Pu'er tea active paste for effectively retaining original tea aroma and taste and preparation method of same

A Pu-erh tea aroma technology, applied in the field of Pu-erh tea active tea paste and its preparation, can solve the problems of single ingredients, distorted proportions, weak tea aroma, etc., and achieve the effect of bright red soup, convenient storage, and strong aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0021] The aroma volatile oil component comprises 2-55% of linalool and 5-40% of linalool oxide in the mass percent.

[0022] The aroma volatile oil component comprises 1,2,3-trimethoxybenzene and / or 2-10% 1,2,4-trimethoxybenzene and / or 2-30% by mass percentage 12% of 1,2-dimethoxybenzene.

[0023] The linalool oxide comprises 1-15% of cis-pyran-linalool oxide or / and 2-28% of trans-pyran-linalool oxide or / and 1~12% cis furan type linalool oxide or / and 2~18% trans furan type linalool oxide.

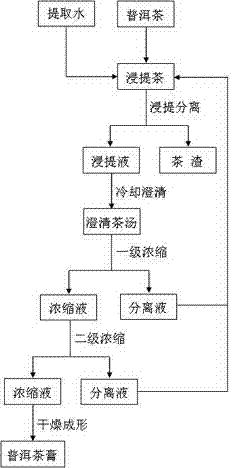

[0024] like figure 1 As shown, the preparation method of the Pu-erh tea active tea extract that effectively retains the aroma and mouthfeel of the original tea described in the present invention includes tea extraction, cooling and clarification, primary concentration, secondary concentration, and drying and forming, specifically:

[0025] A. Tea extraction: Put the raw tea leaves into the extraction tank, add 30-90°C extraction water with a volume ratio of 5-15 times to extract 2-8 ti...

Embodiment 1

[0041] Take 20kg of Pu’er ripe tea to remove impurities, rinse it with cold water, put it into a dynamic countercurrent extraction tank, add 10 times the volume of deionized water for the first extraction, and extract 4 times at a temperature of 60°C, each time for 0.5h, separate The extraction liquid is obtained; the extraction water used for the 2nd, 3rd, and 4th leaching is the concentrated separation liquid of the previous leaching. Naturally cool the extract to 35°C, and filter through a filter membrane with a pore size of 1 μm to obtain clarified tea soup; concentrate and separate the clarified tea soup through a 0.001 μm reverse osmosis membrane to obtain a primary concentrate and a separation liquid; pass the primary concentrate through 0.001 Concentrate with μm reverse osmosis membrane to obtain 24.7kg of secondary concentrate with a solid content of 11.8%; the secondary concentrate is vacuum freeze-dried to a tea paste with a moisture content of 22%, and then molded, ...

Embodiment 2

[0047] Take 15kg of raw Pu-erh tea to remove impurities, crush it, rinse it with cold water, put it into a percolation extraction tank, add 5 times the volume of distilled water for the first extraction, and extract it at a temperature of 30°C for 6 times, each time for 1.5 hours, Separate and obtain the extract; cool the extract to 10°C by electric refrigeration, and filter through a filter membrane with a pore size of 5 μm to obtain clarified tea soup; concentrate and separate the clarified tea soup through a 0.0001 μm reverse osmosis membrane to obtain a primary concentrate and separation liquid; Concentrate the primary concentrated solution at low temperature and reduced pressure to obtain 8kg of secondary concentrated solution with a solid content of 30.4%; spread the secondary concentrated solution on a tray and dry it in a microwave vacuum at 45°C to obtain 2.4kg of shaped Pu-erh active tea paste.

[0048] The detection method in Example 1 was used to detect the prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com