Patents

Literature

65 results about "Spiral membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

MS spiral membrane modules are composed of a combination of PVDF flat membrane sheets separated by a thin meshed spacer material which serves as a porous plastic screen support.

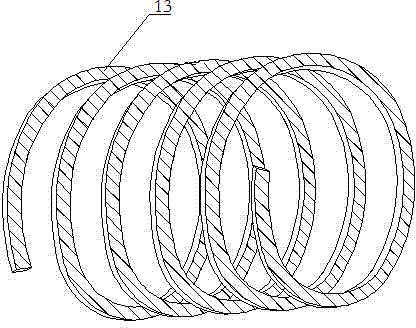

Spiral membrane element and method of manufacturing the same

InactiveUS20050077229A1Reduce total pressure lossReduce manufacturing costSemi-permeable membranesDispersed particle filtrationAdhesiveMembrane surface

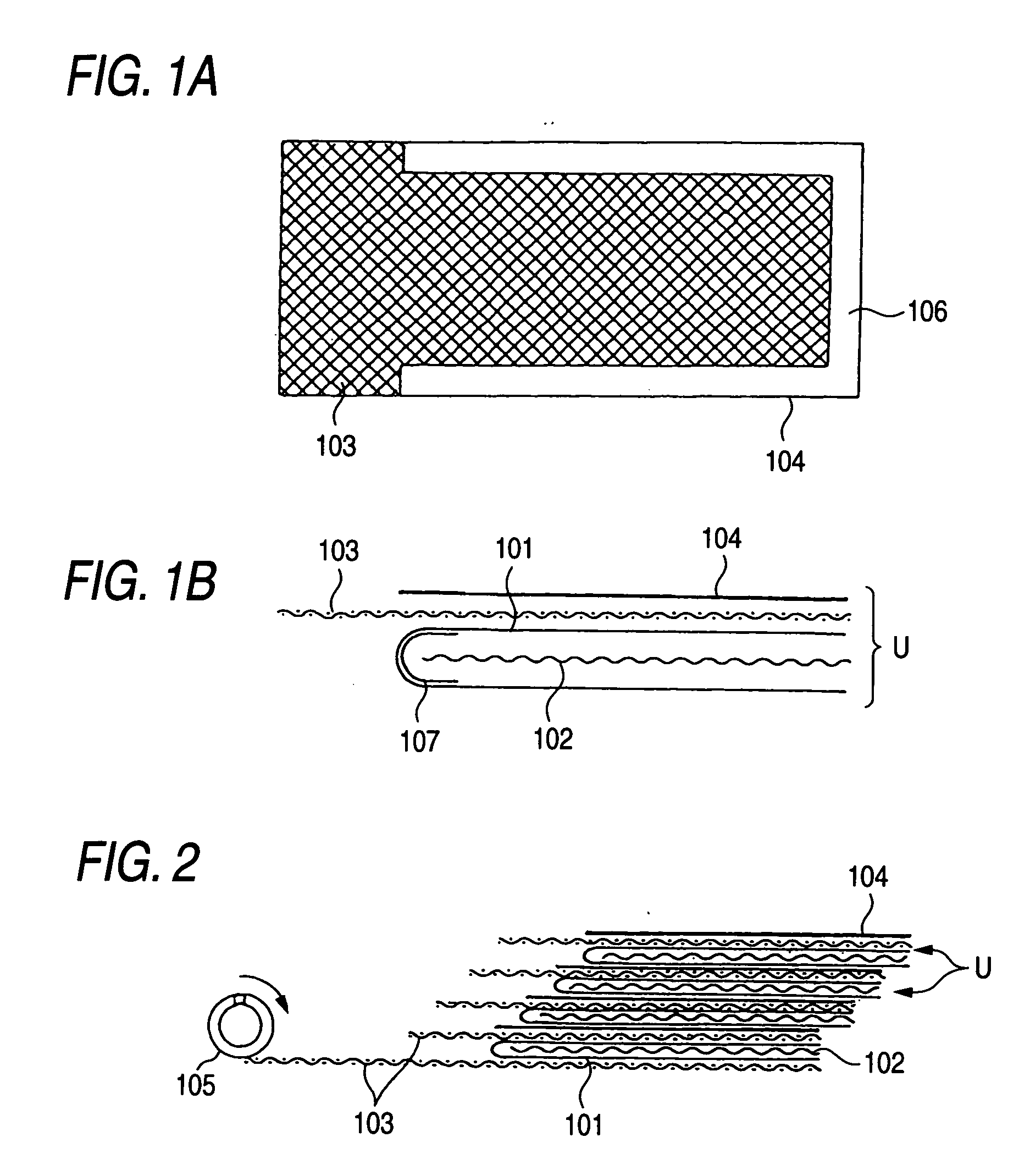

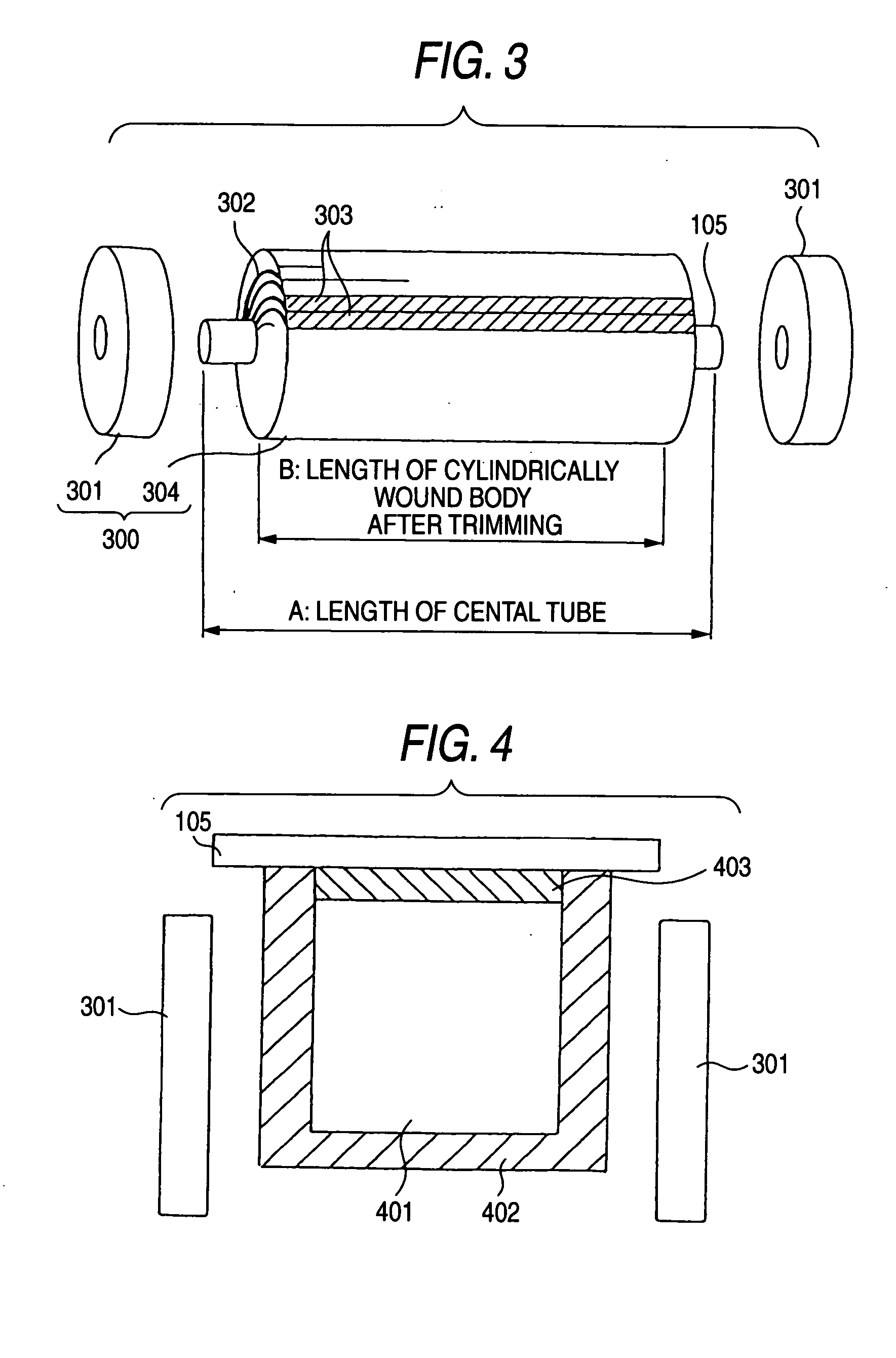

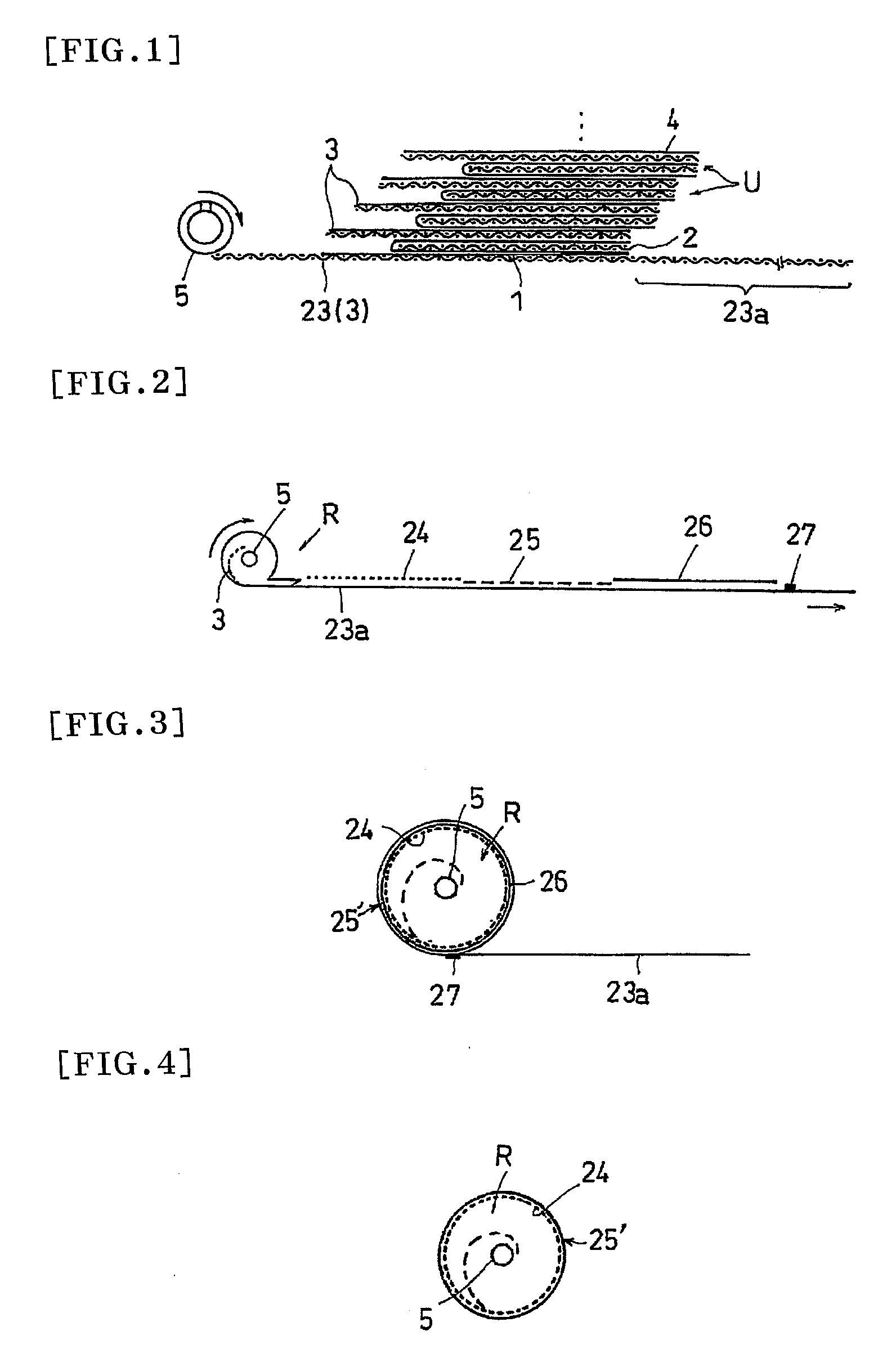

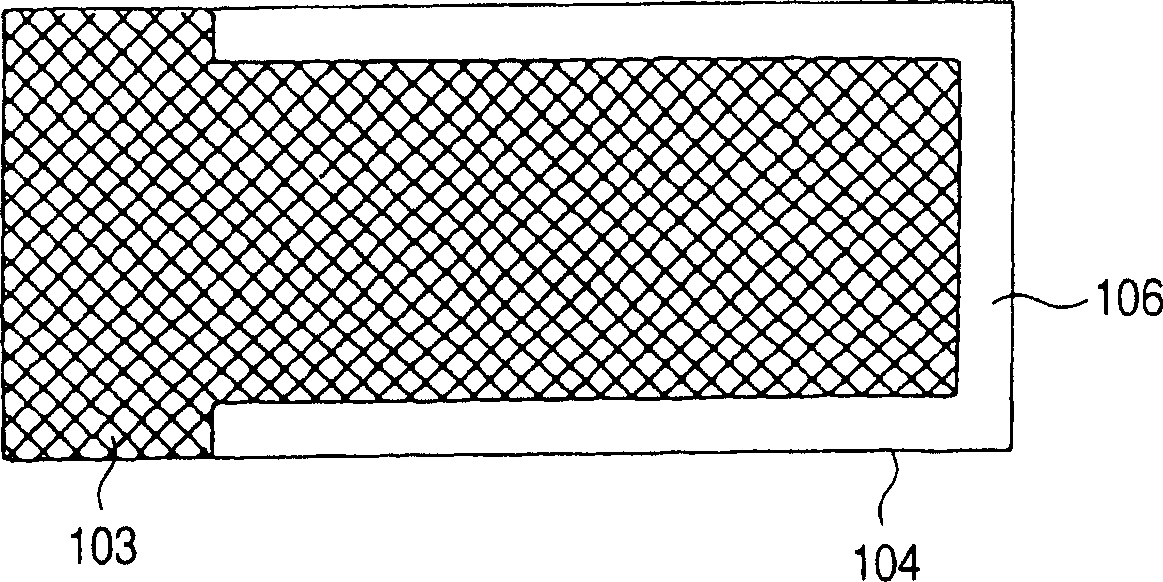

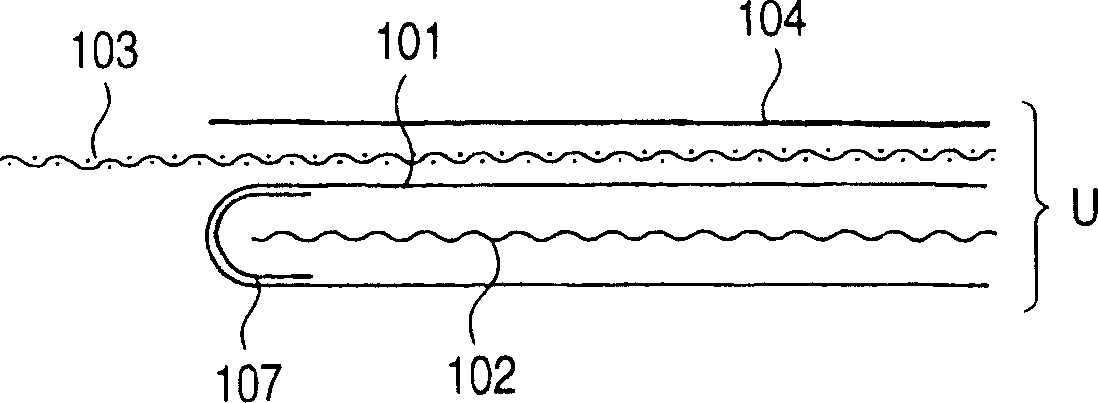

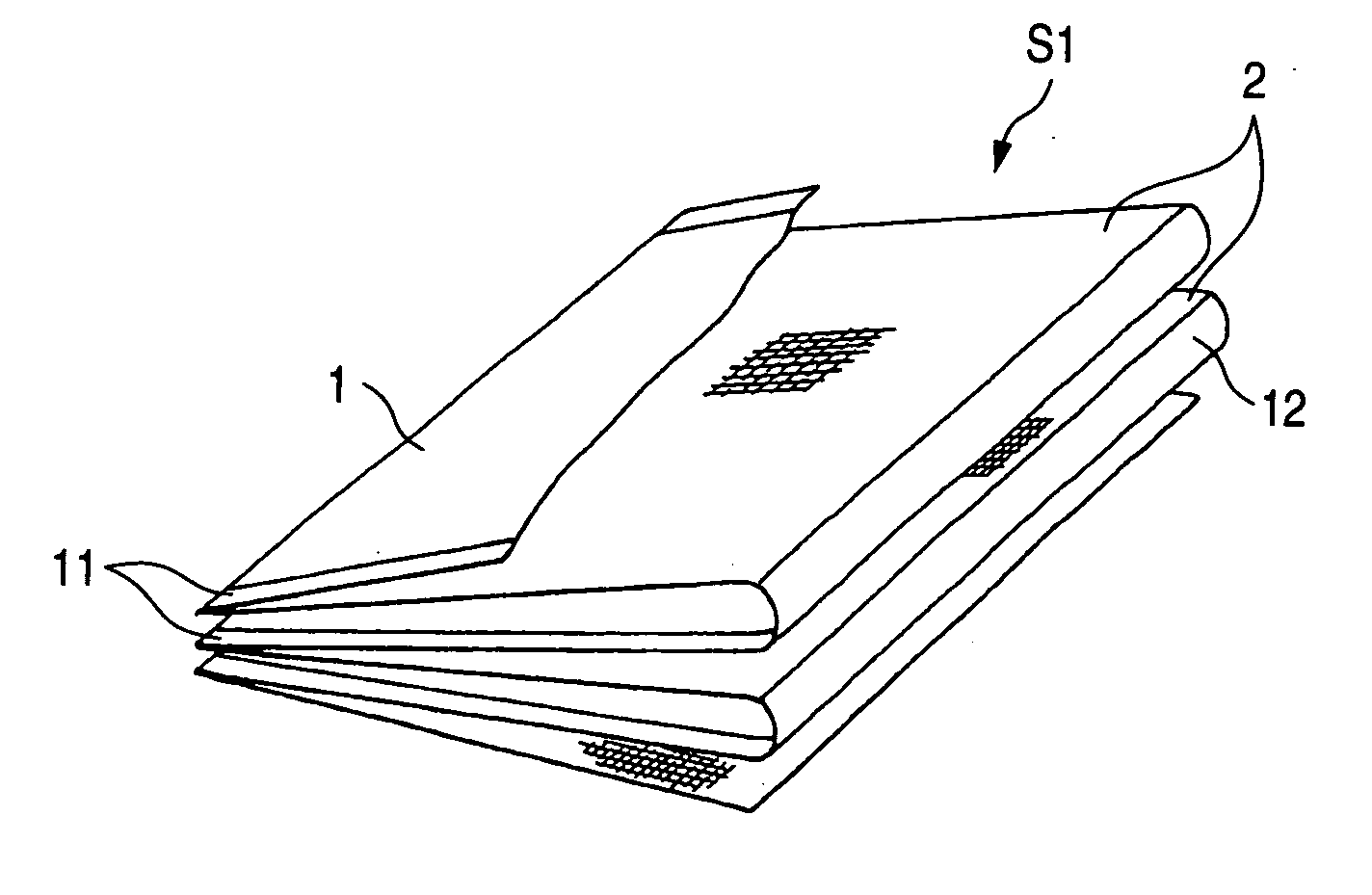

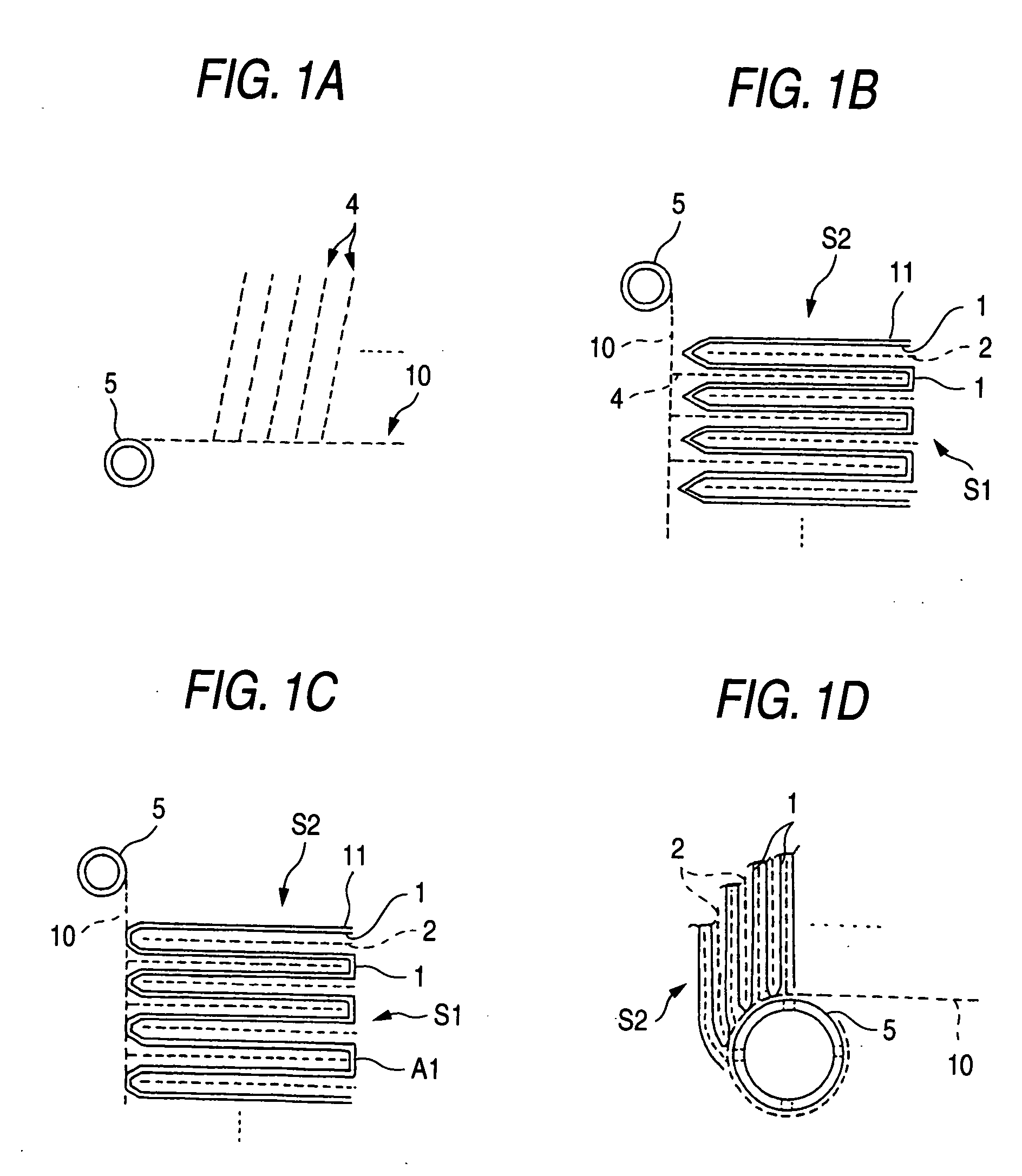

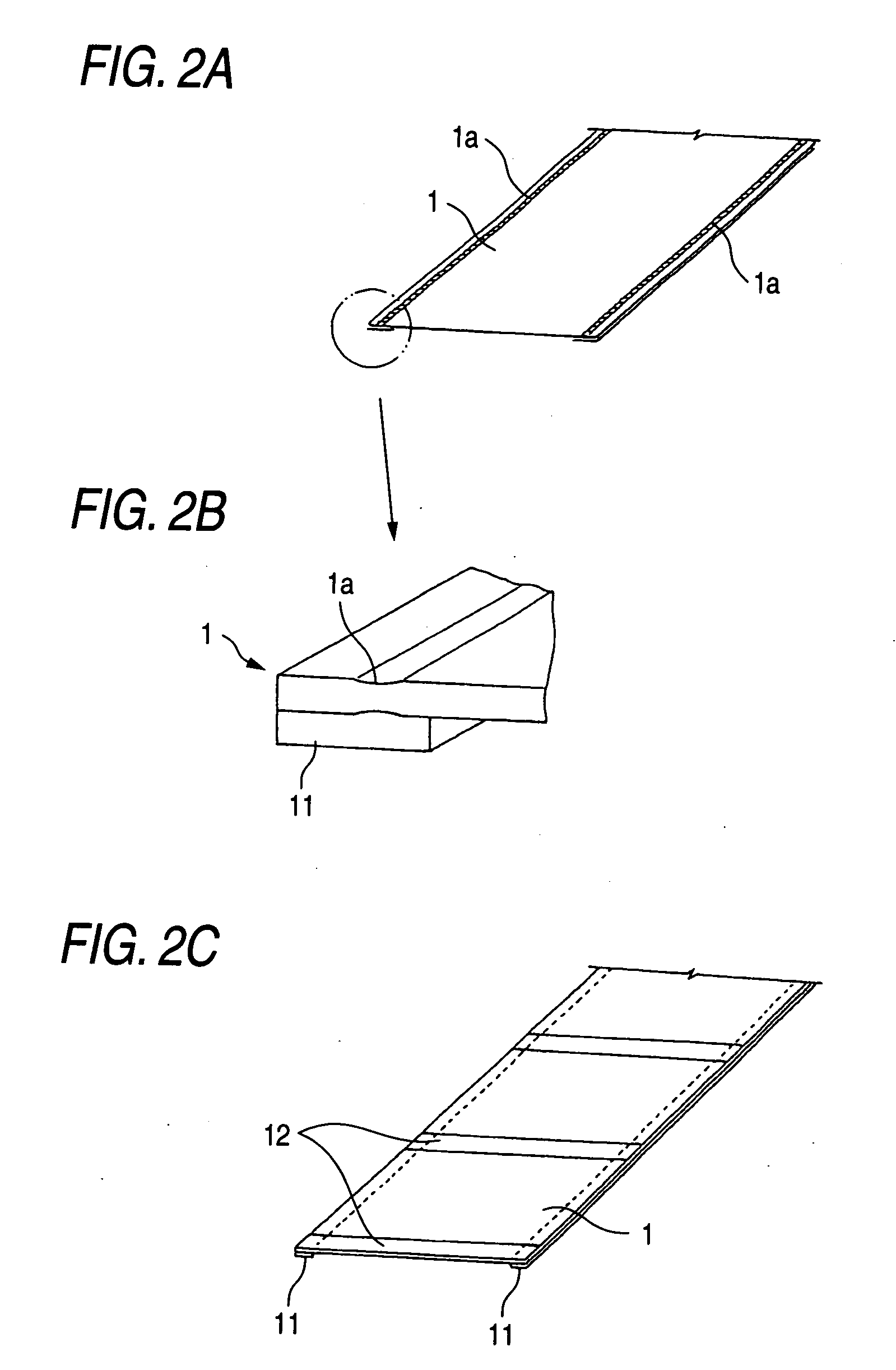

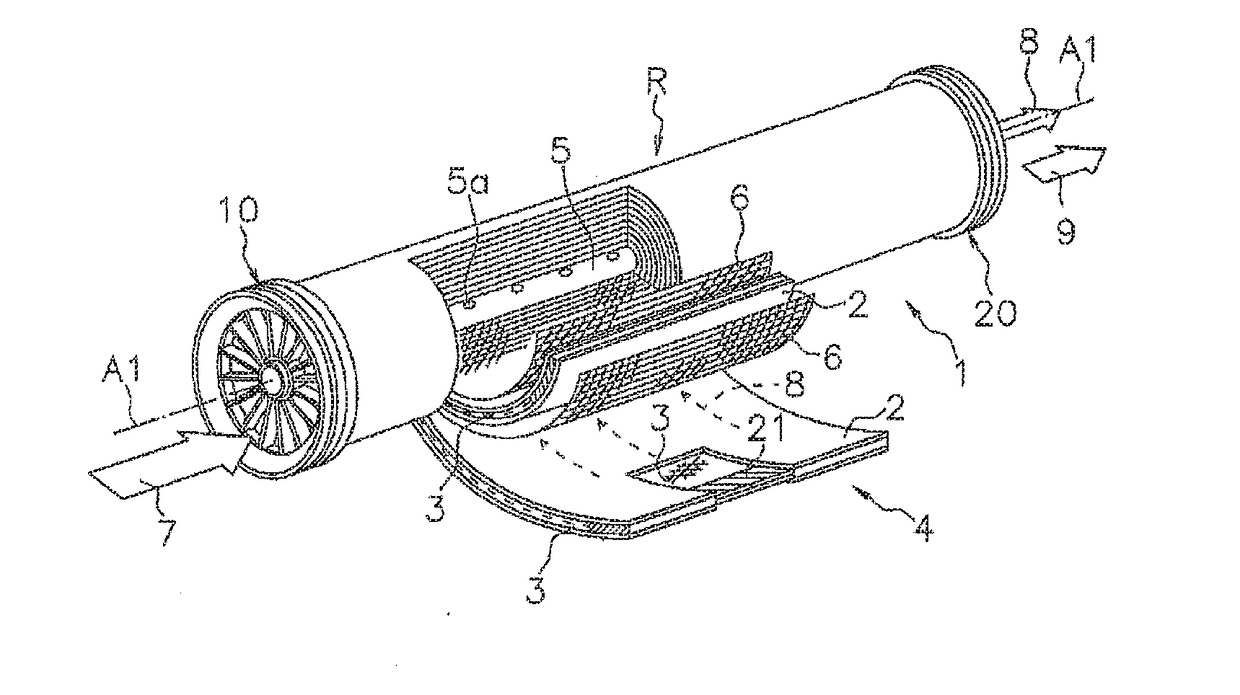

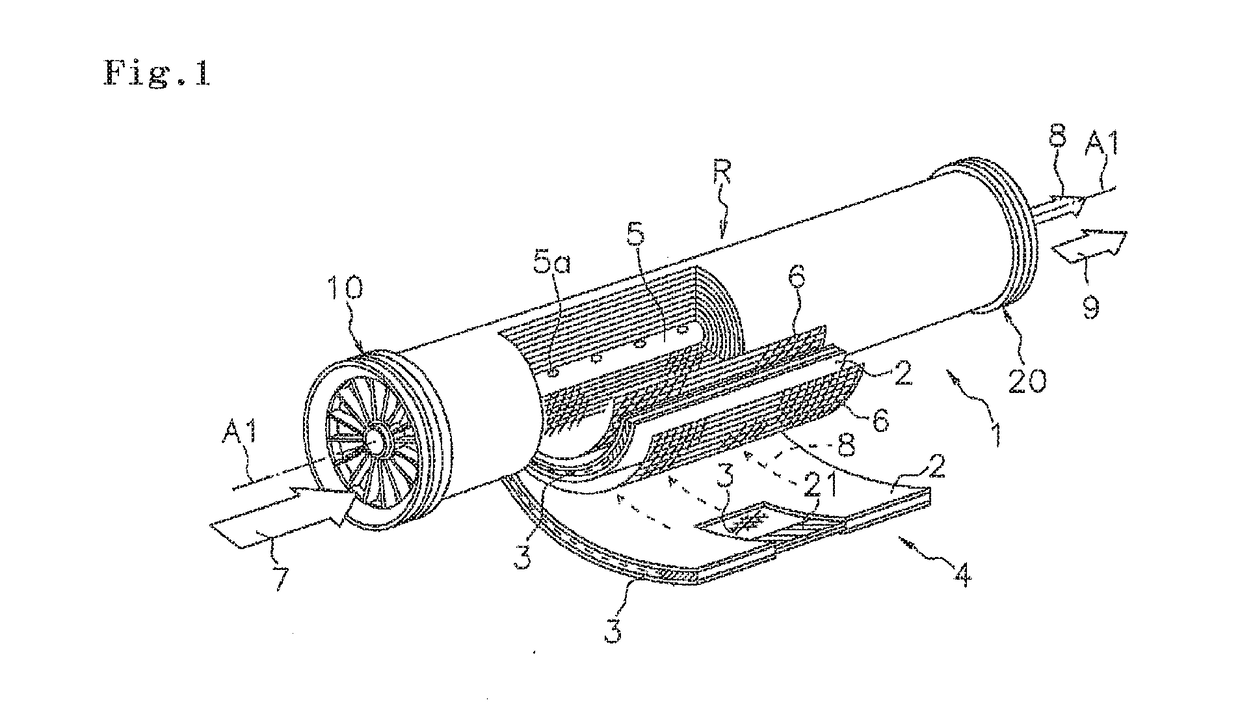

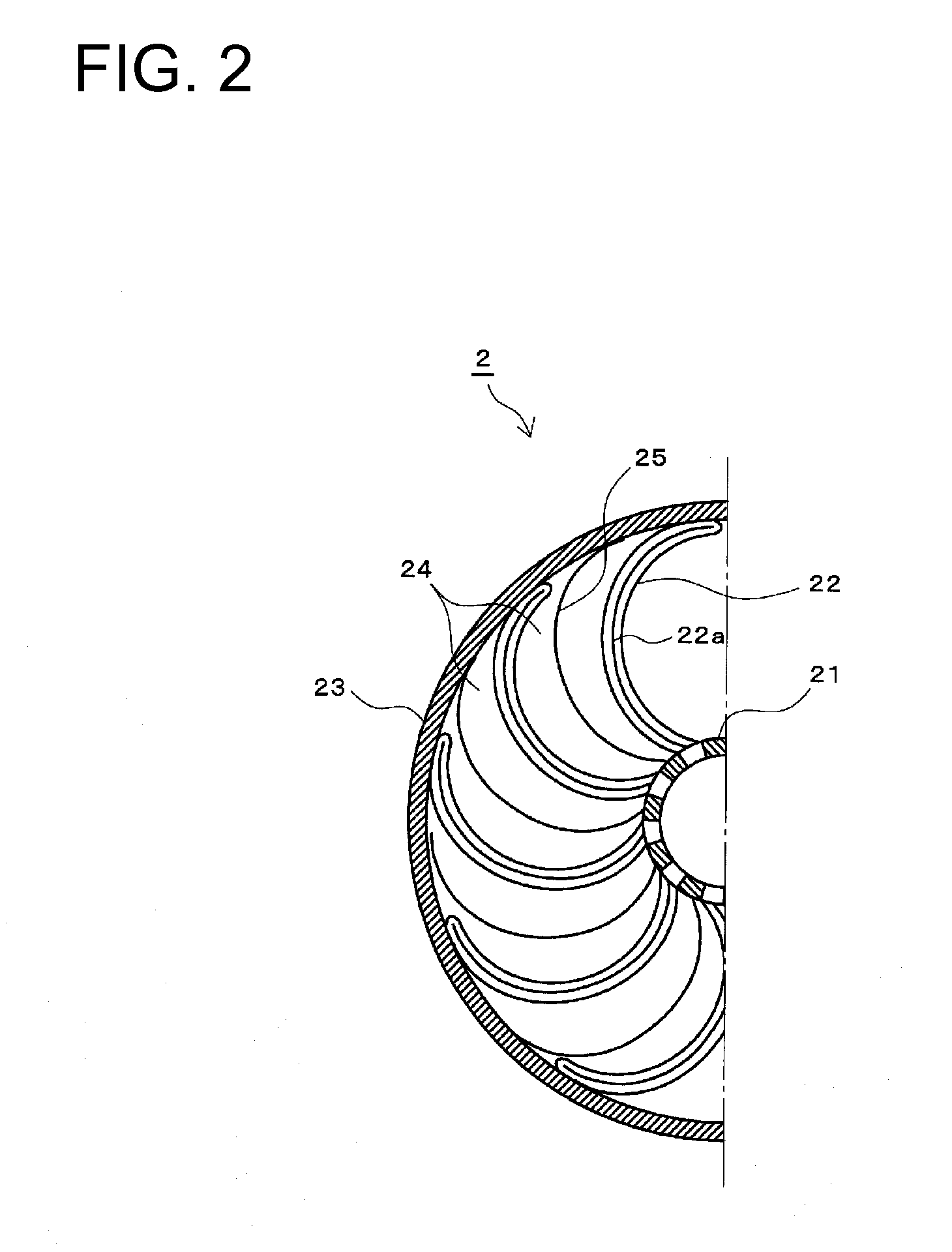

A spiral membrane element having an enlarged effective membrane surface area without having its separation performance lowered, while maintaining the sealing property of any sealing portion of a cylindrically wound body, and a manufacturing method of the same are disclosed. The spiral membrane element includes a cylindrically wound body comprising a perforated central tube and, spirally wound therearound, a separation membrane, a feed-side passage material and a permeation-side passage material in a laminated state, and a sealing portion for preventing a feed-side fluid and a permeation-side fluid from being mixed together, wherein the sealing portion formed at each of both ends of the cylindrically wound body is spirally formed with a substantially constant width by an adhesive and has a trimmed section formed on its whole end surface, and the cylindrically wound body has a ratio of its length to the length of the central tube of 0.96 to 1.00, and a ratio of an ineffective membrane surface area to the entire membrane surface area of 0.02 to 0.10.

