Mobile dehydration drying system for mud

A mobile, mud technology, applied in the direction of water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problems of inability to install large-scale equipment, high cost of site construction, small construction site area, etc. , to achieve the effect of preventing the odor from spreading and disturbing the residents, occupying a small area, and overcoming a large area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

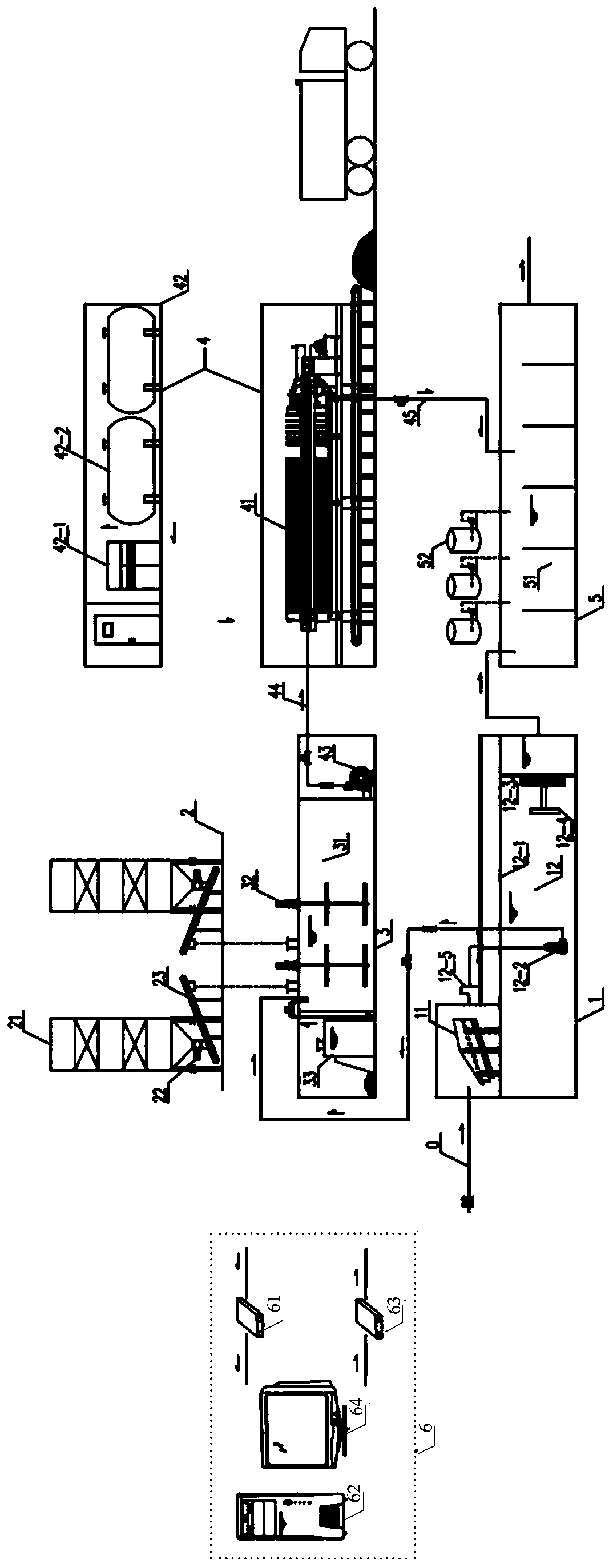

Image

Examples

Embodiment 1

[0059] A mud deep dehydration drying system, which comprises the following steps:

[0060] a. Mud supply: a subway shield mud, the mud concentration is 21%, and the mud is transported to the impurity removal equipment through pipelines;

[0061] b. Use impurity removal equipment to remove impurities from the mud and remove large lumps of mud and garbage in the mud;

[0062] c. Transport the impurity-removed mud obtained in step b to the thickening equipment. The treatment time of the mud in the thickening equipment is about 2 to 6 hours, and the filtrate after mud thickening is discharged to the tail water treatment system through the overflow weir;

[0063] d. Transport the concentrated mud in step c to the curing agent delivery system. According to the dosing ratio of the agent, the curing agent delivery system needs to adjust the amount of mud per unit time, and adjust the unit time of the agent by adjusting the parameters of the control electric cabinet of the equipment. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com