Patents

Literature

91results about How to "Precise Width Control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

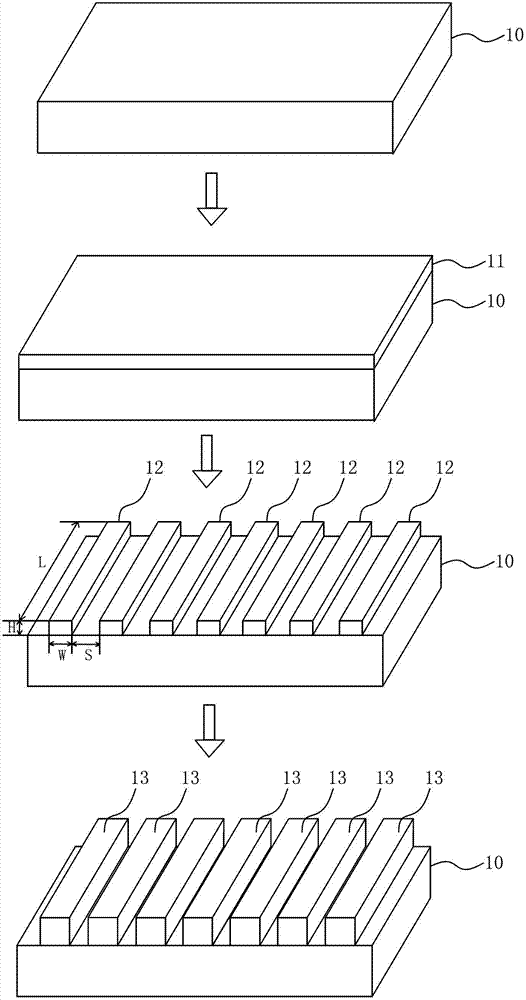

Method for preparing phase shift optical fiber bragg grating based on femtosecond laser direct writing

ActiveCN106291802AEasy to operatePrecise length controlCladded optical fibreOptical waveguide light guideGratingPhase shifted

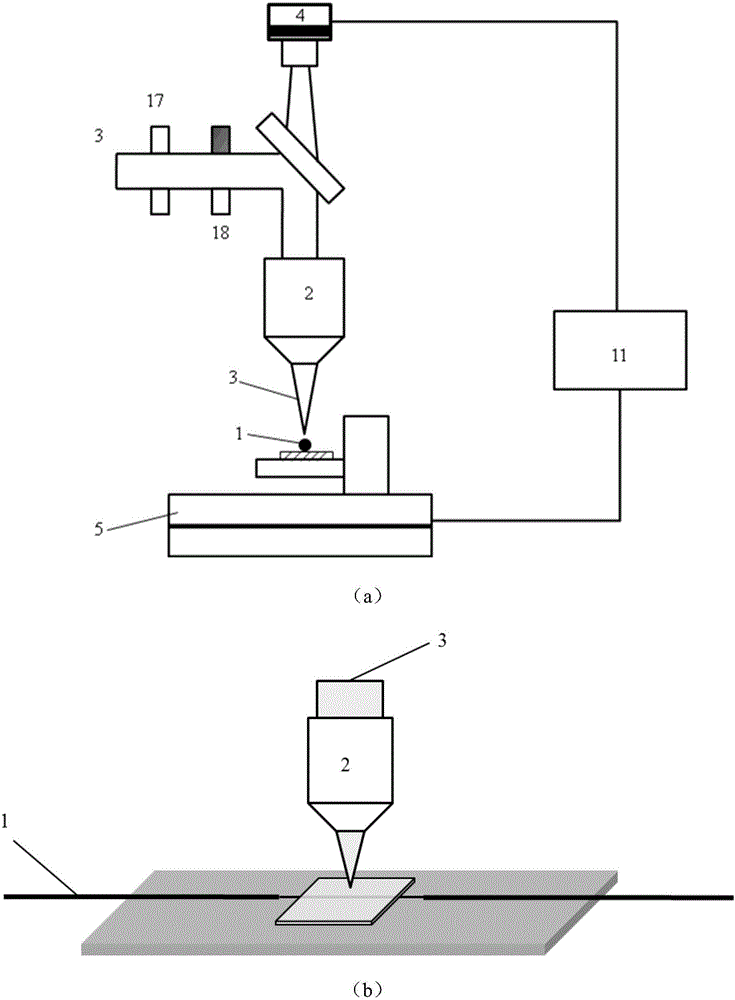

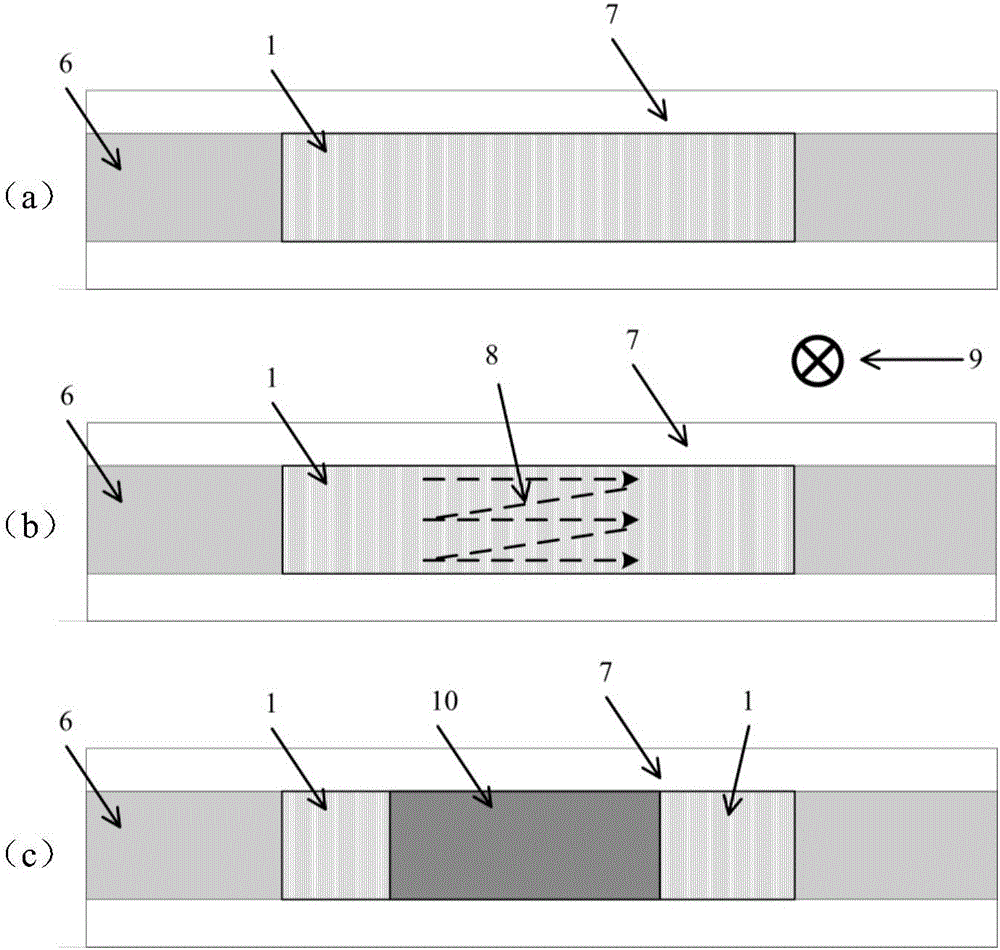

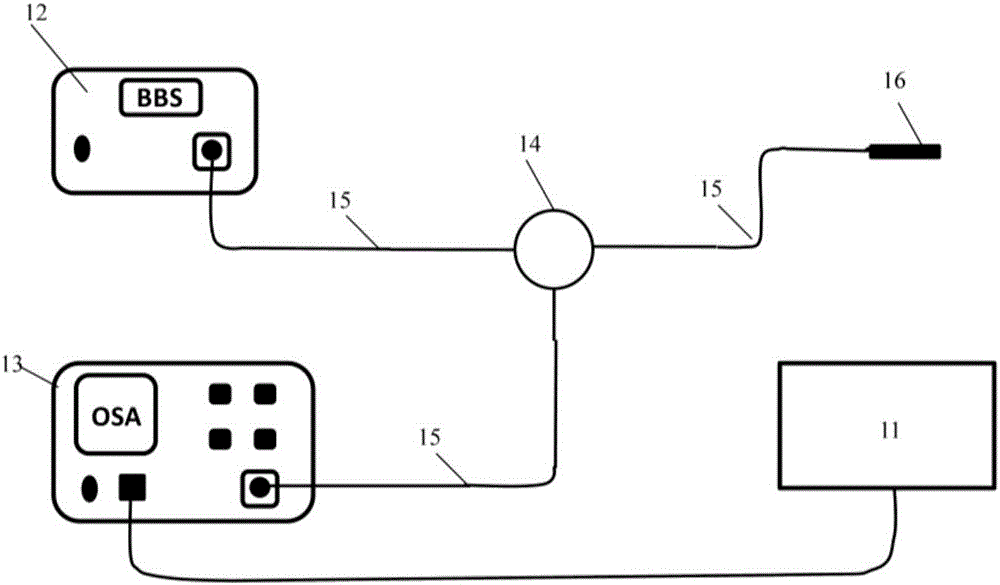

The invention provides a method for preparing phase shift optical fiber bragg grating based on femtosecond laser direct writing. The method comprises the following steps: performing fixed point radiation or scanning in a fiber core area of the optical fiber bragg grating of an ordinary structure by using focused femtosecond laser, forming one or more areas with changed refractive indexes in the fiber core area of the optical fiber bragg grating of the ordinary structure, and forming a phase shift structure, thereby obtaining the phase shift optical fiber bragg grating. Compared with the prior art, the method is relatively simple in processing procedure, high in processing speed and applicable to optical fiber of different materials, and precision control of phase shift within 0-2pi can be achieved. The phase shift optical fiber bragg grating prepared by using the method provided by the invention can be applied to fields of sensation, optical fiber laser and the like.

Owner:XI AN JIAOTONG UNIV +1

Synthetic method for monodisperse spinous gold nanoparticles

ActiveCN107252896APrecise control of the numberPrecise length controlMaterial nanotechnologyTransportation and packagingNanoparticleBiocompatibility Testing

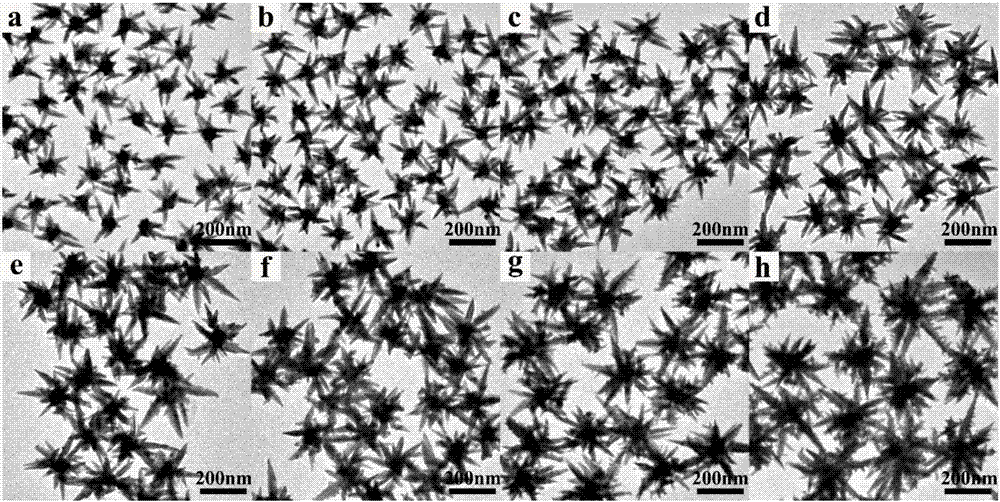

The invention discloses a synthetic method for monodisperse spinous gold nanoparticles. The synthetic method comprises the following steps that (1) a first chloroauric acid solution, a second chloroauric acid solution, a first silver nitrate solution, a second silver nitrate solution, a glutathione solution, a sodium borohydride solution, a first ascorbic acid solution, a second ascorbic acid solution, a hexadecyl trimethyl ammonium bromide solution and a hexadecyl trimethyl ammonium chloride solution are prepared; (2) a growth solution is prepared; (3) an excessive growth solution is prepared; (4) rod-shaped gold nanoparticles are prepared; (5) a rod-shaped gold nanoparticle solution is prepared; and (6) the rod-shaped gold nanoparticle solution, the excessive growth solution and ultra-pure water are mixed and stirred, standing is conducted at the constant temperature, and the monodisperse spinous gold nanoparticles are obtained. According to the method, the monodisperse spinous gold nanoparticles which are high in yield and adjustable in size, number of surface thorns, length and width can be obtained, used ligand can be subjected to ligand exchange with other biocompatibility ligand, and application of the gold nanoparticles is further expanded.

Owner:SHANDONG UNIV

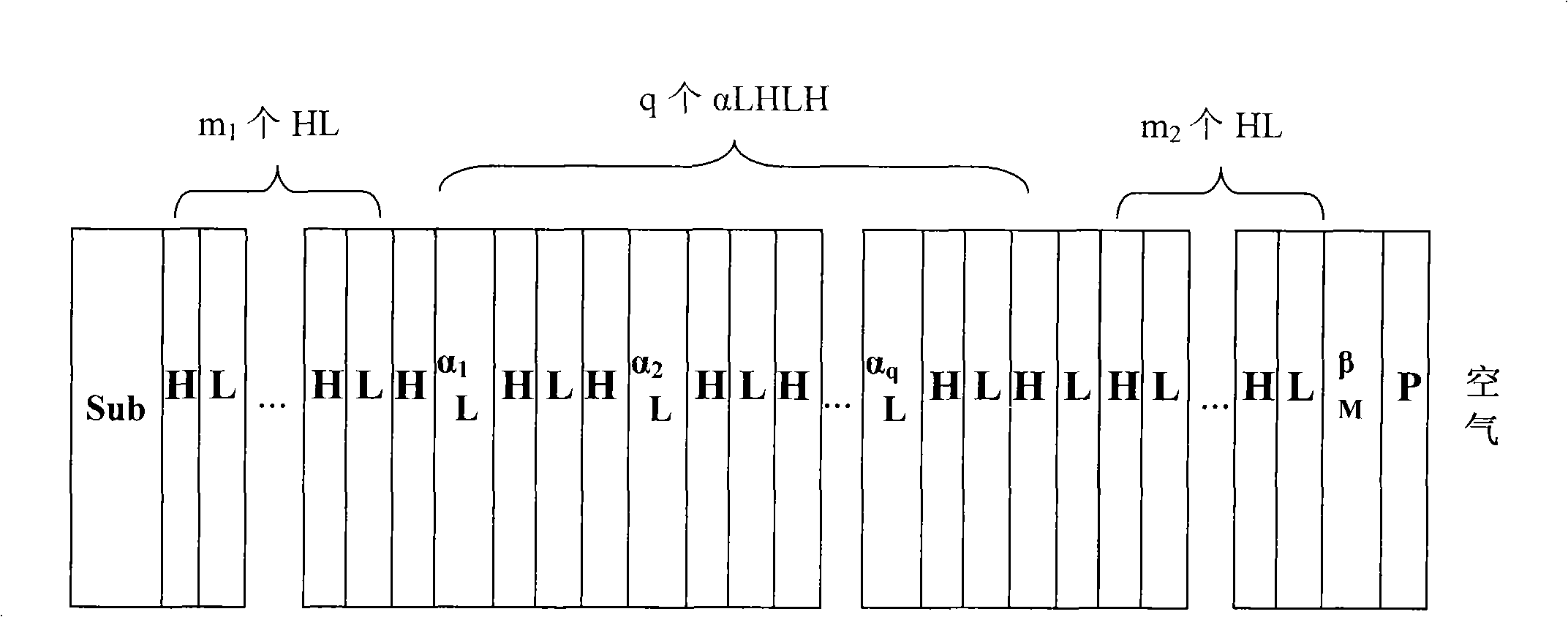

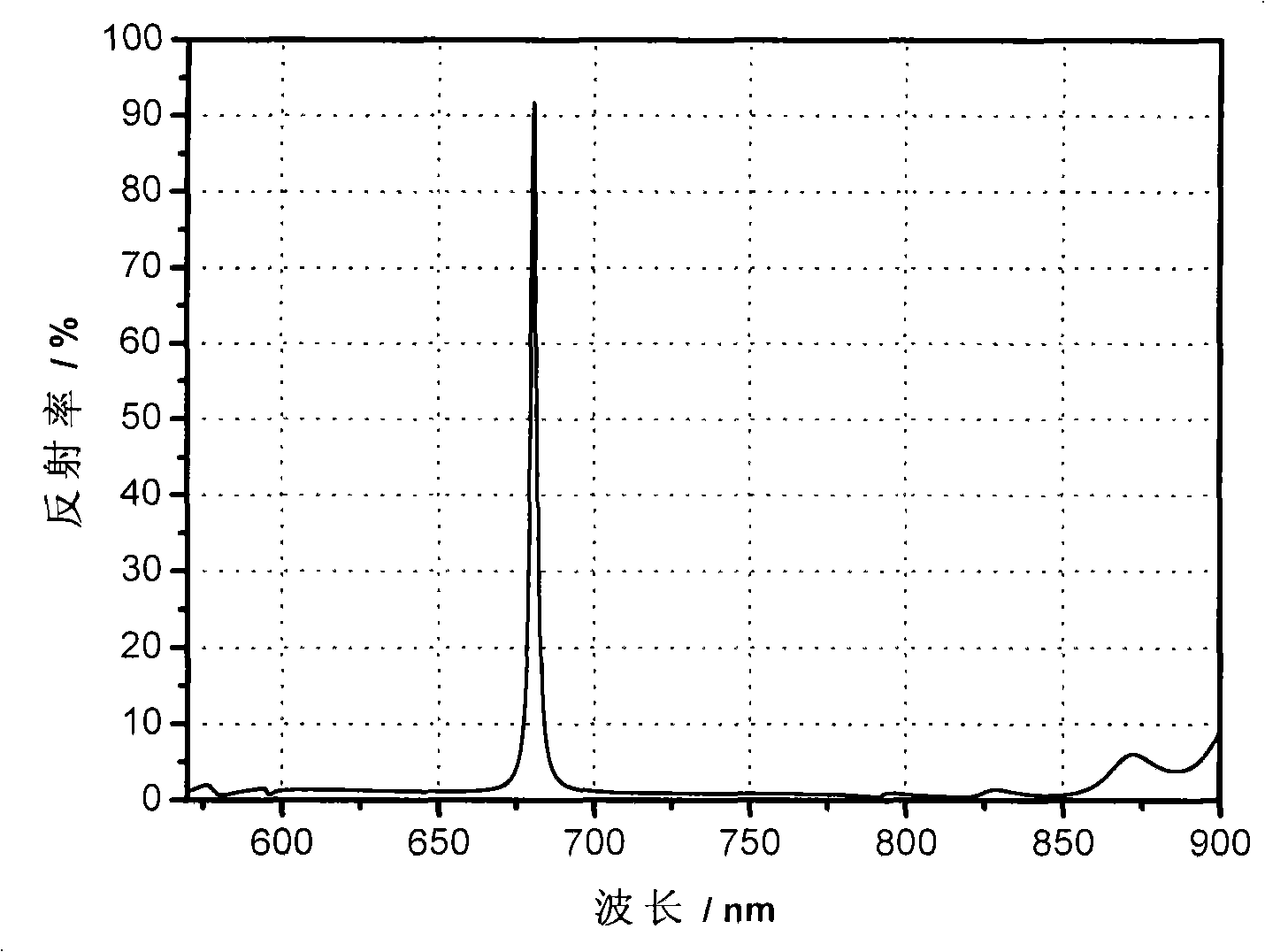

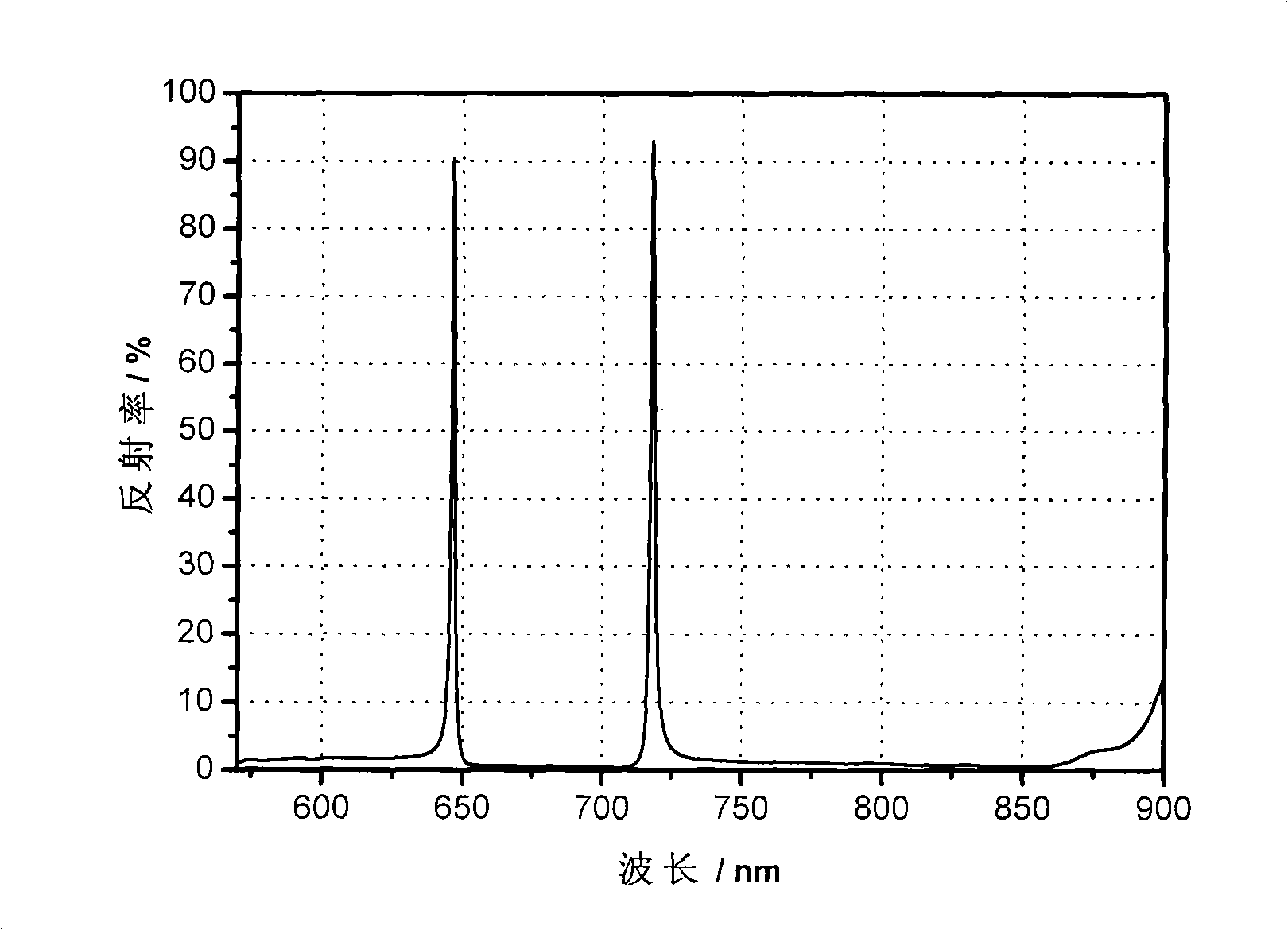

Multiple peak narrowband reflection filter possessing broad low reflecting bypass belt

InactiveCN101266312APrecise Width ControlPrecise position controlOptical elementsGratingRefractive index

The invention provides a singlet narrowband reflection filter with a wide low reflection bypass band, wherein the membrane structure is a medium-metal composite membrane based on the asymmetric Fabry-Perot structure, namely Sub|(HL)m1H(alpha 1LHLH)( alpha 2LHLH)...(alpha qLHLH)L(HL)m2 beta MP|Air, wherein the Sub is optical thin film substrate; Air is air; H, L respectively is high, low index material of 1 / 4 wavelength optical thickness; alpha 1, alpha 2...alpha q is the thickness coefficient of the L space layer and q is the number of the (alpha LHLH) repeating units; M is metal layer; beta is thickness of the metal layer; P is the admittance matching layer; m1, m2 is number of the repeating units. The membrane structure is the medium-metal composite membrane based on the asymmetric Fabry-Perot structure with remarkable difference compared with the existing full medium filter, sub-wavelength grating filter. The number of the reflection peak can be adjusted and controlled and the low reflection bypass band can be greatly expanded. The half width and position of the reflection peak can be adjustable, applied to the optical instrument, astronomy, remote observation and optical communication or the like.