Owner:NITTO DENKO CORP

Spiral membrane element and process for producing the same

InactiveUS20090026130A1Uniform layersMembranesPaper/cardboard wound articlesSpiral membraneMembrane configuration

Owner:NITTO DENKO CORP

Monitoring unit for monitoring the condition of a semi-permeable membrane

InactiveUS20020134716A1Overcome disadvantagesReduce disadvantagesSettling tanks feed/dischargeWater/sewage treatment bu osmosis/dialysisSemipermeable membraneReverse osmosis

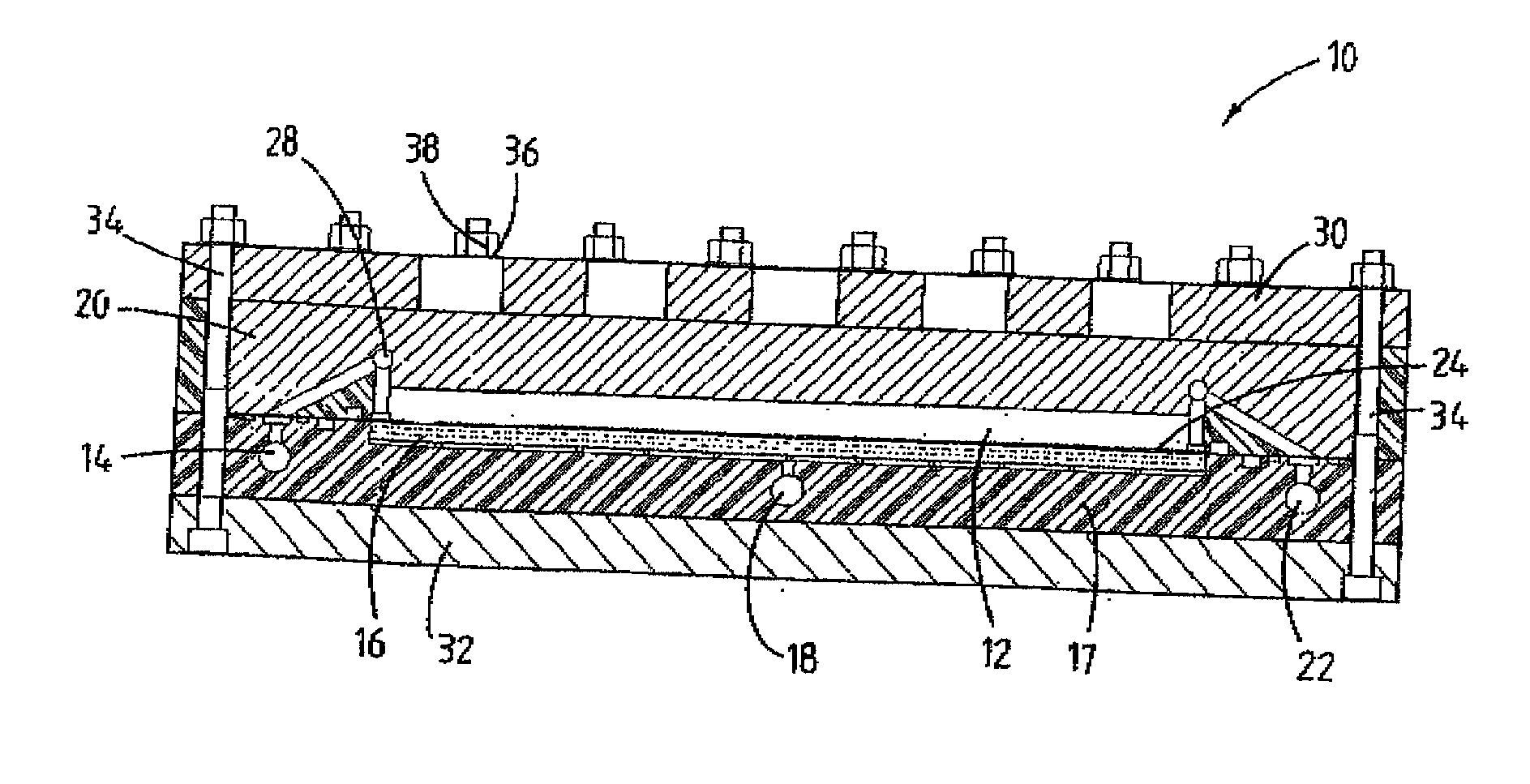

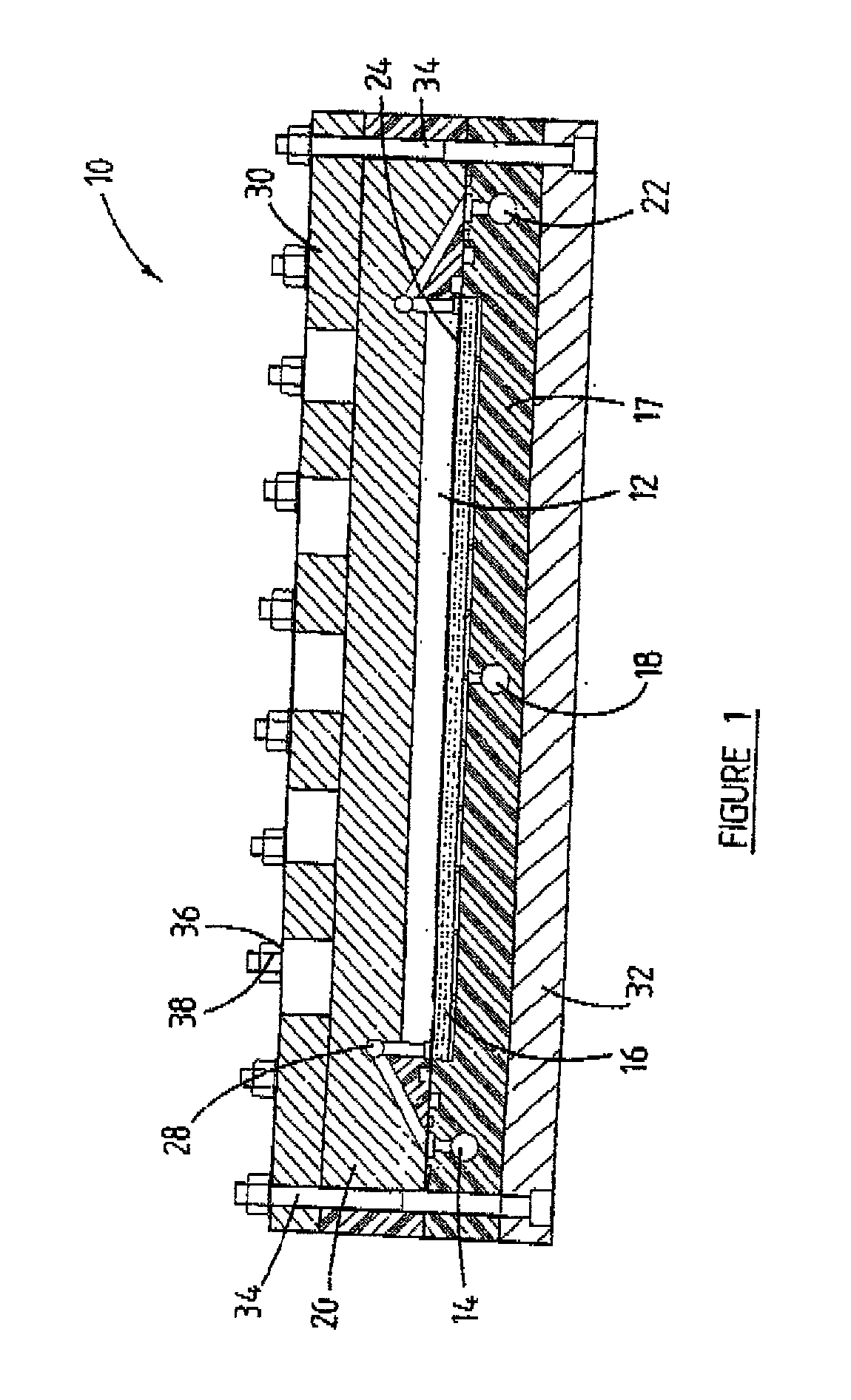

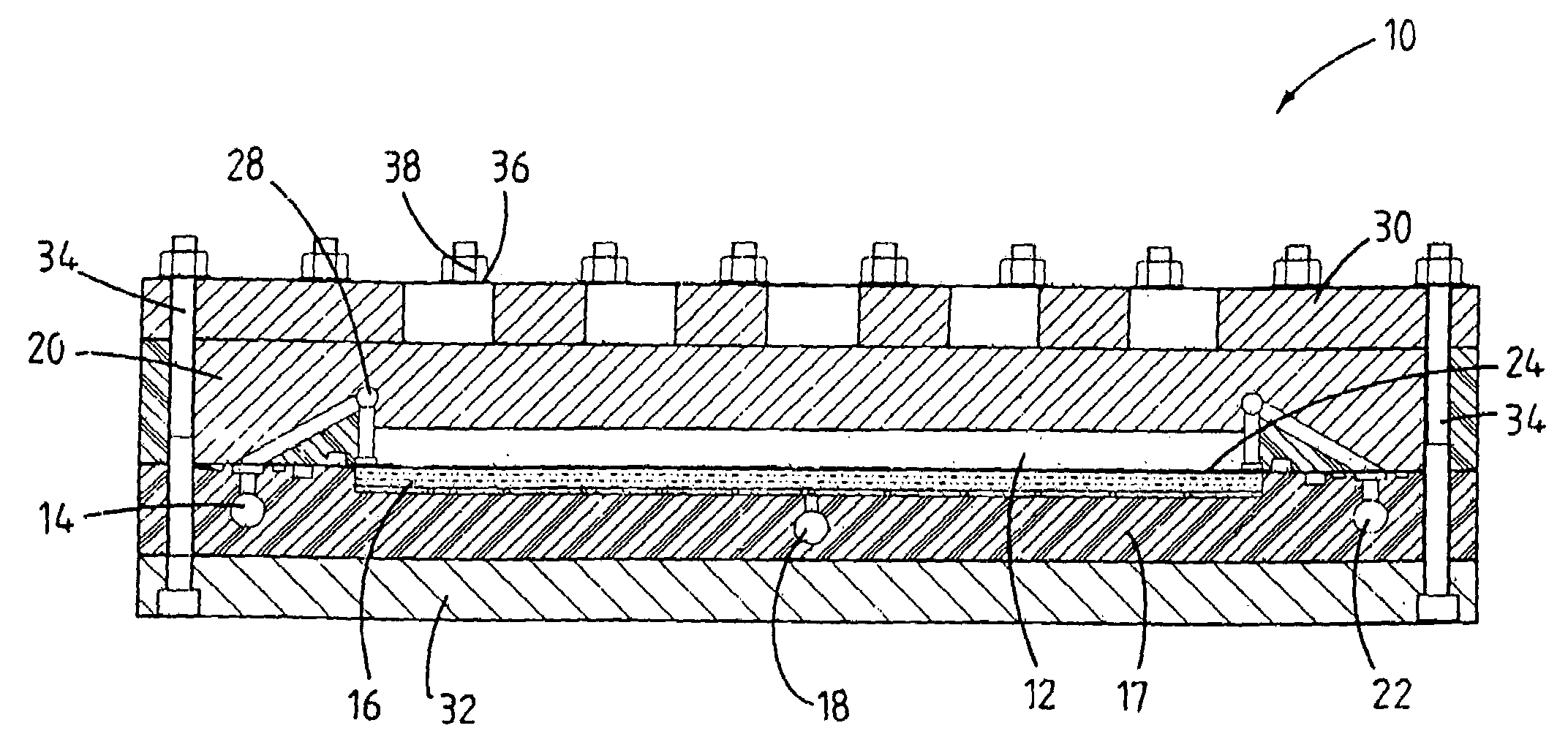

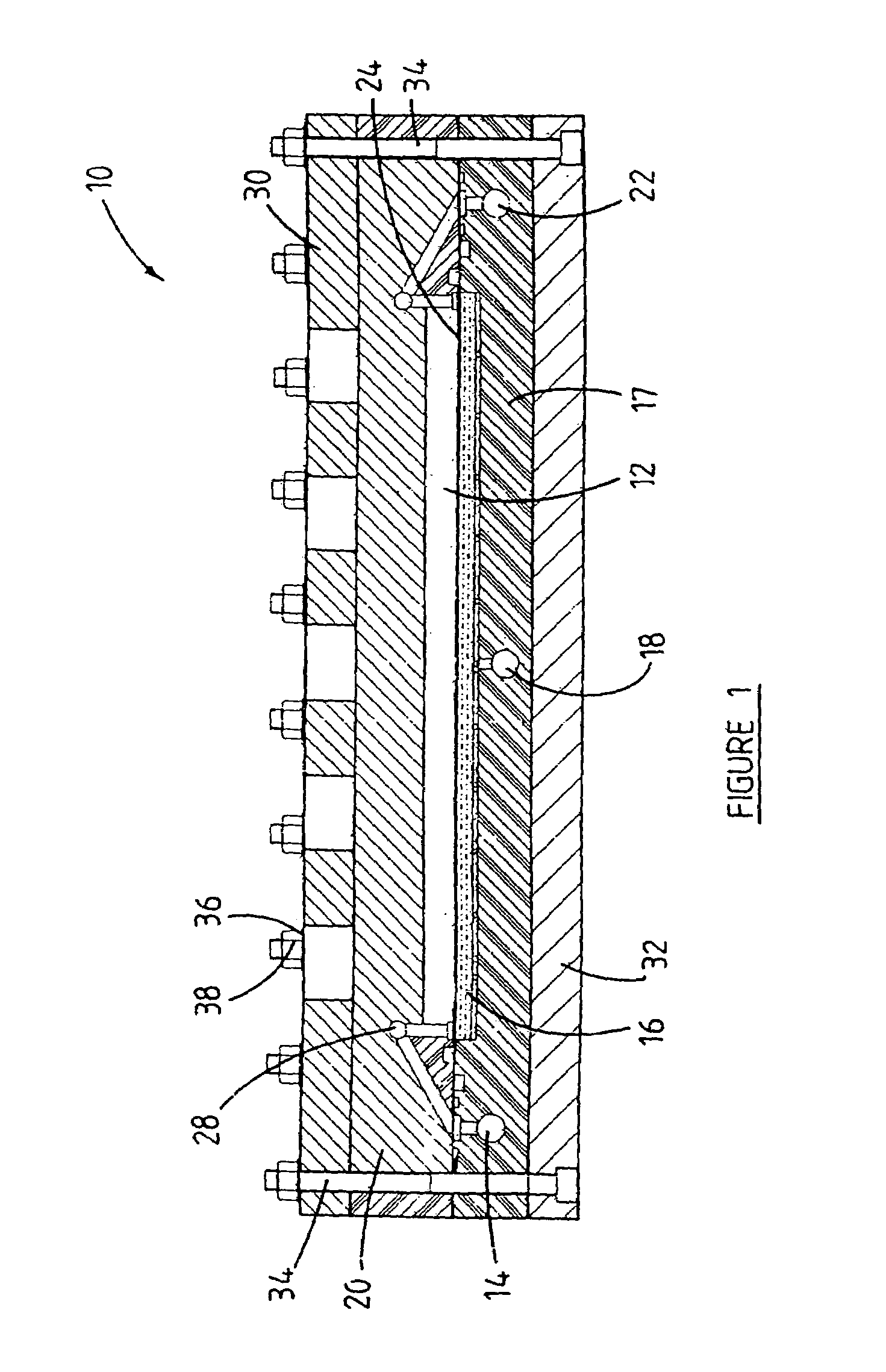

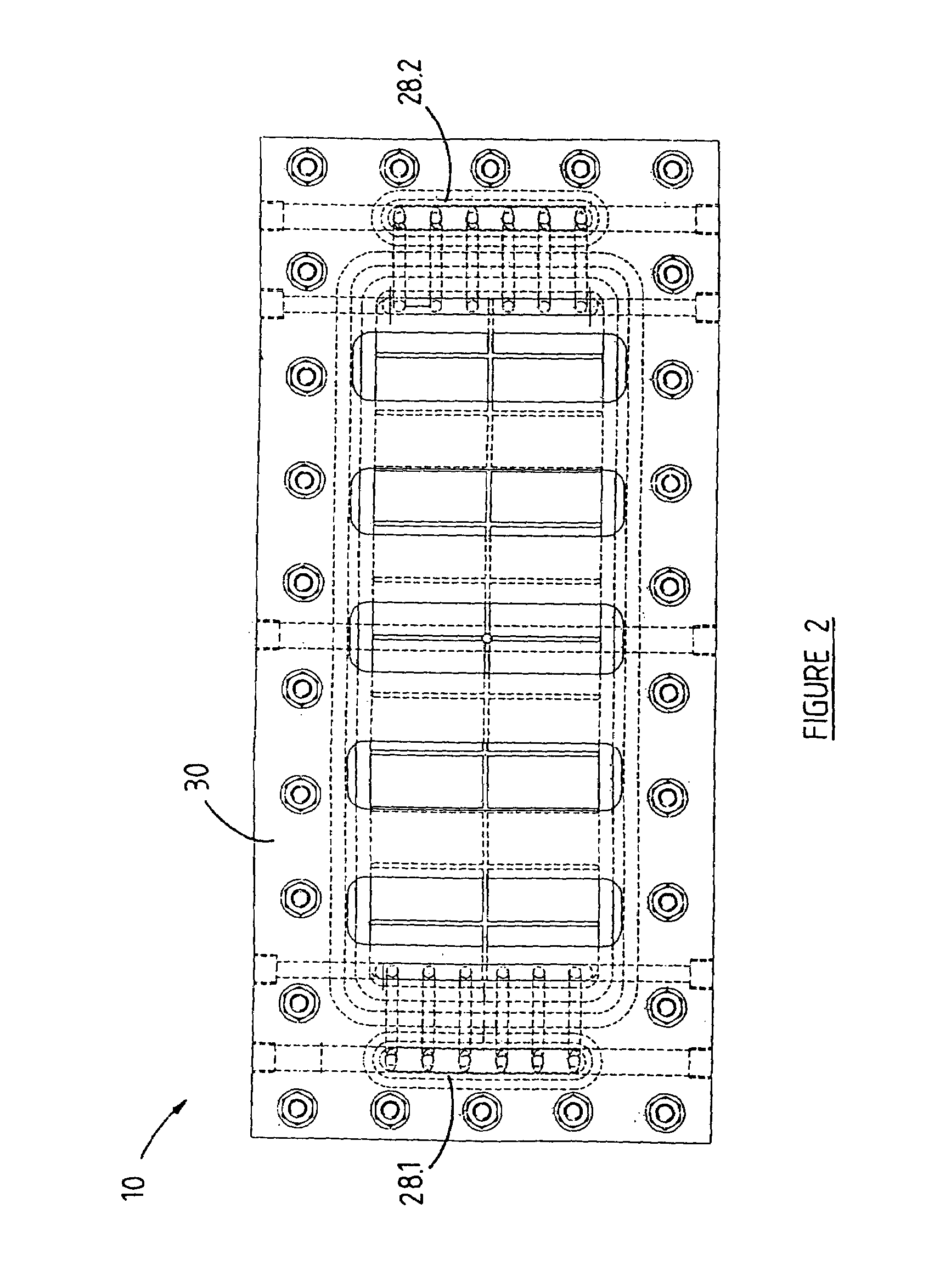

The invention concerns a monitoring unit [10] for monitoring the condition of a semi-permeable membrane [24] in a water purification system, and particularly the condition of spiral membrane in a reverse osmosis water purification system. The monitoring unit [10] comprises a flow chamber [12] that includes an inlet for permitting ingress of a feed fluid into the flow chamber [12], and a feed fluid outlet [22] for permitting at least partial through-flow of the feed fluid through the flow chamber [12] such that cross-flow conditions apply in the flow chamber [12]. The semi-permeable membrane [24] is at least partly supported in the flow chamber [12]. The monitoring unit [10] further comprises at least one fluid outlet [18] arranged in fluid communication with the flow chamber [12] for permitting egress of fluid from the monitoring unit [10] after having passed through the membrane [24]; and an inspection window [20] for permitting visual inspection of the semi-permeable membrane [24]. The invention also extends to the use of such a monitoring unit [10] in evaluating various operating parameters of such a system, and to a water purification system including such a monitoring unit [10] or test cell.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

