Mixed steam condensation heat transfer reinforcement surface, preparation method and application thereof

A technology of heat transfer enhancement and steam condensation, which is applied to the device and coating of the surface coating liquid, which can solve the problems of increasing heat transfer resistance, increasing adhesion force, and weakening droplet movement ability, so as to achieve enhanced Condensation and heat transfer of mixed vapor, enhanced heat and mass transfer, and low solid-liquid adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

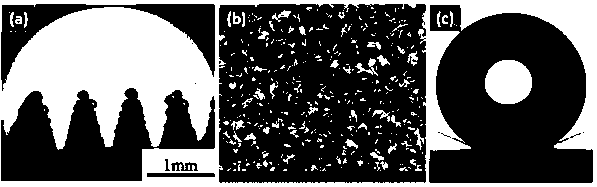

[0038] Using commercially available 2cm*2cm red copper as the substrate, a V-shaped submillimeter structure is constructed, and the surface is oxidized and etched and self-assembled with low surface energy materials to make it super-hydrophobic. Its specific technical process is:

[0039] 1. Copper substrate pretreatment: use 800 mesh, 1200 mesh, 2000 mesh, 3000 mesh sandpaper to grind and polish in sequence.

[0040] 2. Submillimeter V-groove mechanical engraving: use single-line engraving mode, use a flat-bottomed tapered knife with a cone angle of 30° to engrave V-shaped grooves on the copper surface, and the engraving depth is 1mm to obtain a copper surface with a V-shaped structure.

[0041] 3. Oil cleaning treatment: use acetone, ethanol, and deionized water to clean with ultrasonic vibration for 3 minutes, and blow dry with nitrogen.

[0042] 4. Oxidation etching: immerse the cleaned copper surface in an etching solution at 96 degrees Celsius (sodium chlorite, sodium h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com