Owner:TONGJI UNIV

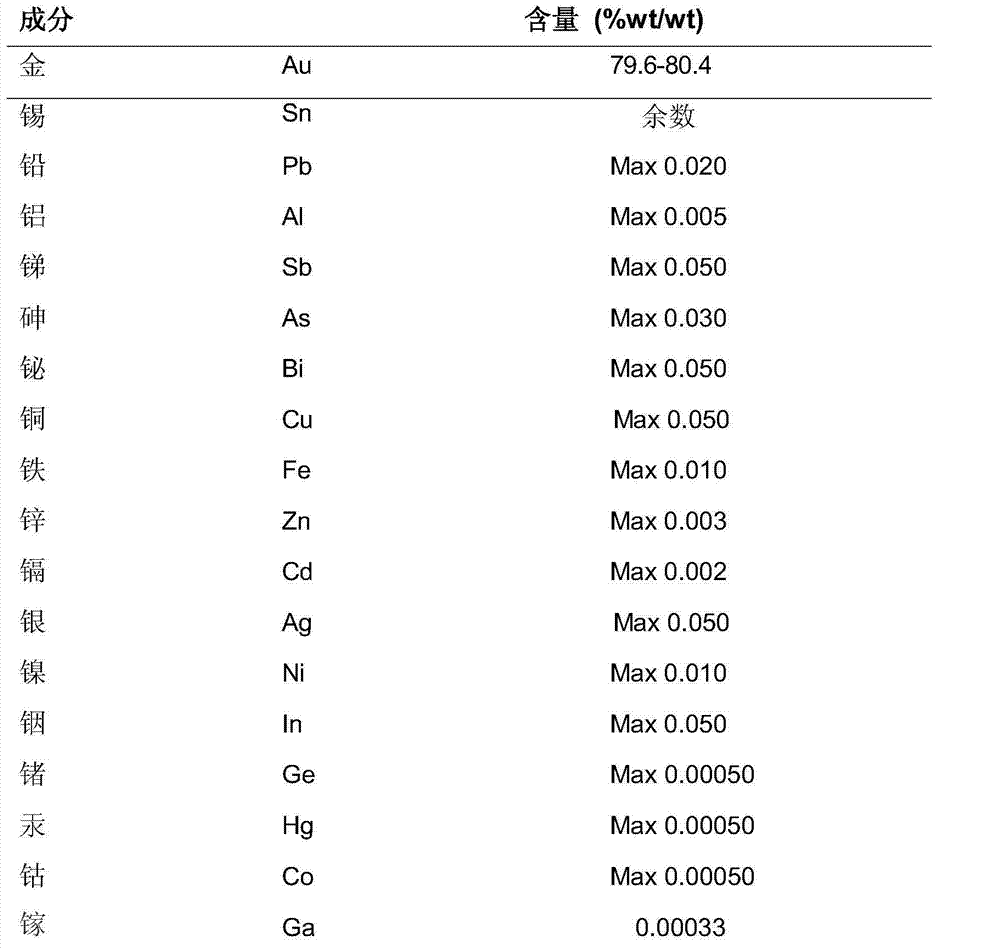

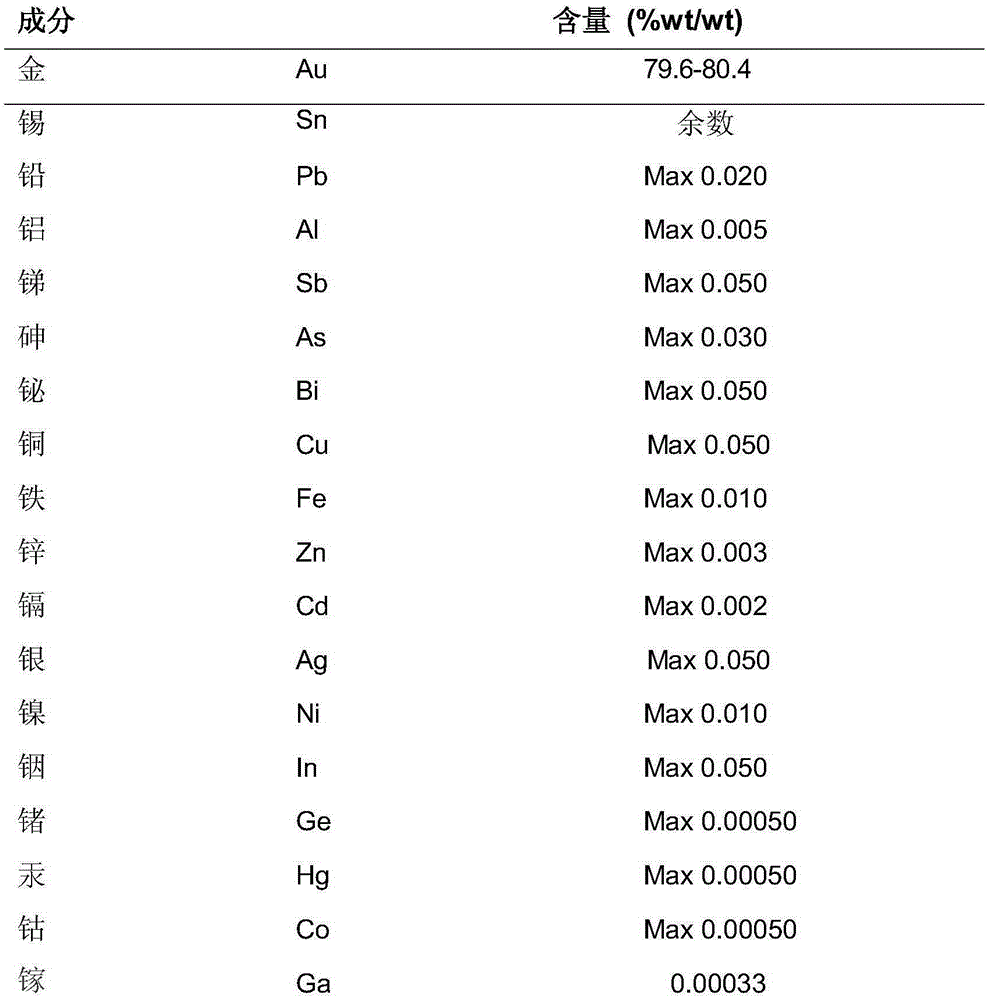

Production method of gold-tin wire, foil belt and preforming welding piece

ActiveCN103753057AMake sure the surface is shinyEnsure that the oxide layer is reducedWelding/cutting media/materialsSoldering mediaMaterials scienceExtrusion

The invention provides a production method of a gold-tin wire, a foil belt and a preforming welding piece and belongs to the welding technical field. The production method comprises step 1, smelting gold and tin into alloy and casting the gold and the tin into an alloy rod; step 2, performing annealing; step 3, performing extrusion forming which comprises arranging a tin wire die with a circular hole at the position of the outlet of an extruding machine first when the ally rod needs to be extruded into a tin wire and arranging a foil belt die with a square hole at the position of the outlet of the extruding machine first when the ally rod needs to be extruded into the foil belt, then placing the product in the step 2 into the extruding machine, adjusting the intensity of pressure of the extruding machine to 250 to 350 Mpa and adjusting the temperature to 150 to 230 DEG C; step 4, cutting the foil belt which is obtained through extrusion in the step 3 into the preforming welding piece. According to the production method of the gold-tin wire, the foil belt and the preforming welding piece, the problem that the machining forming is difficult due to the high brittleness of the gold-tin alloy in the prior art is solved, the technological process is simple and convenient, the mass production can be performed, the product accuracy is good, and the product consistency is good.

Owner:SHENZHEN FUMOSUO METAL PROD

Nodular cast iron laser hardening technology

InactiveCN102477479AShort process cycleIncrease productivityMelting Point TemperatureAutomatic control

The invention relates to a laser hardening technology for a nodular cast iron workpiece. The laser hardening technology for the nodular cast iron workpiece comprises the steps of: fast scanning a workpiece surface by using a laser beam with high energy, and fast heating the workpiece surface by using the laser till the temperature of the workpiece surface is in the temperature range between an austenitic phase transition temperature of the workpiece and a melting point temperature of the workpiece. The hardening layer of the nodular cast iron workpiece has fine and dense textures; the hardness and wear-resisting property of the workpiece are largely improved; as laser quenching has a smaller heat affected zone on a substrate, the deformation and cracks of the workpiece are lightened, and the strengthening quality of the workpiece is high; meanwhile, the technological process is easy to realize automatic control.

Owner:HUNAN UNIV +2

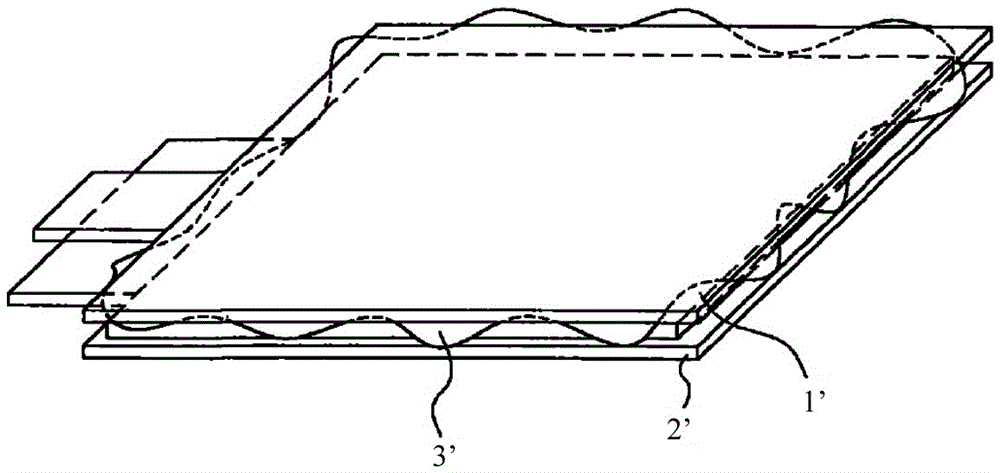

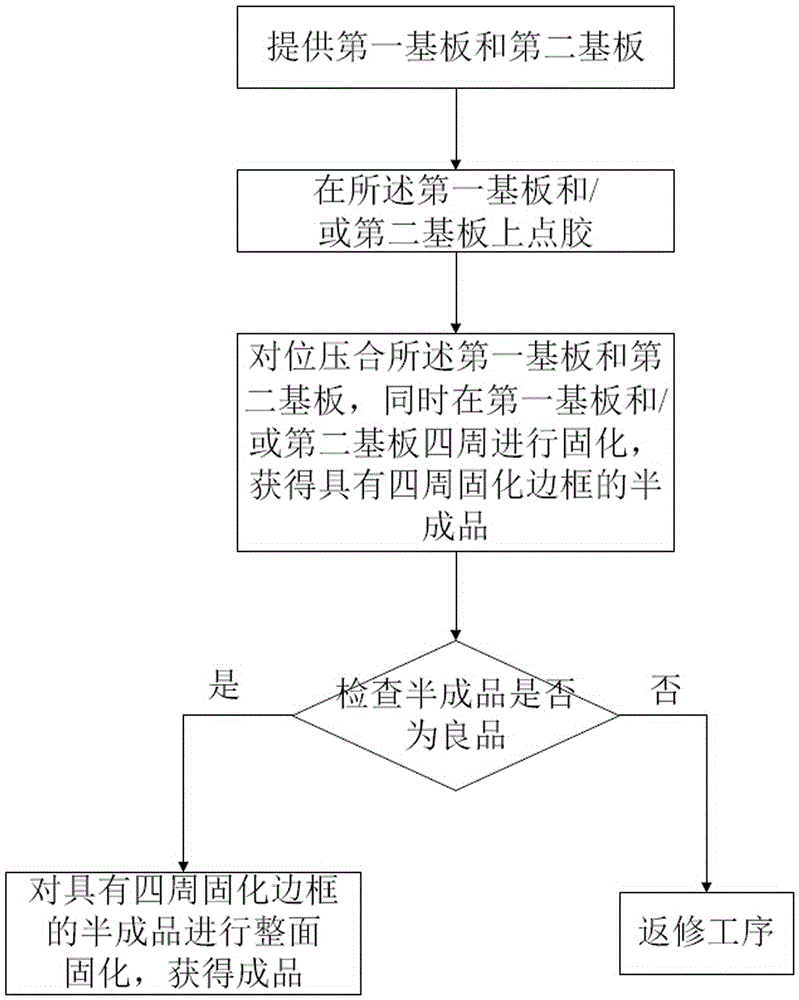

Glue laminating process

InactiveCN105774184APrecise Width ControlEasy to operateLamination ancillary operationsLaminationProduction lineColloid

The invention provides a glue laminating process. The glue laminating process comprises the following steps: (1) providing a first substrate and a second substrate; (2) dispensing a glue to the first substrate and / or the second substrate; (3) carrying out aligned press-fitting on the first substrate and the second substrate, and meanwhile, curing the periphery of the first substrate and / or the second substrate so as to obtain a semifinished product with a periphery-cured frame; and (4) carrying out surface-dressing curing on the semifinished product with the periphery-cured frame, thereby obtaining a finished product. According to the glue laminating process, the periphery of the substrates is cured while the aligned press-fitting of the substrates is completed so as to obtain the periphery-cured frame, thus, the problem of glue overflowing is effectively solved, the width of overflowed glue can be accurately controlled, the broadening of the glue does not occur after curing, secondary misalignment does not occur after curing, the accuracy of press-fitting is further improved, and the actual operation of a production line is facilitated; and the problem of press-fit bubbles can be effectively solved, the leveling of the glue is accelerated, the production time is shortened, and the production efficiency is further increased.