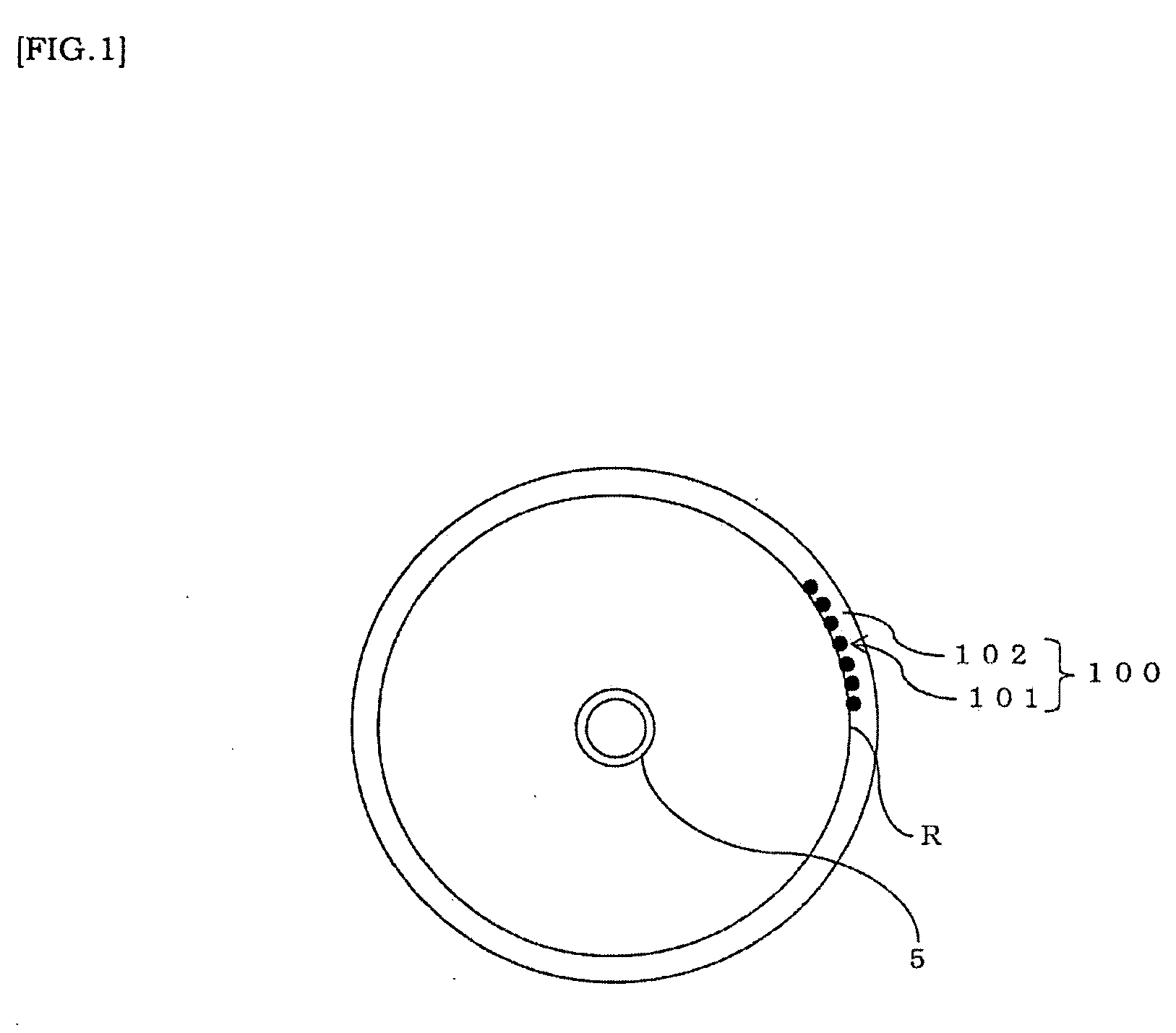

Spiral membrane element

InactiveUS20090065426A1Improve barrier propertiesAvoid crackingSemi-permeable membranesLaminationEngineeringMechanical engineering

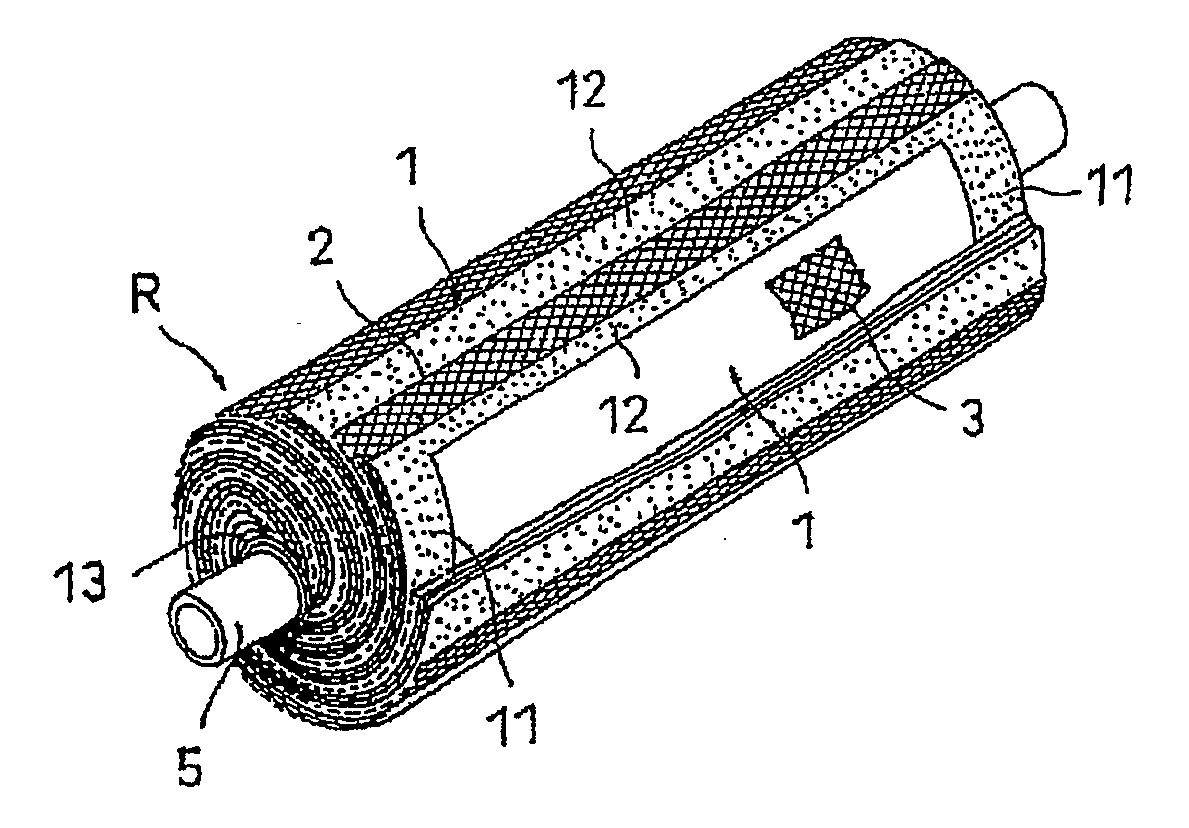

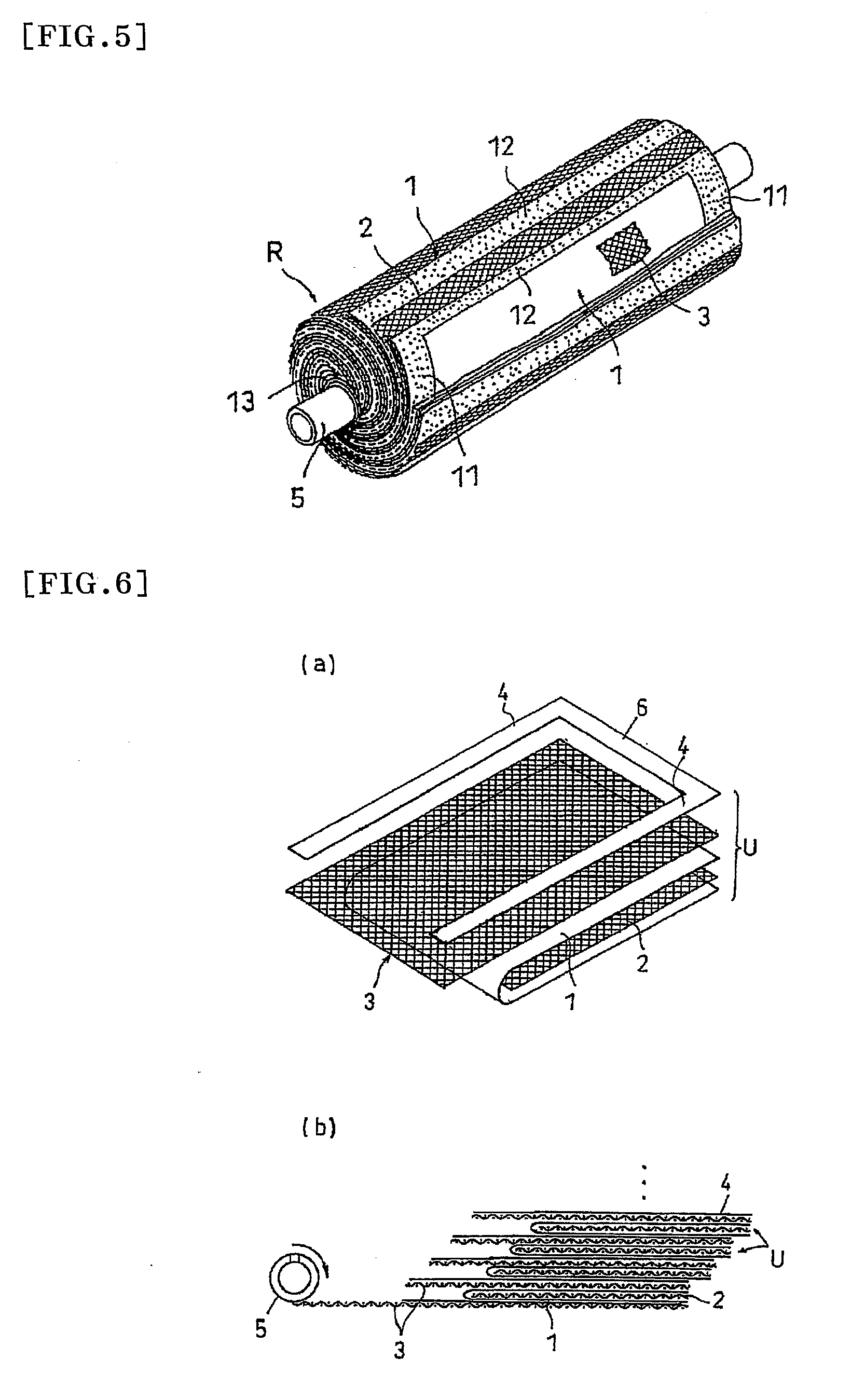

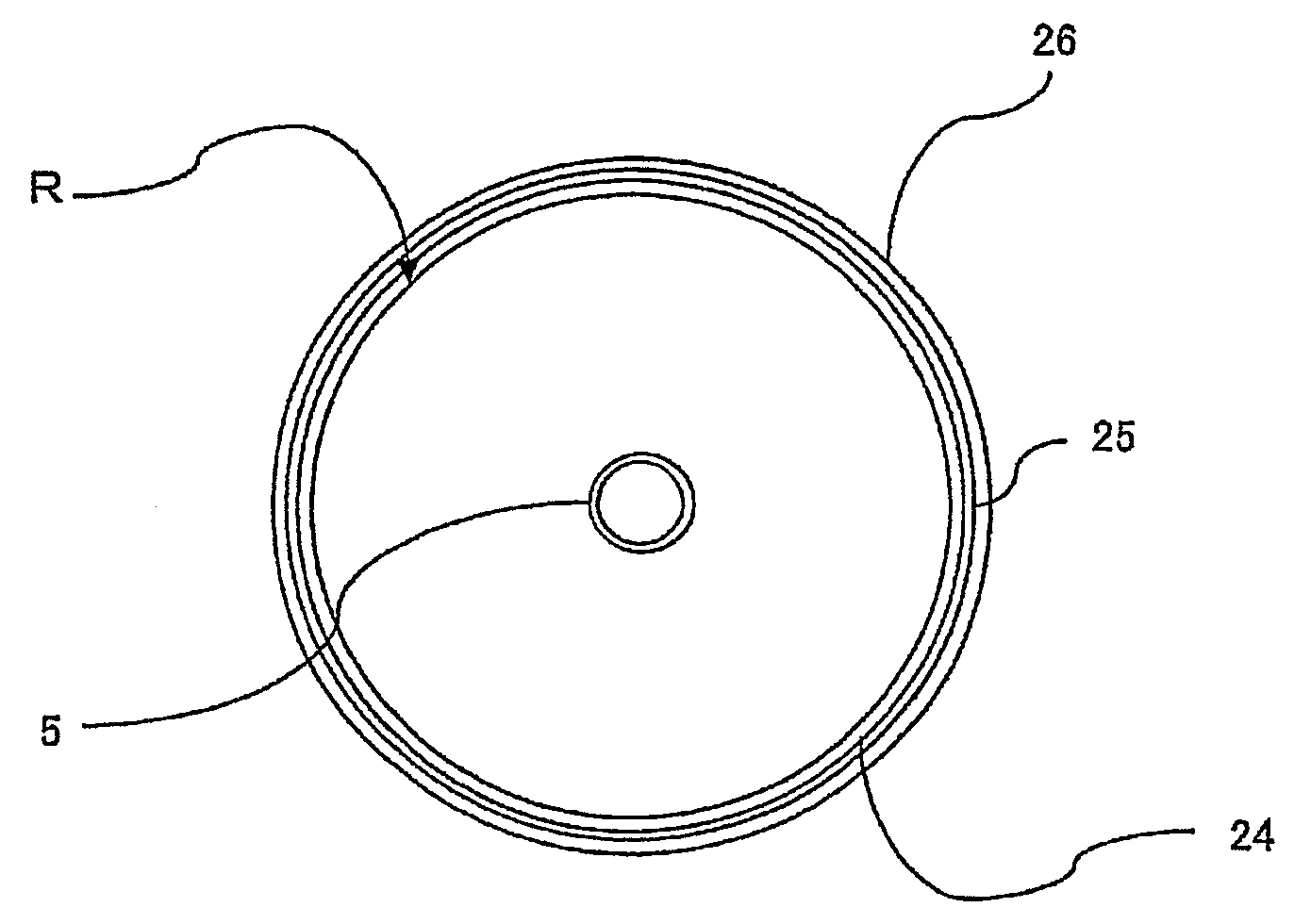

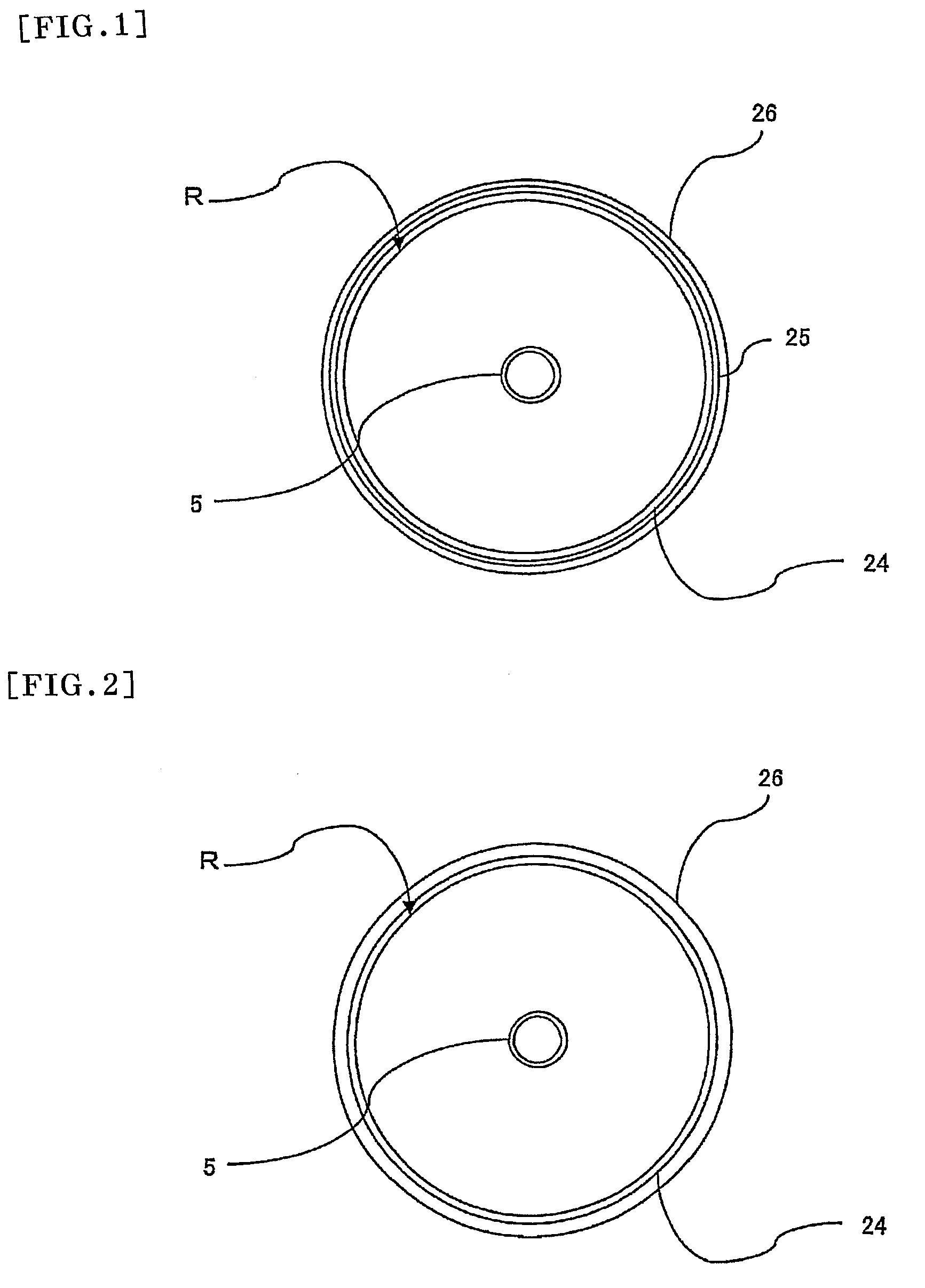

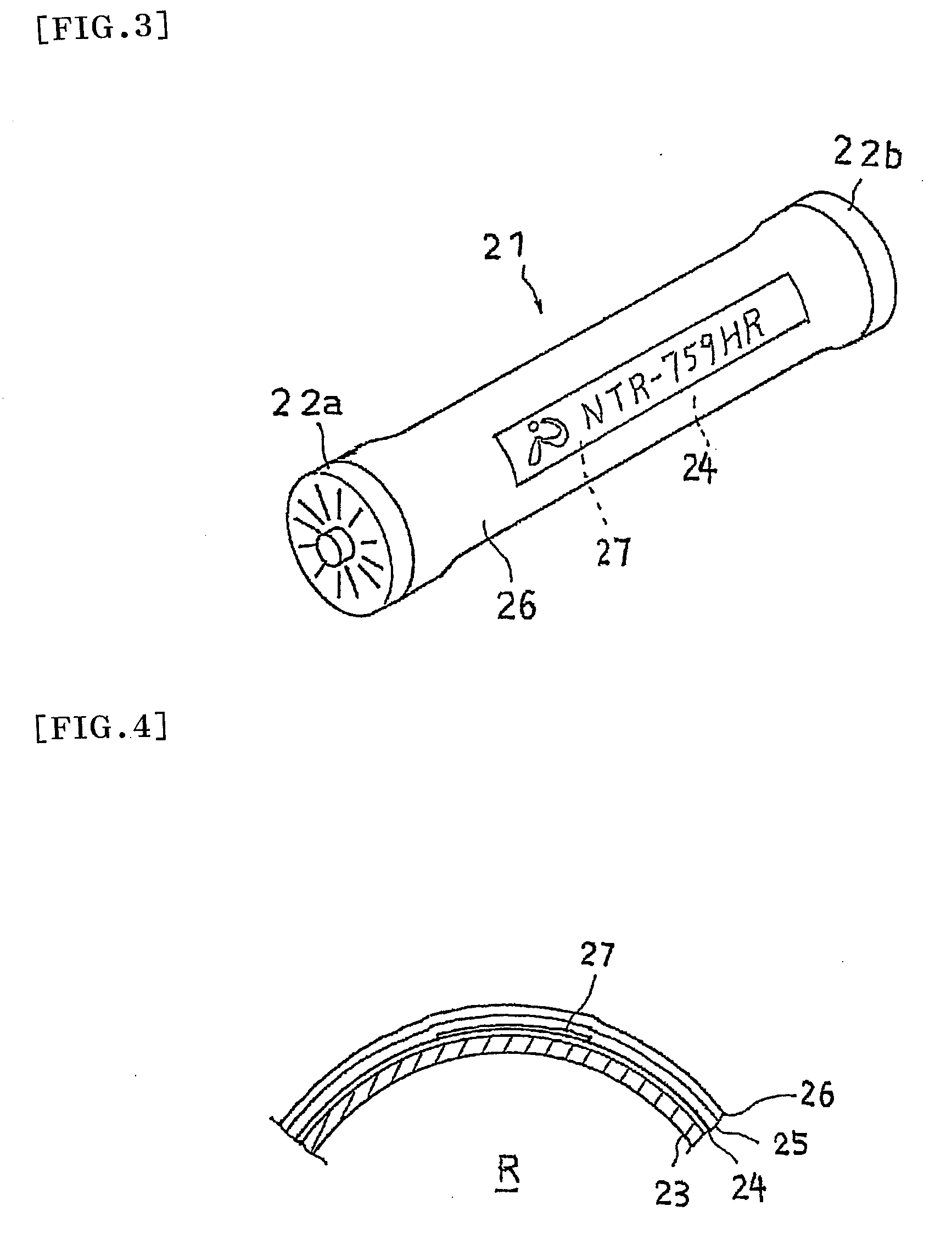

An object of the present invention is to provide a spiral membrane element that can improve the barrier property of a fiber reinforced plastic layer having a fiber roll as a reinforcing phase and that can effectively prevent occurrence of cracks. The spiral membrane element of the present invention is a spiral membrane element containing a cylindrical roll R in which a separation membrane, a feed-side flow passageway member, and a permeate-side flow passageway member are spirally wound in a laminate state around a perforated center tube 5 and in which a sealing part for preventing mixing of feed-side fluid and permeate-side fluid is disposed, wherein a fiber reinforced plastic layer 26 having a fiber roll as a reinforcing phase is formed on the outer circumferential side of said cylindrical roll R, and a plastic layer 24 is disposed in the inner part or on the inner side of the fiber reinforced plastic layer 26 approximately over the entire length and approximately over the entire circumference of the fiber reinforced plastic layer 26.

Owner:NITTO DENKO CORP

Monitoring unit for monitoring the condition of a semi-permeable membrane

InactiveUS7186331B2Avoid areaInhibit growthSettling tanks feed/dischargeReverse osmosisReverse osmosisSemipermeable membrane

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

Coiled membrane filtration system

InactiveUSRE37759E1Strengthens our knowledgeReduce polarizationWater/sewage treatment bu osmosis/dialysisReverse osmosisFiltrationMembrane surface

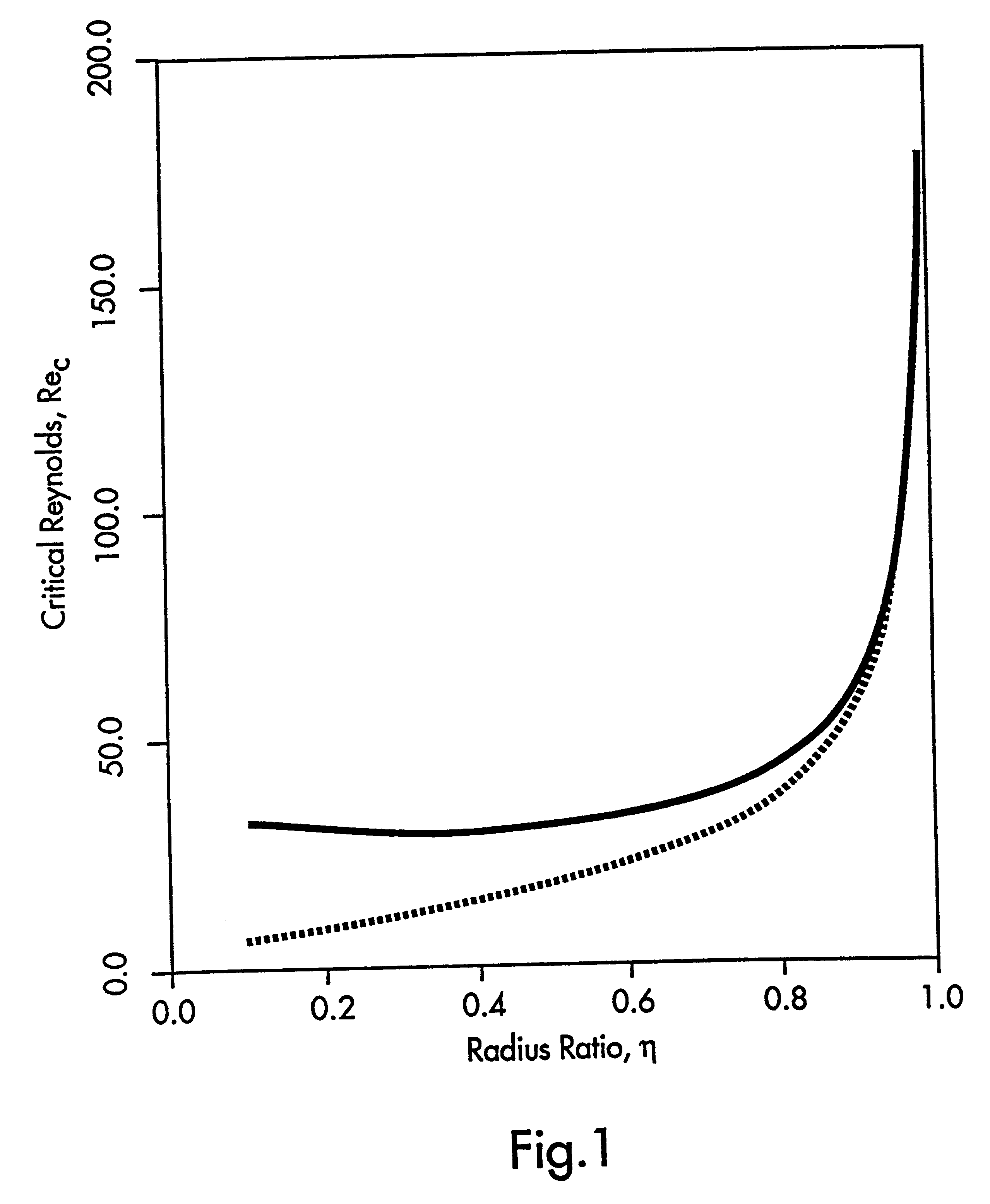

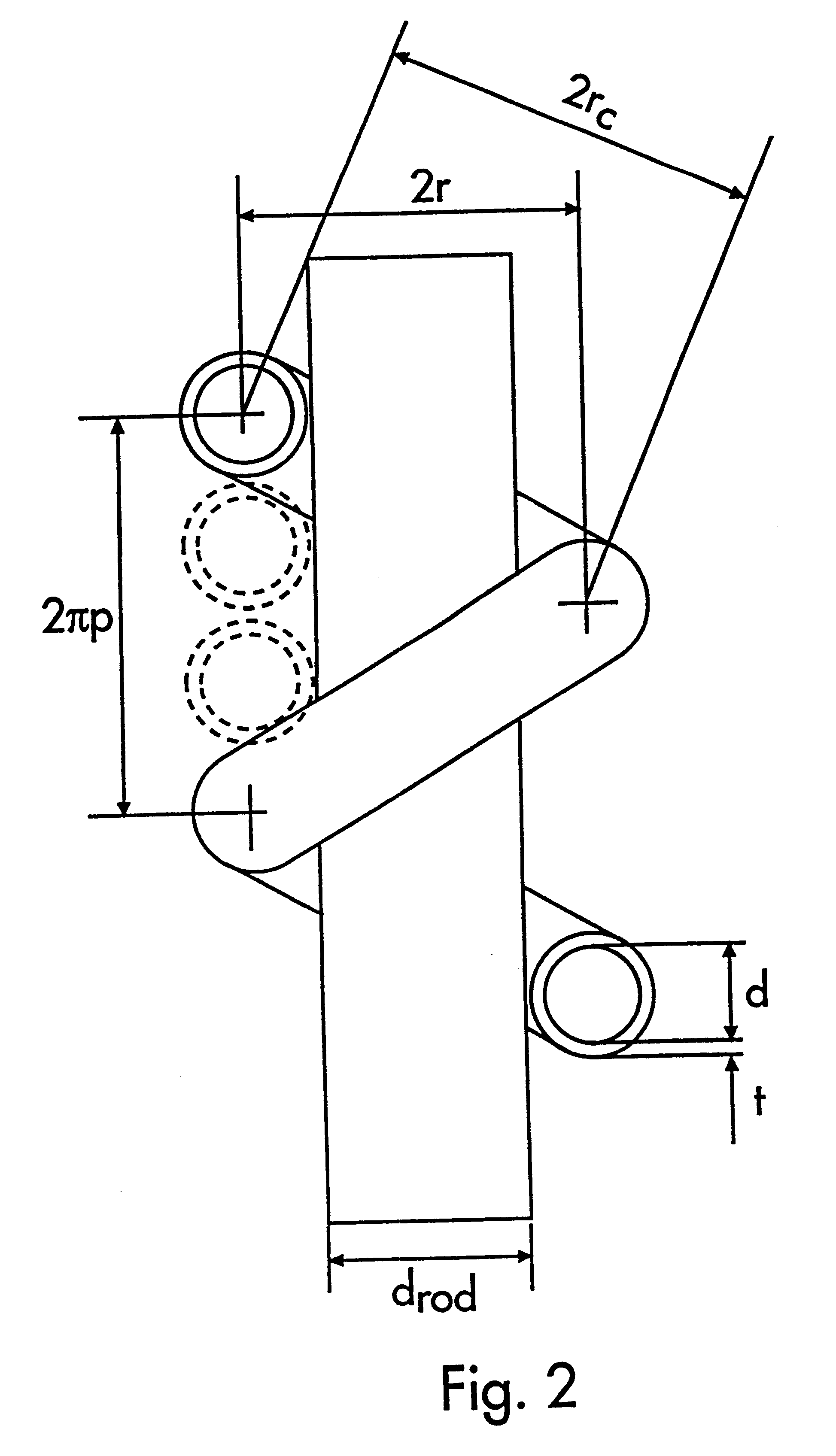

A method and apparatus for achieving reverse osmosis, microfiltration, nanofiltration and ultrafiltration, produces Dean vortices against a membrane surface which is advantageously in a form of a wound helical membrane tube.

