High-efficiency production technology of thin-film capacitor

A film capacitor and production process technology, applied in the field of high-efficiency production process of film capacitors, can solve problems such as low production efficiency, deviation of pin spacing, unstable product capacity, etc., and achieve the effect of accurately controlling the width of the core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] see Figure 3-6 , in an embodiment of the present invention, a high-efficiency production process of a film capacitor, the specific steps are as follows:

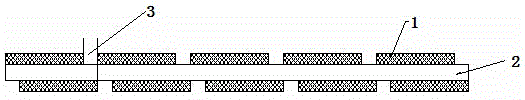

[0024] 1) Evaporate the evaporation layer 1 on the film base film 2 according to the required width on the front and back sides, the evaporation areas and spacing on the front and back sides are fixed, and the staggered sides 3 of the front and back evaporation areas follow the traditional winding process. The side is determined, and five grids are evaporated;

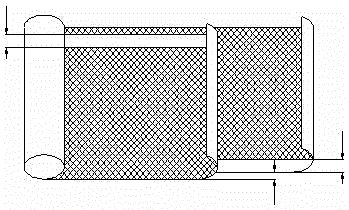

[0025] 2) When winding, the metallized film with evaporated layer 1 evaporated on the front and back sides and a non-evaporated light film 4 are wound together. After the winding is completed, it is equivalent to forming several capacitor cores at one time;

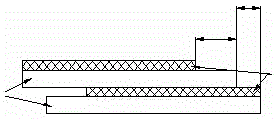

[0026] 3) Pre-flatten the wound core, and cut it into five separate cores according to the required width;

[0027] 4) The slit core is heat-treated at 110°C, so that the non-evaporated light film 4 sh...

Embodiment 2

[0029] see Figure 3-6 , in an embodiment of the present invention, a high-efficiency production process of a film capacitor, the specific steps are as follows:

[0030] 1) Evaporate the evaporation layer 1 on the film base film 2 according to the required width on the front and back sides, the evaporation areas and spacing on the front and back sides are fixed, and the staggered sides 3 of the front and back evaporation areas follow the traditional winding process. The side is determined, and six grids are evaporated;

[0031] 2) When winding, the metallized film with evaporated layer 1 evaporated on the front and back sides and a non-evaporated light film 4 are wound together. After the winding is completed, it is equivalent to forming several capacitor cores at one time;

[0032] 3) Pre-flatten the wound core, and cut it into six separate cores according to the required width;

[0033] 4) The core after slitting is heat-treated at 130°C, so that the non-evaporated light f...

Embodiment 3

[0035] see Figure 3-6 , in an embodiment of the present invention, a high-efficiency production process of a film capacitor, the specific steps are as follows:

[0036] 1) Evaporate the evaporation layer 1 on the film base film 2 according to the required width on the front and back sides, the evaporation areas and spacing on the front and back sides are fixed, and the staggered sides 3 of the front and back evaporation areas follow the traditional winding process. The side is determined, and seven grids are evaporated;

[0037] 2) When winding, the metallized film with evaporated layer 1 evaporated on the front and back sides and a non-evaporated light film 4 are wound together. After the winding is completed, it is equivalent to forming several capacitor cores at one time;

[0038] 3) Pre-flatten the wound core, and cut it into seven separate cores according to the required width;

[0039] 4) The slit core is heat-treated at 165°C, so that the non-evaporated light film 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com