Owner:TRULY OPTO ELECTRONICS

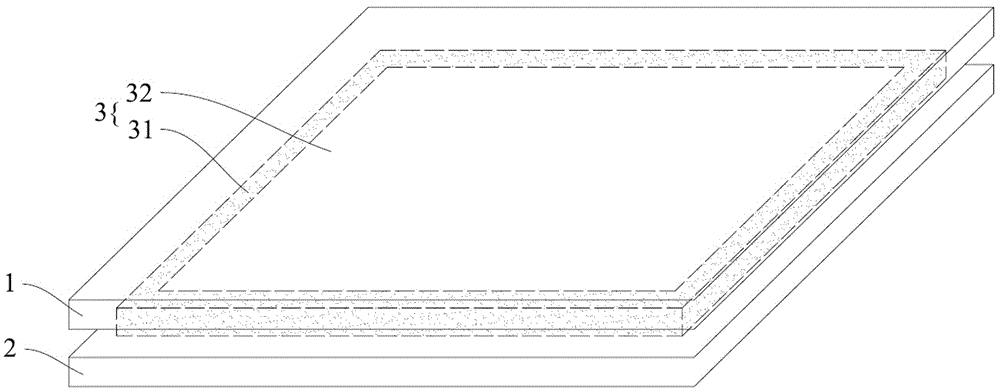

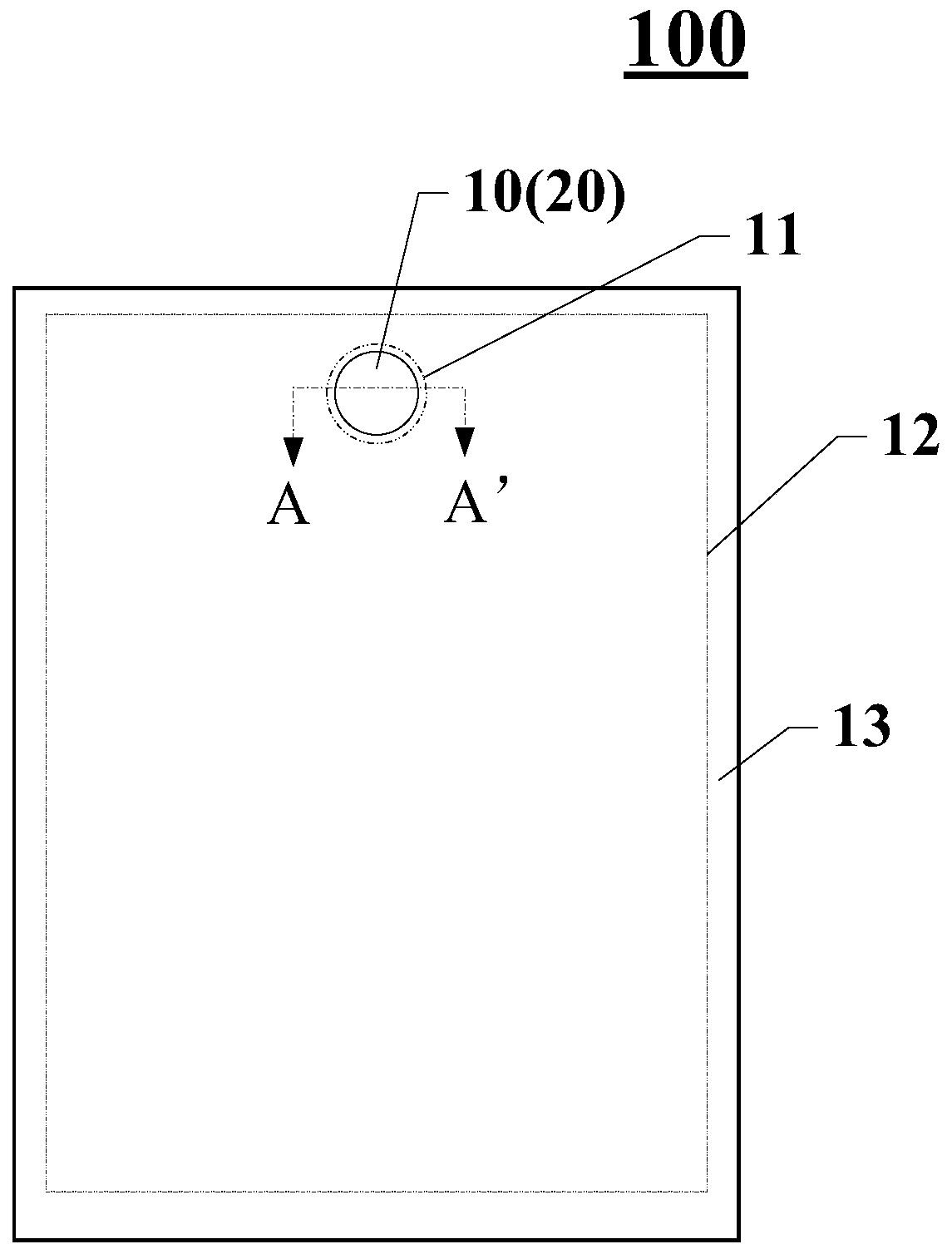

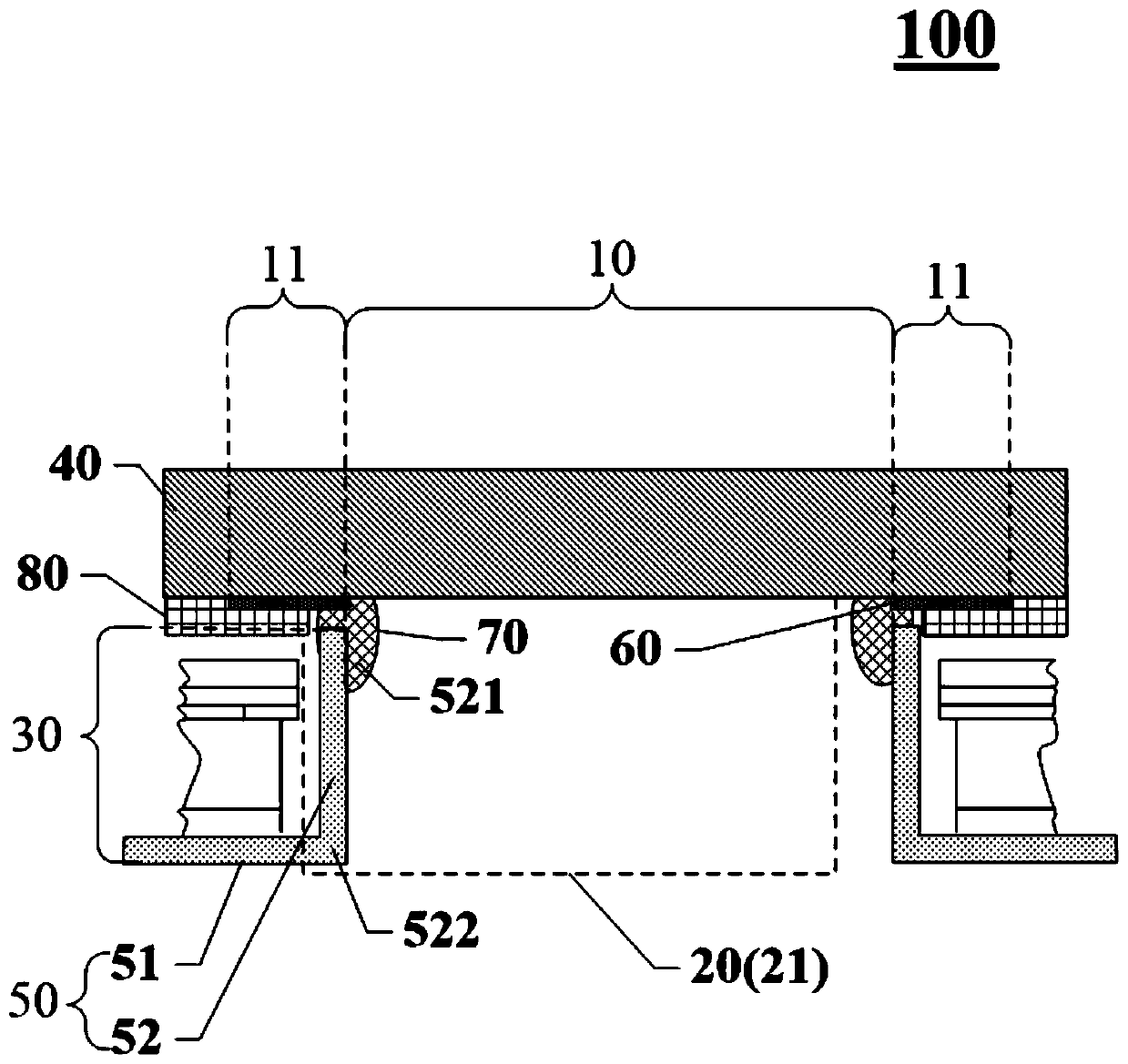

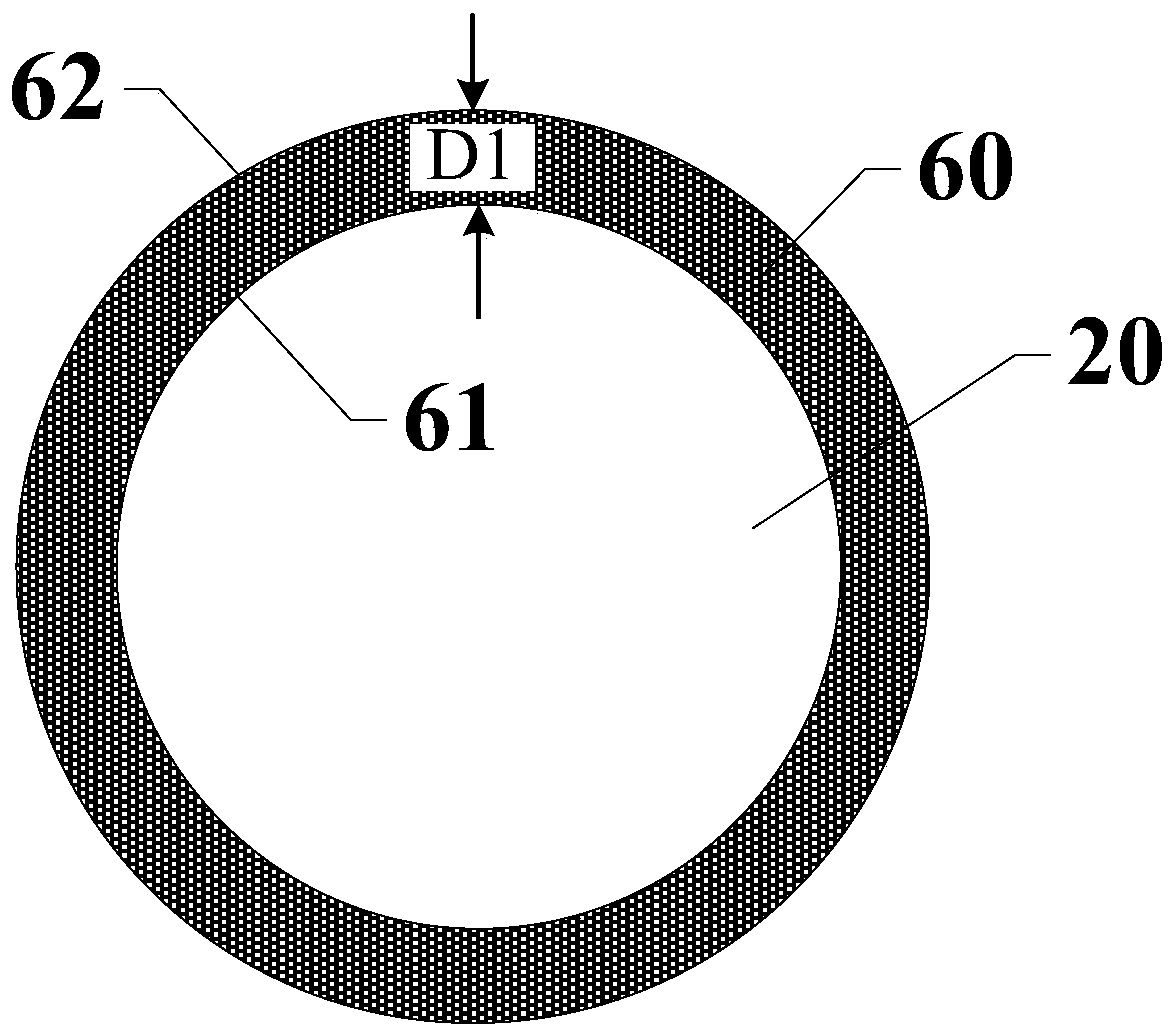

Display module and manufacturing method thereof and display device

InactiveCN110796954AReduce sealing processPrecise Width ControlNon-linear opticsIdentification meansDisplay deviceEngineering

The invention discloses a display module and a manufacturing method thereof, and a display device, and relates to the technical field of the display. The display module comprises a blind hole locatedat a hollow area, a backlight module, and a display panel arranged at one side of a light-emitting surface of the backlight module; the blind hole penetrates through the backlight module, and a holding space is formed by the blind hole and one side, towards the backlight module, of the display panel; a back frame of the backlight module comprises a base and a bending part, the bending part is benttowards the display panel, and the bending part form the hole wall of the blind hole; the bending part comprises a first end and a second end which are oppositely arranged along a direction verticalto a plane located by the display panel, the second end is connected with the base, and the first end is located at one side, close to the display panel, of the second end; the display module furthercomprises an ink layer and a sealant layer; the ink layer and the sealant layer are located at one side, towards the backlight module, of the display panel; the ink layer is covered on a first non-display area, the sealant layer is filled between the first end and the display panel and contacts with the ink layer. Therefore, the sealant manufacturing process can be reduced when the narrow frame isrealized.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

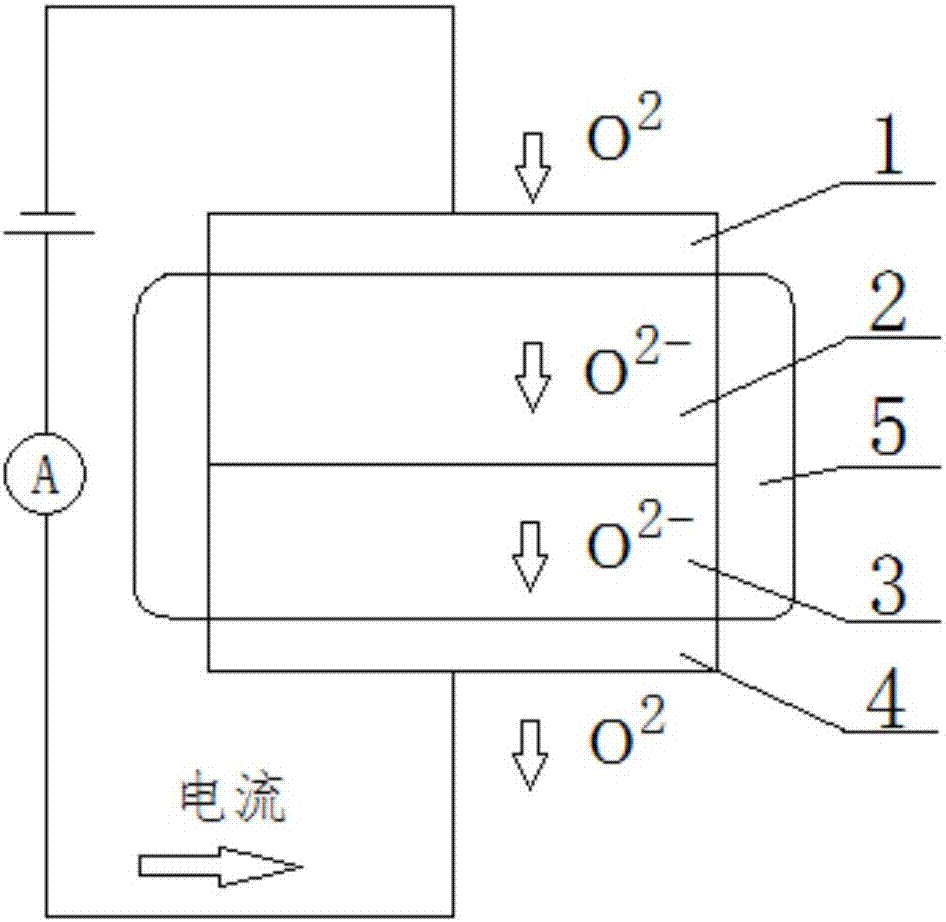

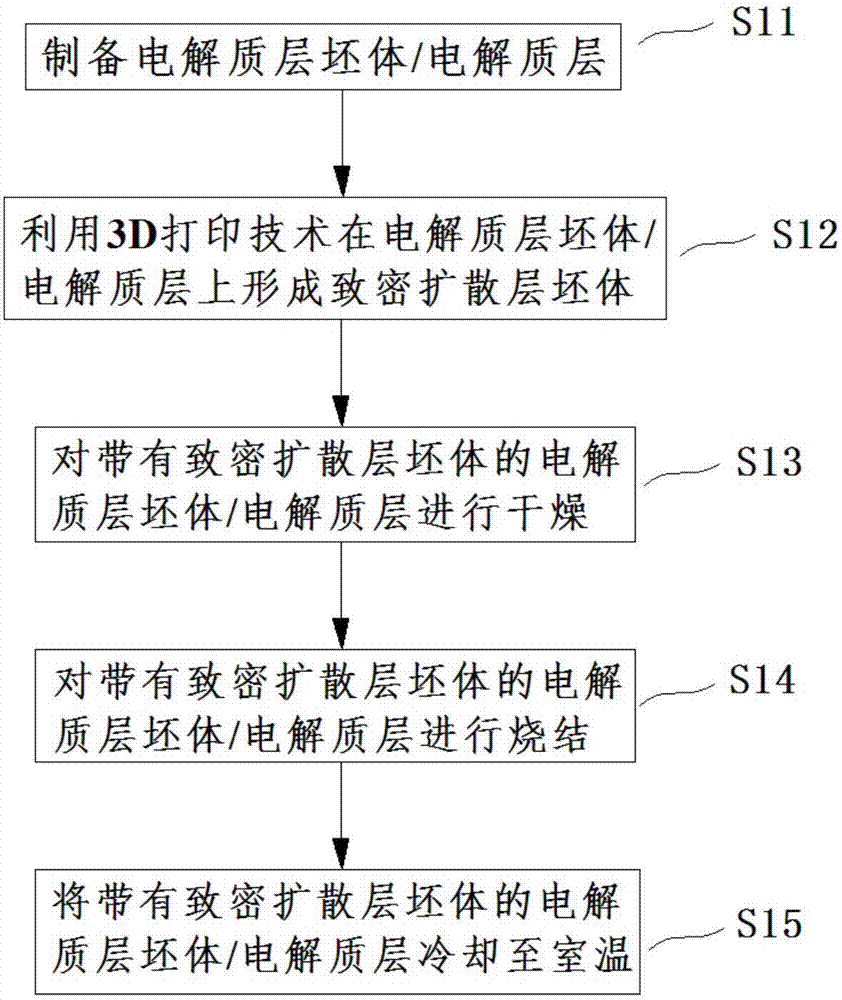

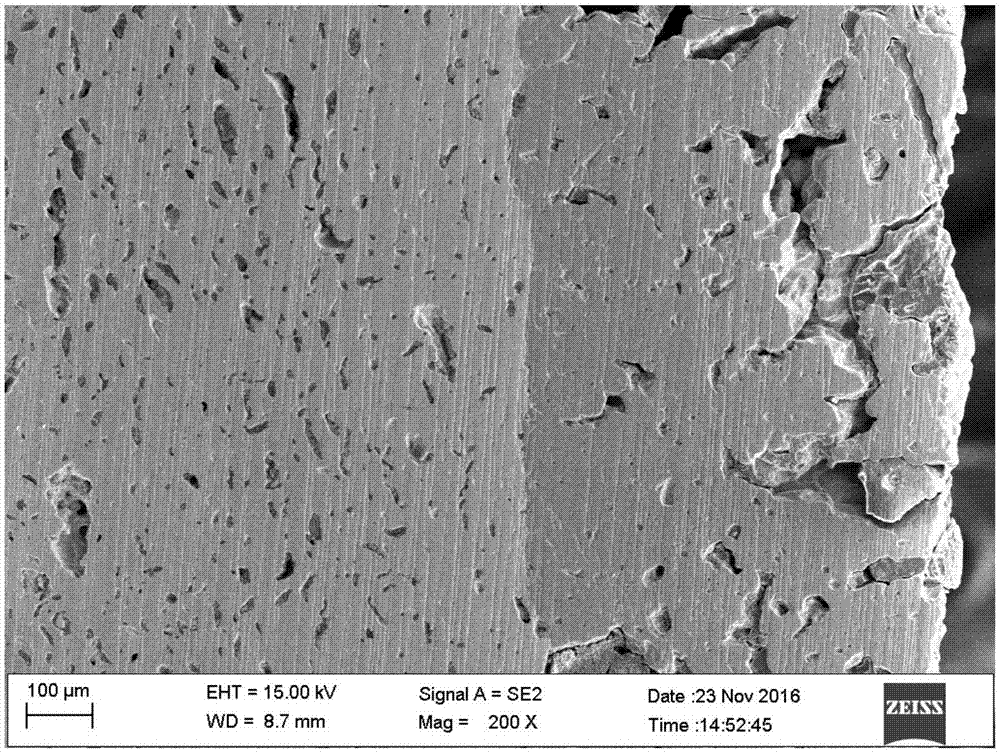

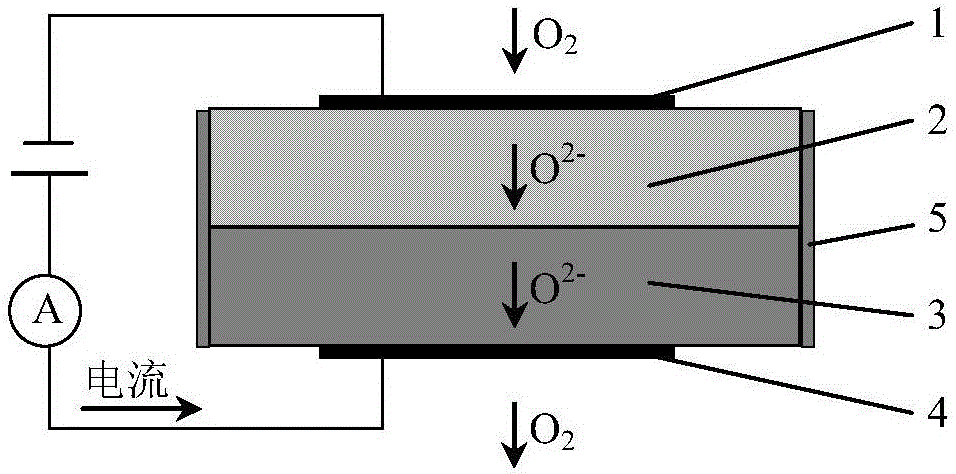

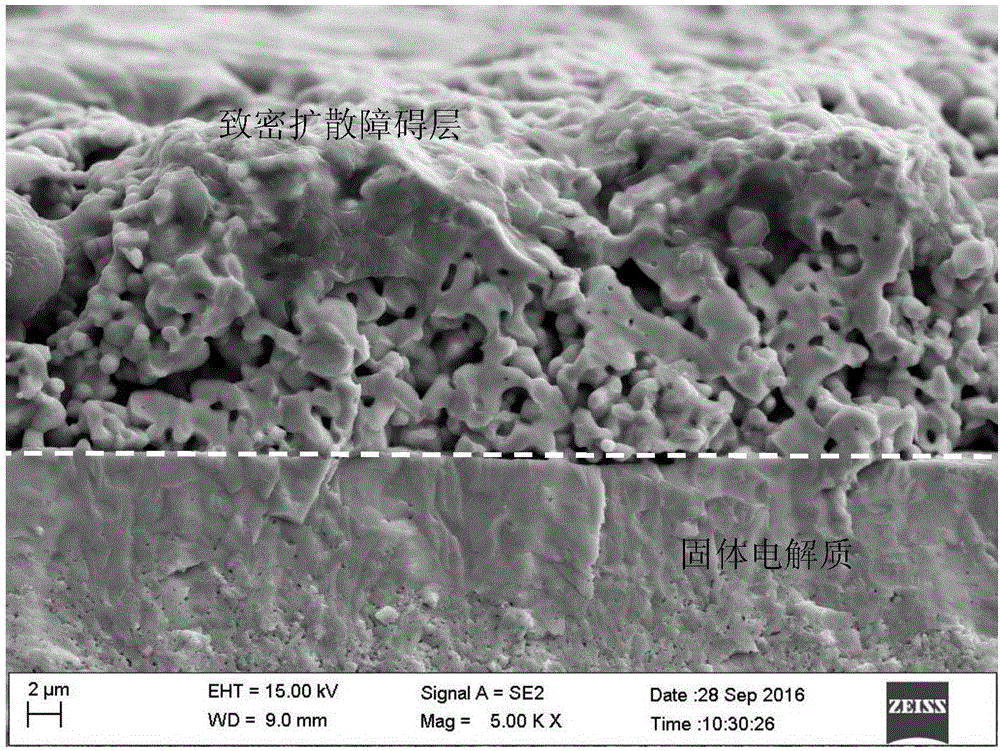

Manufacturing method of double-layer structure of electrolyte layer and compact diffusion layer for oxygen sensor

ActiveCN107389770AUniform and dense tissueReduce porosityMaterial analysis by electric/magnetic meansElectrolyteDiffusion layer

The invention relates to the technical field of an electrochemical oxygen sensor, in particular to a manufacturing method of a double-layer structure of an electrolyte layer and a compact diffusion layer for an oxygen sensor. A 3D printing technology is used for forming a compact diffusion layer blank on an electrolyte layer blank body / electrolyte layer; or the 3D printing technology is used for forming the compact diffusion layer on the electrolyte layer. Through the application of the 3D printing technology, the tissues of the finally formed compact diffusion layer is compact and uniform; the air pores are obviously reduced; the bonding intensity with the electrolyte layer is high; the heat influence region range and the deformation of the electrolyte layer can be reduced to the minimum degree; cracks cannot easily occur; the performance of the oxygen sensor with the double-layer structure and performance stability are improved. In addition, the width and the thickness of the compact diffusion layer can be precisely controlled; the 3D printing speed is high; the preparation period is short; the method is applicable to large-scale production.

Owner:NORTHEASTERN UNIV

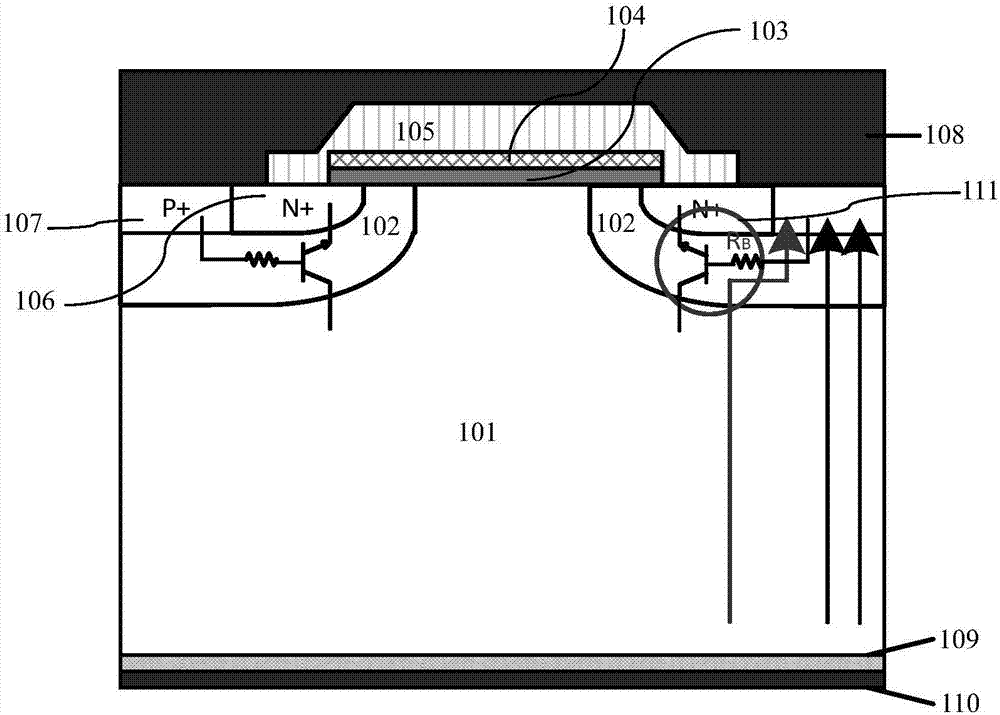

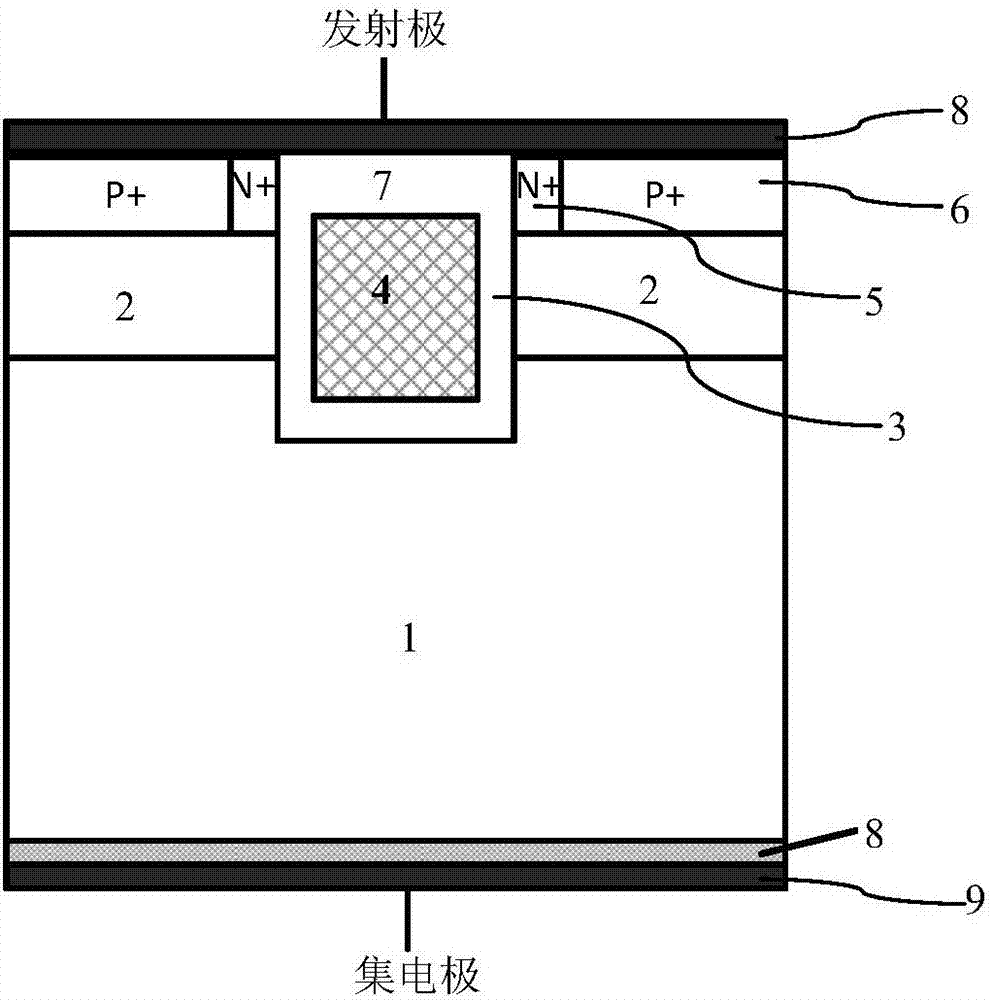

Trench gate IGBT and manufacturing method

InactiveCN106876453AReduce contact widthReduce parasitic resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricZone melting