Owner:RENESSELAER POLYTECHNIC INST

Spiral membrane element and method of manufacturing the same

InactiveCN1676203AGuaranteed tightnessLarge effective membrane surface areaSemi-permeable membranesMembranesAdhesiveMembrane surface

A spiral membrane element having an enlarged effective membrane surface area without having its separation performance lowered, while maintaining the sealing property of any sealing portion of a cylindrically wound body, and a manufacturing method of the same are disclosed. The spiral membrane element includes a cylindrically wound body comprising a perforated central tube and, spirally wound therearound, a separation membrane, a feed-side passage material and a permeation-side passage material in a laminated state, and a sealing portion for preventing a feed-side fluid and a permeation-side fluid from being mixed together, wherein the sealing portion formed at each of both ends of the cylindrically wound body is spirally formed with a substantially constant width by an adhesive and has a trimmed section formed on its whole end surface, and the cylindrically wound body has a ratio of its length to the length of the central tube of 0.96 to 1.00, and a ratio of an ineffective membrane surface area to the entire membrane surface area of 0.02 to 0.10.

Owner:NITTO DENKO CORP

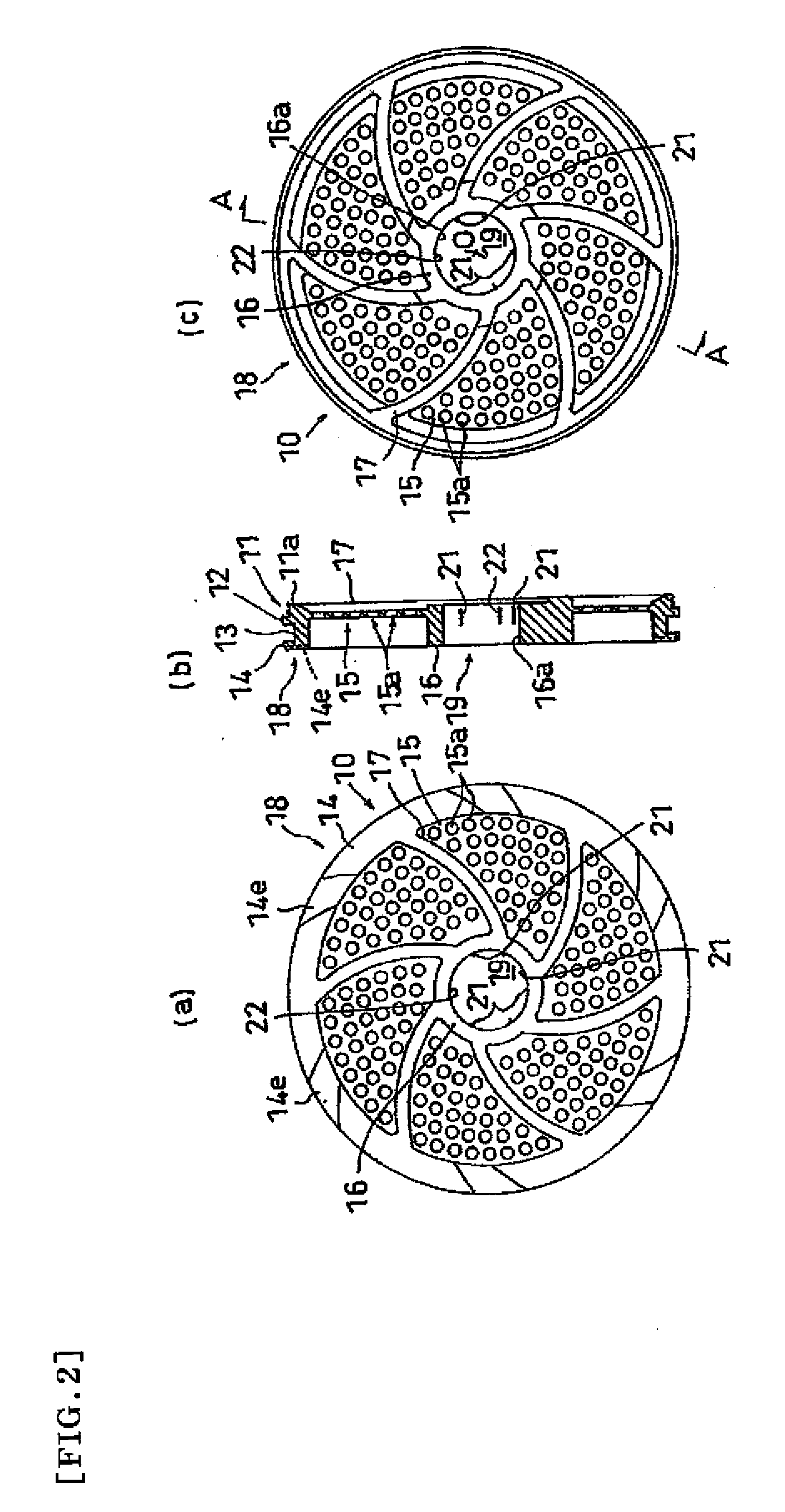

Process for producing spiral membrane element

InactiveUS20040124133A1Improve productivityDegree of improvementSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisProduction rateEngineering

