Automatic shaping and forming machine for flat flange

A molding machine, flat flange technology, applied in the direction of perforation tools, other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of insufficient width accuracy, easy-to-break radian accuracy, low rolling quality, etc., to reduce production costs. , The effect of improving product quality and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

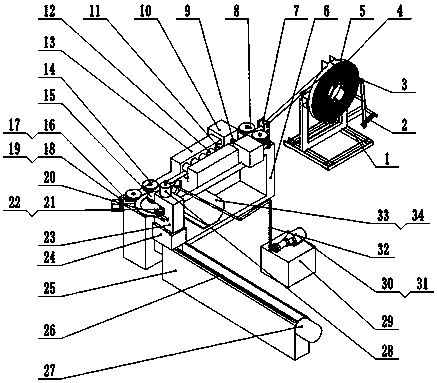

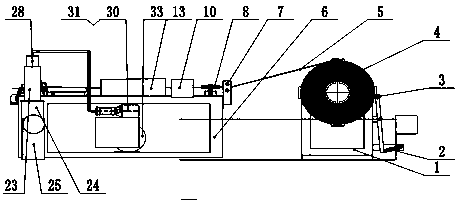

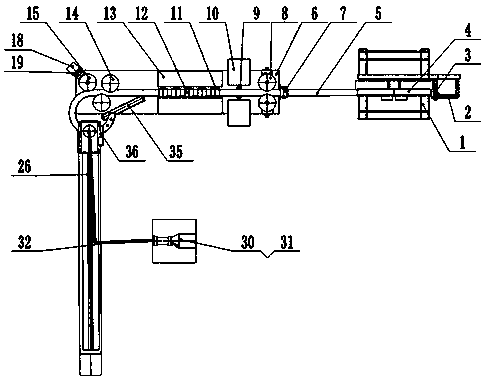

[0024] The present invention is made up of main motor 33, plate and coil rack 1, feeding device, edge milling device, leveling part, forming part.

[0025] figure 1 , 2 , 3 show that the plate and coil material frame 1 is an upright steel frame, and there are horizontal support sleeves and pressure wheel tension spring 2 and pressure wheel 3 on the steel frame, and the pressure wheel 3 is on the side of the pressure wheel spring 2. Compress the material roll 4 under tension to prevent the material roll 4 from loosening. The material roll 4 is located in the vertical direction. The center hole of the material roll 4 is set on the support sleeve, and the material roll 4 can be rotated under the support of the support sleeve. The strip steel plane of the material coil 4 is located in the horizontal plane, and the front end of the strip steel 5 of the material coil 4 enters the leveling part through the feeding device and the edge milling device.

[0026] figure 1 , 2 , 3 show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com