The invention discloses a trench gate IGBT, including a drift region, a collection zone and P-type body regions. The trench gate IGBT also comprises a gate trench, wherein a gate dielectric layer is formed on the surface and the side surface of the bottom of the gate trench, and a polysilicon gate fills the gate trench. The top surface of the polysilicon gate is lower than the top surface of zone melting silicon, and source regions are formed in the zone melting silicon at two sides of the gate trench on the top of the polysilicon gate by self-aligning ion implantation with an inclination angle. The trench gate IGBT also comprises P+ contact regions formed on the surface of the P-type body regions. The P+ contact regions and the source regions are connected to an emitter electrode through contact holes. The invention also discloses a manufacturing method of the trench gate IGBT. The width of the source regions can be reduced by self-aligning ion implantation, so that the parasitic resistance of the P-type body regions is reduced, and the anti-latching capability of the device is improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

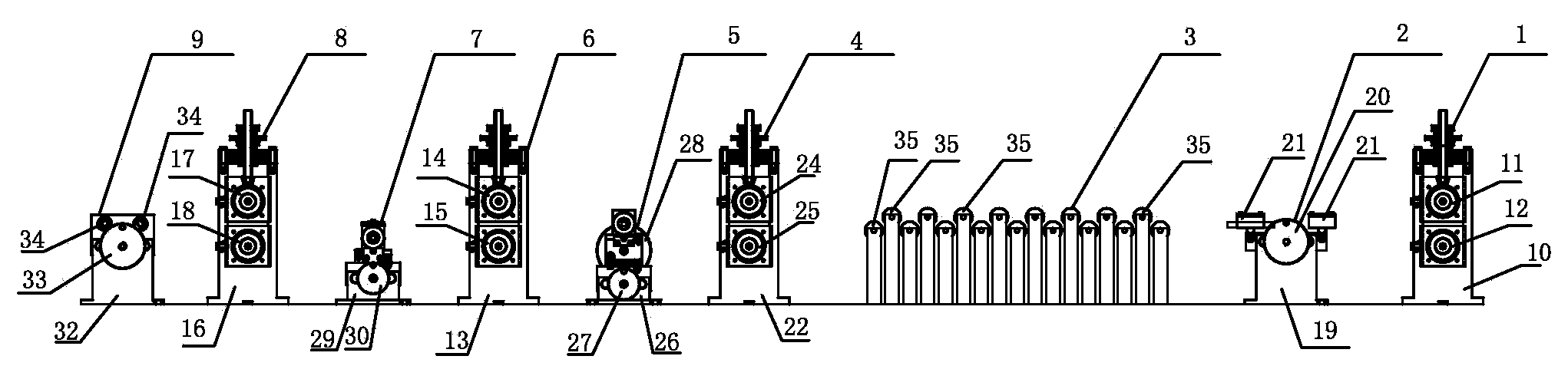

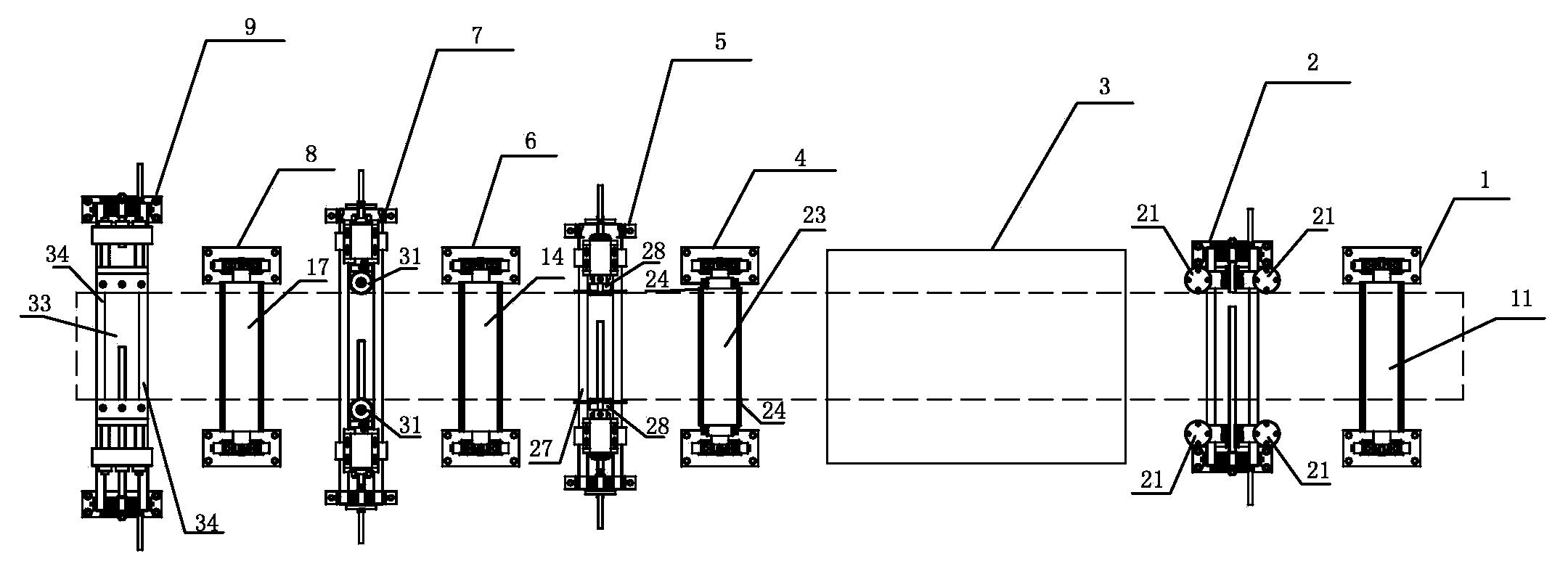

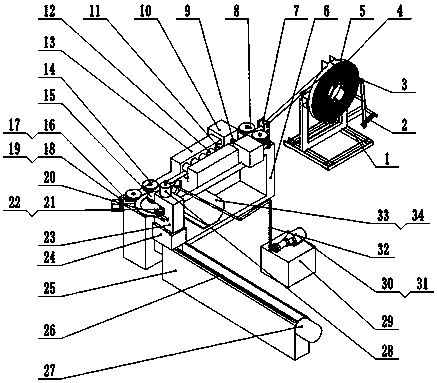

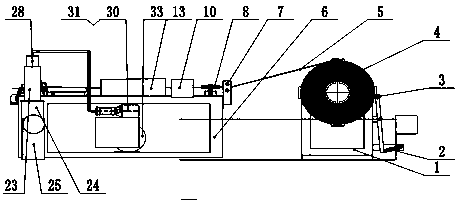

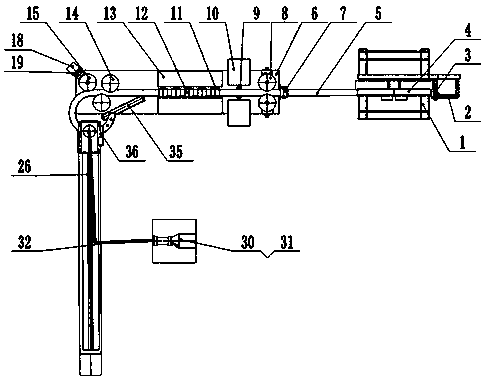

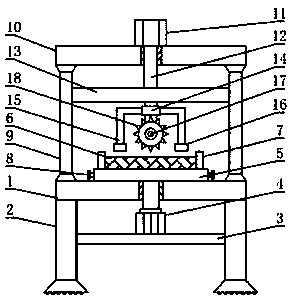

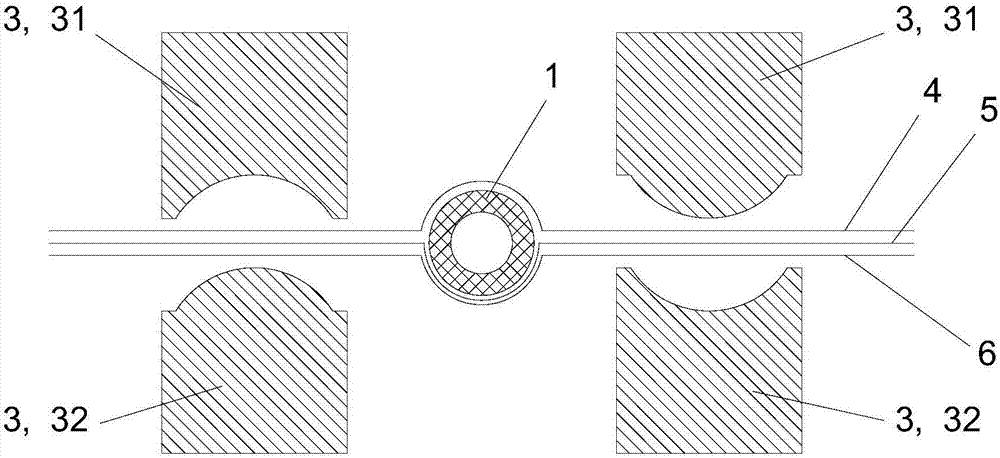

Copper strap edge processing equipment for five-in-one voltage transformer

ActiveCN103447819AGood shape conditionGuaranteed continuityOther manufacturing equipments/toolsTransformerStructural engineering

The invention discloses copper strap edge processing equipment for a five-in-one voltage transformer. The equipment is directly arranged on the ground; a first supporting device, an edge positioning device, a flattening device, an edge rolling device, an edge scraping device, a second supporting device, an edge extruding device, a third supporting device and an edge scrubbing device are sequentially arranged on the ground from right to left. The equipment can be used for eliminating defects such as sharp corners, burrs and flanged edges at the edge of a copper strap, meanwhile can meet the requirements of the copper strap of the voltage transformer for shapes of special edges such as round corners and round corner edges.

Owner:浙江力博实业股份有限公司

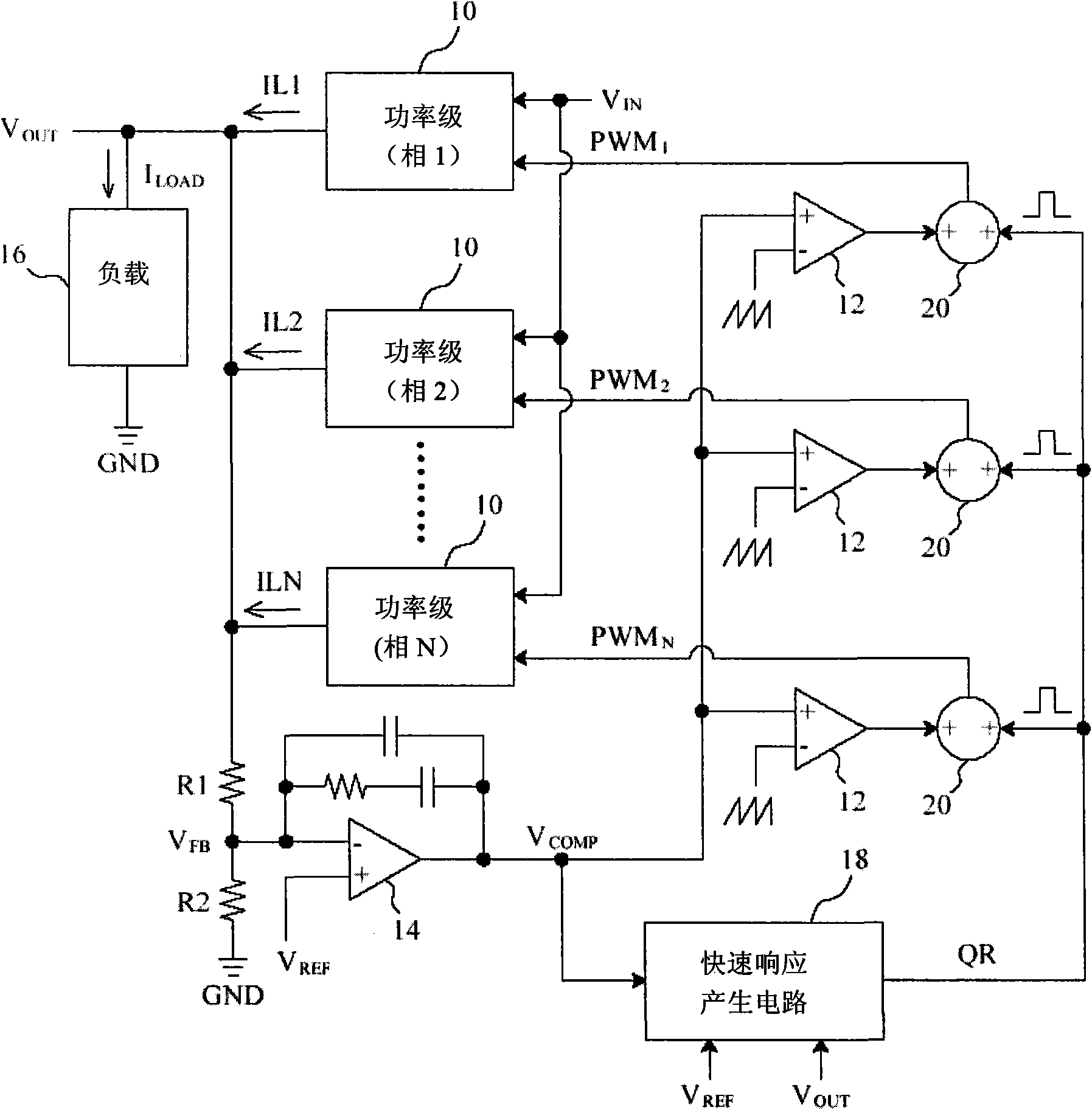

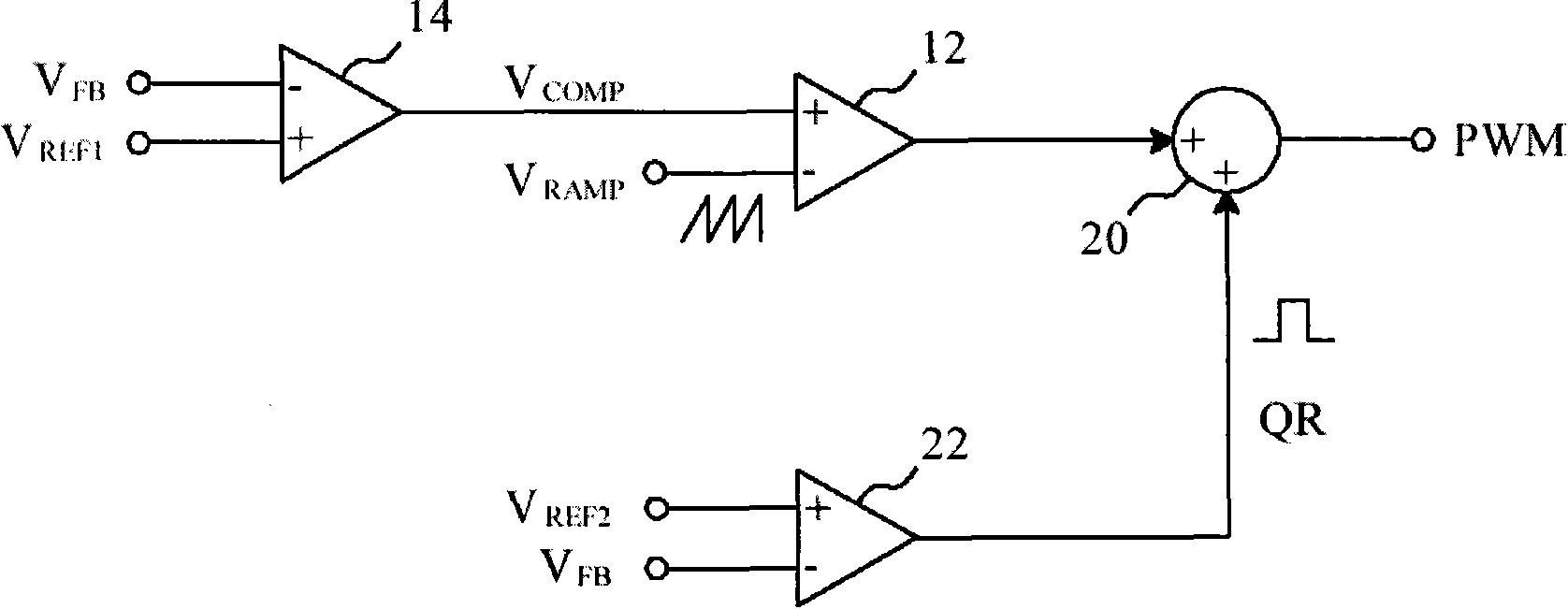

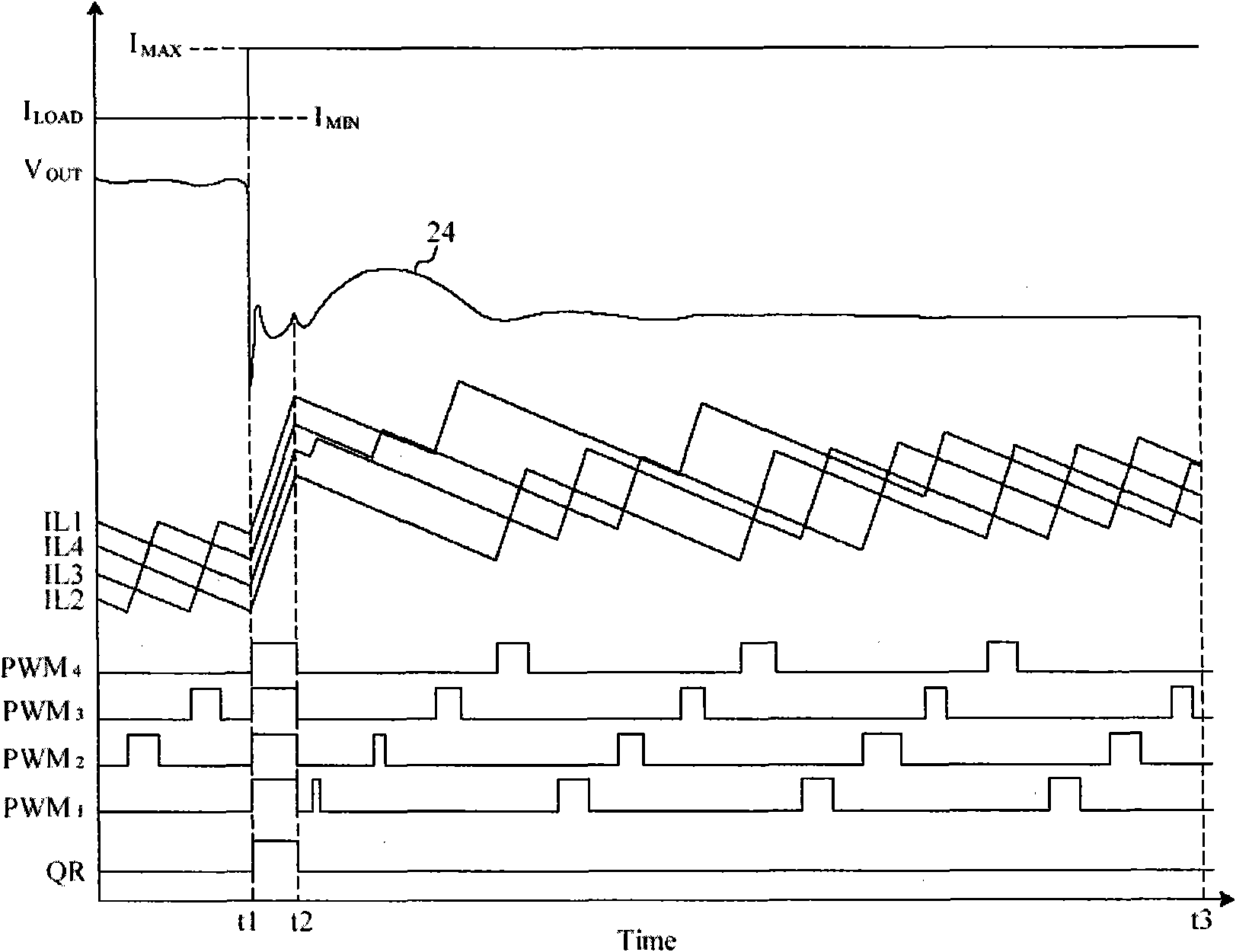

Quick-response generating circuit for voltage regulator, method and application thereof

ActiveCN101557161APrecise control triggerPrecise Width ControlDc-dc conversionElectric variable regulationVoltage regulationVoltage reference

The invention relates to a quick-response generating circuit for a voltage regulator. The voltage regulator is used for generating regulated output voltage on a power output end and comprises a first quick-response comparator, a second quick-response comparator, a quick-response signal generating circuit and a switch, wherein the switch is connected between a power input end and the power output end and switched by a pulse-width modulation signal. The quick-response generating circuit for the voltage regulator is characterized in that the first quick-response comparator compares first reference voltage and a feedback signal derived from the output voltage to generate a set signal; the second quick-response comparator compares the feedback signal and second reference voltage to generate a reset signal; the quick-response signal generating circuit generates a quick-response signal according to the set signal and the reset signal so as to determine a quick-response pulse used for being inserted into the pulse-width modulation signal; and the switch is turned on in a quick-response pulse period to connect the power input end to the power output end.