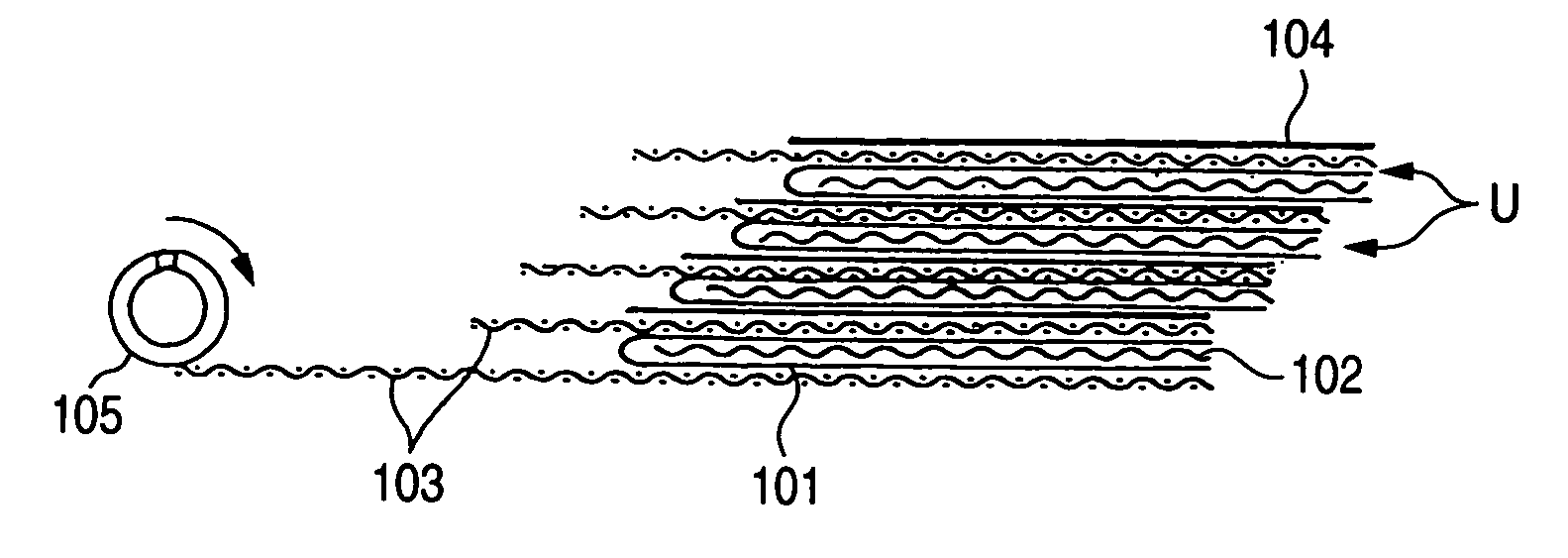

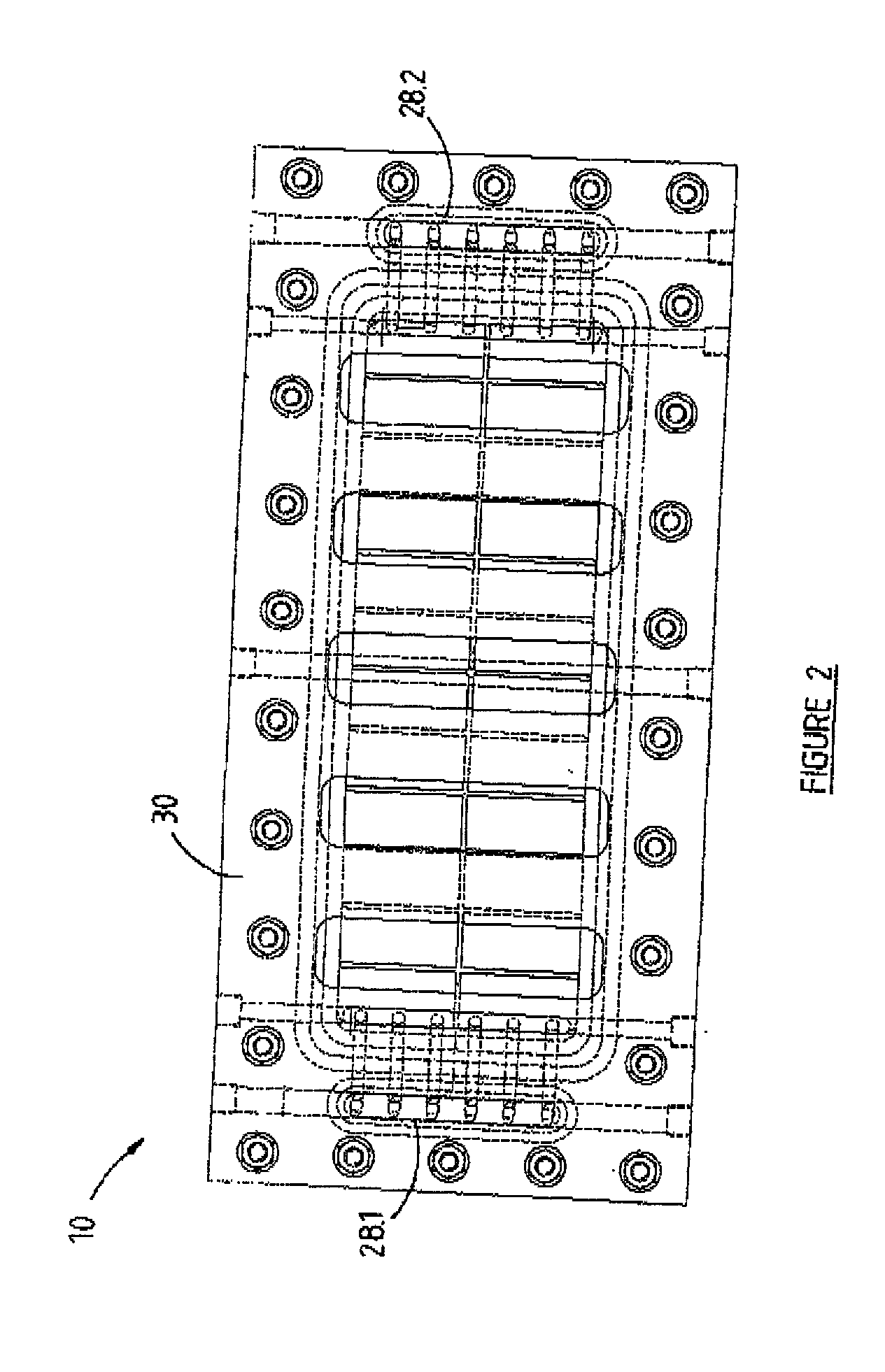

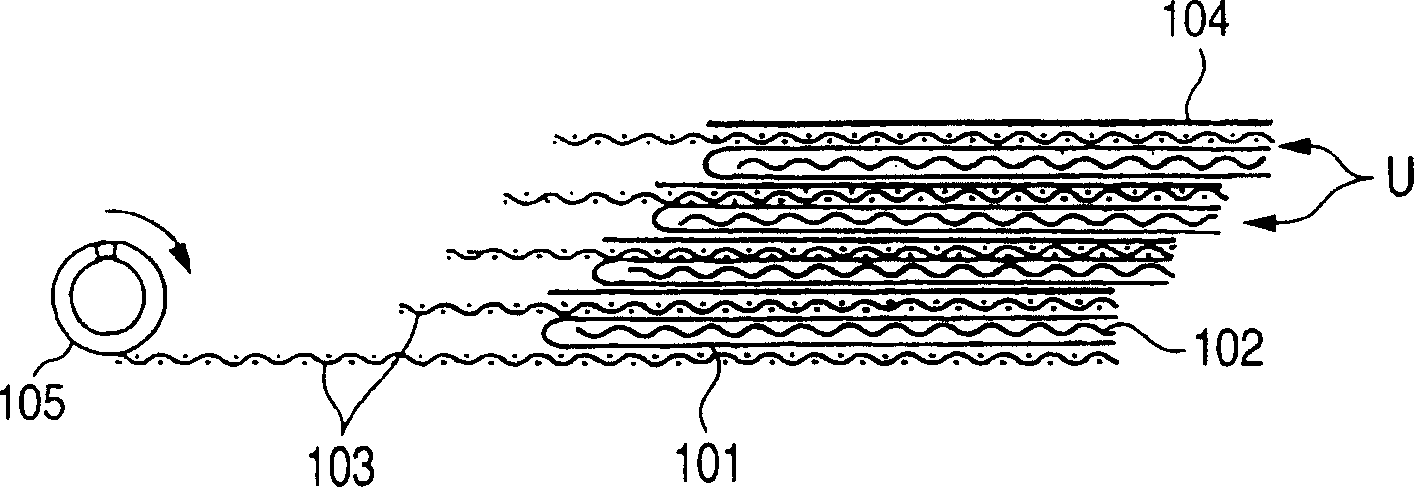

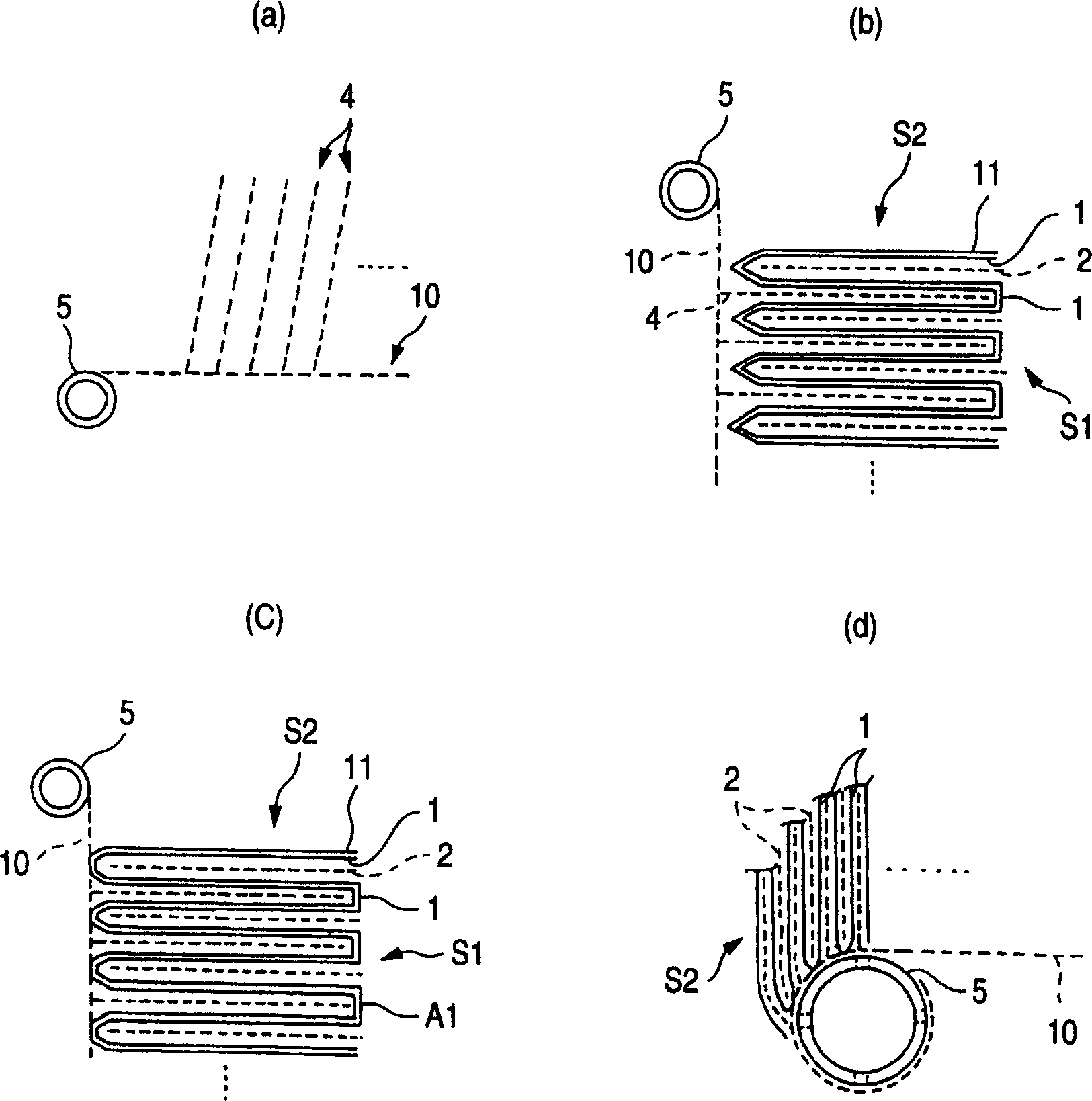

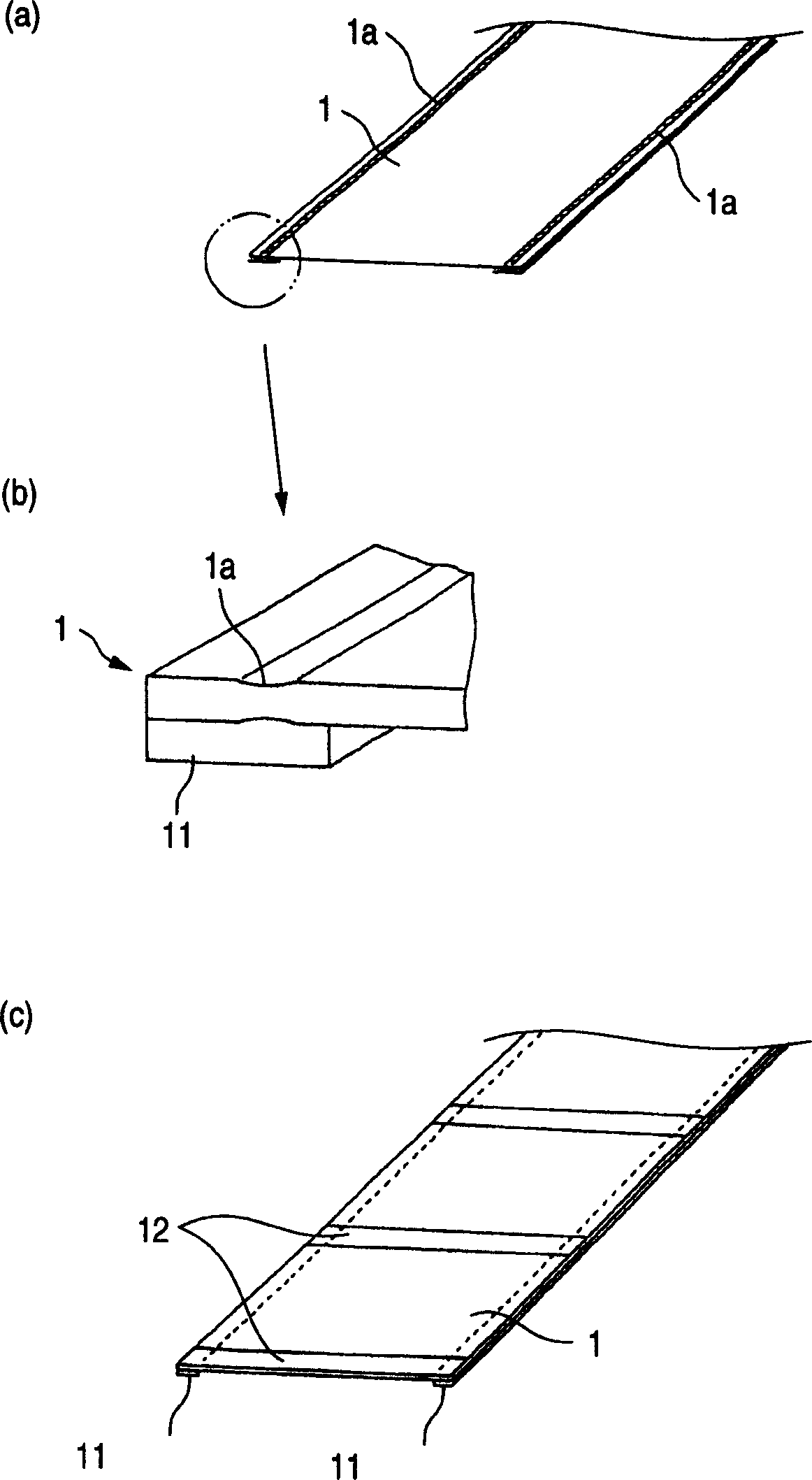

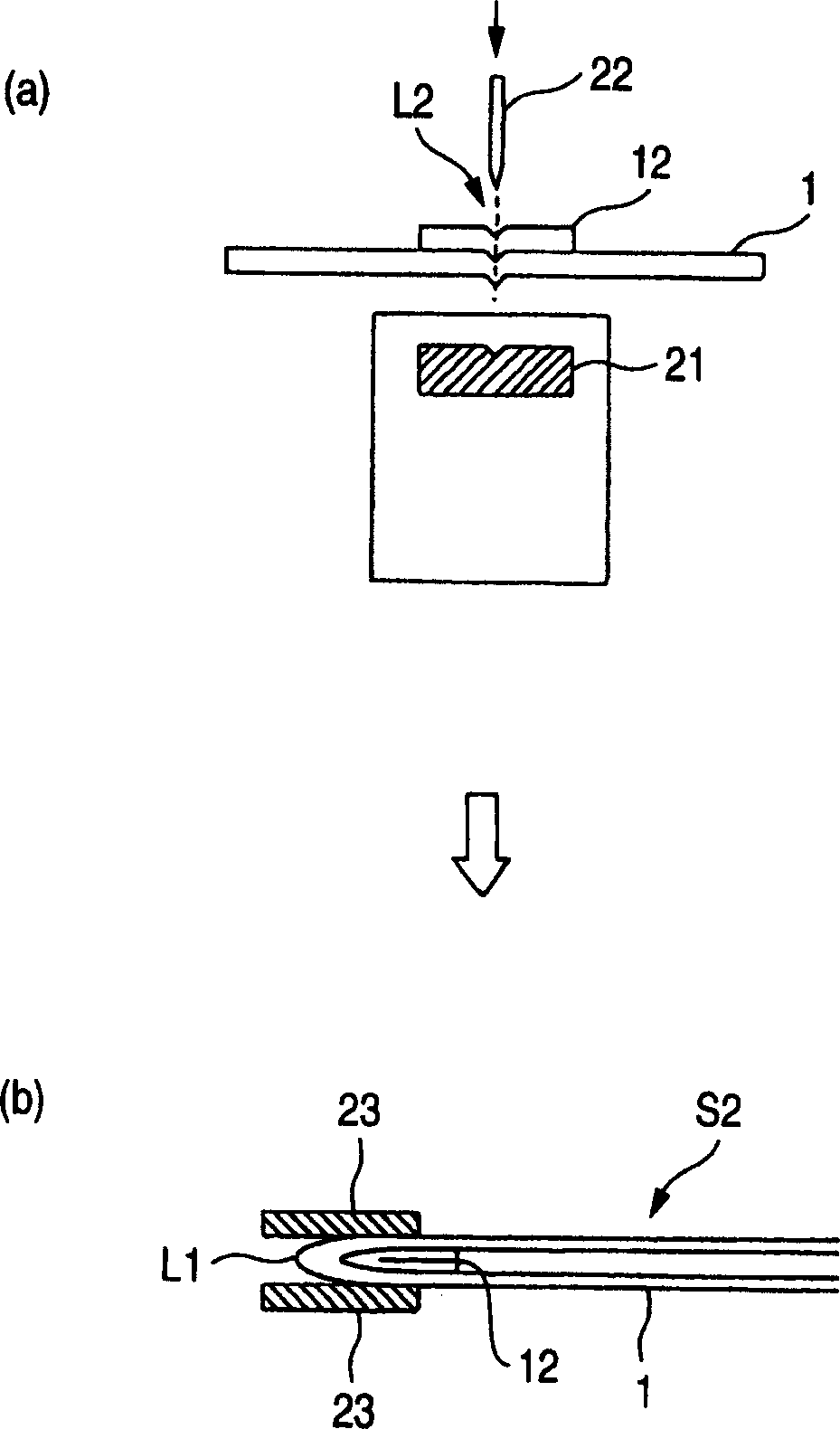

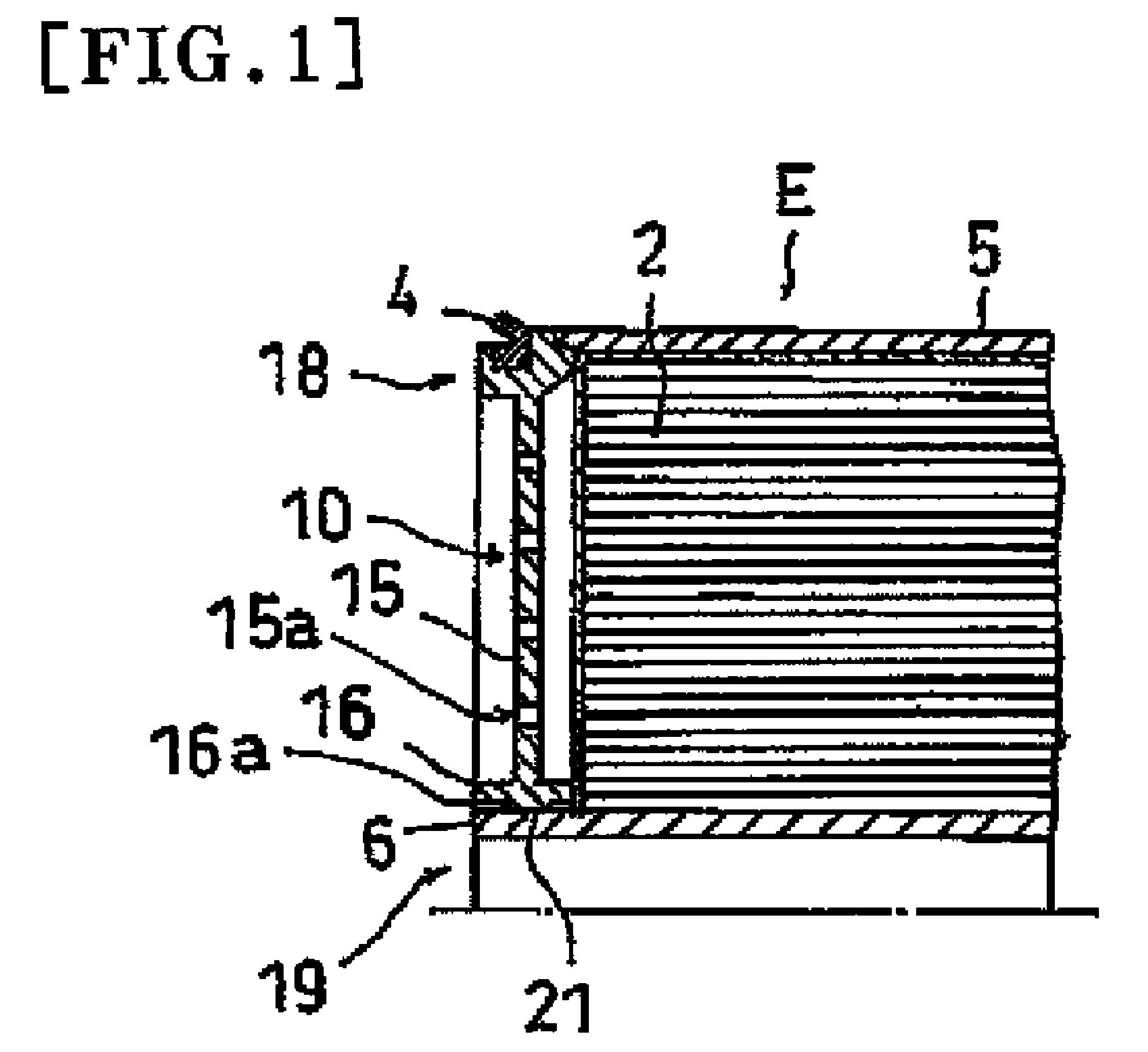

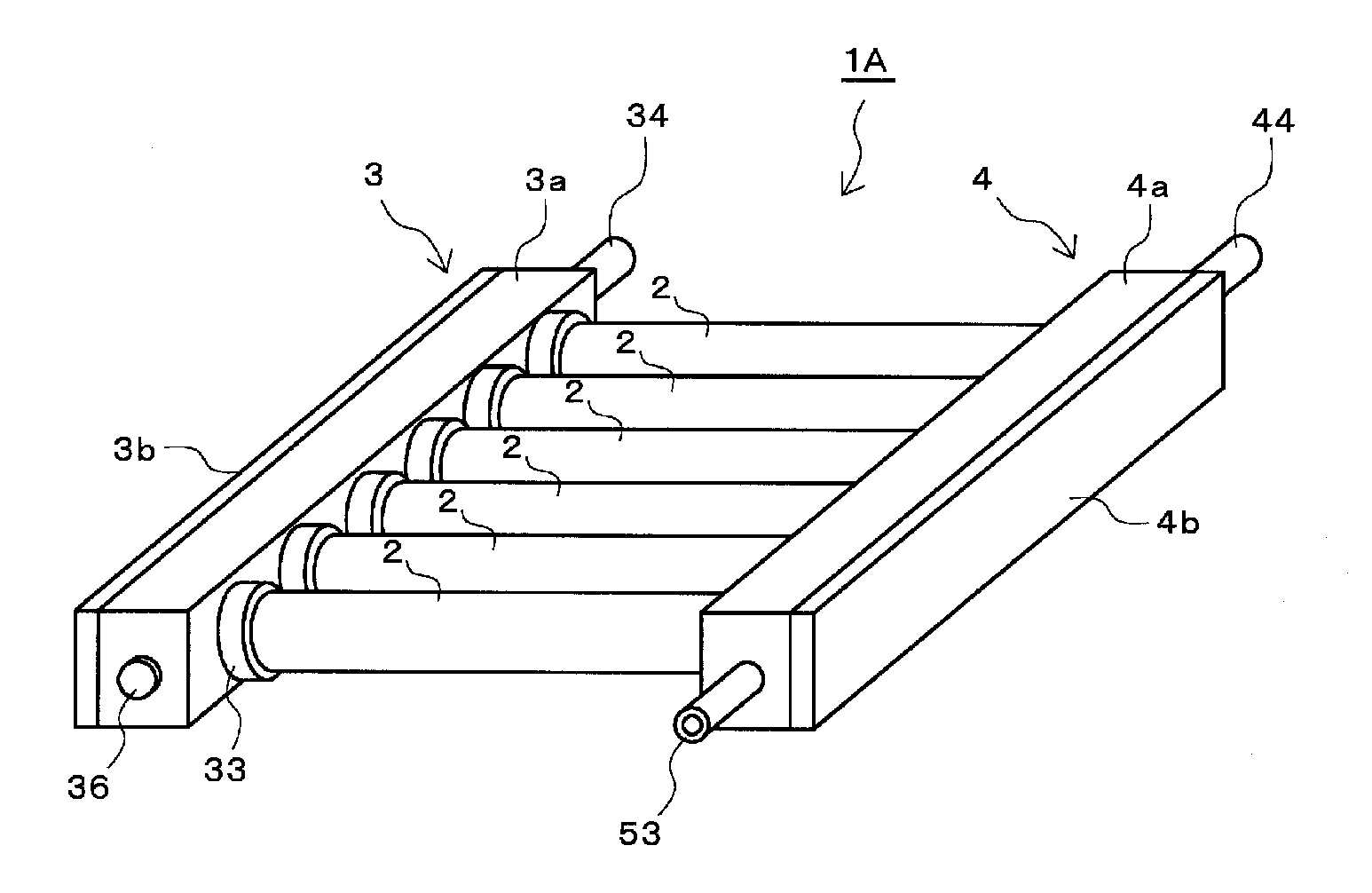

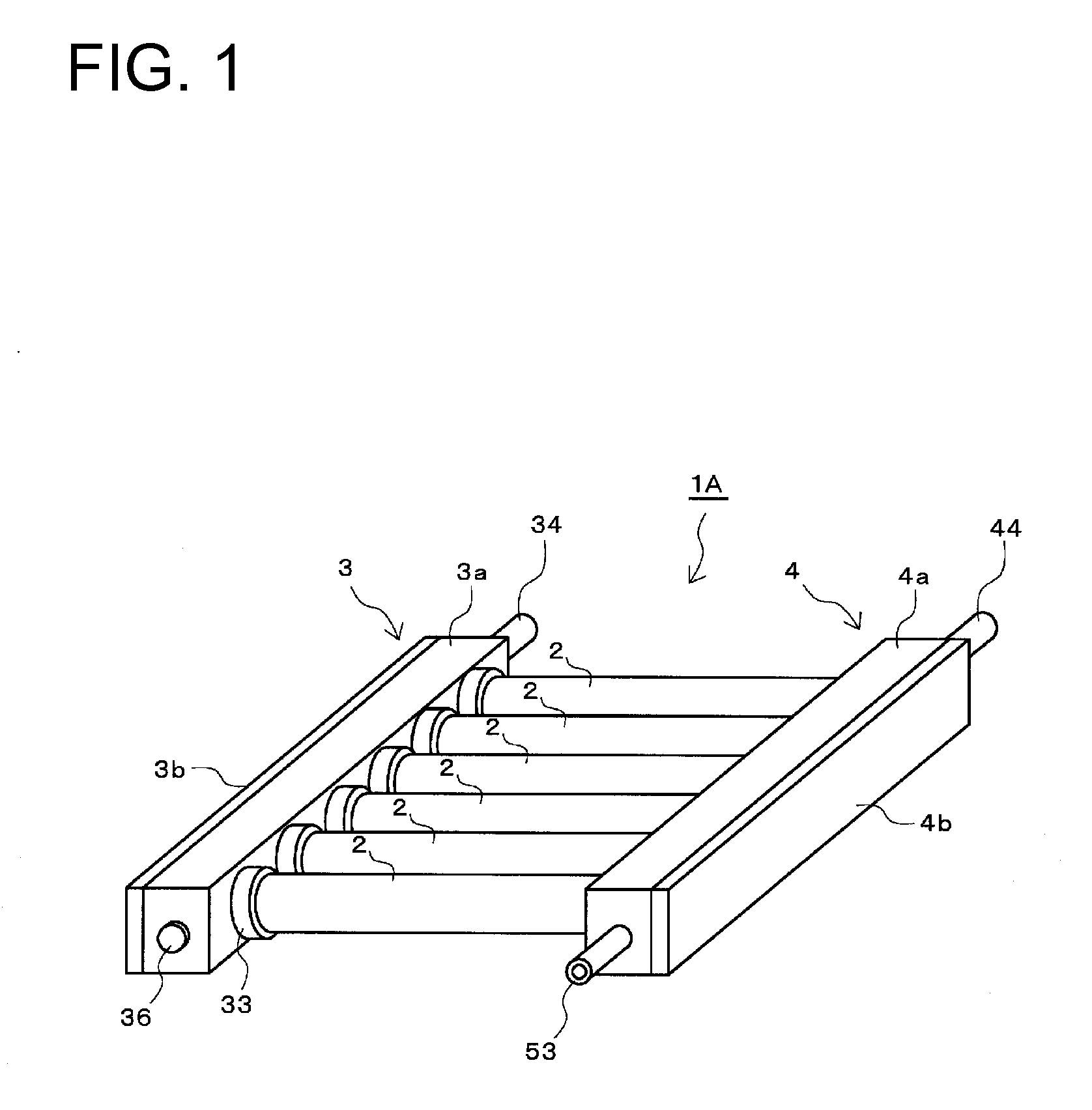

A process for spiral membrane element production is disclosed which attains high productivity, eliminates the material "wrinkling" or "breakage" caused by material distortion or core tube distortion, and can increase the degree of tightening of the whole element. The process includes a step in which a multilayer structure including a feed-side passage material interposed between opposed membranes on their feed side and a permeation-side passage material interposed between opposed membranes on their permeation side is spirally wound on a perforated core tube, wherein the winding of the multilayer structure on the core tube is conducted by rotating the core tube 5 while pressing one or more rolls 15 against the periphery of the wound structure R1.

Owner:NITTO DENKO CORP

Filtration element and method of constructing a filtration assembly

InactiveUS20060070940A1Easily and securely couplingMinimized contact areaSemi-permeable membranesGeneral water supply conservationFiltrationEngineering

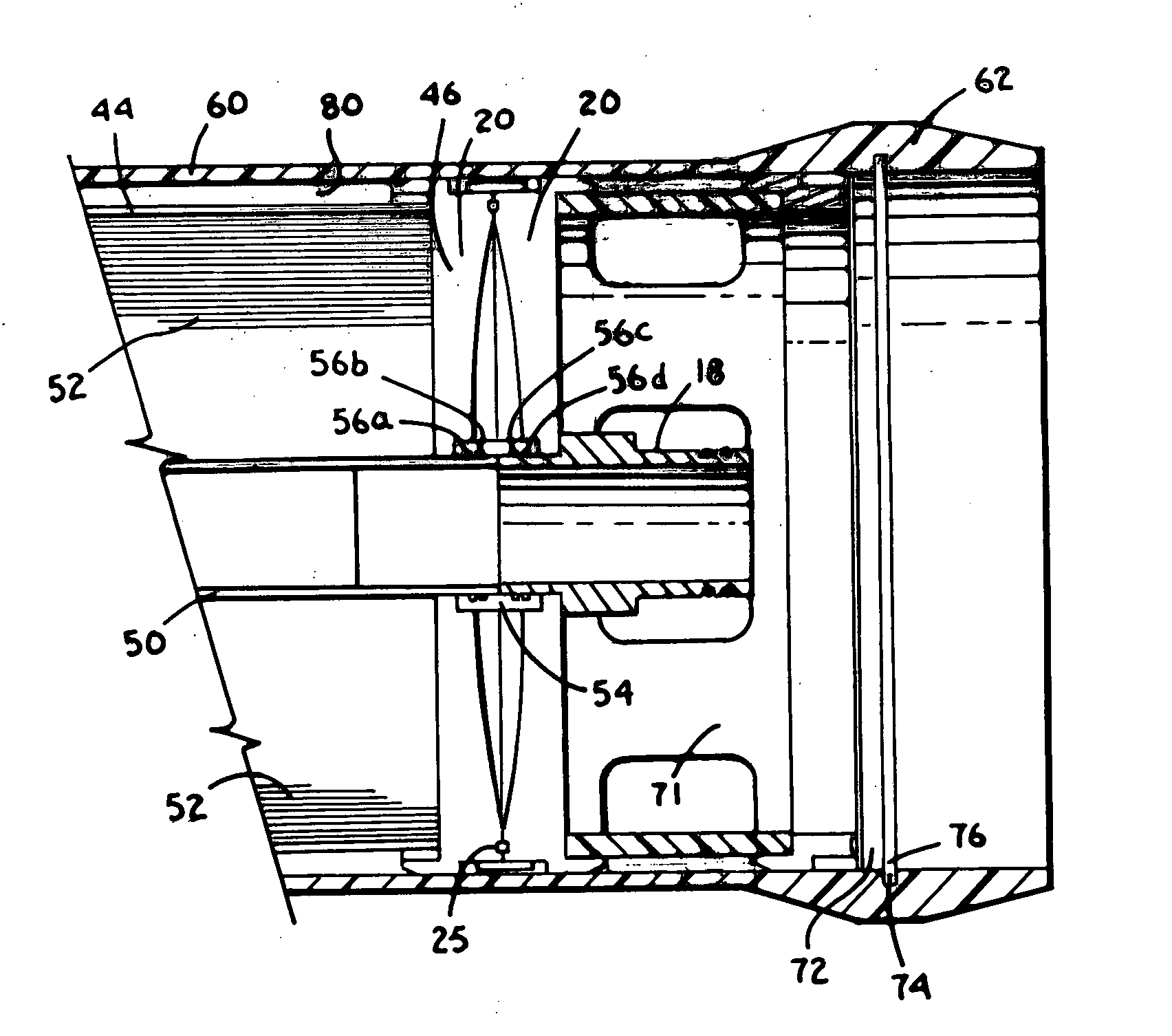

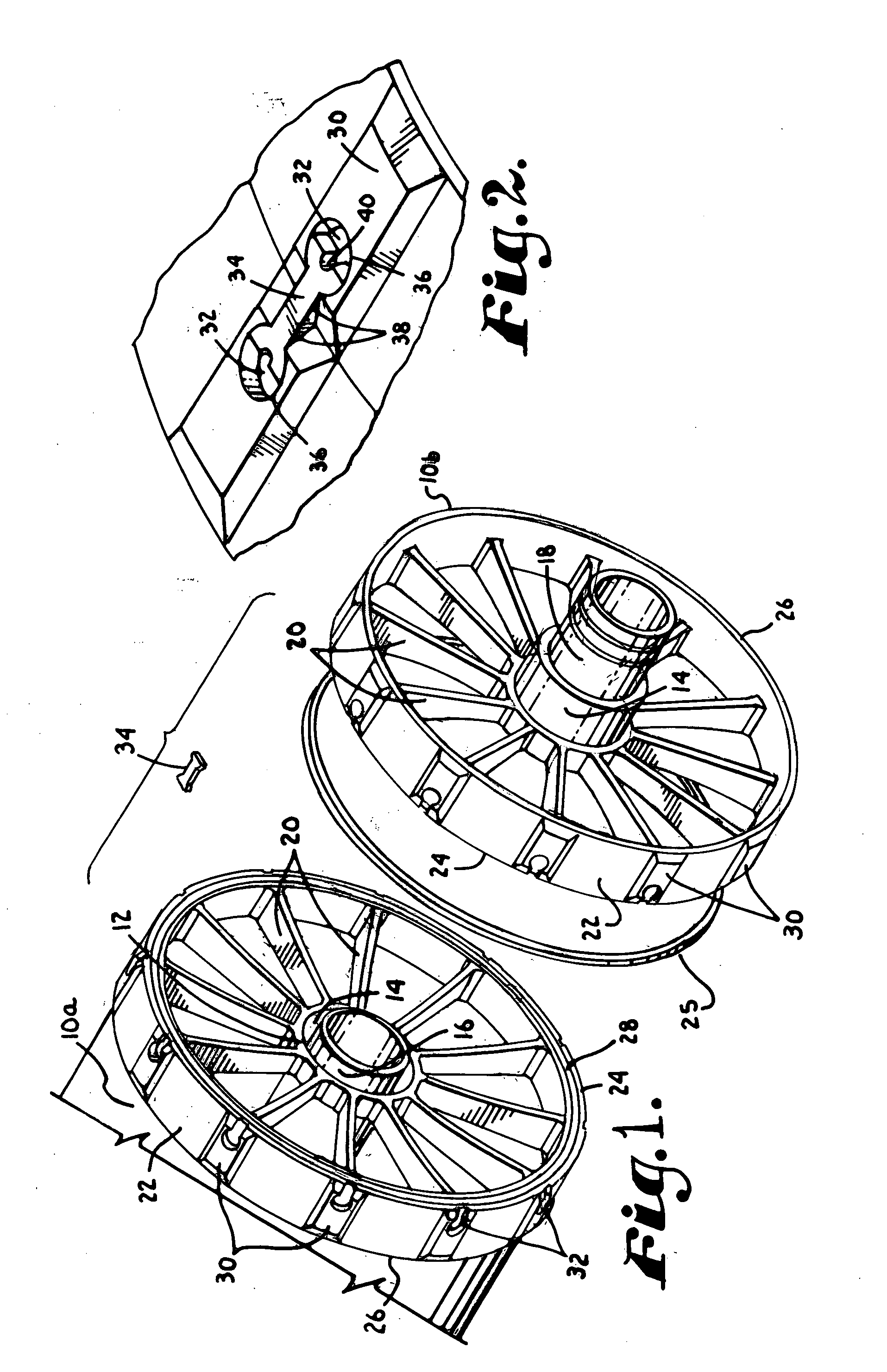

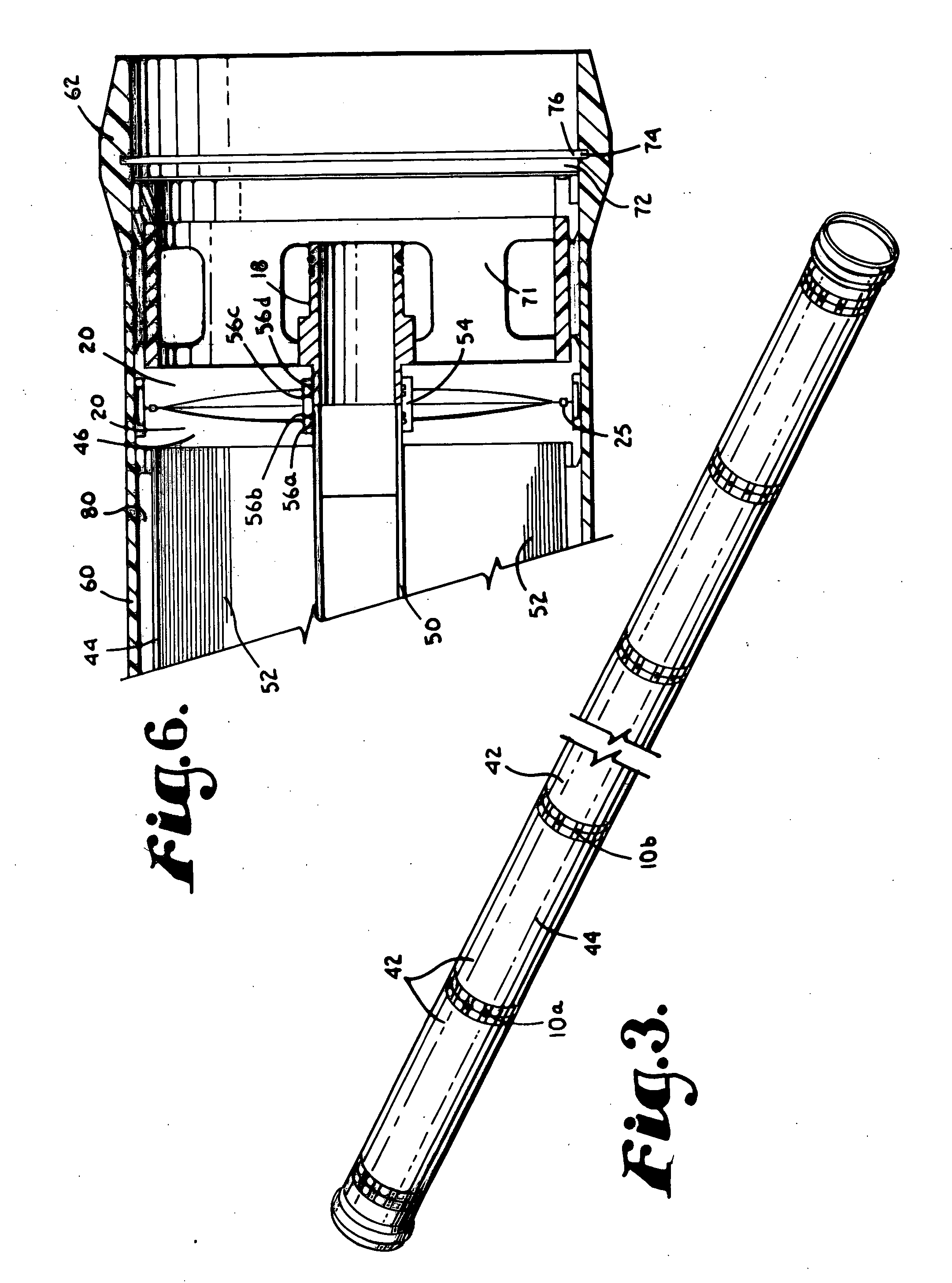

A coupler for a spiral membrane filtration element having a spiral membrane enclosed within a rigid outerwrap includes a center support, a plurality of spokes extending outwardly from the center support, a circular rim coupled with the spokes, with the face of the rim being perpendicular to the axis of the overwrap. The rim includes a channel on its face for receiving a compressible seal, and a plurality of receptacles around its outer surface for joining two face-to-face adjacent couplers when a pair of aligned keepers is place in each receptacle. Exemplary embodiments of the coupler and filtration elements and filtration assemblies are provided, as well as an associated method.

Owner:KOCH MEMBRANE SYST

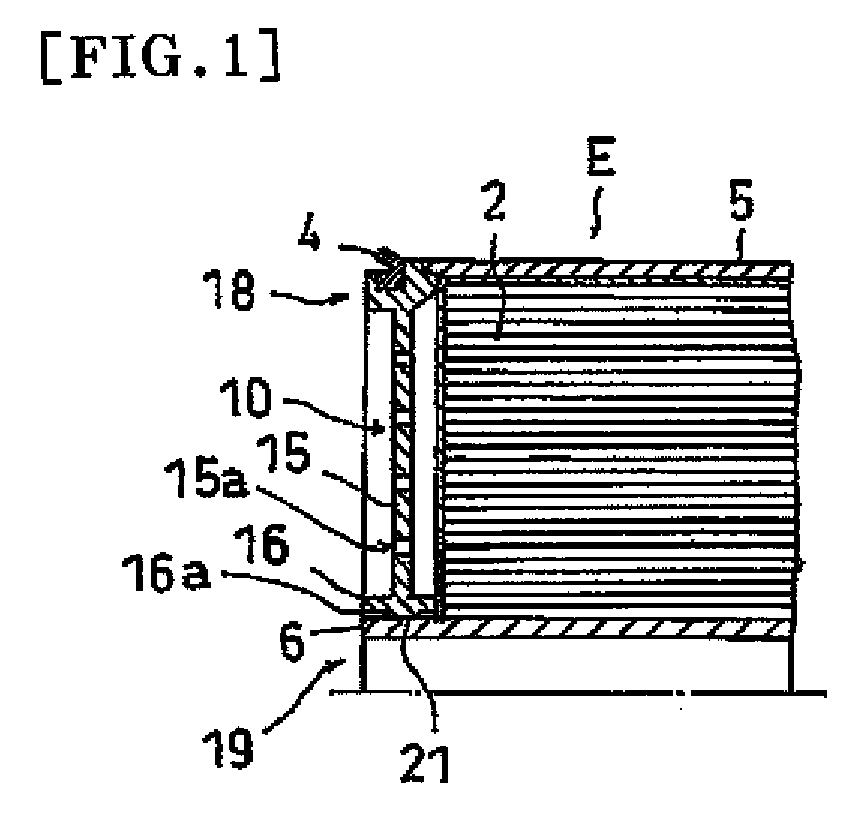

Membrane element sealing material holding member and membrane element

ActiveUS20090095670A1Smooth deformationEasy to insertMembranesSemi-permeable membranesBiomedical engineeringSpiral membrane

