phosphorus and synthesizing magnesium ammonium phosphate

A treatment method, ammonium magnesium phosphate technology, applied in water/sewage treatment, neutralized water/sewage treatment, water/sludge/sewage treatment, etc., can solve complex process, large equipment footprint, phosphorus element removal rate It needs to be further improved to achieve the effect of overcoming the complexity of the process, good effect and overcoming the large area occupied by the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

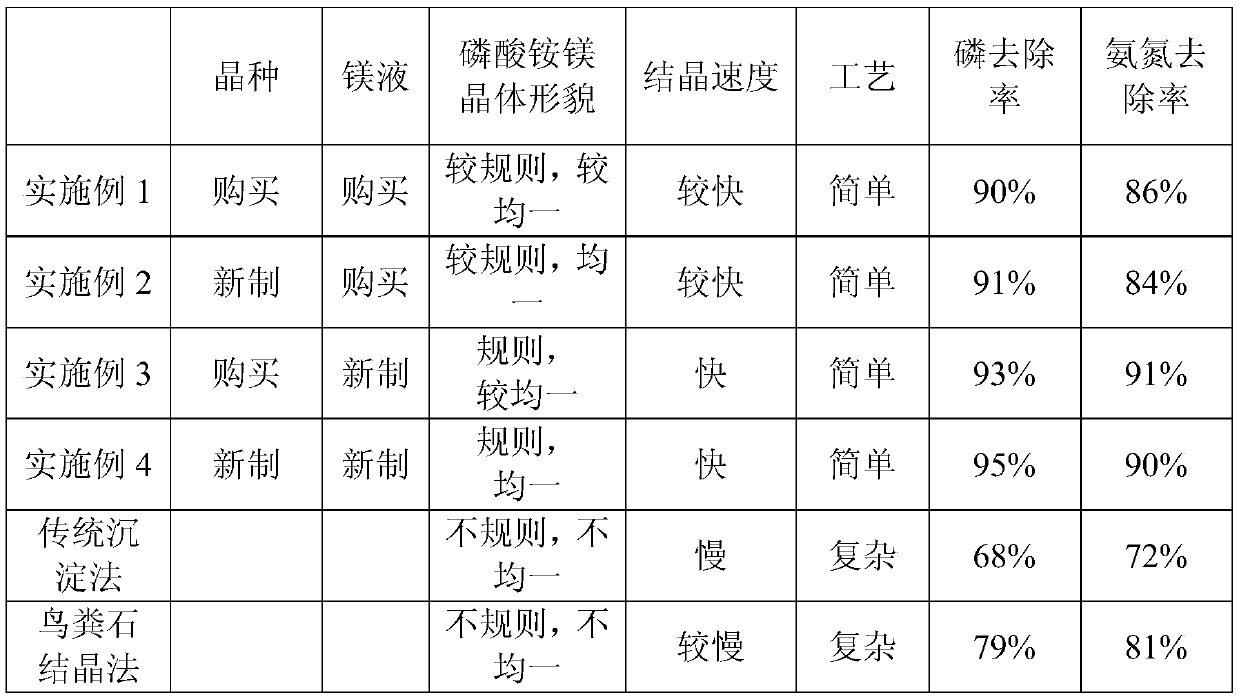

Examples

Embodiment 1

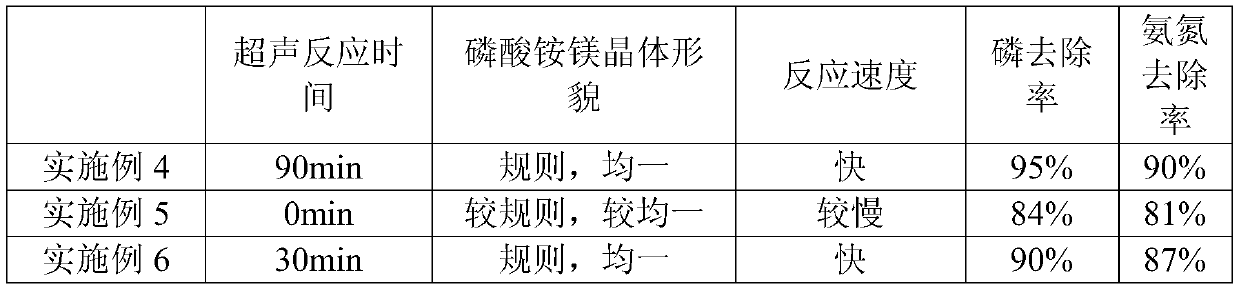

[0029] First open the fluidized bed, add 20g of magnesium ammonium phosphate seed crystals purchased in the fluidized bed, control the waste water flow rate to make the crystal seeds in a fluidized state, adjust the pH in the fluidized bed to alkaline conditions with ammonia water, and adjust the pH value to 9.5, add the magnesium solution of magnesium chloride purchased and turn on the reflux water, the adding speed of the magnesium solution is 0.35m 3 / h, the speed of backflow water is 0.12m 3 / h, raise the water temperature to 55-65°C, and continuously feed the waste water at a speed of 0.2m 3 / h, make the waste water and magnesium liquid react continuously in the fluidized bed, lower the water temperature to 40°C, insert the ultrasonic vibrating rod into the fluidized bed, turn on the ultrasonic vibrating rod for ultrasonic reaction for 90min, the power is 100KHZ, and at the same time, the flow rate of the reflux water Increase to 0.2m 3 / h, turn off the ultrasonic vibra...

Embodiment 2

[0031] Pour 200g of analytically pure magnesium ammonium phosphate hexahydrate into a 1L beaker, add 200ml of deionized water, stir with a magnetic stirrer for 20min, turn off the magnetic stirrer and stop stirring, then let it stand for 20min, filter to remove the supernatant, and remove the large particles at the bottom Put the magnesium ammonium phosphate seed into the oven and dry in the oven at 70°C for 24 hours to prepare the magnesium ammonium phosphate seed, open the fluidized bed, and add 20g of newly prepared magnesium ammonium phosphate seed to the fluidized bed to control the waste water The flow rate makes the crystal seed in a fluidized state, adjust the pH in the fluidized bed to alkaline conditions with ammonia water, adjust the pH value to 9.5, add the magnesium solution of magnesium chloride purchased and turn on the reflux water, the adding speed of the magnesium solution is 0.35m 3 / h, the speed of backflow water is 0.12m 3 / h, raise the water temperature t...

Embodiment 3

[0033] First, use deionized water to dissolve magnesium chloride to prepare a magnesium solution with a concentration of magnesium ions of 0.5mol / L. Turn on the fluidized bed, add 20g of purchased magnesium ammonium phosphate seed crystals to the fluidized bed, and control the flow of waste water so that the crystal seeds are in a fluid state. The pH in the fluidized bed is adjusted to alkaline conditions with ammonia water, the pH value is adjusted to 9.5, the newly prepared magnesium solution is added and the reflux water is turned on, and the adding speed of the magnesium solution is 0.35m 3 / h, the speed of backflow water is 0.12m 3 / h, raise the water temperature to 55-65°C, and continuously feed the waste water at a speed of 0.2m 3 / h, make the waste water and magnesium liquid react continuously in the fluidized bed, lower the water temperature to 40°C, insert the ultrasonic vibrating rod into the fluidized bed, turn on the ultrasonic vibrating rod for ultrasonic reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com