Owner:RICHTEK TECH

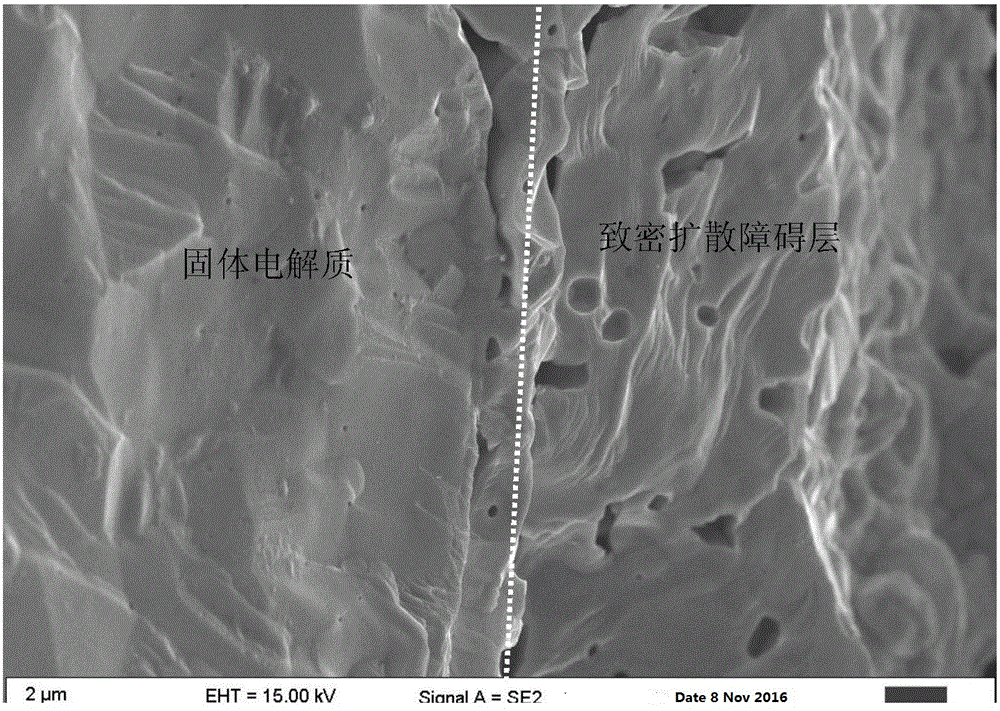

Spin coating preparation method for dense diffusion barrier layer of limiting current type oxygen sensor

InactiveCN106770583AUniform and dense tissueHigh bonding strengthMaterial analysis by electric/magnetic meansMass ratioOxygen sensor

The invention discloses a spin coating preparation method for a dense diffusion barrier layer of a limiting current type oxygen sensor, and belongs to the technical field of chemical gas sensors. The method comprises the following steps: dissolving a binder in a solvent, forming an organic carrier, and uniformly dispersing LSM in the organic carrier, thus preparing LSM of dense diffusion barrier layer slurry, wherein the mass ratio of LSM to the solvent to the binder is equal to (2- 6) : (5-10) : (0.01-0.05); spinning at 1000 to 10000r / min for 1 to 10min by a spin-coating instrument, coating the dense diffusion barrier layer slurry on the surface of YSZ uniformly, then drying to obtain a solid electrolyte which has a layer of the dense diffusion barrier layer on the dried surface; sintering for 5 to 7h at the temperature of 1000 to 1600 DEG C, thus preparing the dense diffusion barrier layer of the limiting current type oxygen sensor coated on the solid electrolyte. The dense diffusion barrier layer prepared by the method is dense and uniform in structure, compact and pore-free, high in bonding strength with a substrate, precisely controllable in thickness and short in manufacturing cycle.

Owner:NORTHEASTERN UNIV

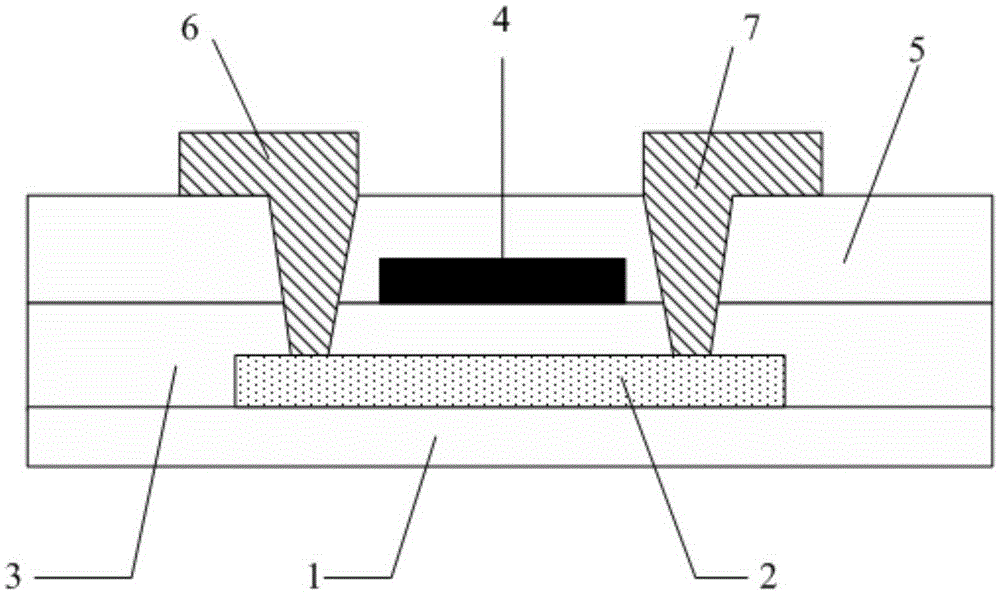

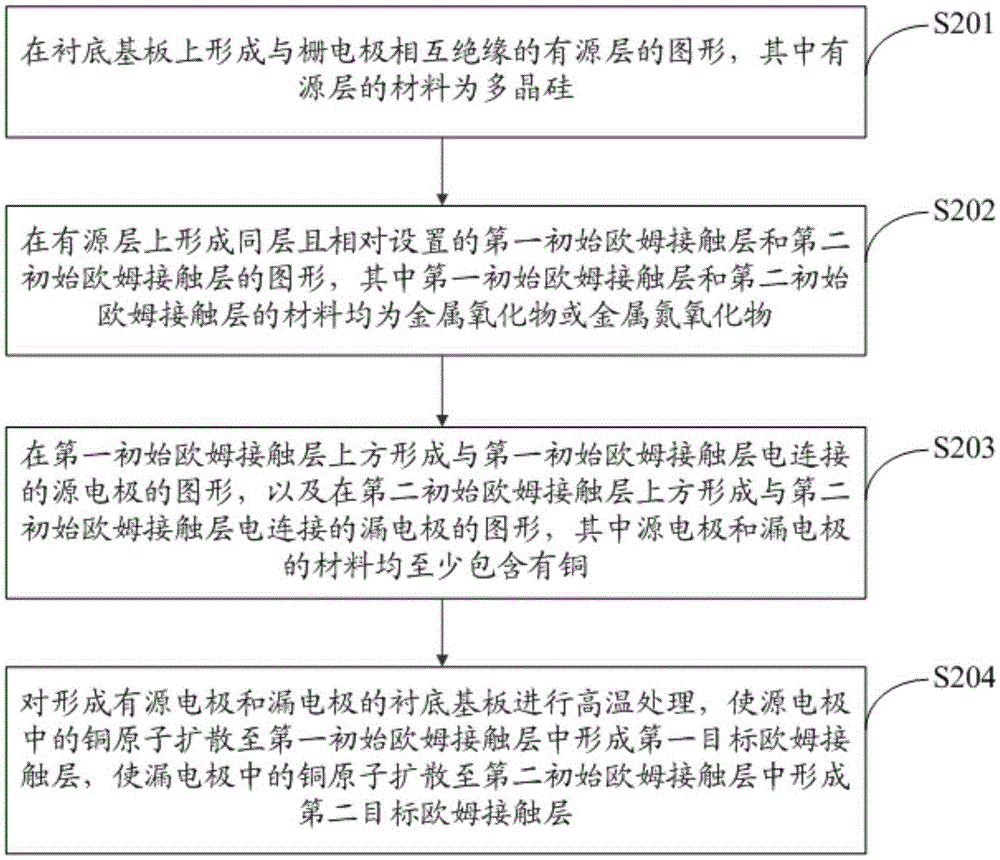

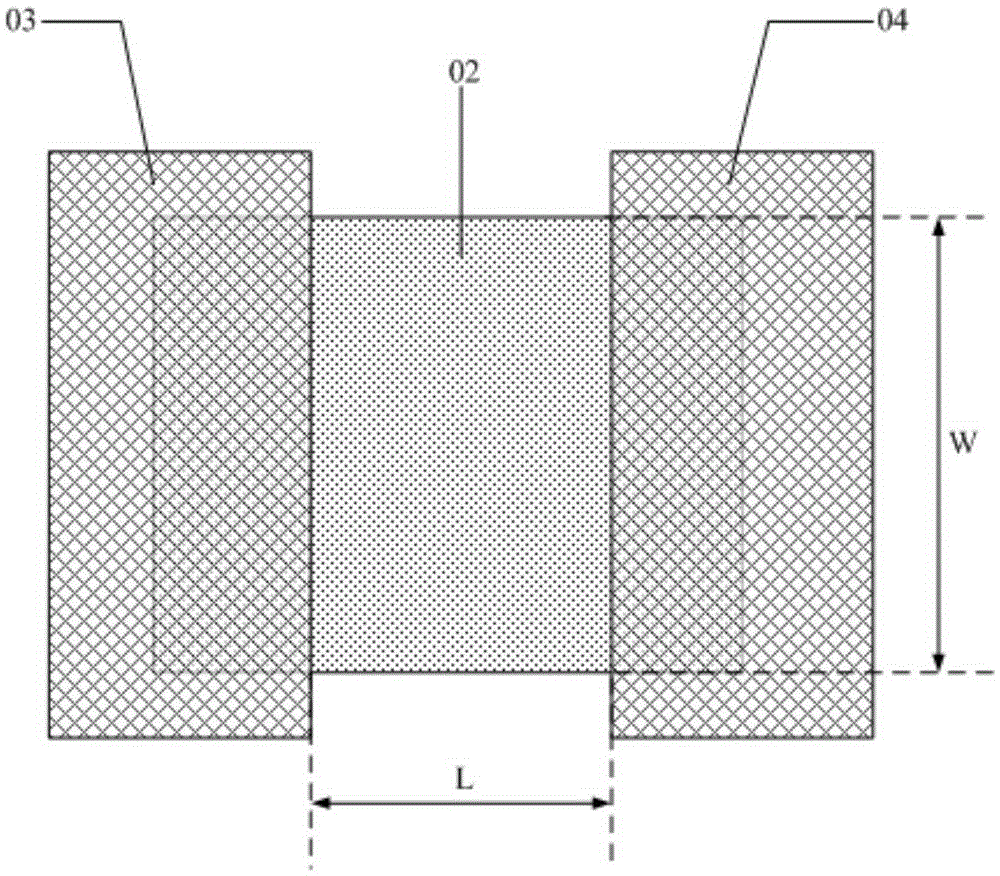

Thin film transistor, preparation method of the thin film transistor, array substrate and display apparatus

ActiveCN105261636AImprove performanceImprove conductivityTransistorSolid-state devicesCopper atomOhmic contact

The invention discloses a thin film transistor, a preparation method of the thin film transistor, an array substrate and a display apparatus. After forming of an active layer and before forming of a source electrode and a drain electrode, a first initial ohmic contact layer and a second initial ohmic contact layer are formed on the active layer, and are arranged oppositely; the materials for the first initial ohmic contact layer and the second initial ohmic contact layer are oxide materials; after the source electrode and the drain electrode are formed, high temperature processing of the oxide materials are performed so that the copper atoms in the source electrode and the drain electrode can be diffused to the first initial ohmic contact layer and the second initial ohmic contact layer, so the oxide materials are higher in conductivity. Compared with the prior art, the first initial ohmic contact layer with high conductivity is arranged between the source electrode and the active layer and the second initial ohmic contact layer with high conductivity is arranged between the drain electrode and the active layer so that better ohmic contact can be realized between the source electrode and the active layer, and between the drain electrode and the active layer, and the performance of the thin film transistor can be improved.

Owner:BOE TECH GRP CO LTD

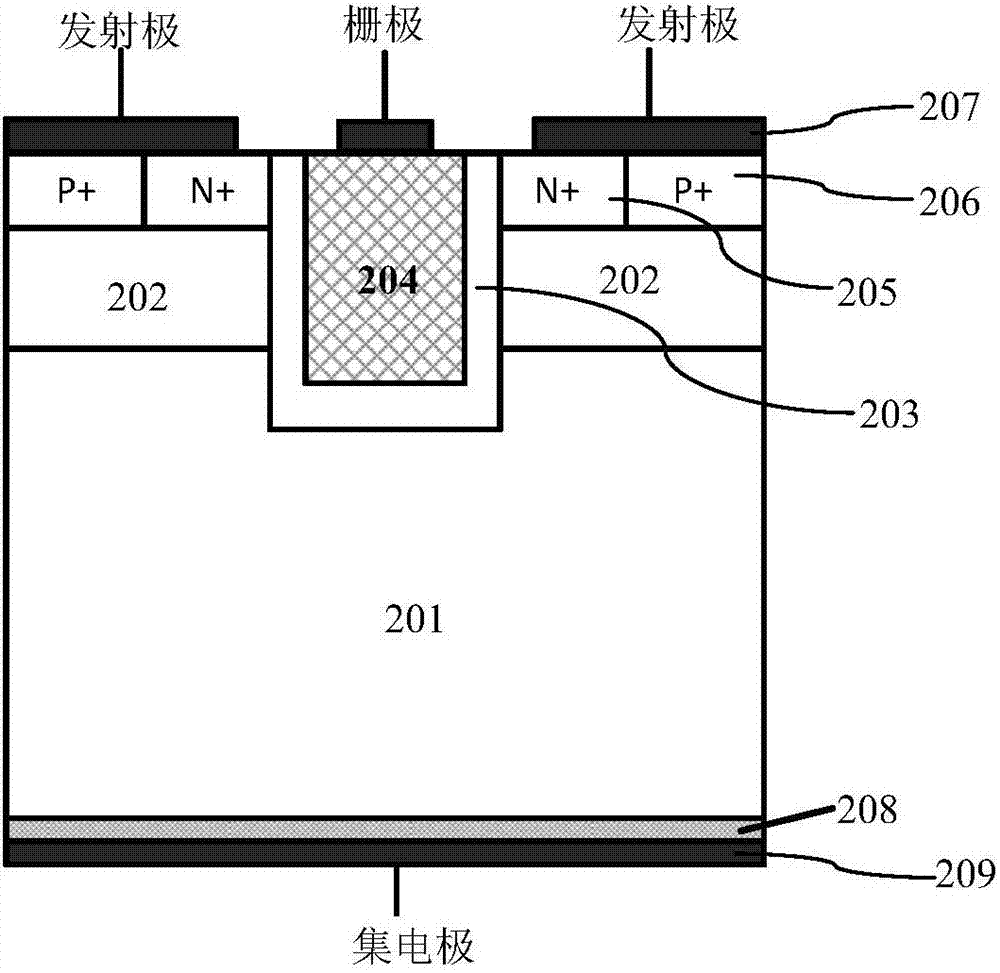

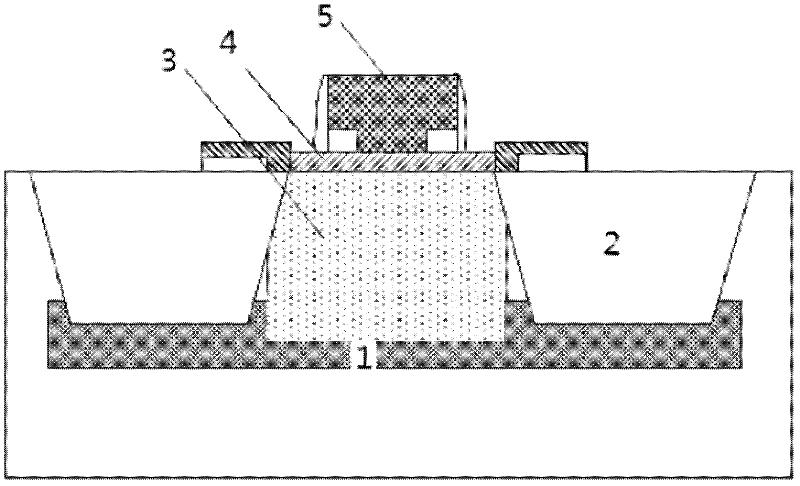

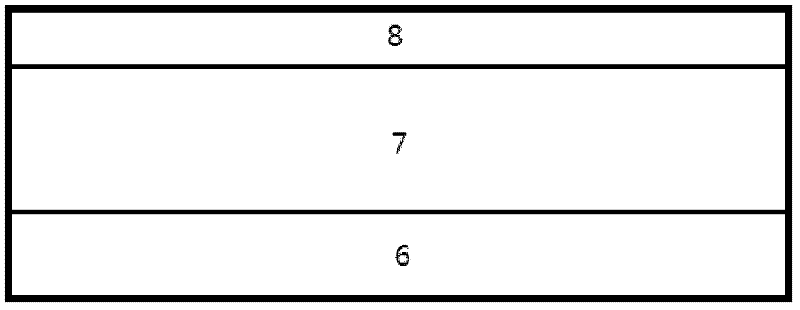

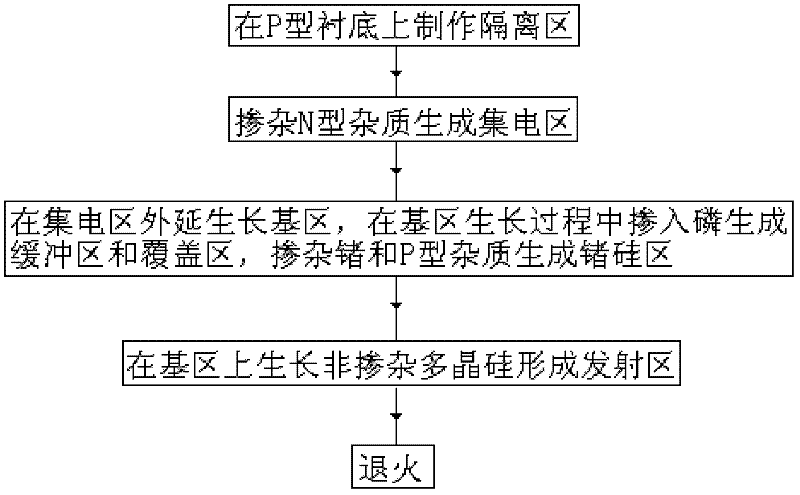

SiGe heterojunction triode device structure and manufacture method thereof

ActiveCN102412285AImprove uniformityPrecise Width ControlSemiconductor/solid-state device manufacturingSemiconductor devicesHeterojunctionImpurity

The invention discloses a SiGe heterojunction triode device structure which comprises a P type substrate, an isolation region, a collecting zone, a base region and an emitter region. The collecting zone and the isolation region are parallel above the P type substrate. The collecting zone, the base region and the emitter region are arranged on the P type substrate from bottom to top. The base region has a buffer area, a SiGe zone and an overlay region which are arranged in order. The buffer area and the collecting zone are adjacent. The overlay region and the emitter region are adjacent. Both the overlay region and the buffer area have an N type impurity. The invention also discloses a manufacture method of the SiGe heterojunction triode device structure. According to the structure and the method in the invention, high characteristic frequency (such as more than 100 GHz) is realized, positions of a CB junction and an EB junction can be controlled accurately, adjustment of reverse withstand voltage of the EB junction is realized, base region width of a SiGe heterojunction triode can be controlled accurately, influence of base region P type ion diffusion on the base region is eliminated, and technology stability is raised.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