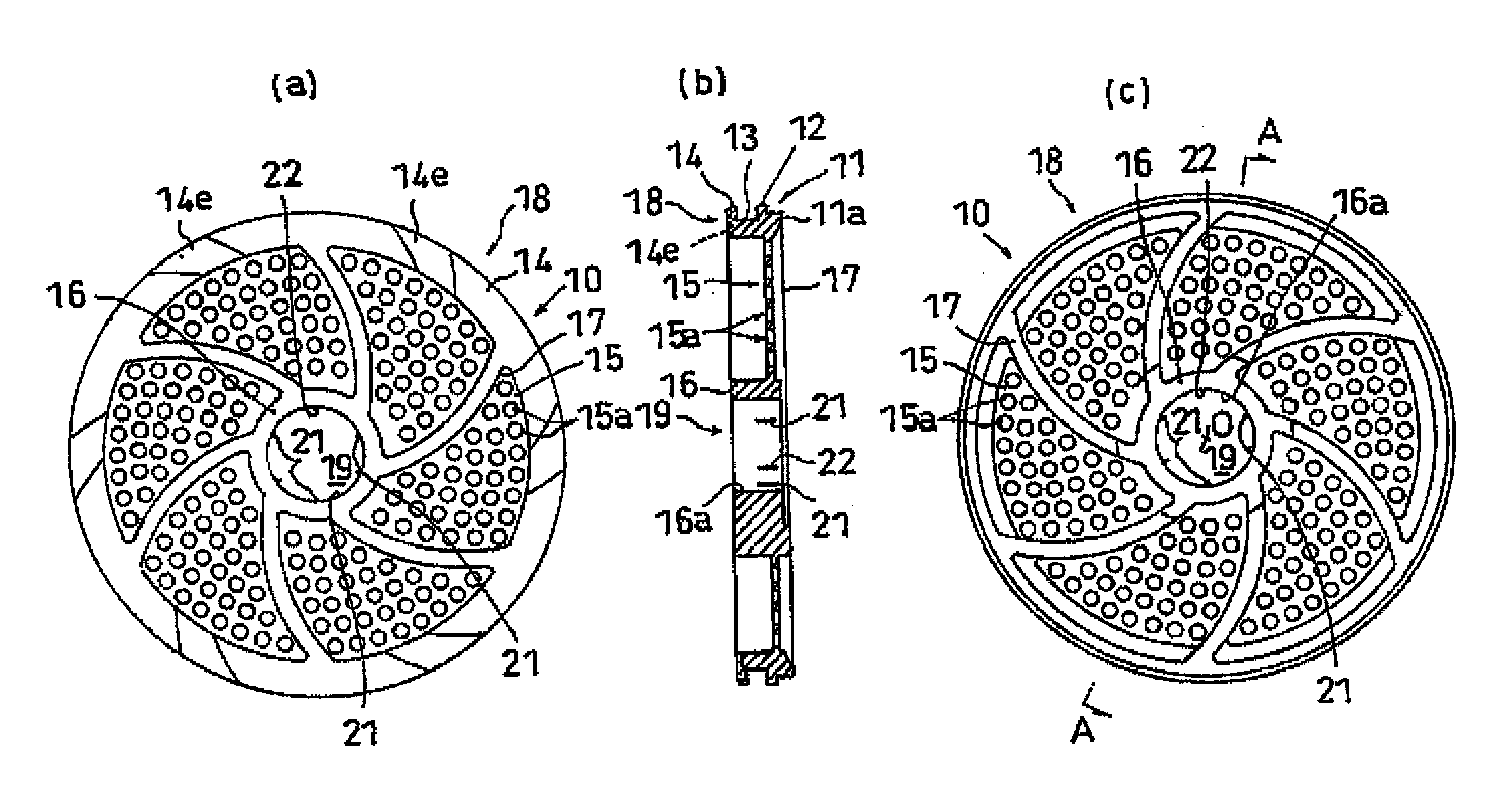

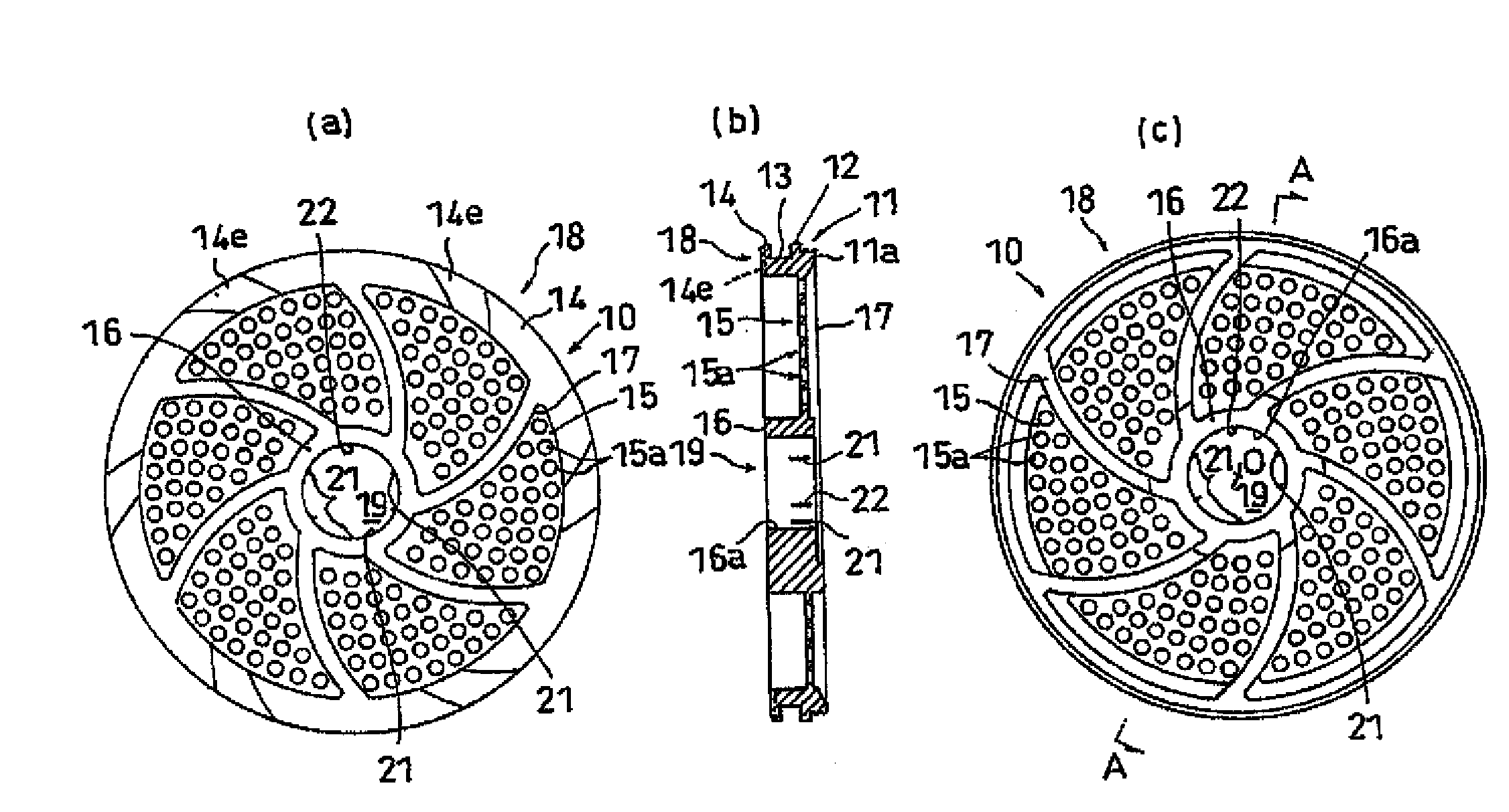

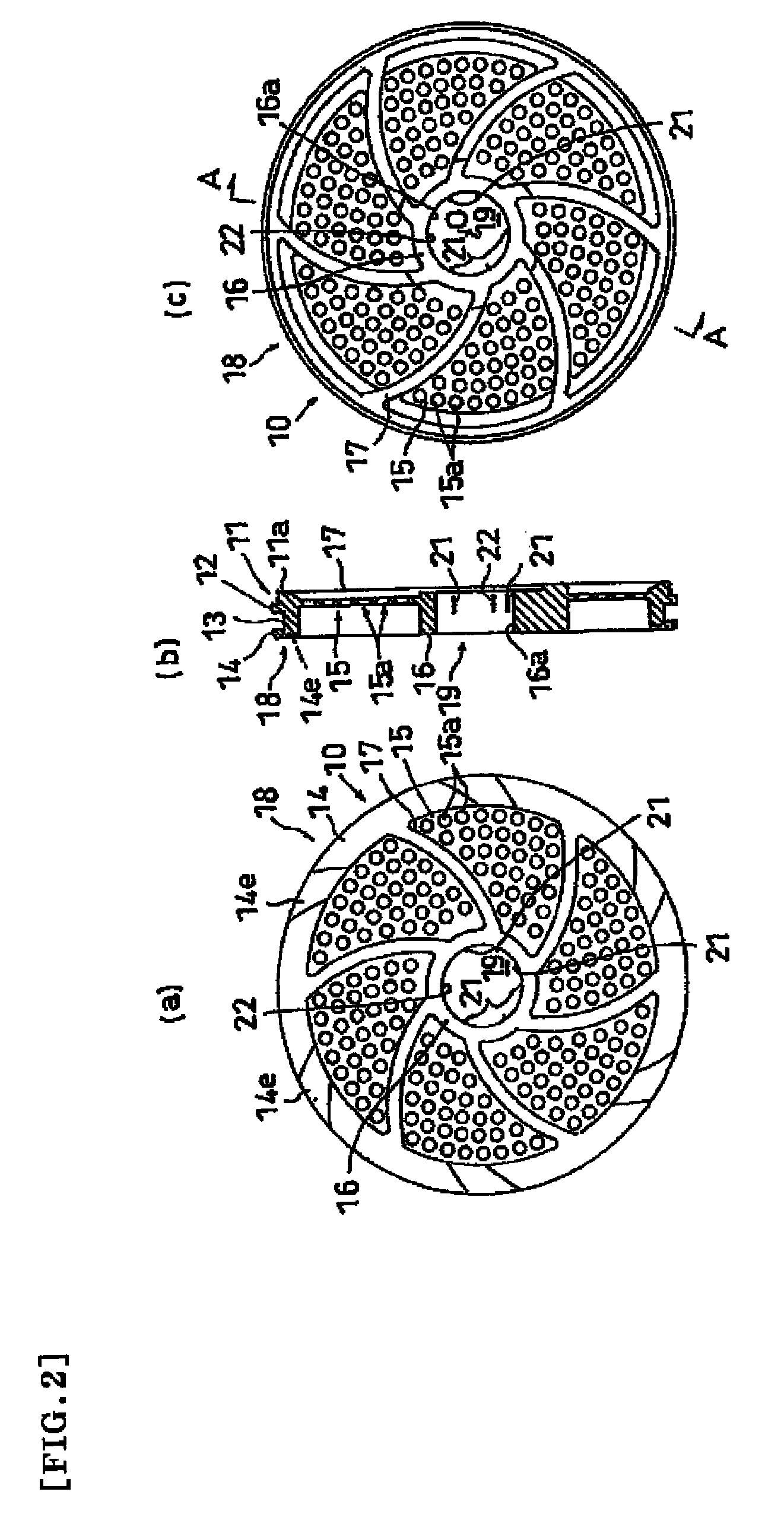

A membrane element sealing material holding member that even when the dimension of outer diameter of center tube varies, enables holding of the center tube in the center and further enables easy insertion of the center tube; and a membrane element utilizing the same. The membrane element sealing material holding member comprises central opening (19) for insertion of a center tube of spiral membrane element, peripheral orifice (15a) for flowing of a raw liquid into a membrane end portion of membrane element and outer circumferential part (18) for holding of circular sealing material, wherein the central opening (19) has inner circumferential surface (16a) of cylindrical form with a diameter larger than the outer diameter of the inserted center tube, and wherein at three or more positions on the inner circumferential surface (16a), there is provided projection (21) that has sloping face (21a) on its side of center tube (6) insertion and is deformable at the time of insertion of center tube (6) with an outer diameter larger than that of incircle.

Owner:NITTO DENKO CORP

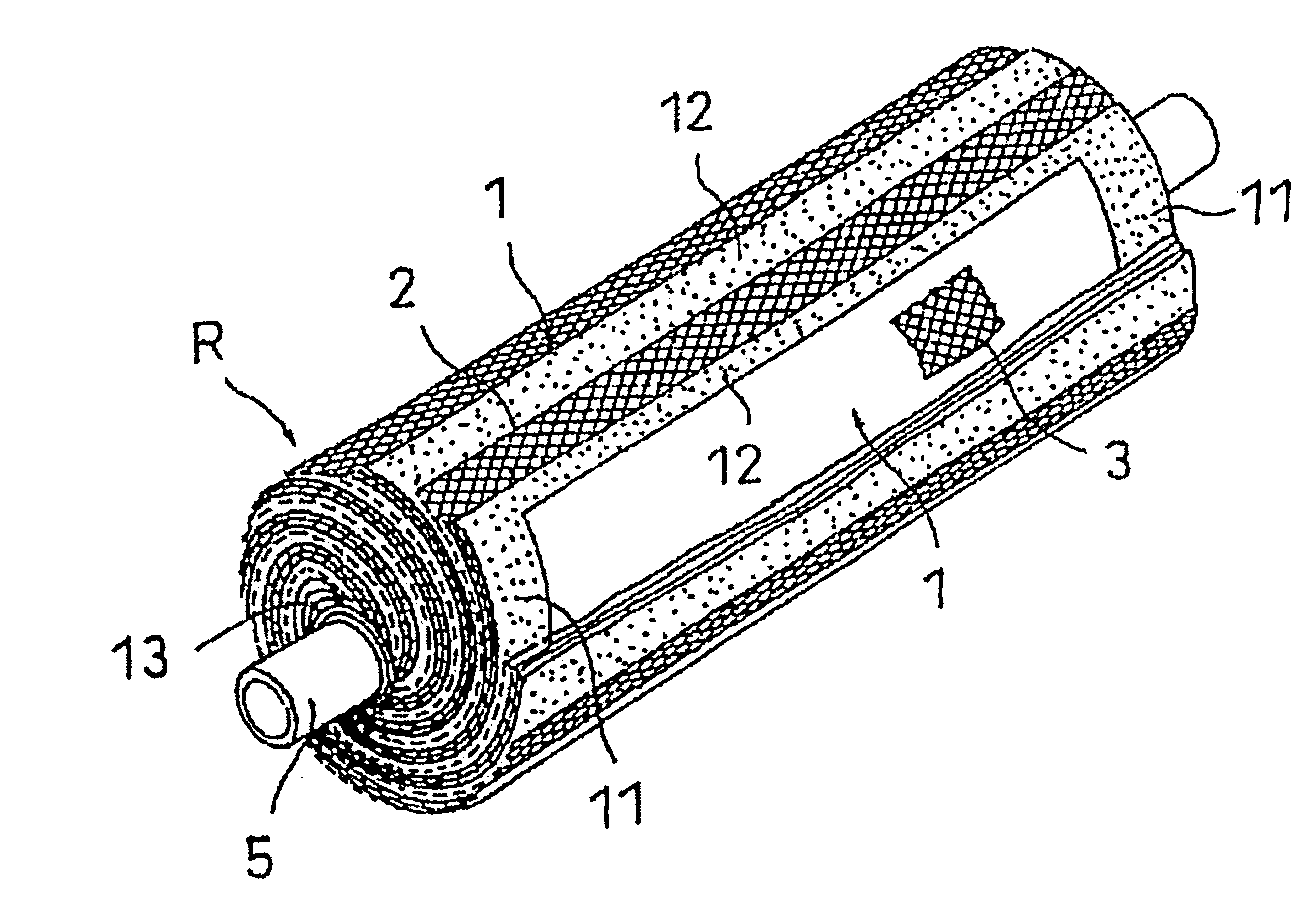

Spiral membrane element and method of producing the same

ActiveUS20080302719A1Avoid mixingHigh strengthSemi-permeable membranesLiquid surface applicatorsEngineeringSpiral membrane

A spiral membrane element that can reduce the dimension increase in the length direction is provided by forming a fiber reinforced resin layer having a reinforcing fiber layer and a strengthening fiber layer. Also, a method for producing a spiral membrane element is provided having a step of forming a fiber reinforced resin layer having a reinforcing fiber layer and a strengthening fiber layer. The spiral membrane element is provided with a cylindrical wound body in which a separation membrane, a feed-side channel material, and a permeate-side channel material in a laminated state are wound in a spiral form around a center tube having a hole, and a sealing part for preventing feed-side fluid and permeate-side fluid from being mixed with each other, wherein a fiber reinforced resin layer having a reinforcing fiber layer and a strengthening fiber layer enclosed and buried with the same resin is provided on an outer circumferential side of the cylindrical wound body.

Owner:NITTO DENKO CORP

Method for producing spiral diaphragm pieces

InactiveCN1509803ALow bending resistanceAvoid damageSemi-permeable membranesConductor CoilPermeation

Owner:NITTO DENKO CORP

Spiral membrane module

ActiveUS20090277825A1DisplacementFirmly connectedSemi-permeable membranesMembranesEngineeringMembrane configuration

