Spiral-wound membrane element manufacturing method

A production method and roll-type membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problem that the effective area of the membrane bag cannot be accurately controlled, it is difficult to accurately control the width of the membrane bag edge, and the glue is easy to impregnate to Other parts and other problems, to achieve the effect of shortening the production cycle, avoiding wrinkles, and large membrane area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention proposes a new manufacturing method of spiral wound membrane elements by studying the rolling methods of flat membrane spiral membrane elements such as reverse osmosis membranes, nanofiltration membranes, ultrafiltration membranes and the like. Through the production method of the present invention, the production process of flat membrane membrane elements such as reverse osmosis membranes, nanofiltration membranes, ultrafiltration membranes, etc. can be completed quickly and accurately, and the effective membrane area of the membrane bag made by traditional glue bonding is larger, And it can save the consumption of glue raw materials and the parking time required for glue curing, so it is easier to realize automatic continuous production.

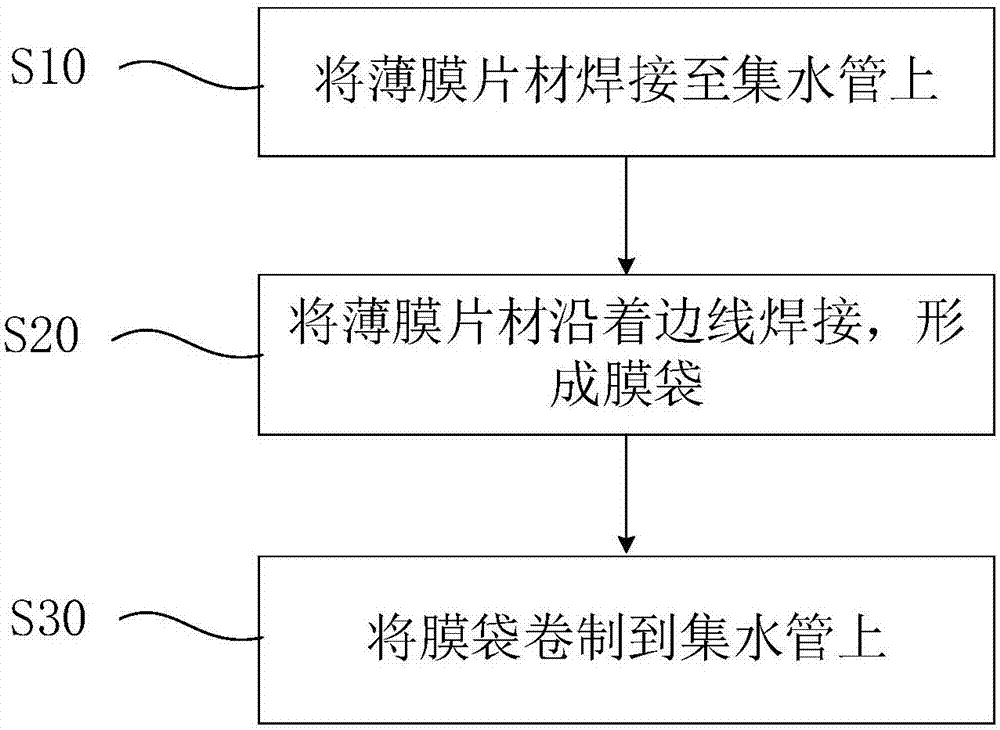

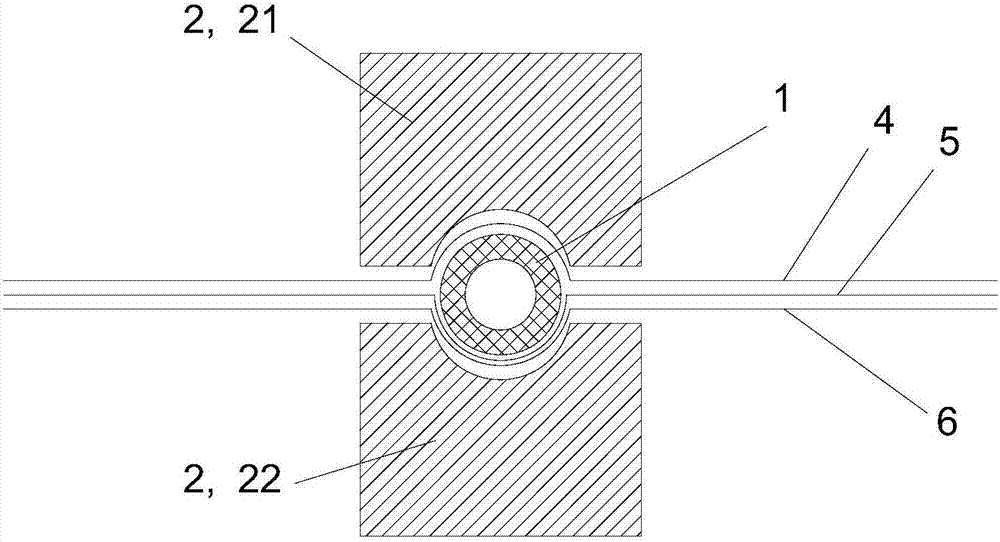

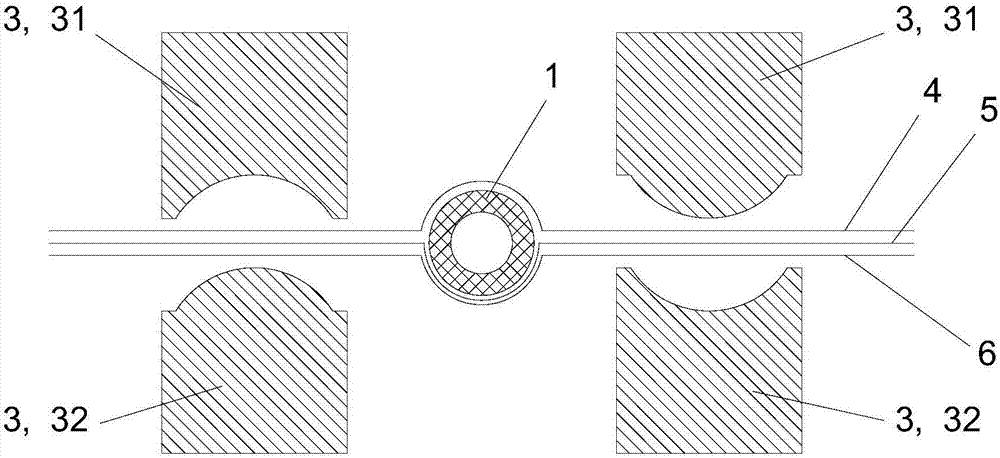

[0030] The spiral wound membrane element involved in the present invention includes a water collection pipe and at least one film bag wound around the water collection pipe. The manufacturing method of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com