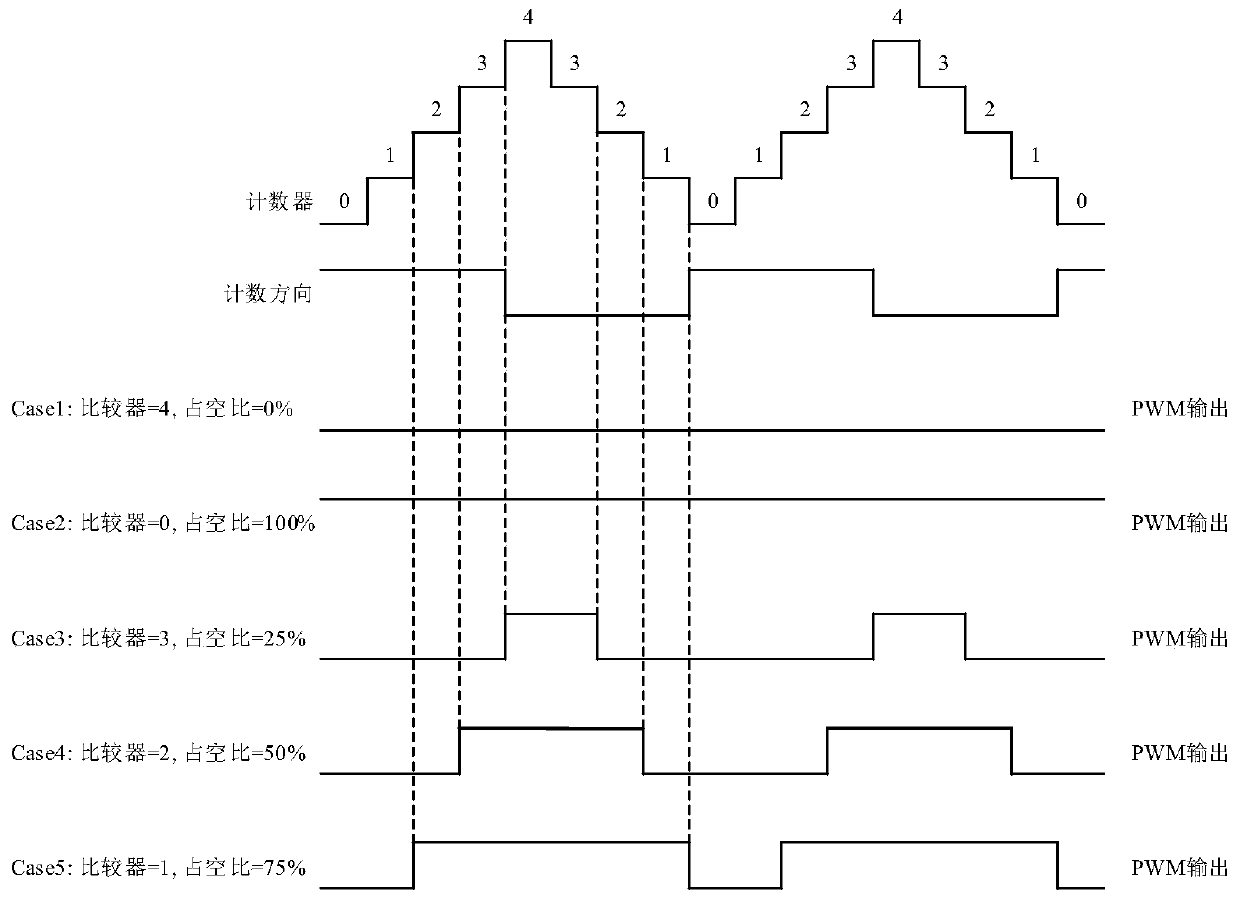

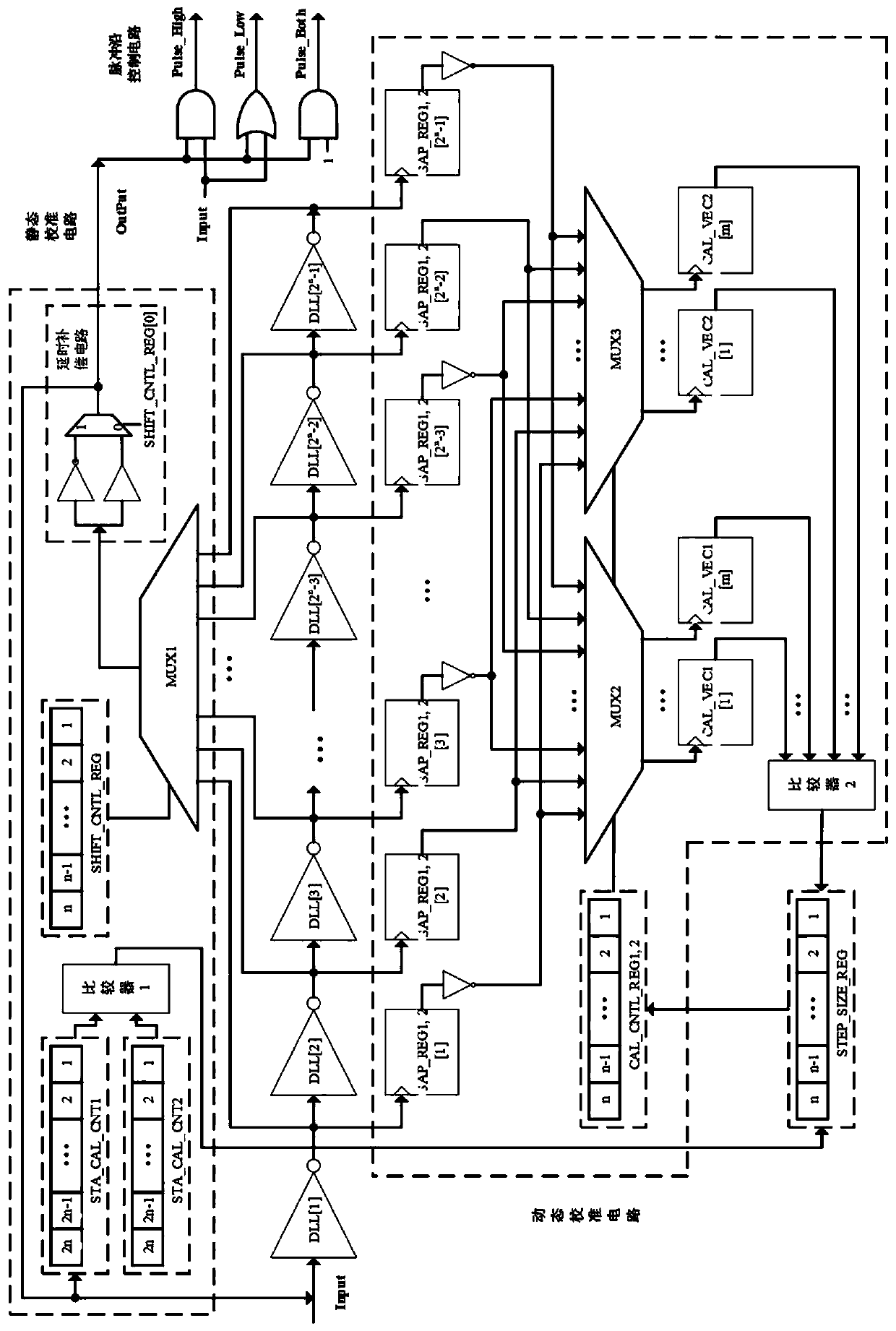

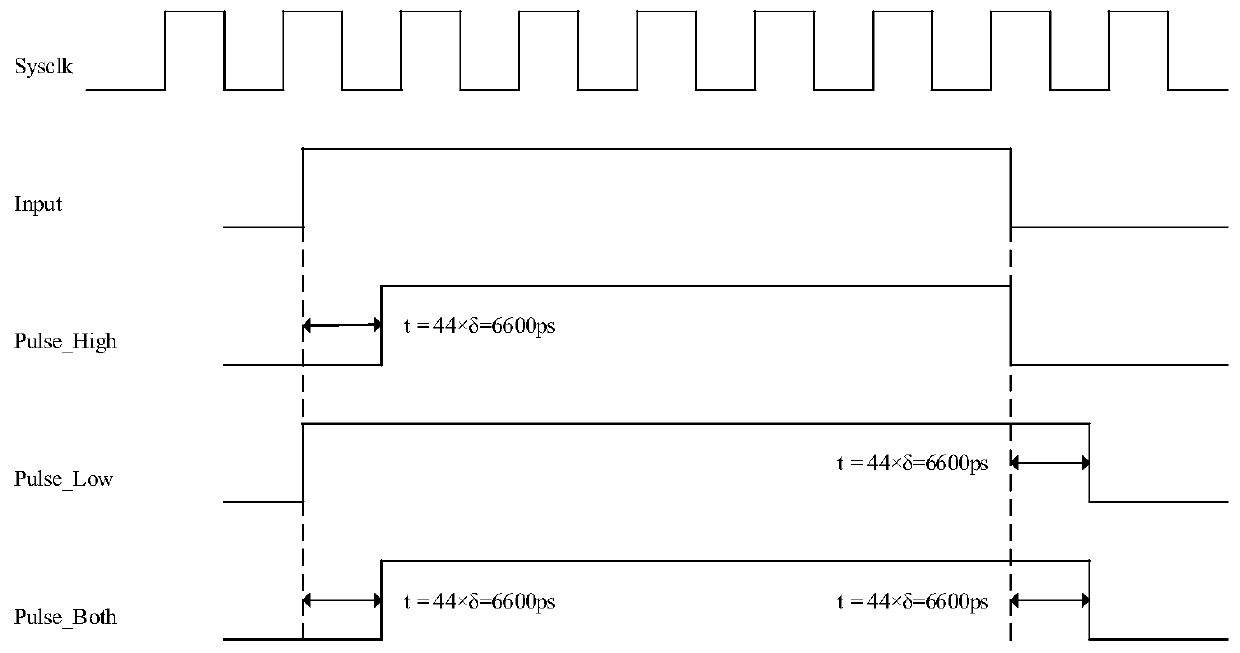

Ultrahigh-precision digital pulse signal generation circuit and method

ActiveCN111327298ASimple structureHigh precisionElectric pulse generatorPulse duration/width modulationSignal onTime delays

The invention discloses an ultrahigh-precision digital pulse signal generation circuit and method, and the circuit comprises a pulse edge control circuit which is used for generating a certain amountof time delay for a signal on an input pin Input, and precisely controlling the positions of a rising edge and a falling edge of a pulse signal, thereby precisely controlling the width of a pulse, andgenerating an ultrahigh-precision pulse; the static calibration circuit is used for calculating step length information representing the relationship between the working clock period of the system and the delay of a delay unit in the pulse edge control circuit at the beginning of power-on work of the system, and storing the step length information; wherein the step length information is the number of delay units through which the signal propagates in a system clock period; and the dynamic calibration circuit is used for dynamically calculating the step length information in real time when therising edge or the falling edge of each pulse on the input pin Input comes. The method is implemented based on the circuit. The invention has the advantages of simple structure, easiness in implementation, high precision, wide supported pulse frequency range and the like.

Owner:HUNAN GREAT LEO MICROELECTRONICS CO LTD

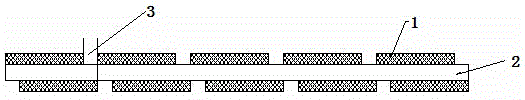

High-efficiency production technology of thin-film capacitor

InactiveCN105070505APrecise Width ControlIncrease productivityThin/thick film capacitorStacked capacitorsManufacturing cost reductionEngineering

The invention discloses a high-efficiency production technology of a thin-film capacitor. The production technology comprises: vapor plating of vapor plating layers is carried out on a front side and a back side of a thin base film according to a needed width, wherein the vapor plating zones and intervals of the front side and the back side are set fixedly and vapor plating of multiple grids is carried out; during winding, the metalized thin film having the front side and back side with the vapor plating layers and an optical film not processed by vapor plating are wound; a wound core is processed by pre-flattening treatment and is cut into multiple independent core units according to the needed width; heat treatment is carried out on the cut core units at the temperature of 110 to 165 DEG C, the optical film not processed by vapor plating is contracted uniformly and the end surfaces of the vapor plating layers at the two ends are exposed, and thus metal spraying is carried out at the two end surfaces reliably during the subsequent process and pins are led out. According to the invention, an objective that multiple core units can be wound by one-time winding can be achieved. The production technology being simple is easy to realize and the core width can be controlled accurately; and the production efficiency of the metallic thin-film capacitor can be substantially improved and the manufacturing cost can be lowered.

Owner:NISTRONICS JIANGXI

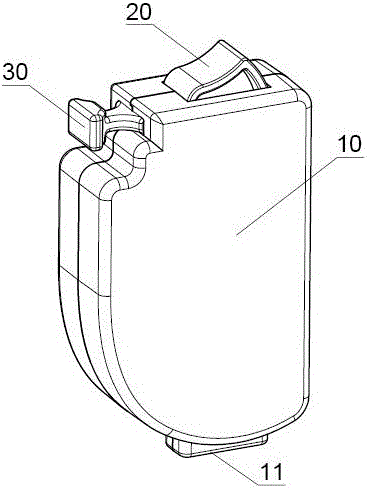

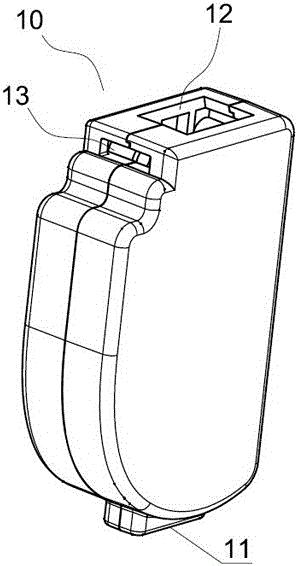

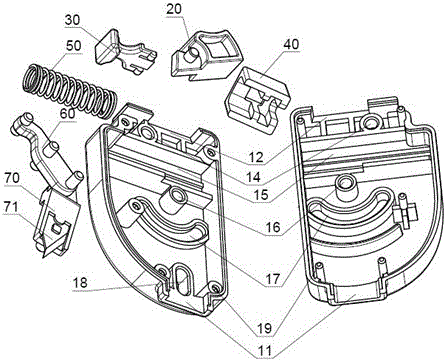

Infant heel blood collector

PendingCN107518905ARealize the action of scratching bloodPrecise Width ControlDiagnostic recording/measuringSensorsEngineeringMedical institution

The invention discloses an infant heel blood collector. A sliding block is fixed by a trigger key and is locked by a safety bolt in an initial state, and an elastic part is in the state of storing elastic potential energy. When the infant heel blood collector is used, the safety bolt is pulled out, sliding block locking can be relieved by slightly pressing the trigger key, the elastic potential energy stored by the elastic part is released instantly, the elastic potential energy drives the sliding block to slide in a sliding cavity so as to drive a connecting rod to rotate with a rotating pin as a center, a second sliding pin slides in an arc-shaped sliding groove, a third sliding pin on a driving seat slides from the upper end to the lower end of a sliding groove II and returns to the upper end so as to form a one-time reciprocating action, a blade extends from a blade outlet along an arc-shaped trajectory one time, and infant heel cutting and blood collecting actions are achieved. The structure includes fewer structural parts, the transverse movement of the sliding block is converted into the arc-shaped moving trajectory of the blade through the connecting rod, and the infant heel blood collector has the technical advantages of being simple in structural principle, lower in cost and capable of accurately controlling the cutting depth and width of the blade and is suitable for large-range popularization and use in medical institutions.

Owner:PROMISEMED HANGZHOU MEDITECH

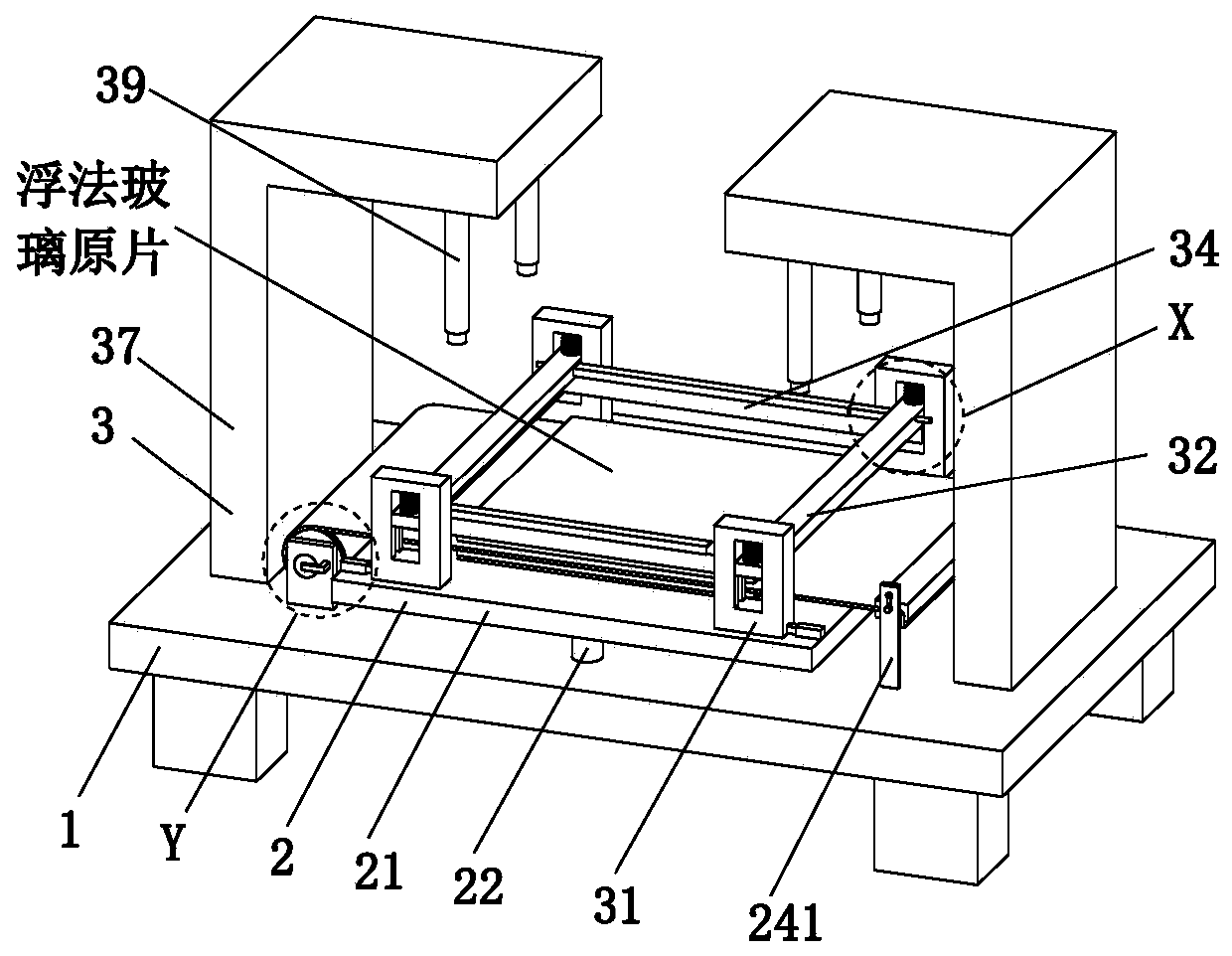

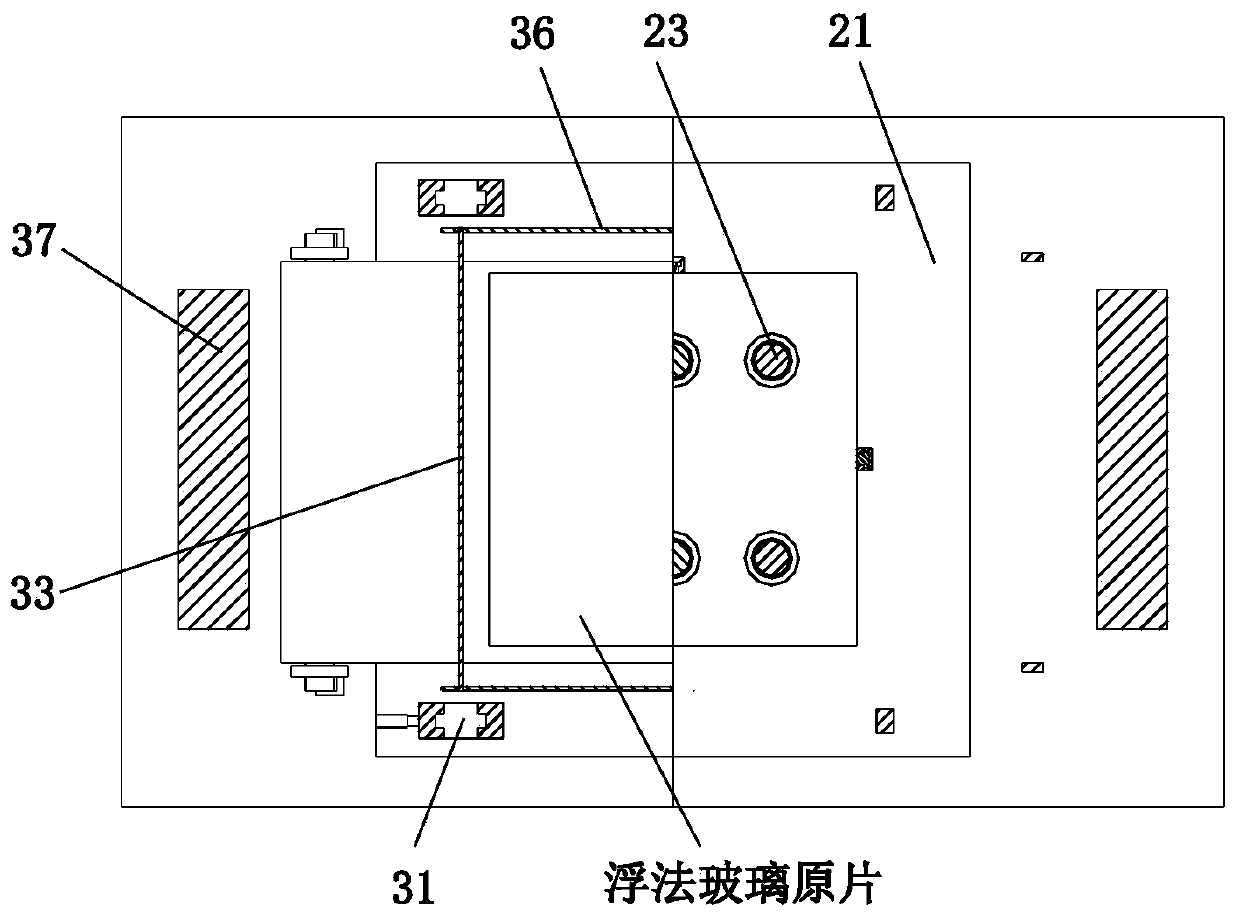

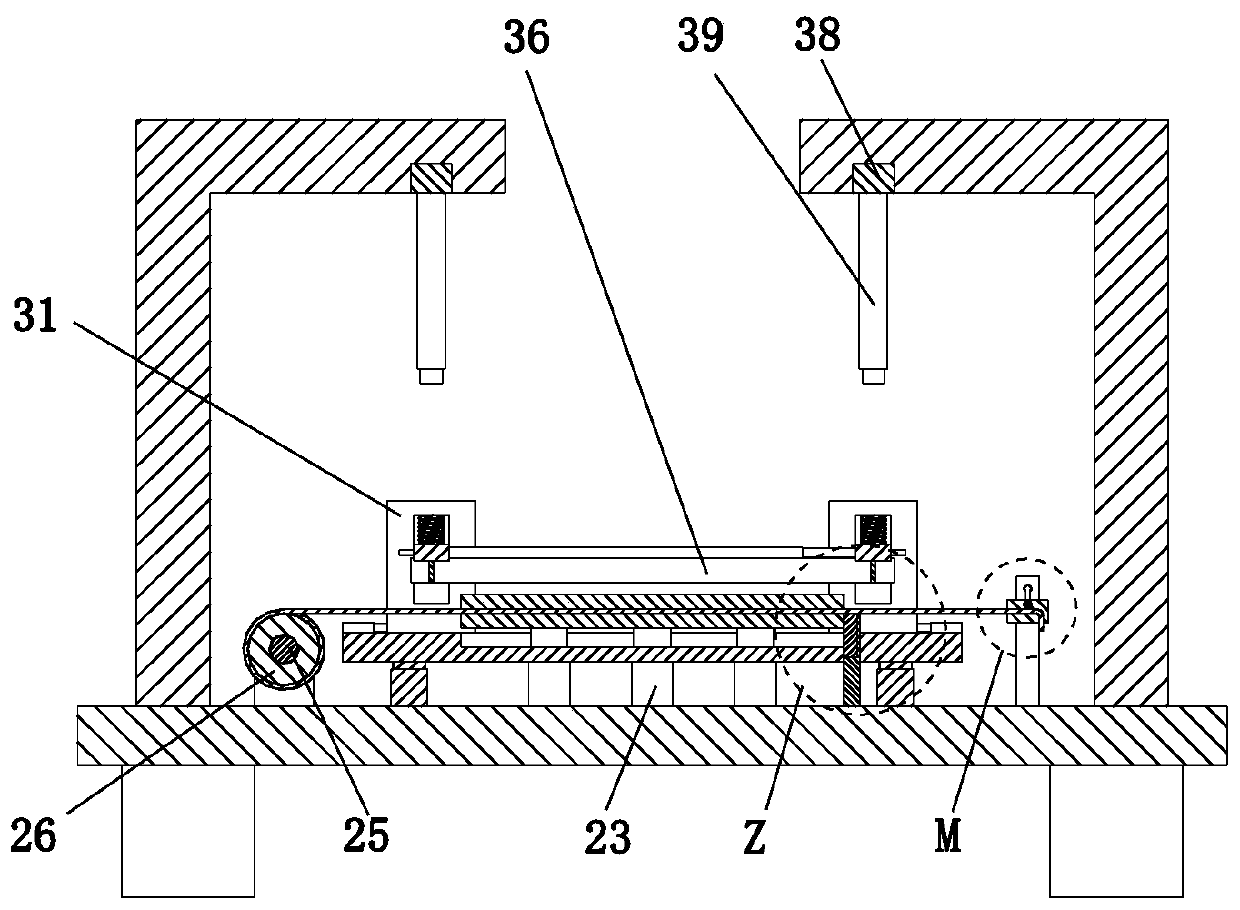

Method for producing laminated glass by using raw float glass sheet

ActiveCN110950552APlay a fixed roleReduce driftLamination ancillary operationsLaminationWorkbenchFloat glass

The invention relates to a method for producing laminated glass by using a raw float glass sheet, the method uses a device for producing the laminated glass by using the raw float glass sheet, the device for producing the laminated glass by using the raw float glass sheet comprises a workbench, a clamping and rolling mechanism and a cutting mechanism, the clamping and rolling mechanism is arrangedin the middle of the upper end surface of the workbench, and the cutting mechanism is arranged at the upper end of the clamping and rolling mechanism; according to the method for producing the laminated glass by utilizing the raw float glass sheet, the laminated glass is produced by adopting a design concept of multiple fixation and adjustability, the raw float glass sheet and a membrane are bothclamped and fixed, the relative stability between the float glass raw sheet and the membrane is improved, and the production efficiency of the laminated glass is improved. And meanwhile, the installation of the raw float glass sheet is guided, so that the raw float glass sheet and the membrane are kept in an opposite state.