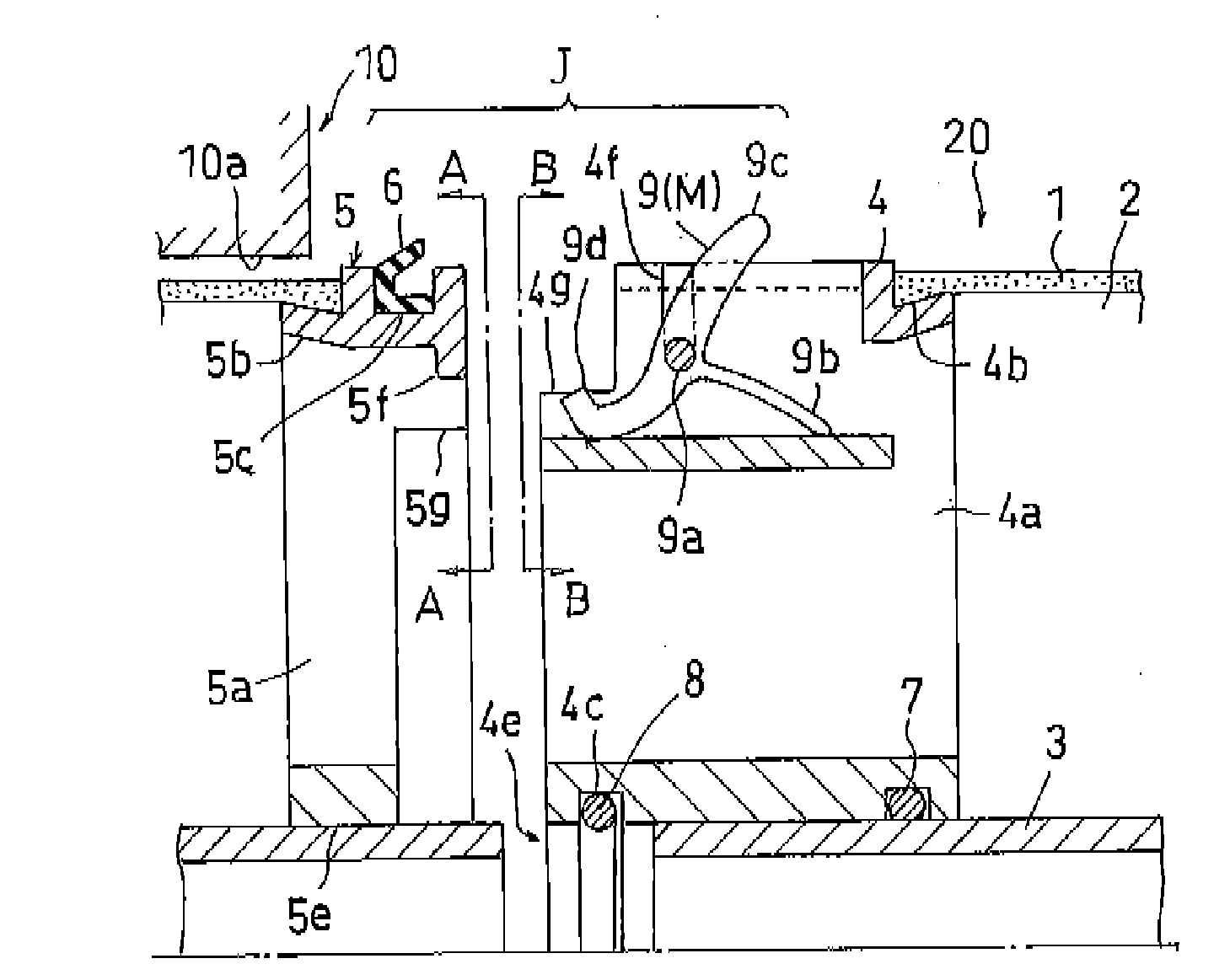

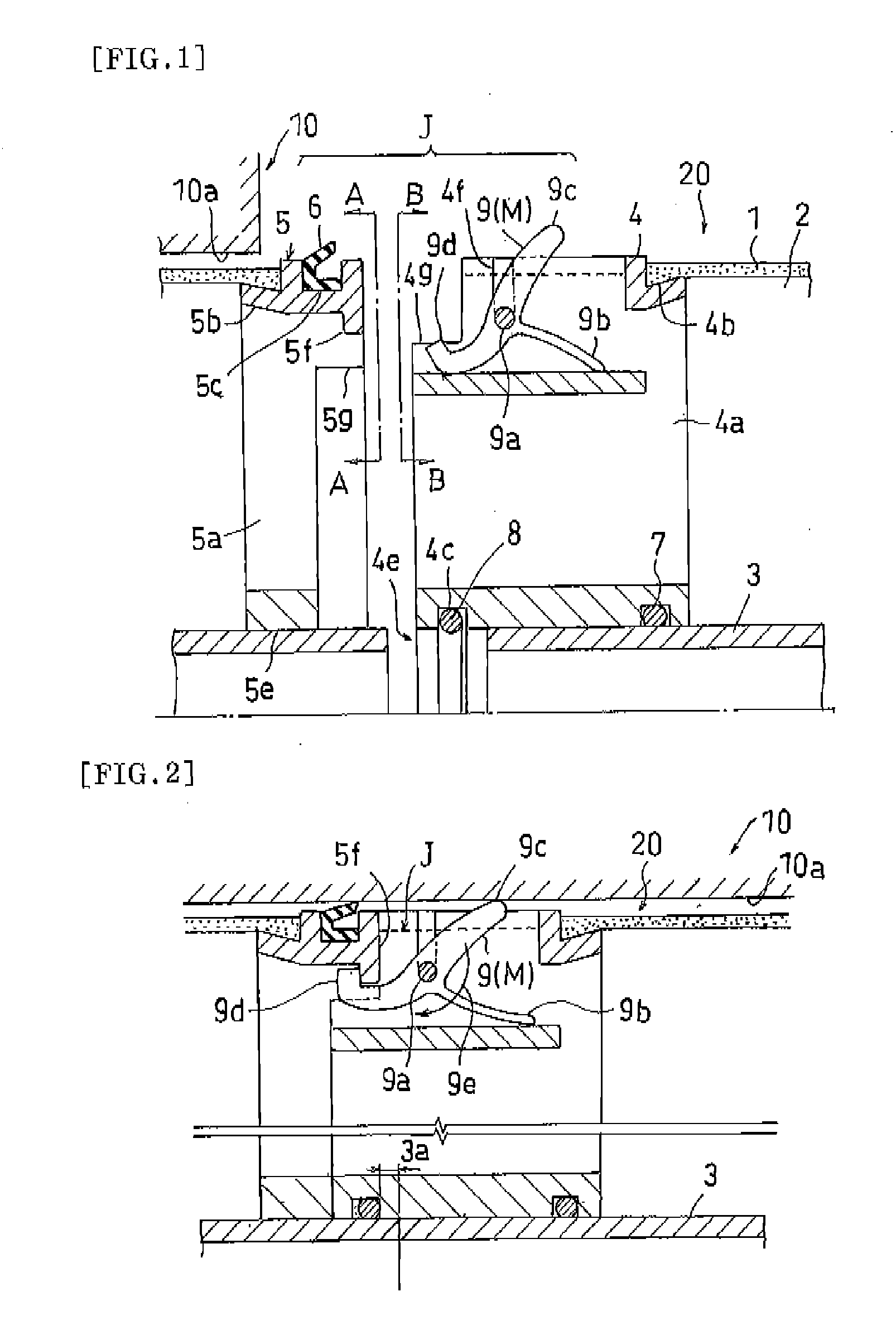

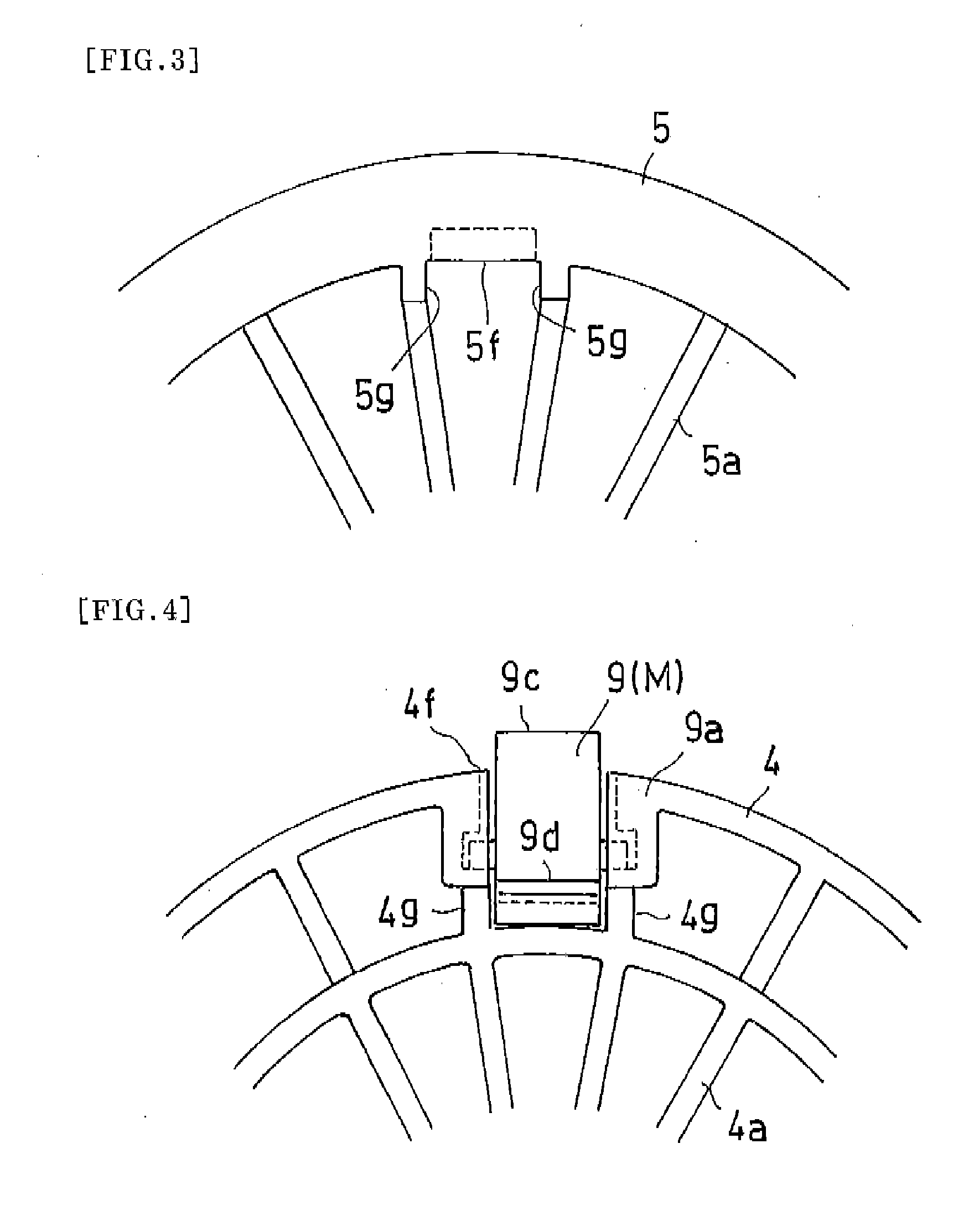

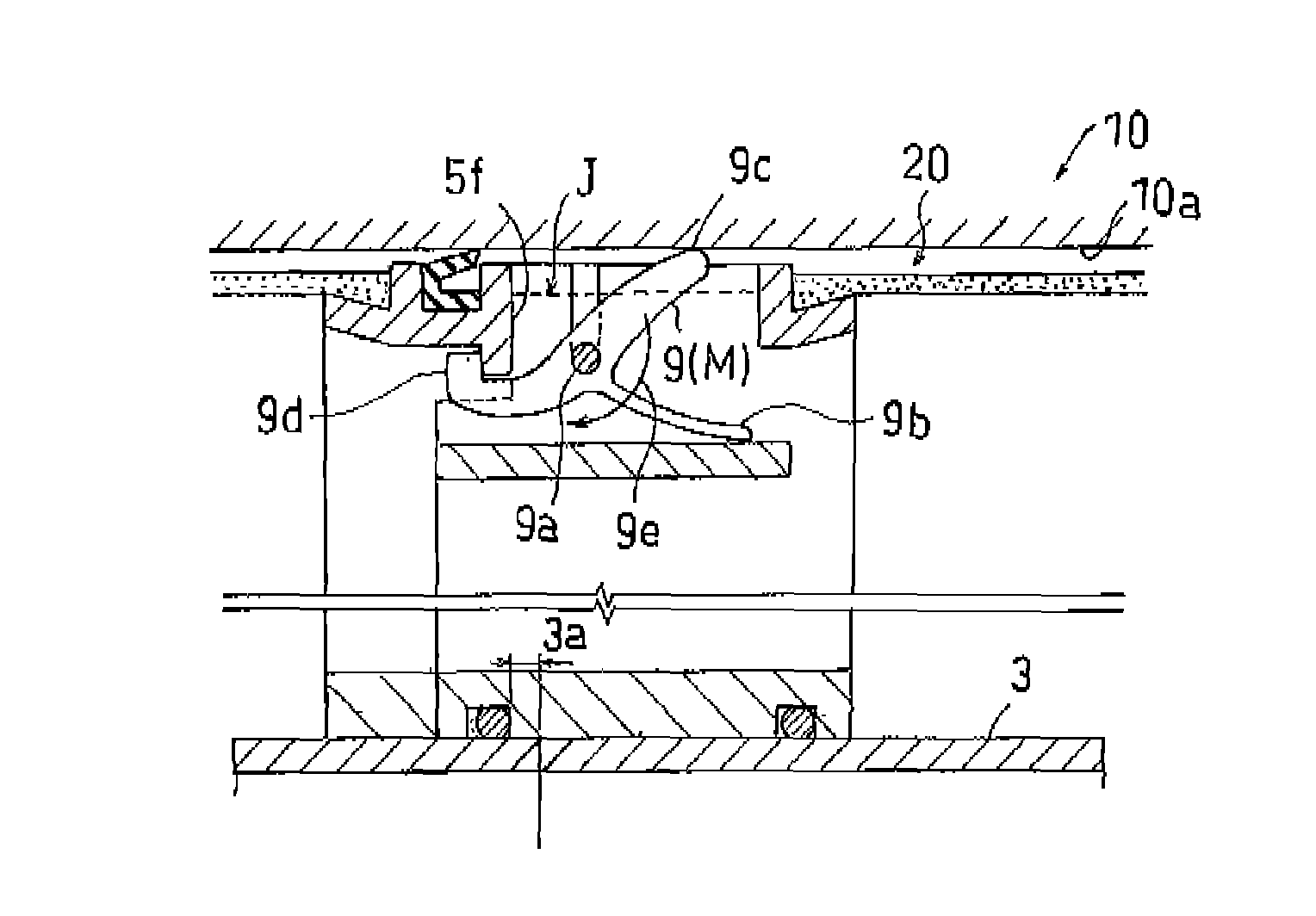

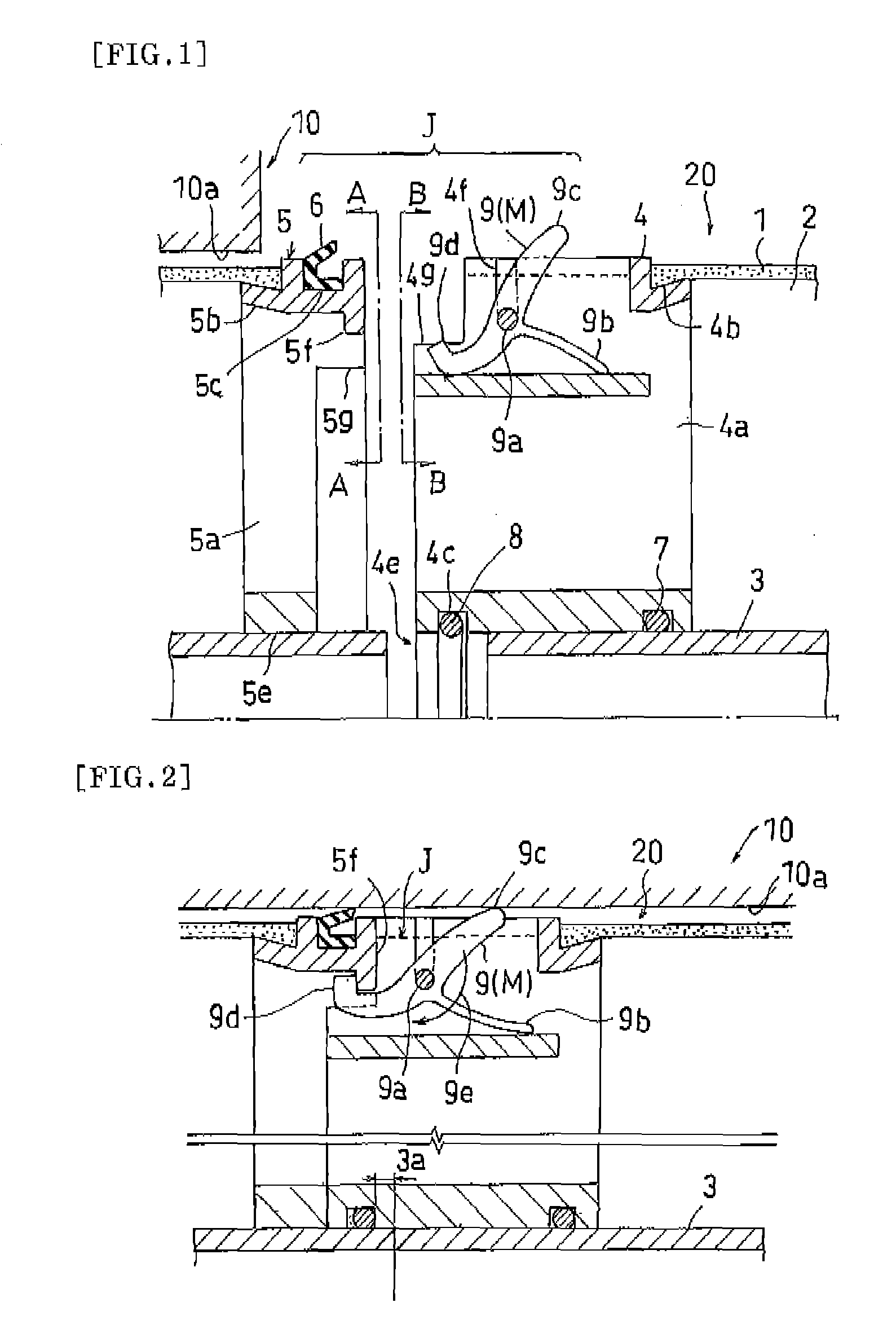

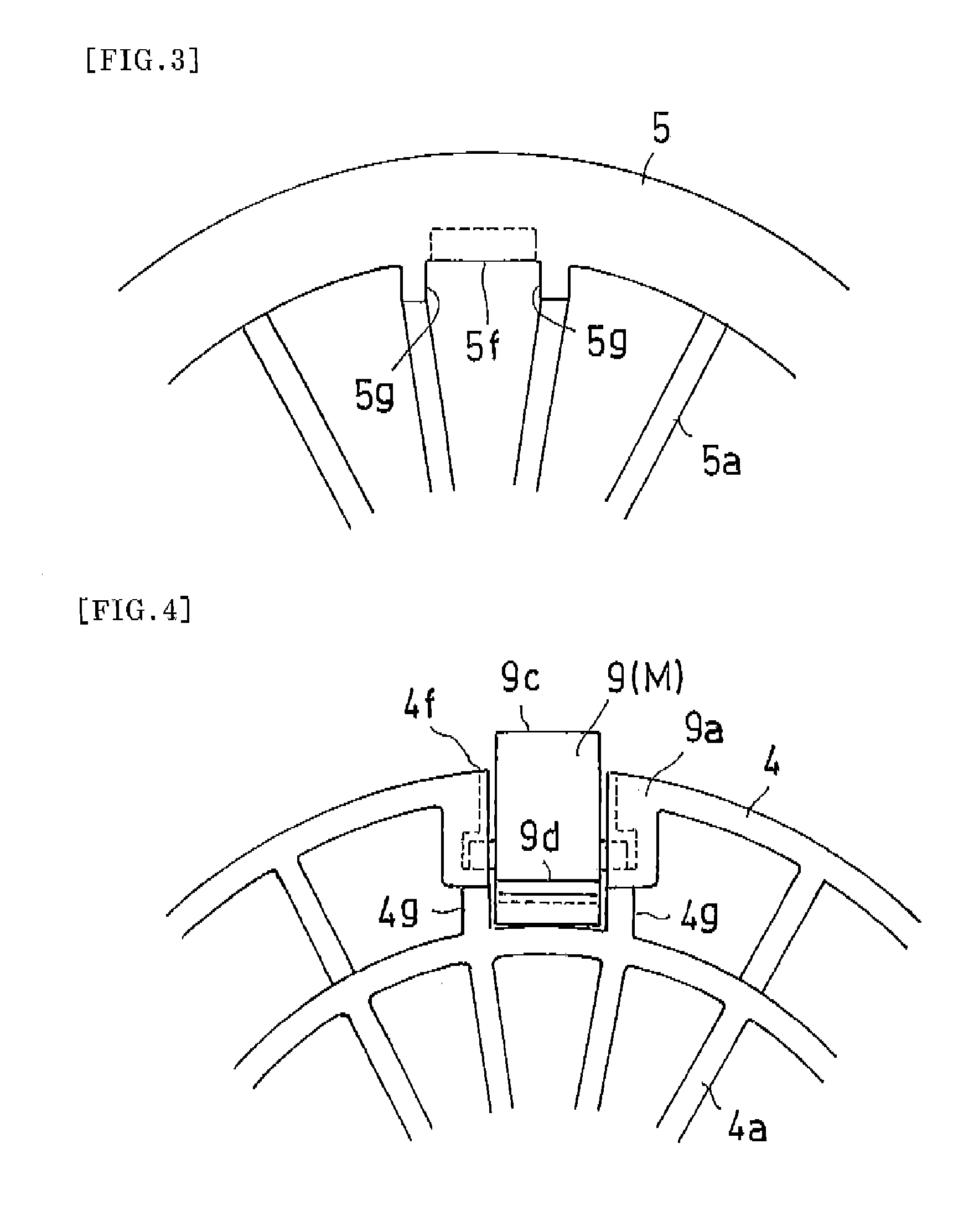

A spiral membrane module where membrane elements are easily connected to each other and the connection thereof is prevented from being loosened. The spiral membrane elements (20) are each formed in multiple layers by winding membranes and channel materials around a center tube (3) having holes and are received in a pressure vessel (10) such that they are connected in series with connection mechanisms (J) placed between the membrane elements (20). Each connection mechanism (J) has a movable member (M) installed at either the upstream side end part or the downstream side end part of each membrane element (20) and having an engagement part (9d) engageable with the other of the upstream side end or the downstream side end. The movable member (M) has a contact part (9c) coming into contact with the inner wall (10a) of the pressure vessel (10) and locking the engagement by the engagement part (9d).

Owner:NITTO DENKO CORP +1

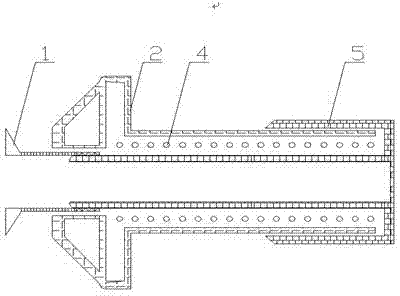

Raw water separator for spiral membrane module, membrane module containing separator and reverse osmosis membrane device

InactiveCN103316590ASave engineering investmentLow running costWater/sewage treatment bu osmosis/dialysisReverse osmosisWire rodConcentration polarization

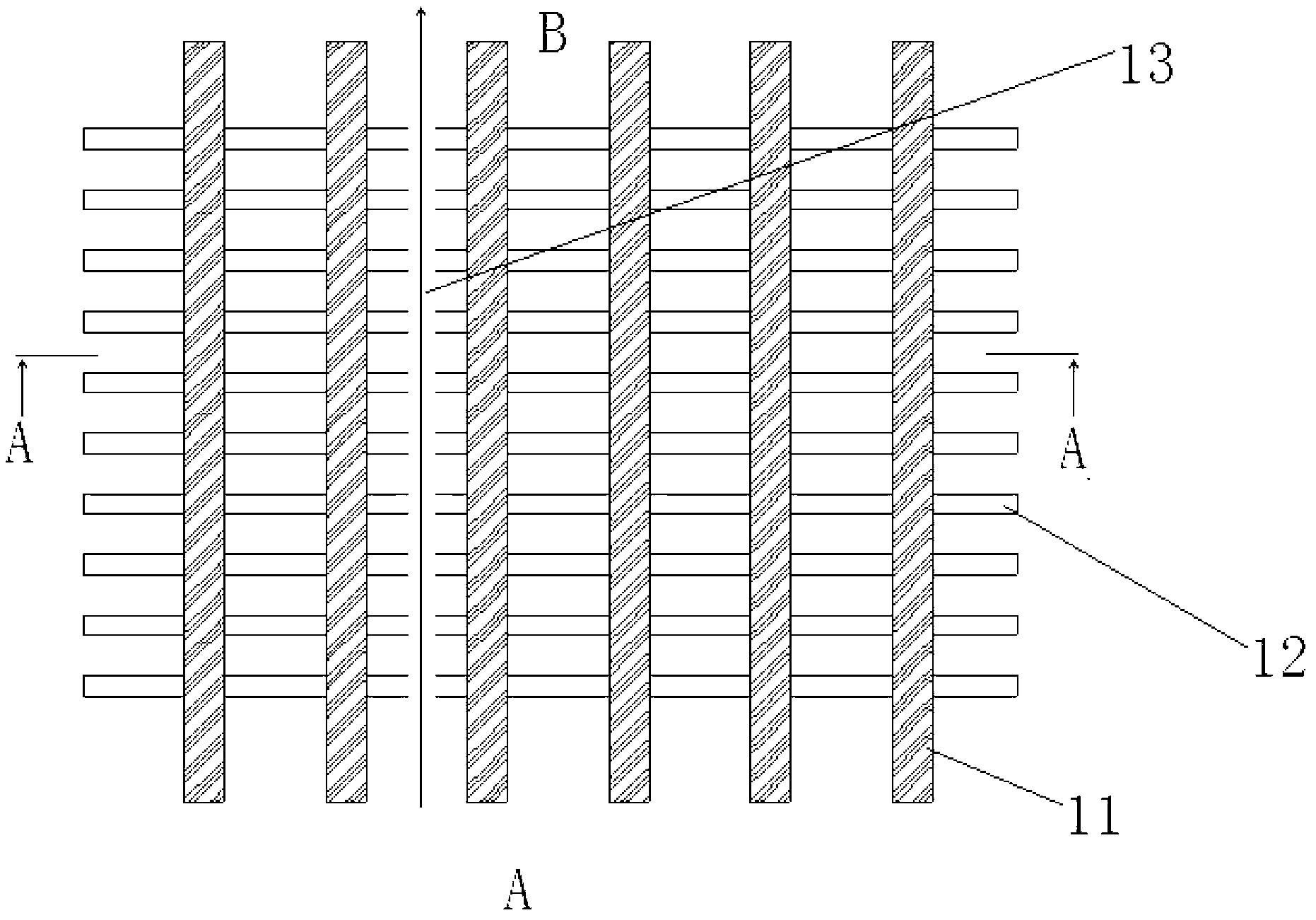

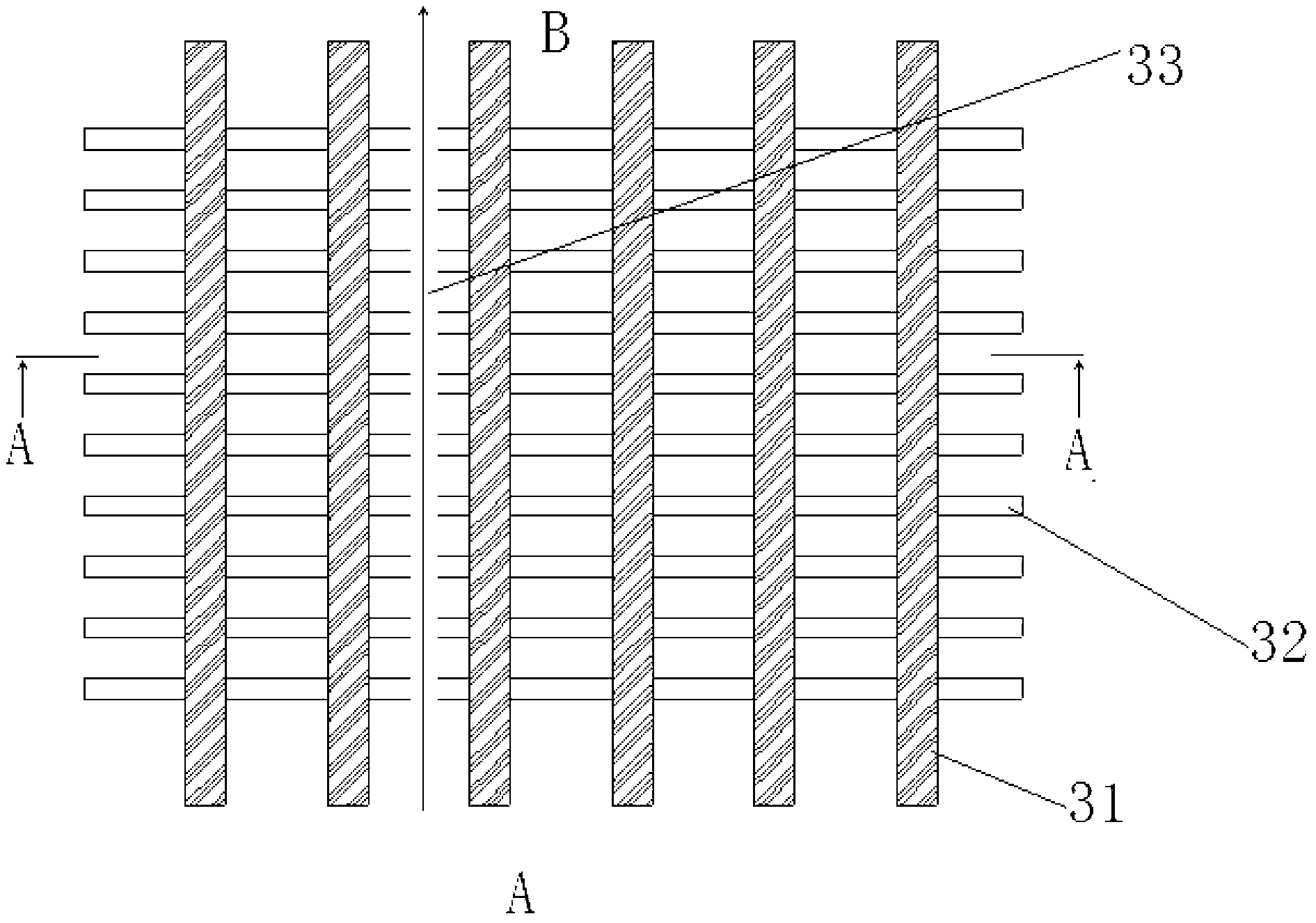

The invention relates to a raw water separator for a spiral membrane module, a membrane containing the separator and a reverse osmosis membrane device. The raw water separator is a net structure formed by intersecting warp wire rods and weft wire rods. The warp wire rods are parallel to the raw water flow direction of the membrane module. The weft wire rods are arranged in the direction perpendicular to the warp wire rods. A channel which is consistent with the raw water flow direction is formed between the warp wire rods and the weft wire rods and the spiral membrane. The weft wire rods of the raw water separator are perpendicular to the direction of the channel so as to obstruct raw water flowing along the channel. Thus, turbulent is generated, and concentration polarization of raw water and pollutant clogging are avoided. Through the raw water separator, the membrane module can be applied in higher TDS and COD high-salt complex wastewater treatment. By the utilization of the reverse osmosis membrane device, part of pretreatment facilities can be minimized or canceled during the application process, and the same salt rejection and product water recovery rate are realized. Therefore, project investment is greatly minimized and operating cost is reduced.

Owner:BGT GRP CO LTD

Purification method of stevioside RC (rebaudioside C)

InactiveCN102127130AMeet different needsSugar derivativesSugar productsPurification methodsUltrafiltration

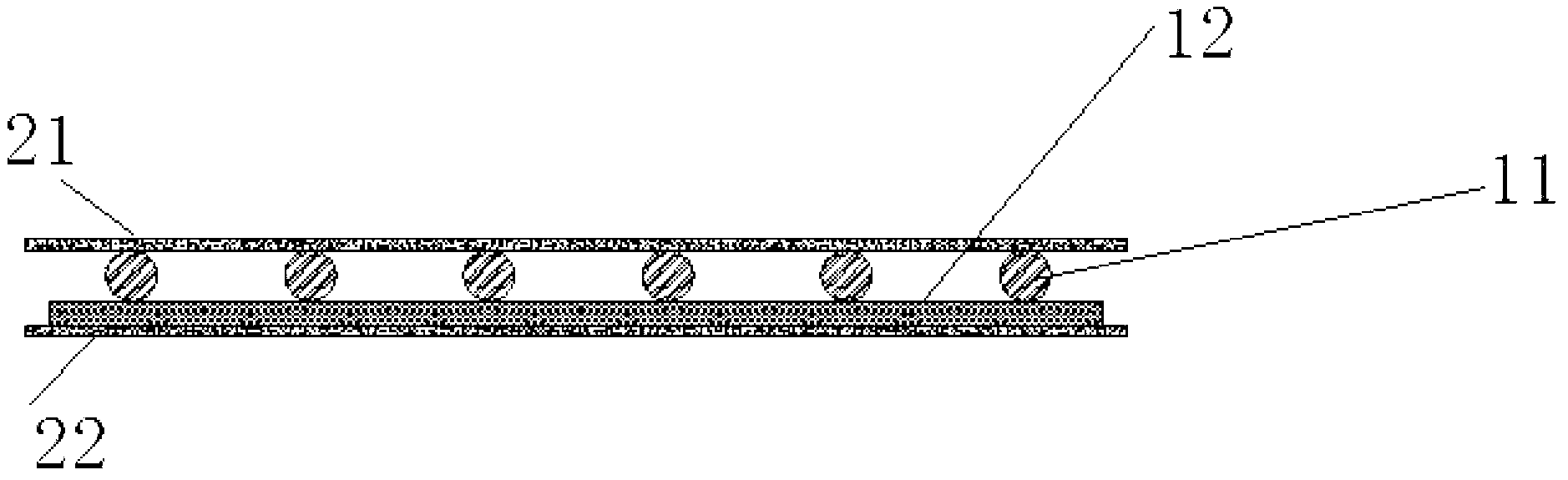

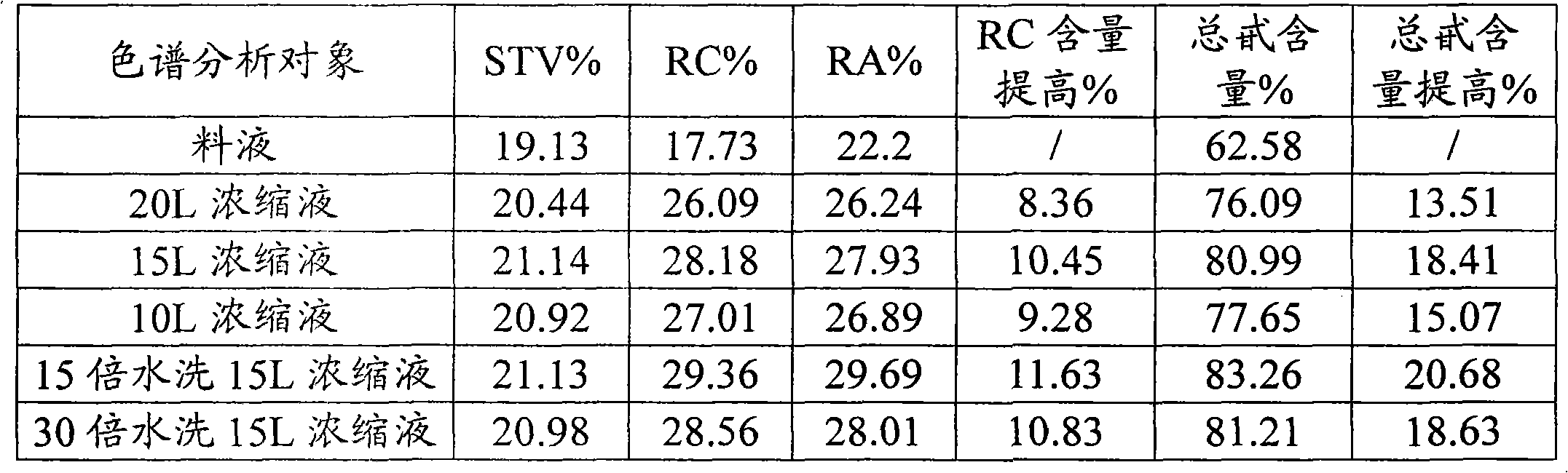

The invention discloses a purification method of stevioside RC (rebaudioside C), comprising the following steps of: preparing feed liquid with the mass concentration of 0.5-1% from mother liquid sugar, enabling the feed liquid to flow through an ultrafiltration membrane device at the flow rate of 25-35L / m<2>h, and controlling the pH at 6.5-7.5, wherein the ultrafiltration membrane is preferred to be polyvinylidene fluoride (PVDF) spiral membrane of which the pore diameter is 0.01-0.2mu m, the surface layer thickness is 0.05mu m, the bottom layer thickness is 300mu m, and the cutting molecular weight is 5500-6500DA; concentrating the concentrated solution at the temperature of 55-65 DEG C; and respectively drying the obtained solid and liquid to obtain crude stevioside. The purity of the stevioside prepared by the method is higher, the total glycoside content can be improved by 13-20%, the RC content can achieve above 30%, and the RC content in the stevioside can also achieve above 85% by a refining step.

Owner:安徽润海生物科技股份有限公司

Spiral membrane module

ActiveUS8034241B2DisplacementFirmly connectedMembranesSemi-permeable membranesEngineeringSpiral membrane

A spiral membrane module where membrane elements are easily connected to each other and the connection thereof is prevented from being loosened. The spiral membrane elements (20) are each formed in multiple layers by winding membranes and channel materials around a center tube (3) having holes and are received in a pressure vessel (10) such that they are connected in series with connection mechanisms (J) placed between the membrane elements (20). Each connection mechanism (J) has a movable member (M) installed at either the upstream side end part or the downstream side end part of each membrane element (20) and having an engagement part (9d) engageable with the other of the upstream side end or the downstream side end. The movable member (M) has a contact part (9c) coming into contact with the inner wall (10a) of the pressure vessel (10) and locking the engagement by the engagement part (9d).

Owner:NITTO DENKO CORP +1

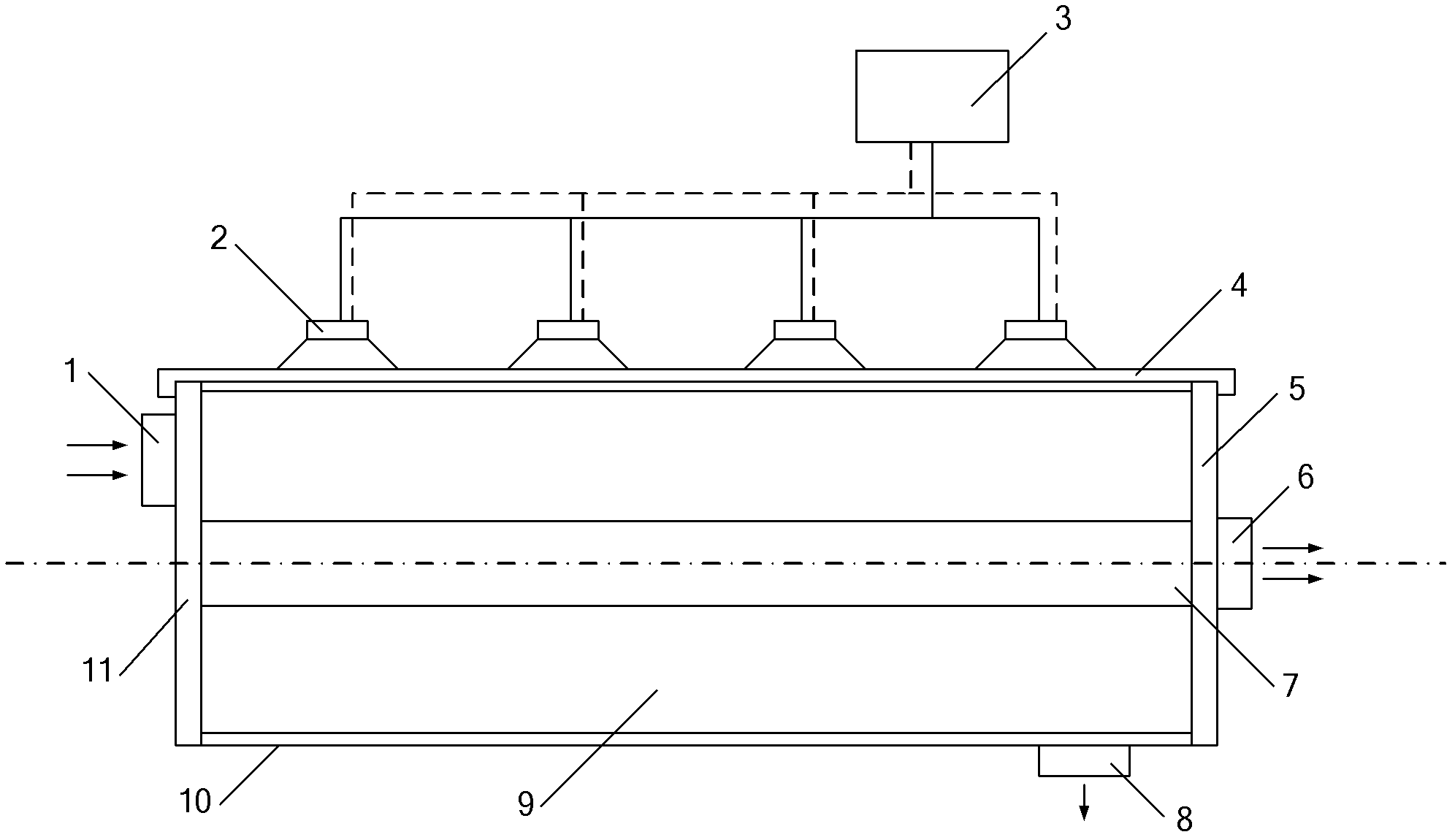

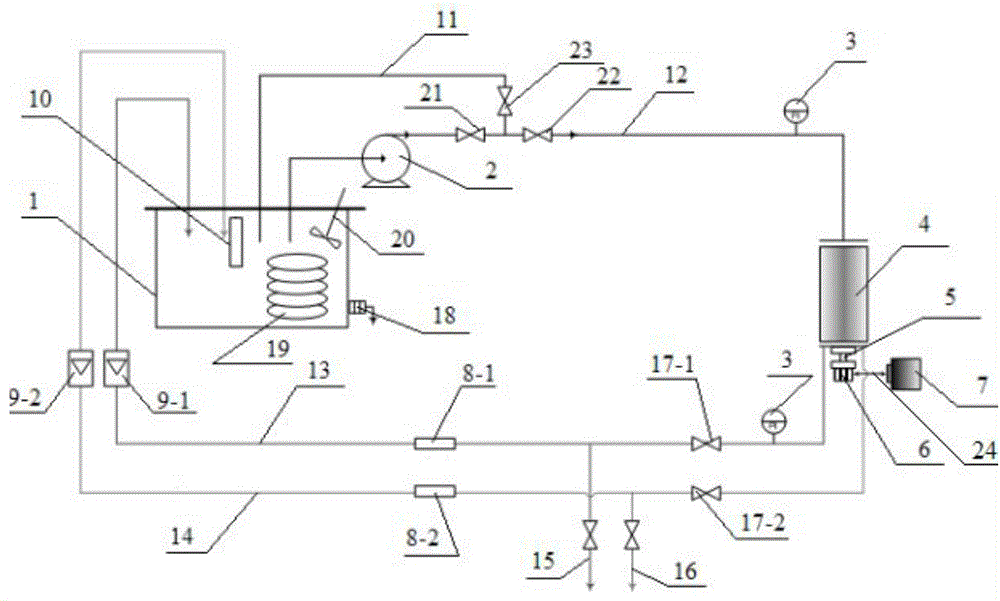

Integrated membrane module including on-line ultrasonic monitoring and cleaning

InactiveCN102423640ANot easy to cause damageExtended service lifeSemi-permeable membranesAnalysing solids using sonic/ultrasonic/infrasonic wavesConcentration polarizationCavitation