Owner:宣恩县茂源玻璃制品有限公司

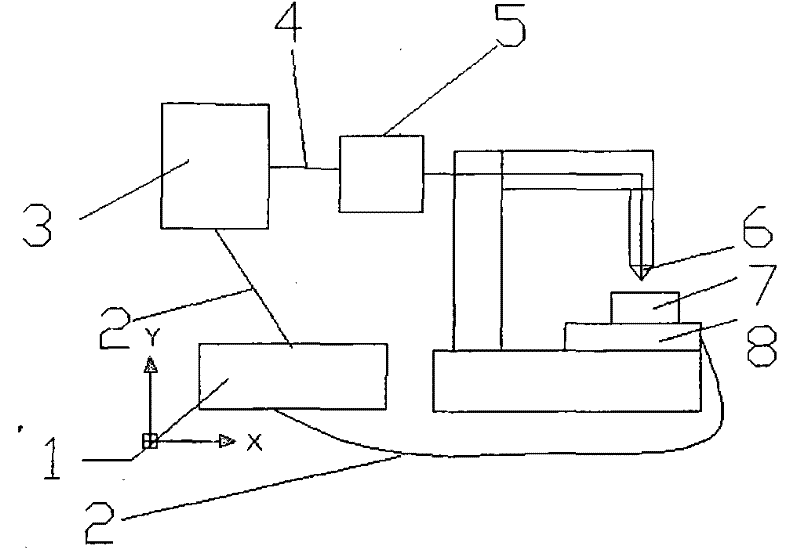

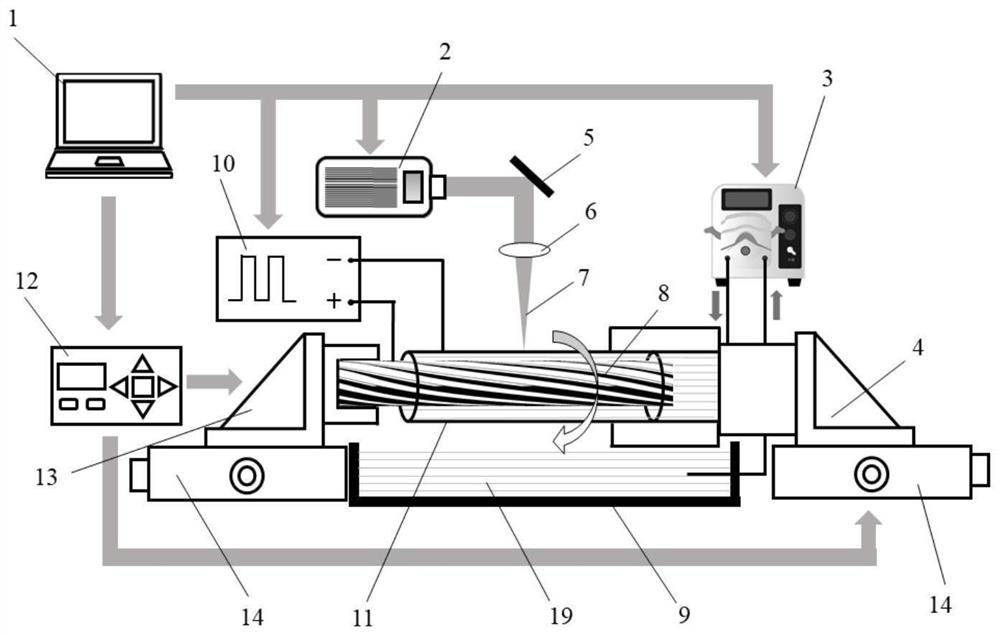

Method and device for carrying out localized electro-deposition repair on inner wall of material through laser composite electrochemical technology

InactiveCN113481555ANo electrodeposition reactionEasy to operateCellsElectrodesElectrochemical responseElectrochemistry

The invention discloses a method and device for carrying out localized electro-deposition repair on the inner wall of a material through a laser composite electrochemical technology, and relates to the field of non-traditional machining. According to the method, a workpiece is repaired under the laser and electrochemical reaction composite action, a tool anode is arranged in the center in the workpiece, a certain gap is kept between the tool anode and the workpiece, laser beams are focused on the outer surface of the workpiece, and localized repair of the inner wall is achieved. The method and device aim at the problem that coatings on the inner walls of tubular and shaft-shaped parts with large aperture ratios fall off, lose efficacy and are difficult to repair, the characteristic of high heat conductivity of workpieces is utilized, the laser heat effect and electrochemical deposition are cooperated, localized coating repair of the inner walls of workpieces is realized, the electrodeposition reaction does not occur in other areas which do not need to be repaired, the operation process is simple, the plating solution cost is greatly saved, and the problem that normal use cannot be achieved due to the consequences that the bore pressure is low, the precision is reduced, and the size of an inner bore is increased due to the fact that the coating on the inner surface of the deep tube inner bore falls off is solved.

Owner:JIANGSU UNIV

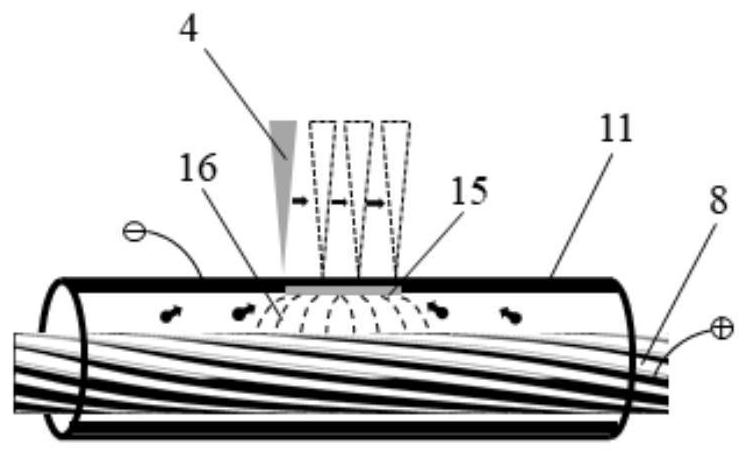

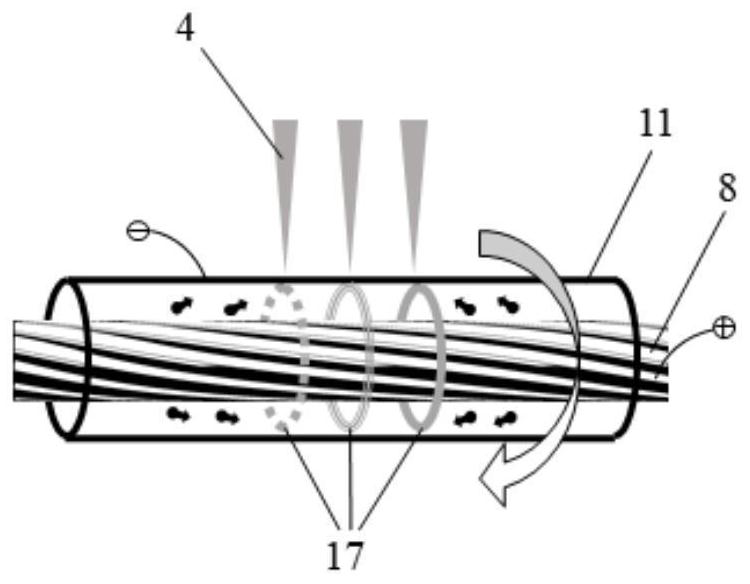

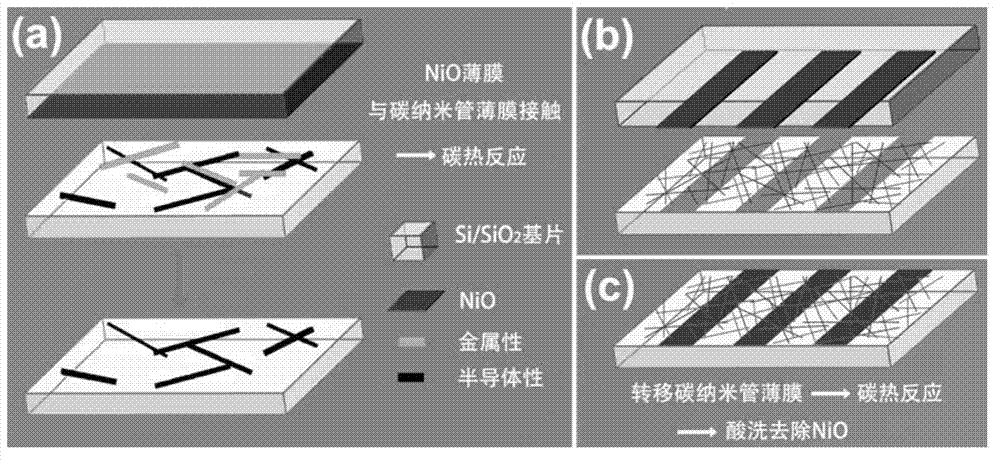

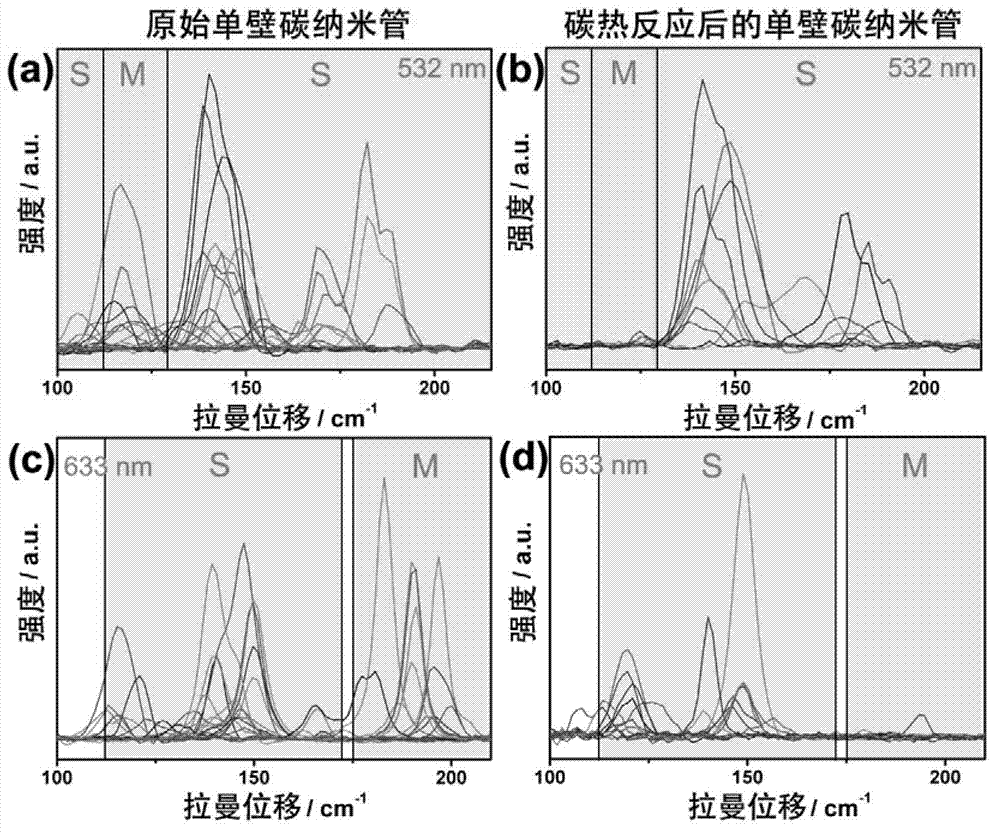

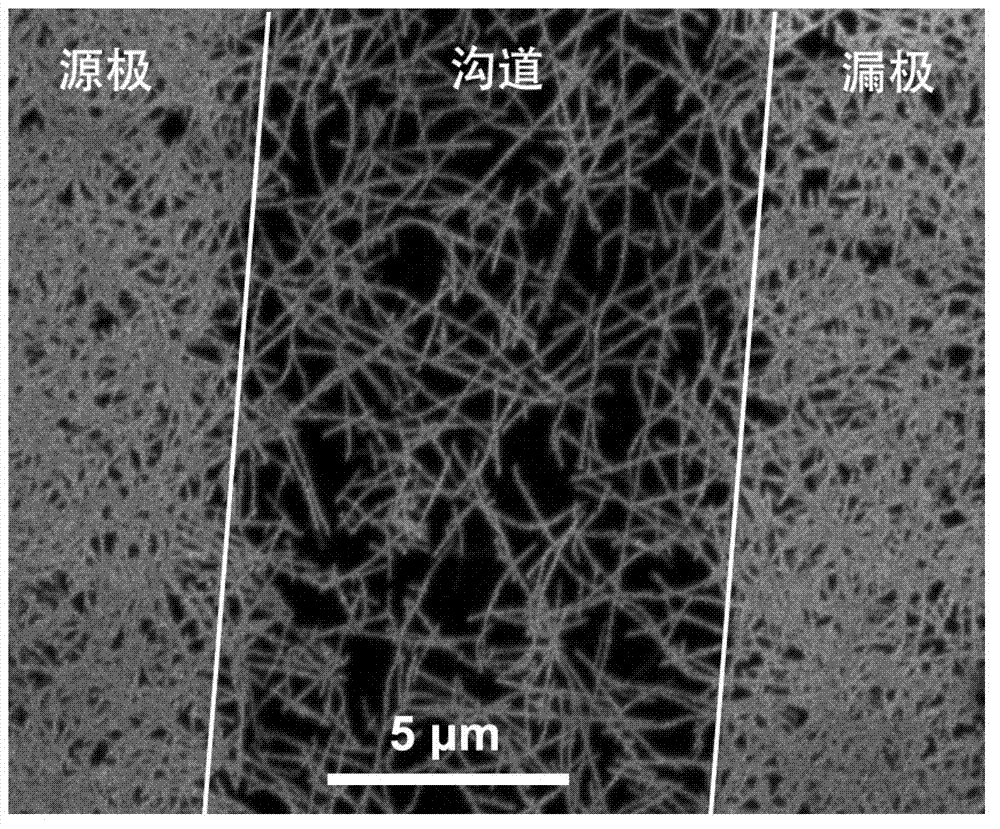

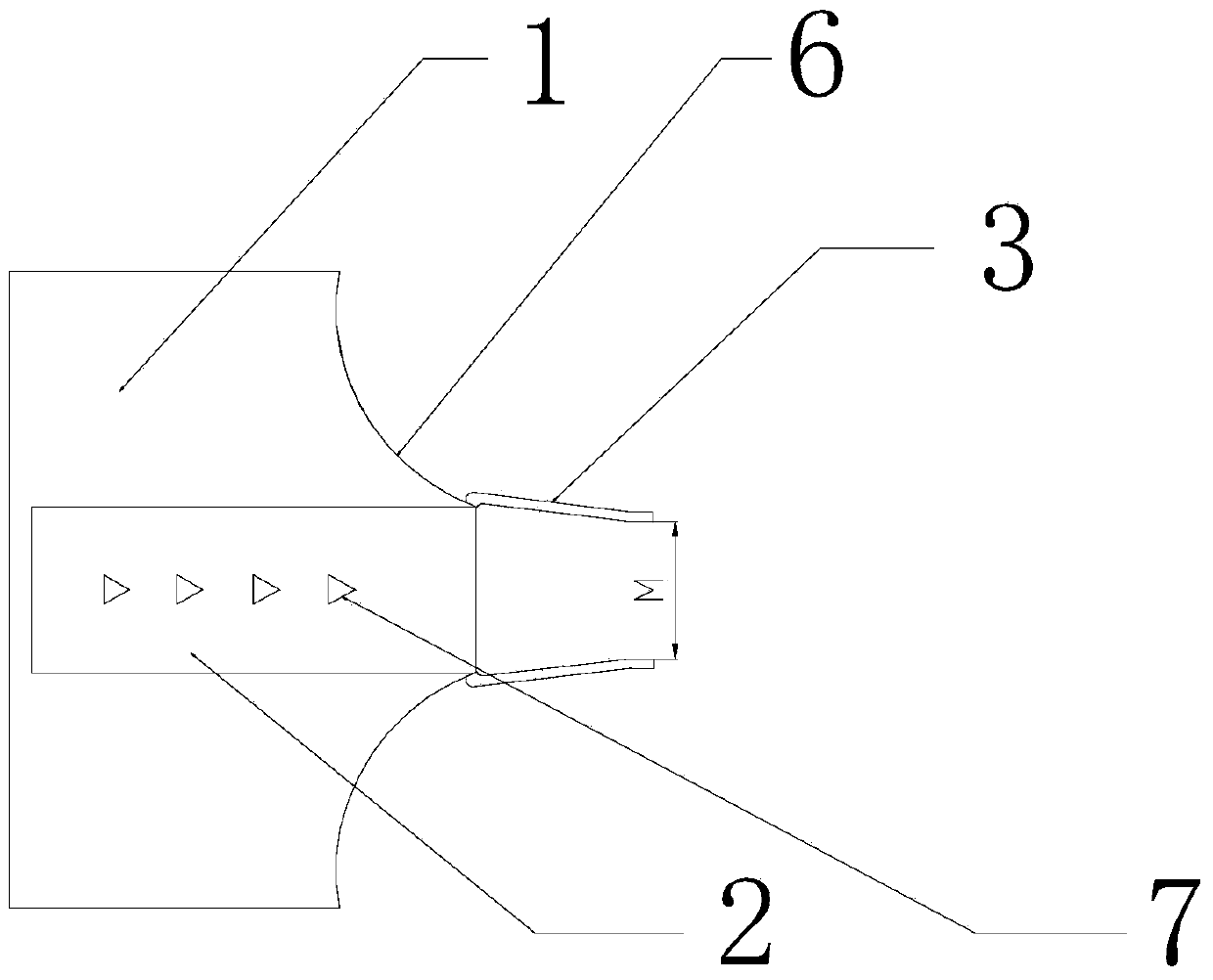

All-single-walled carbon nanotube field effect transistor and preparation method thereof

ActiveCN102903747AHigh reactivityPrecise Width ControlNanoinformaticsSemiconductor/solid-state device manufacturingCarbon nanotubeCarbon nanotube field-effect transistor

The invention relates to the field of single-walled carbon nanotubes, in particular to an all-single-walled carbon nanotube field effect transistor and a preparation method thereof. Semiconductor single-walled carbon nanotubes are utilized as channels of field effect transistors, and metallic / semiconductor single-walled carbon nanotube mixtures are used as source and drain electrodes. Metallic oxide and the single-walled carbon nanotubes can be in carbon heat reaction at proper temperature, and high-chemical-activity metallic single-walled carbon nanotubes are selectively etched to obtain semiconductor single-walled carbon nanotubes. A metal film is deposited on a Si / SiO2 substrate by using photolithography, and is pre-oxidized to obtain a metallic oxide film. Only the semiconductor single-walled carbon nanotubes are reserved in the single-walled carbon nanotube film and a reaction region which is in contact with metal oxide and are used as the channels of the field effect transistors, and the single-walled carbon nanotubes which are unaffected and are positioned out of the channels are utilized as the source and drain electrodes. Metal electrodes are not required to be deposited; and the all-single-walled carbon nanotube field effect transistor can be used for flexible devices, has the characteristics of cleanness and high efficiency, and can be used for manufacturing large-scale all-carbon integrated circuits possibly.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for preparing furnace protection type blast furnace carbon brick through laser cladding

InactiveCN106929617AUniform and dense tissueHigh bonding strengthBlast furnace componentsBlast furnace detailsPressure rangeCarbide coating

The invention provides a method for preparing a furnace protection type blast furnace carbon brick through laser cladding. The method includes the steps that firstly, 400-mesh metallographical abrasive paper is used for polishing the surface of a micropore carbon brick base material to be subjected to cladding, clean water is used for cleaning, and drying is conducted in a drying machine for 2 hours at the temperature ranging from 120 DEG C to 150 DEG C, the formula of a cladding material is composed of TiN and TiC ceramic powder with the volume ratio of 1:1, a roller type powder mixer is used for powder mixing, and the powder mixing time is 8 h to 12 h till powder mixing is even; a synchronous powder sending manner is adopted, the laser cladding material is used for conducting laser cladding on the surface of the micropore carbon brick base material under the argon shield atmosphere with the air pressure ranging from 0.01 MPa to 1 MPa, and after laser cladding is completed, a hard alloy coating on the surface of the micropore carbon brick base material is polished; and finally, cladding of a high-melting-point TiN, TiC and Ti(C and N) mixture protection layer is conducted on the surface of the micropore carbon brick base, the functions of high temperature resistance, corrosion resistance and circulation scouring resistance are achieved in the molten iron long-term contact process, corrosion of molten iron to the carbon brick is inhibited, and the service life of a hearth and a furnace bottom is prolonged.

Owner:鞍山盛晨耐火材料有限公司 +1

Band steel traction connection structure and band penetration method for continuous band steel unit

InactiveCN104209350AThe ring structure is firmAvoid excessive concentrationFlexible work arrangmentsMetal rolling arrangementsTension controlMaterials science

The invention discloses a band steel traction connection structure and a band penetration method for a continuous band steel unit, and particularly relates to the field of band steel production. The band steel traction connection structure which is firm in connection, is capable of reducing the band breaking frequency and is provided by the invention comprises a band steel end part, a band steel traction head, a pull ring and a traction band, wherein one end of the band steel traction head and the band steel end part are of an integrated structure, and the other end of the band steel traction head is riveted on the band steel end part, so that an annular structure is firmer. The band penetration method for the continuous band steel unit, which is provided by the invention, comprises the following steps: a, lowering a loop trolley to a zero position; b, winding the traction band around each roller group; c, fixedly connecting the band steel traction connection structure with one end of band steel; d, tensioning a loop; e, filling the loop with the traction band; f, performing band penetration operation. The tension of the traction band is accurately controlled through automatic tension control equipment, so that breaking of the traction band due to the fact that a certain part is over-tensioned is avoided.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

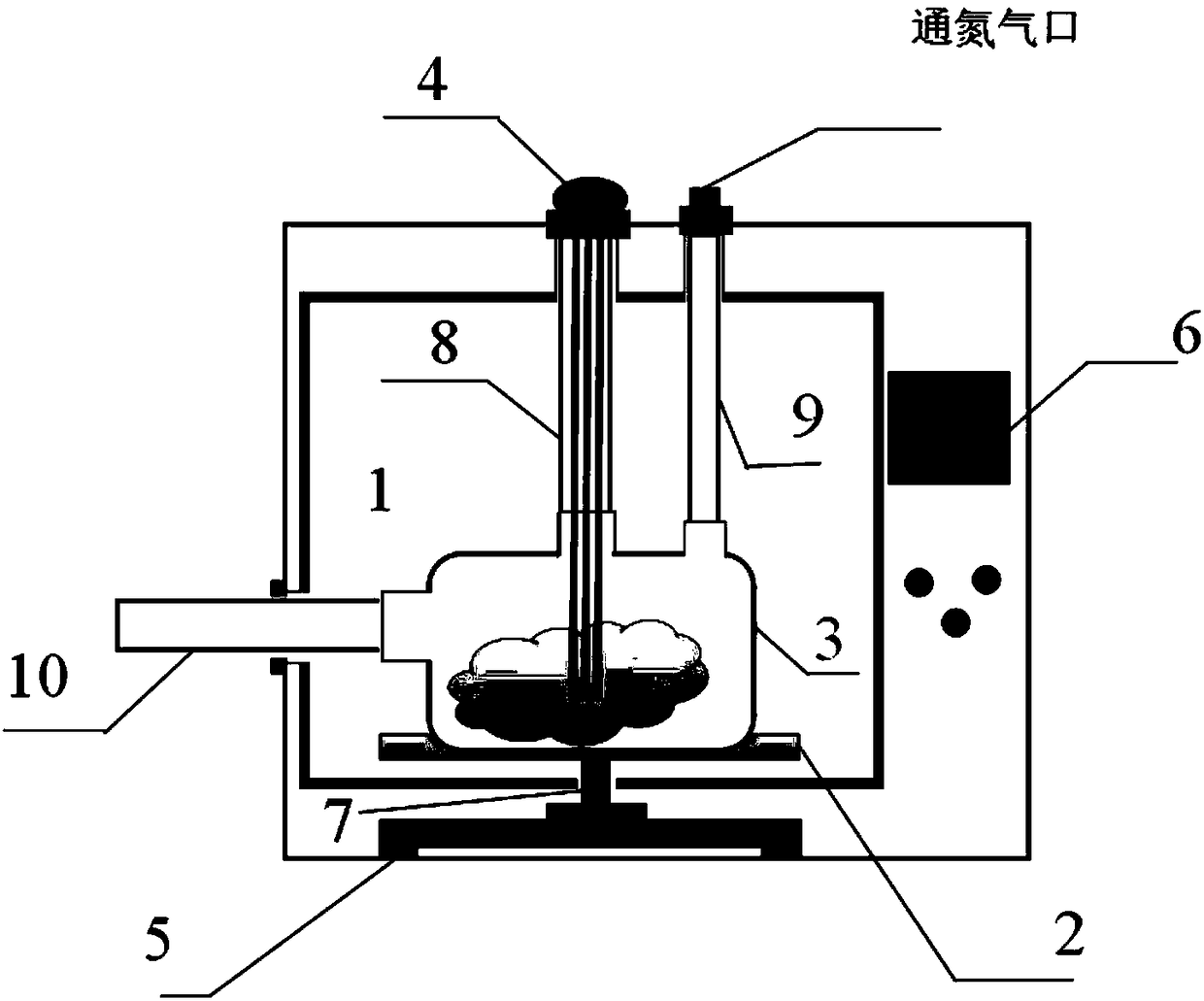

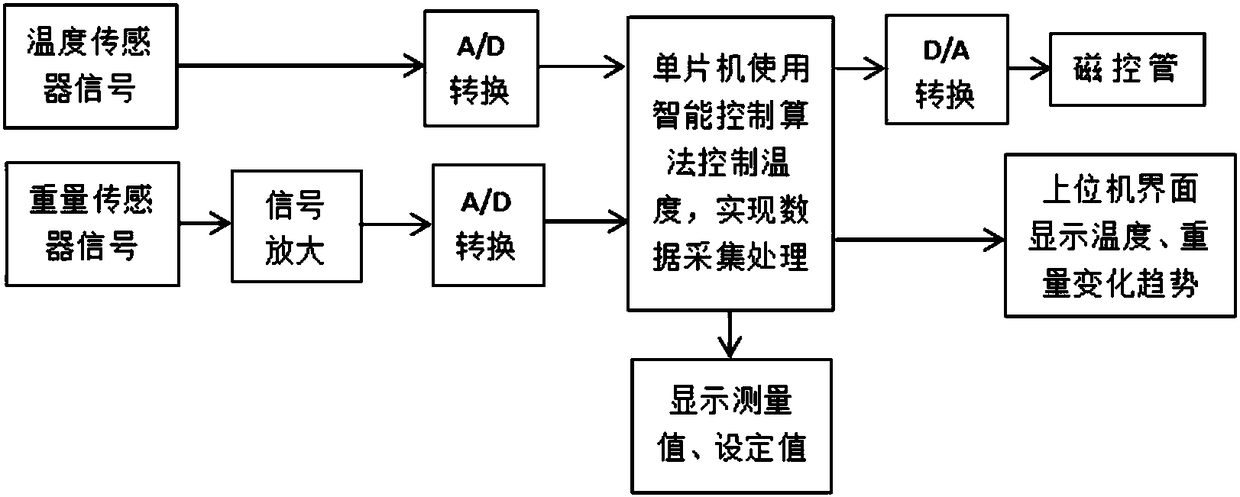

Microwave thermogravimetric analysis system

PendingCN108489853AControl temperature changesQuick responseWeighing by removing componentPreparing sample for investigationChemical reactionMicrowave pyrolysis

The invention relates to the technical field of microwave pyrolysis , and especially relates to a microwave thermogravimetric analysis system. The analysis system includes a thermocouple temperature sensor, a gravity sensor, a control circuit, a display module, a chemical reaction system material pyrolysis part, a subsidiary part, a magnetron and a computer. The microwave power in the invention isadjustable, reaction temperature and weight change data in the microwave pyrolysis process of a material are highly precisely measured, thermogravimetric analysis and reaction kinetics analysis of the microwave pyrolysis reaction of the material are performed, a chemical reaction module is externally connected to realize the condensation separation of a product and catalyst refining and upgrading, and other analytical instruments also can be externally connected to achieve the mechanism analysis of the pyrolysis reaction of the material.

Owner:JIANGSU UNIV

Method of producing super-thick steel plate through three-dimensional deformation of continuous casting billet

The invention provides a method of producing a super-thick steel plate through three-dimensional deformation of a continuous casting billet. In the method, the total reduction rate in the thickness direction of both forging and rolling is not less than 23%. The continuous casting billet is forged through a technology including three directions of length, width and thickness, wherein the continuous casting billet is firstly forged in the length direction, then is forged in the width direction and is finally forged in the thickness direction. One-time forging amounts in the length direction and the width direction are 120-230 mm and the one-time forging amount in the thickness direction is not less than 50 mm. The slow cooling time after forging is not less than 48 h. The heating temperature of rolling the billet is 1100-1250 DEG C. The roll beginning temperature is higher than 1050 DEG C. The slow cooling temperature after forging is not less than 400 DEG C and the slow cooling time is not less than 24 h. The method achieves production of the super-thick steel plate being not more than 270 mm in thickness at a low compression ratio with the continuous casting billet, wherein the steel plate can reach standard requirements in performances and is not less than 90% in defect detection qualified rate. The size range of the steel plate is effectively increased. The method allows accurate production aiming to the size of the steel plate, wherein the length, the width and the thickness are accurately controlled, thereby increasing the yield of the steel plate.

Owner:ANGANG STEEL CO LTD

A kind of preparation method of gold-tin-tin wire, foil tape and solder preform

ActiveCN103753057BKeep it brightAvoid formingWelding/cutting media/materialsSoldering mediaAlloyMachining

The invention provides a production method of a gold-tin wire, a foil belt and a preforming welding piece and belongs to the welding technical field. The production method comprises step 1, smelting gold and tin into alloy and casting the gold and the tin into an alloy rod; step 2, performing annealing; step 3, performing extrusion forming which comprises arranging a tin wire die with a circular hole at the position of the outlet of an extruding machine first when the ally rod needs to be extruded into a tin wire and arranging a foil belt die with a square hole at the position of the outlet of the extruding machine first when the ally rod needs to be extruded into the foil belt, then placing the product in the step 2 into the extruding machine, adjusting the intensity of pressure of the extruding machine to 250 to 350 Mpa and adjusting the temperature to 150 to 230 DEG C; step 4, cutting the foil belt which is obtained through extrusion in the step 3 into the preforming welding piece. According to the production method of the gold-tin wire, the foil belt and the preforming welding piece, the problem that the machining forming is difficult due to the high brittleness of the gold-tin alloy in the prior art is solved, the technological process is simple and convenient, the mass production can be performed, the product accuracy is good, and the product consistency is good.

Owner:SHENZHEN FUMOSUO METAL PROD

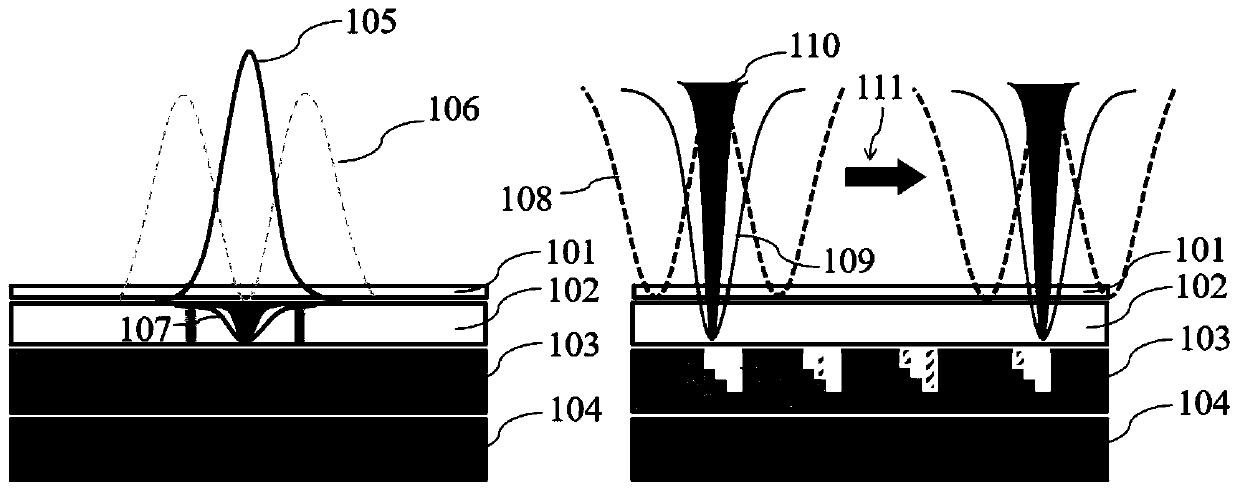

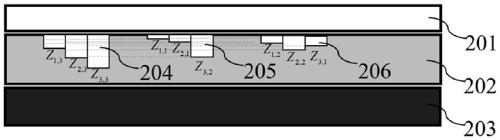

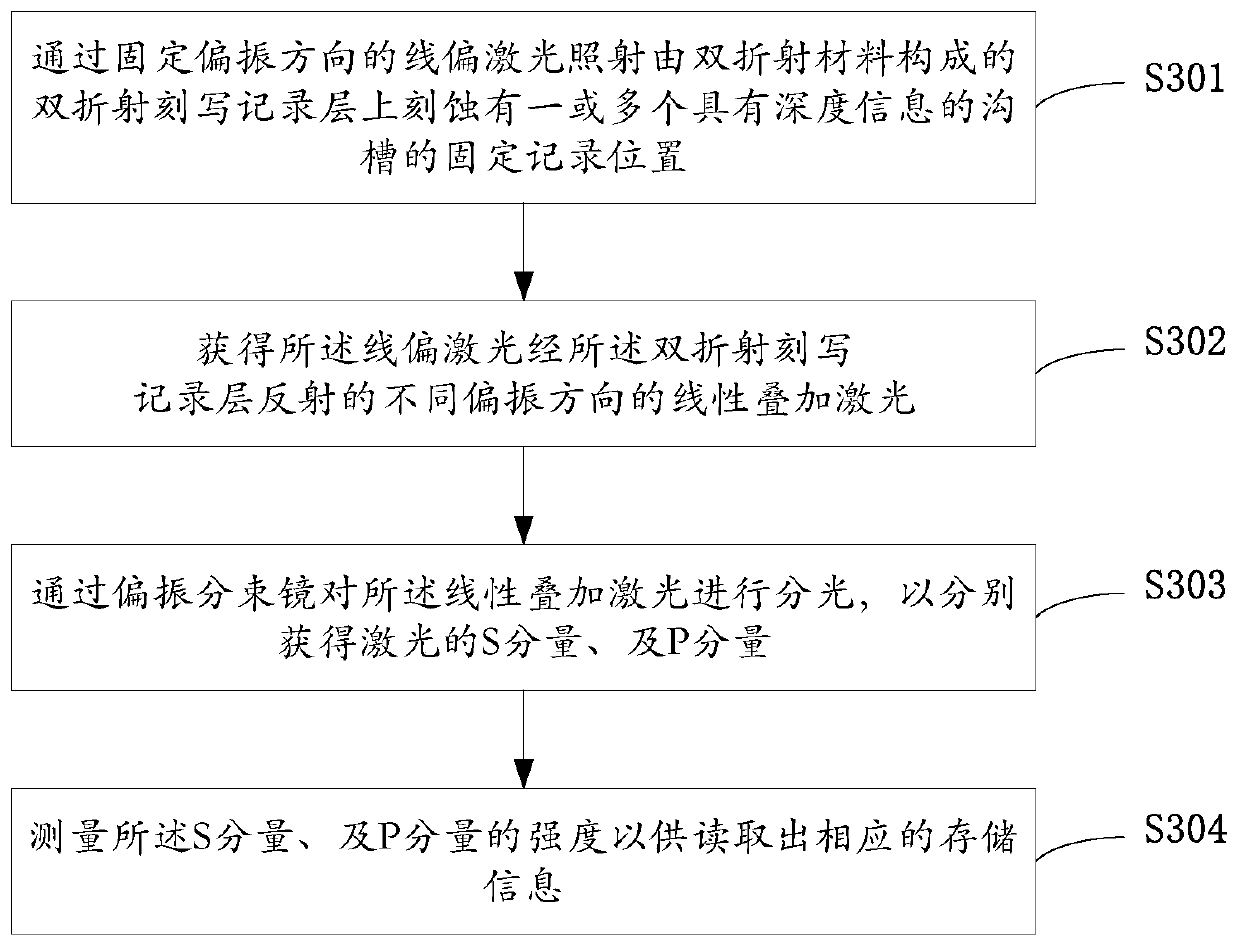

Polarization balance measurement reading method and device based on nano photoetching optical disc

ActiveCN111508534AImprove storage densityImprove the storage dimensionOptical beam sourcesRecord information storageOptical disk storageHigh density

The invention provides a polarization balance measurement reading method and device based on a nano photoetching optical disc. The storage information of an ultra-high density optical disc is inscribed by adopting a nano photoetching method, the information is stored by adopting a birefringence inscribing recording material, and erasable information is stored by adopting a photoinduced birefringence recording material, so that erasable repeated information recording of the nano photoetching optical disc can be realized. The reading method comprises the following steps: reading optical disc information by a polarization balance measurement reading method; realizing quick reading of multi-dimensional storage information of the optical disc by adopting a digital information encoding and decoding method. According to the invention, the size and the spacing of the information recording points are reduced, the storage density of the optical disc is improved, the stable and long-term storageof the optical disc storage information is realized, and the effective and high-speed extraction of the ultra-high density optical disc storage information is realized.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Method for realizing submicron-level process line width in manufacturing of silicon carbide power electronic devices

InactiveCN102832108APrecise Width ControlSimple processSemiconductor/solid-state device manufacturingLine widthSilicon oxide

The invention discloses a method for realizing a submicron-level process line width in manufacturing of silicon carbide power electronic devices. The method comprises the following steps of: a, taking a silicon carbide semiconductor film; b, growing a silicon thin film layer on the silicon carbide semiconductor film; c, obtaining a silicon thin film pattern on the silicon thin film layer by using a photoetching technology; and d, carrying out oxidation on a sample, and through controlling the oxidation time, enabling multiple separated silicon thin films to be expanded to the two sides thereof, so that after the two sides of the silicon thin film pattern are widened to a certain value, a silicon oxide thin film with a submicron line width is formed and can be used as a mask layer in manufacturing of silicon carbide power electronic devices. According to the invention, through controlling the conditions such as oxidation temperature and time and the like, the width of the silicon thin film subjected to oxidation can be accurately controlled to be increased by 0.01-10mu m, so that a gap between silicon oxide thin films can be accurately controlled to 0.1mu m even a smaller magnitude, thereby realizing the submicron-level process line width in manufacturing of silicon carbide power electronic devices.

Owner:DONGGUAN TIANYU SEMICON TECH

Automatic shaping and forming machine for flat flange

PendingCN110280625APrecise Width ControlSave raw materialsPerforating toolsOther manufacturing equipments/toolsPunchingMolding machine

The invention relates to an automatic shaping and forming machine for a flat flange and belongs to the technical field of metal plate processing machinery and equipment. The automatic shaping and forming machine for the flat flange is used for performing shaping, bending formation, punching and cut-off operation on the flat flange. The technical scheme is as follows: a material reel is arranged on a plate reeling rack; a shaping wheel and a leveling wheel are arranged on a main platform respectively; a band steel plane of the material reel passes through the shaping wheel and the leveling wheel; a horizontal fixed forming wheel and an adjusting shaping wheel are arranged on the upper plane of the main platform respectively; the band steel plane passes through the fixed forming wheel and the adjusting forming wheel; a hydraulic oil cylinder is arranged above a die-cutting bracket; a cutter and a punching mould are arranged in the die-cutting bracket respectively; and the cutter and the punching mould are opposite to the band steel plane which passes through the fixed forming wheel and the adjusting forming wheel. The automatic shaping and forming machine for the flat flange can perform edge milling, sharp corner and burr removal, leveling, arcuation formation, punching and cut-off on the band steel, can manufacture flat flanges with different diameters according to requirements and can perform automatic punching and cut-off on the flat flanges so as to save raw materials and improve the product quality.

Owner:冀中能源井陉矿业集团元氏矿业有限公司

Cutting device based on adhesive product adhesive tape and cutting method

InactiveCN108858369AAchieve clampingPrecise Width ControlNon-rotating vibration suppressionMetal working apparatusElastic compressionAdhesive

The invention discloses the technical field of adhesive products, and relates to a cutting device based on an adhesive product adhesive tape. The cutting device comprises a working table, an adhesivetape body is arranged in the middle of the top of a rotary disc, clamping plates are arranged at the left and right ends of the adhesive tape body, a hydraulic device is arranged in the center of thetop of a top plate, the two ends of a movable transverse plate are connected with guide supports on the left and right sides, the other end of a folding auxiliary rod is provided with an elastic compression block, and the output end of a cutting motor is connected with a cutter through a coupler. The cutting device is simple in operation; an adjusting handle is rotated to enable the clamping plates to move on the outer wall of a screw, the adhesive tape body is clamped, scale marks are arranged on the top of the rotary disc, and the cutting width needed by the adhesive tape body is conveniently and accurately controlled; guide sliding rods are inserted into the two ends of the movable transverse plate, and cutting errors, caused by inclining falling of the movable transverse plate, of theadhesive tape body are avoided; and rubber anti-sliding gaskets are installed at the bottoms of four supporting feet, and therefore vibration of the device during cutting work is effectively reduced.

Owner:苏州盛迪通电子科技有限公司

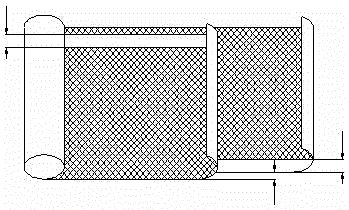

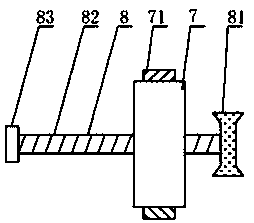

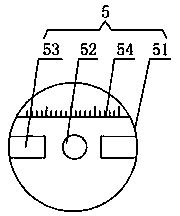

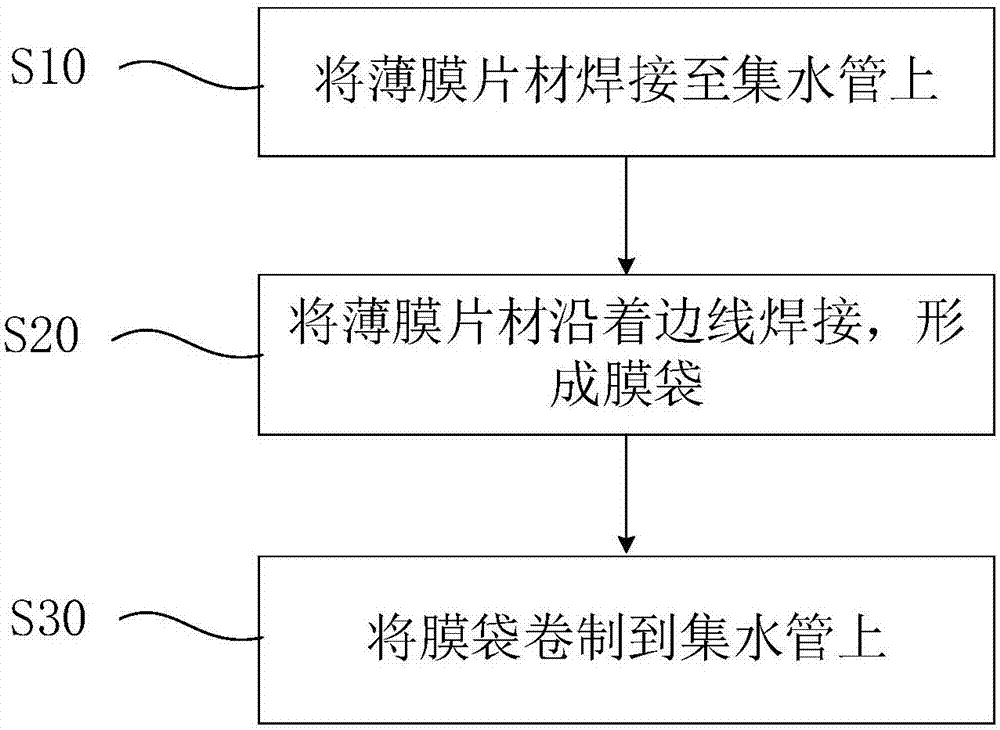

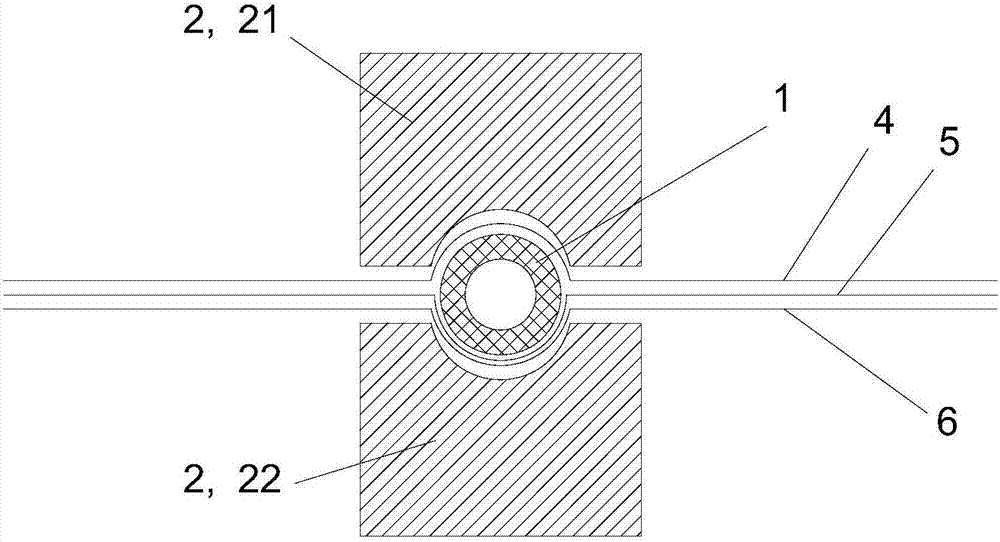

Spiral-wound membrane element manufacturing method

ActiveCN107081071AQuality improvementAvoid wrinklesSemi-permeable membranesThin membraneNanofiltration

The invention discloses a spiral-wound membrane element manufacturing method. A spiral-wound membrane element comprises a water collecting tube and at least one membrane bag wound around the periphery of the water collecting tube. The spiral-wound membrane element manufacturing method comprises the steps that S10, a thin membrane sheet for forming the membrane bag is welded on the water collecting tube; S20, the thin membrane sheet for forming the membrane bag is welded together along a side boundary to form a single membrane bag; S30, at least one membrane bag is wound around the water collecting tube. By adopting the spiral-wound membrane element manufacturing method, the membrane bag side boundary width of flat sheet membrane spiral-wound membrane elements such as a reverse osmosis membrane, a nanofiltration membrane and an ultrafiltration membrane can be accurately controlled, accordingly effective membrane area is larger, meanwhile membrane bag side boundary bonding can be completed within a short time, and a production period can be shortened.

Owner:JIANGSU BANGTEC ENVIRONMENTAL SCI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com