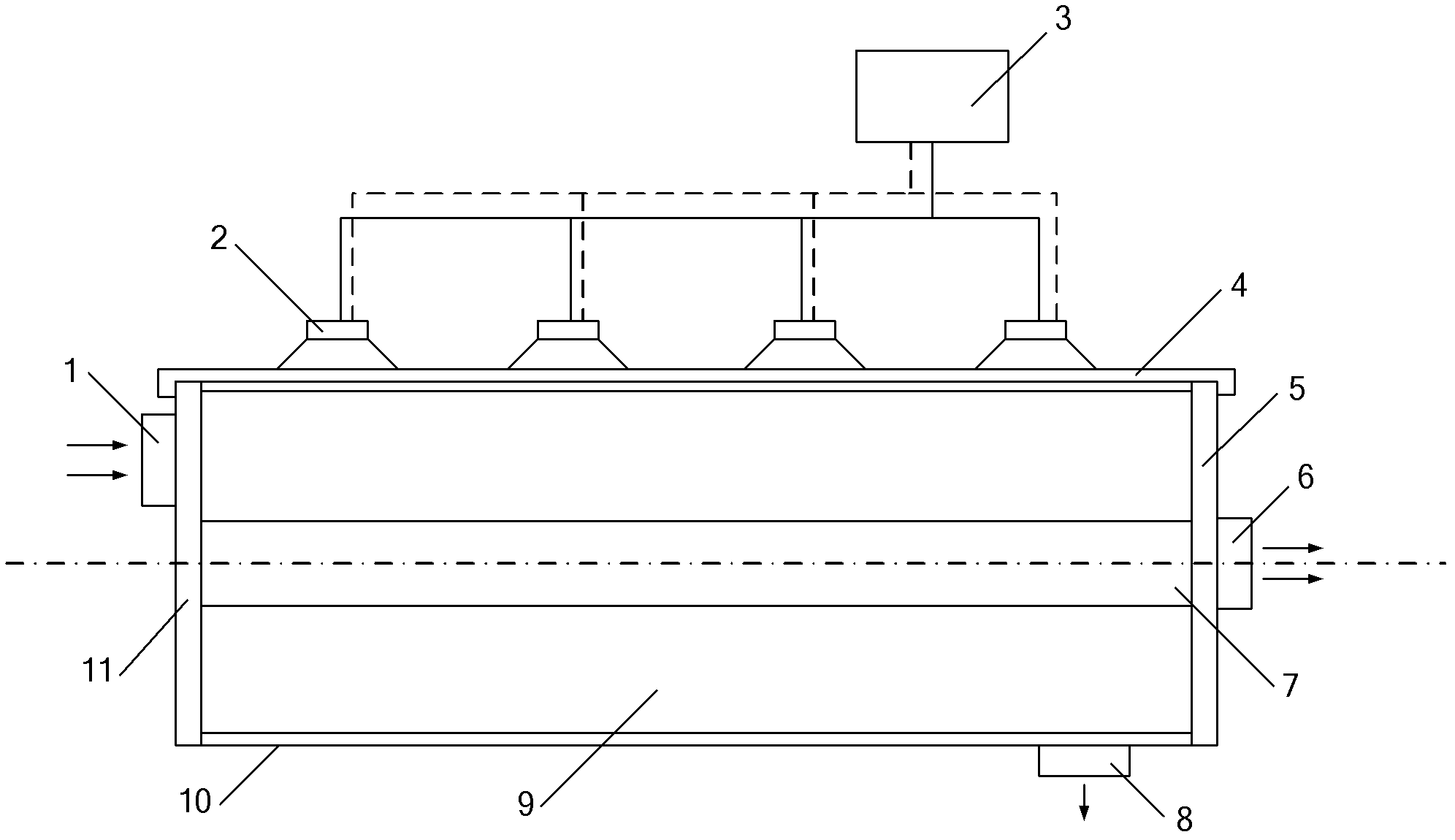

The invention discloses a membrane module realizing the on-line monitoring and control of membrane pollution by using the ultrasonic technology, belonging to the technical field of water treatment. The membrane module comprises a water inlet plate, a membrane wall, a spiral membrane, a water outlet plate, an ultrasonic transducer, a permeate outlet, a condensed water outlet, and an intelligence control system. The membrane module disclosed herein can monitor the membrane pollution in real time, utilizes the effects of ultrasound to destroy the concentration polarization according to a set switch-on strategy, and disturbs and alleviates the formation of membrane pollution, and the cavitation can enhance the effect of membrane cleaning. According to the invention, by using a special mode of using ultrasound, the damage of ultrasound for the membrane material is greatly reduced, the application range of ultrasound is enlarged, the service time of the membrane module is prolonged. The membrane module is suitable for ultrafiltration, nanofiltration, reverse osmosis and the like.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

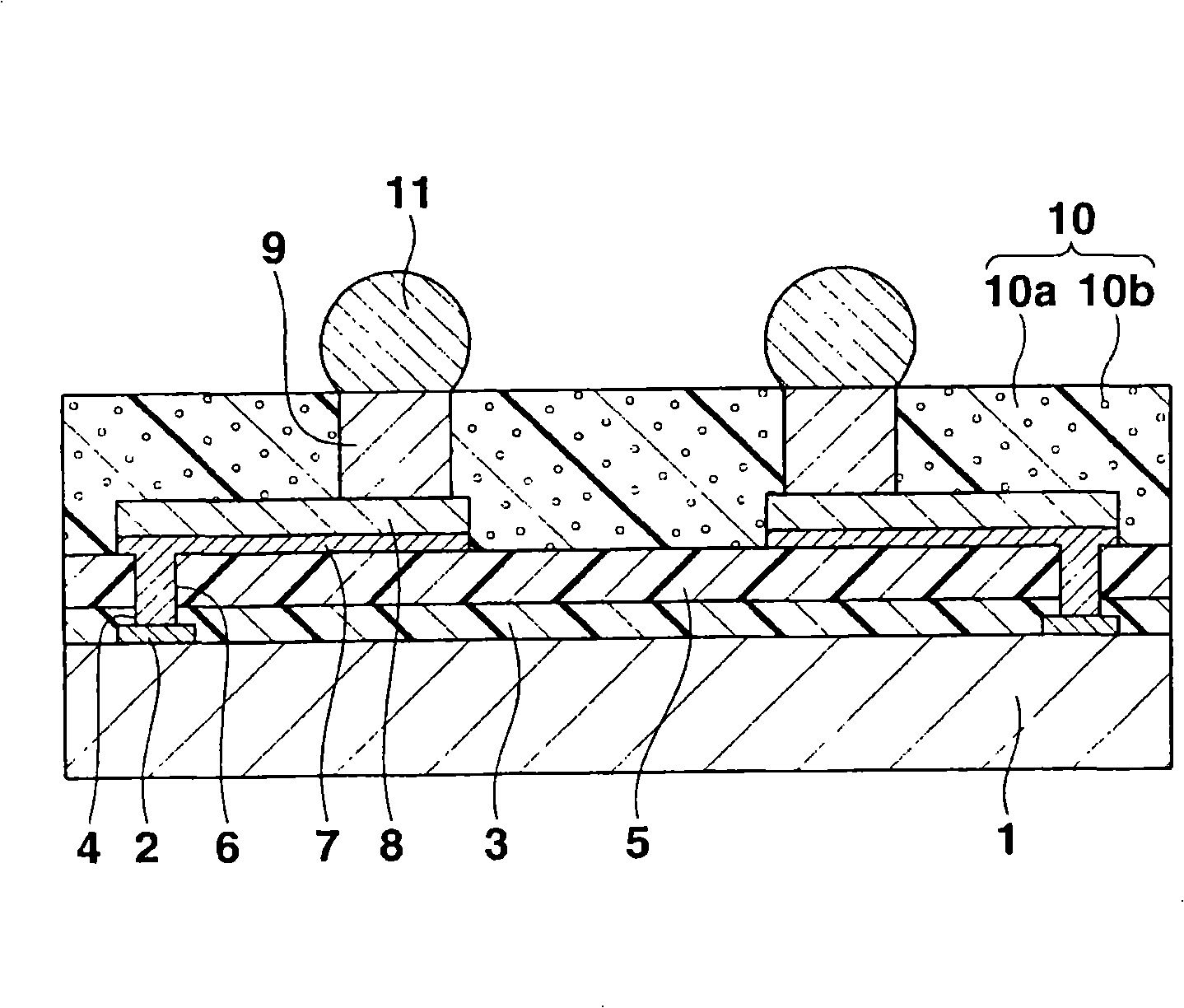

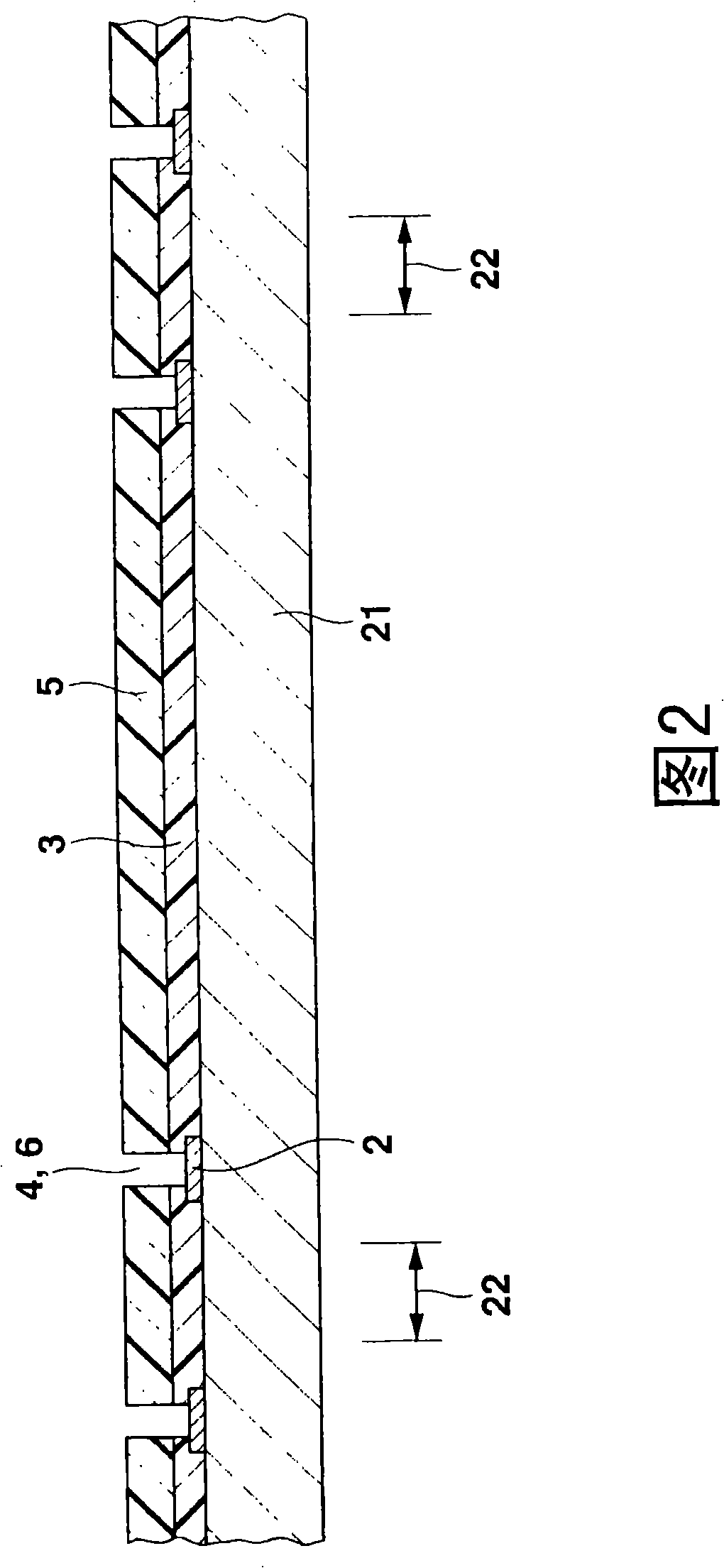

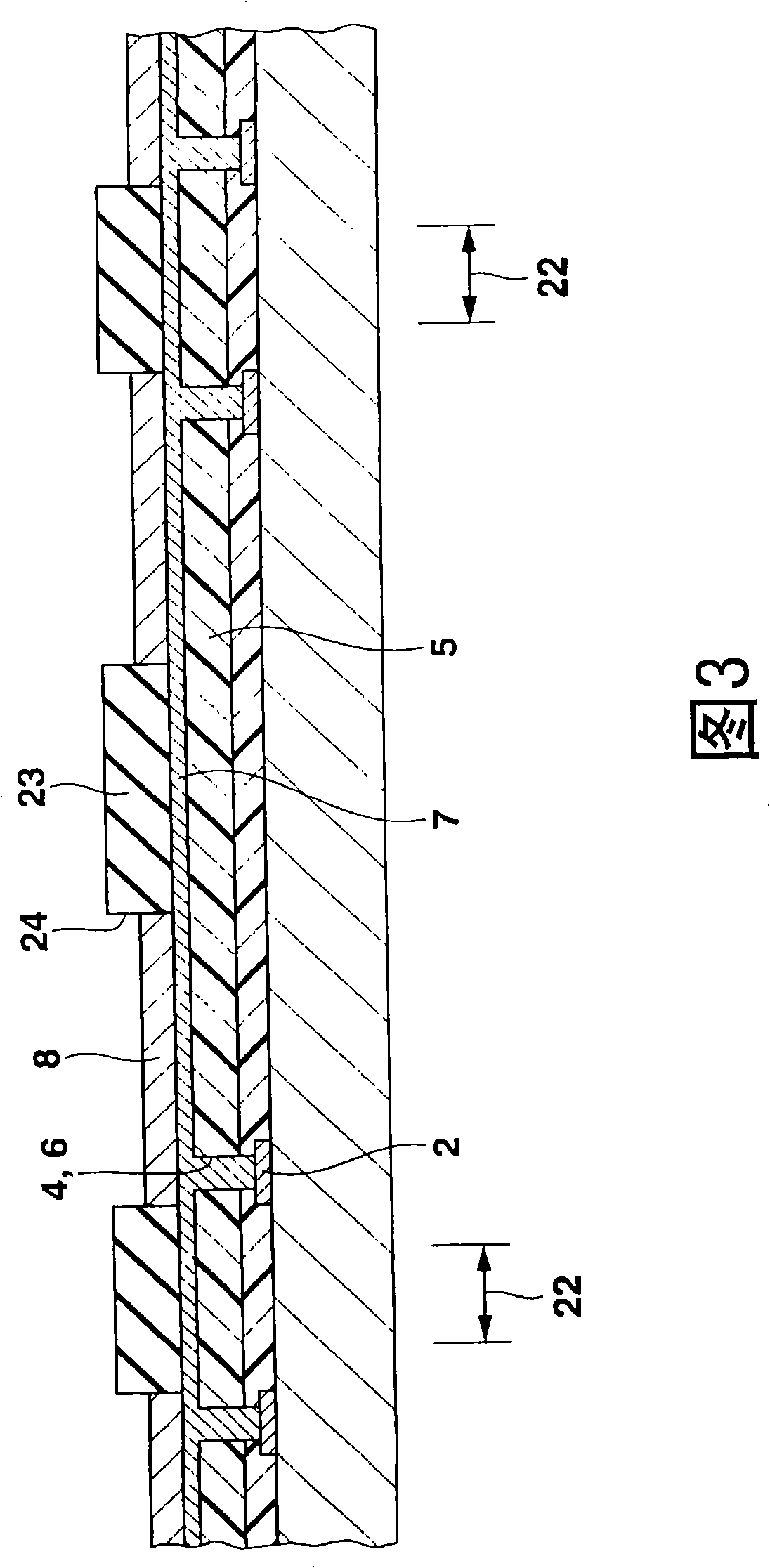

Semiconductor device and manufacturing method thereof

InactiveCN101320726ASuppression of interference electromagnetic radiation noiseReduce eddy current lossSemiconductor/solid-state device detailsSolid-state devicesEddy currentElectromagnetic radiation

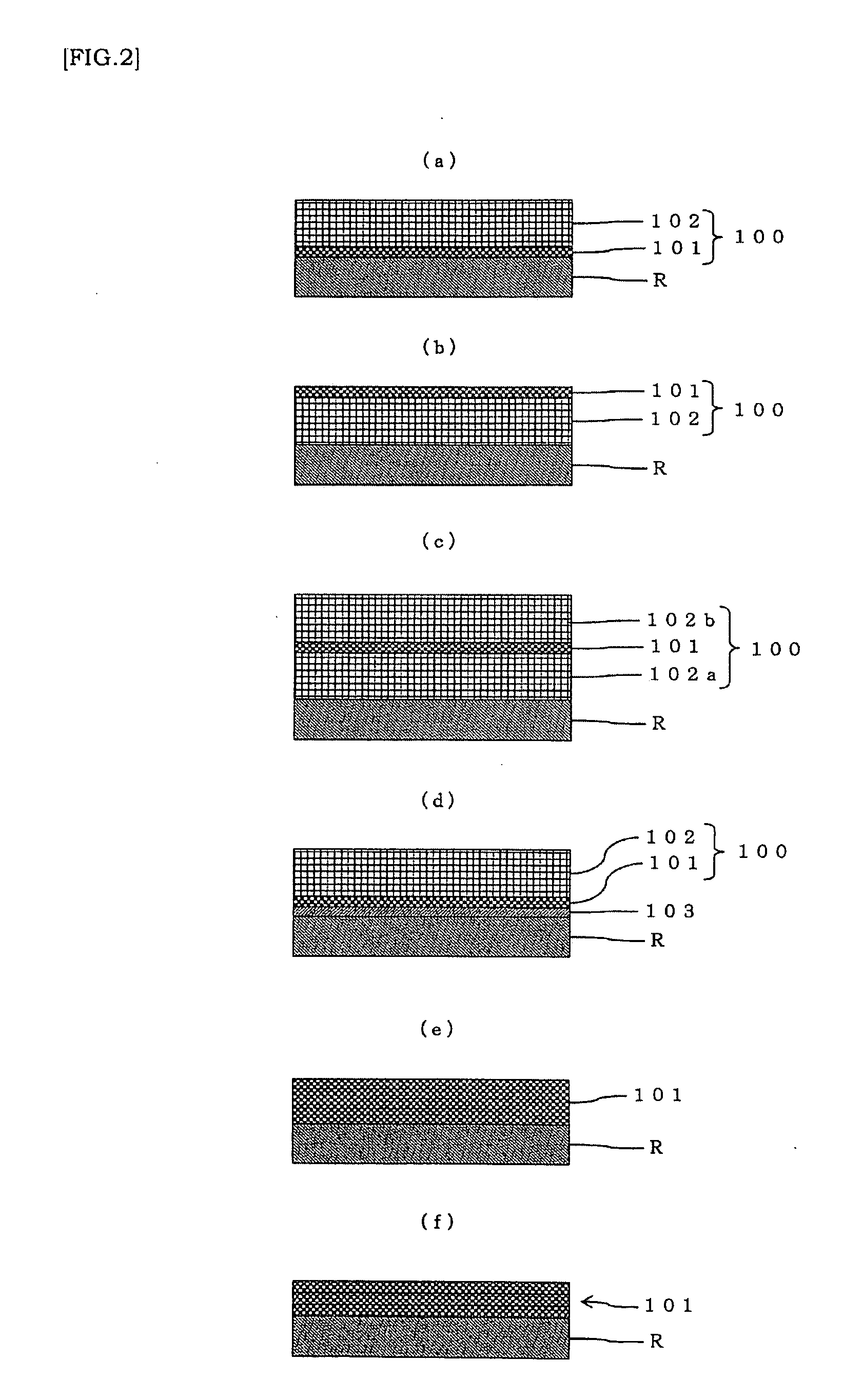

The invention relates to a semiconductor device mixed with magnetic powder and a manufacturing method thereof. According to the invention, because a material mixed with the magnetic powder in the resin forms a sealing membrane, interfering electromagnetic radiation noise can be restrained from an integrated circuit on the upper surface of a semiconductor substrate to the exterior or inversely from the exterior to an integrated circuit on the upper surface of a semiconductor substrate. In addition, in a semiconductor device comprising a spiral membrane inductive component named as CSP, a magnetic membrane formed by a material mixed with the magnetic powder in the resin is arranged between the semiconductor substrate and the membrane inductive component, thereby reducing eddy current loss of the membrane inductive component caused by eddy current generated in the semiconductor substrate.

Owner:AOI ELECTRONICS CO LTD

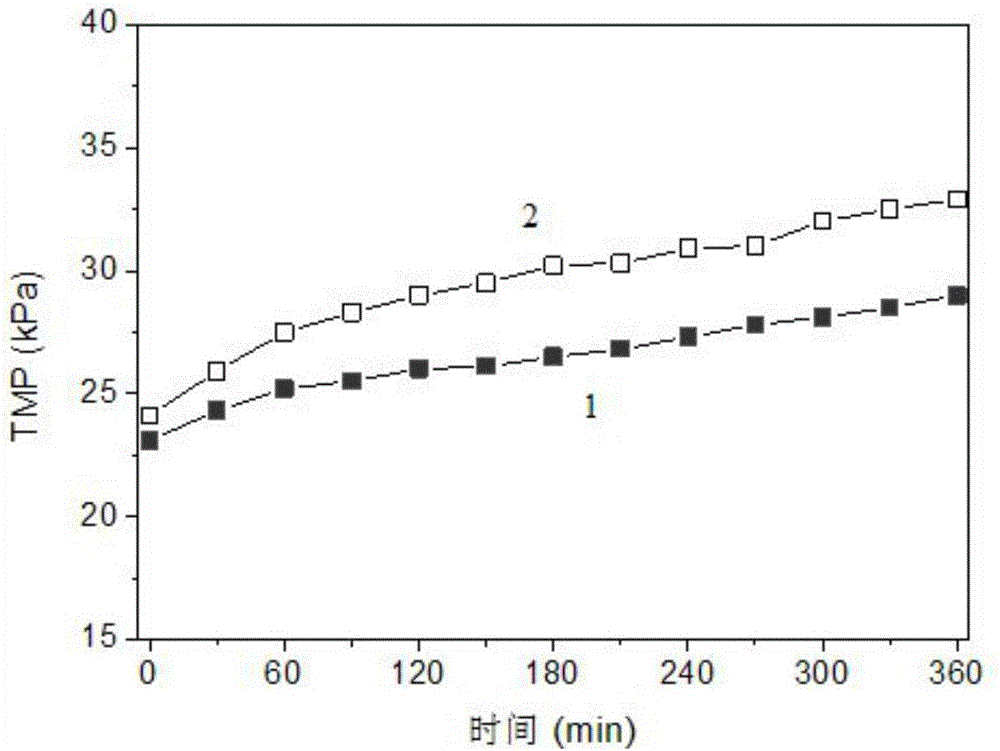

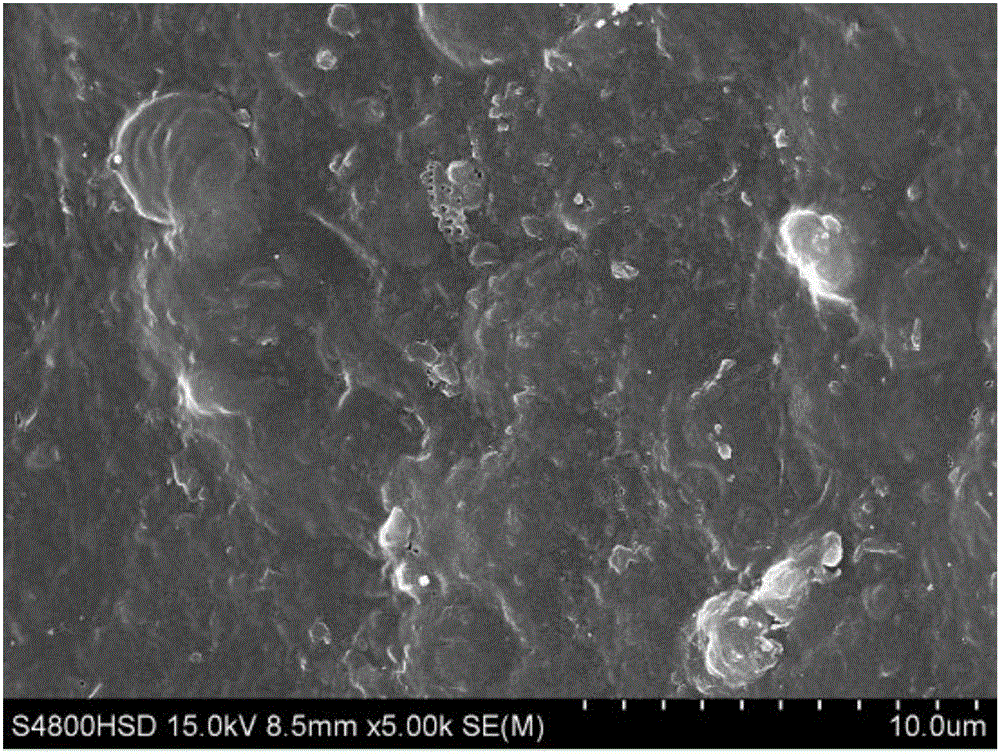

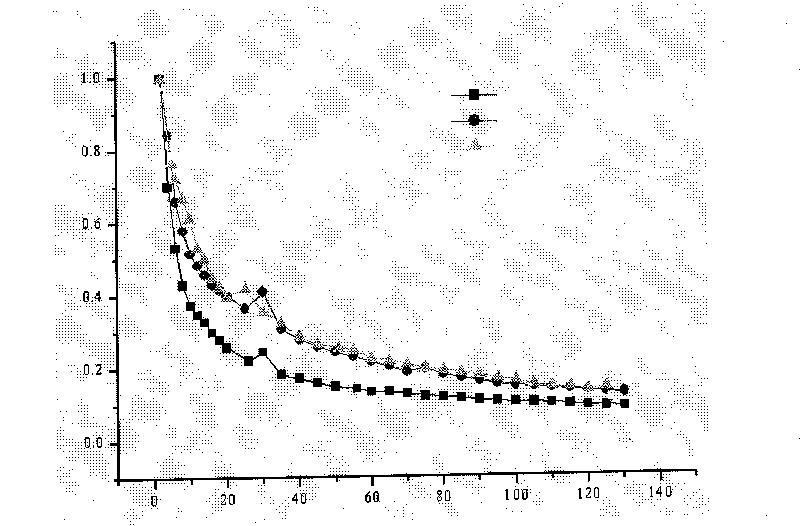

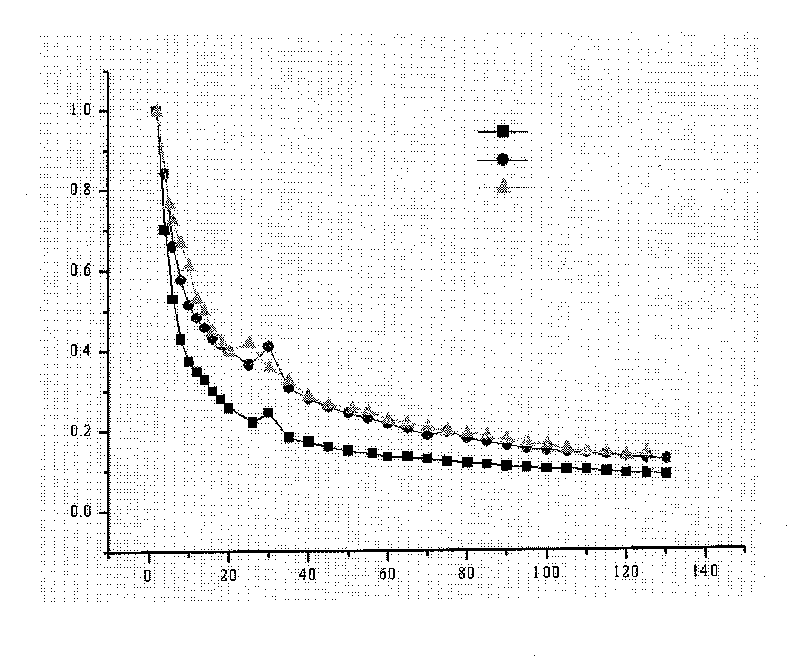

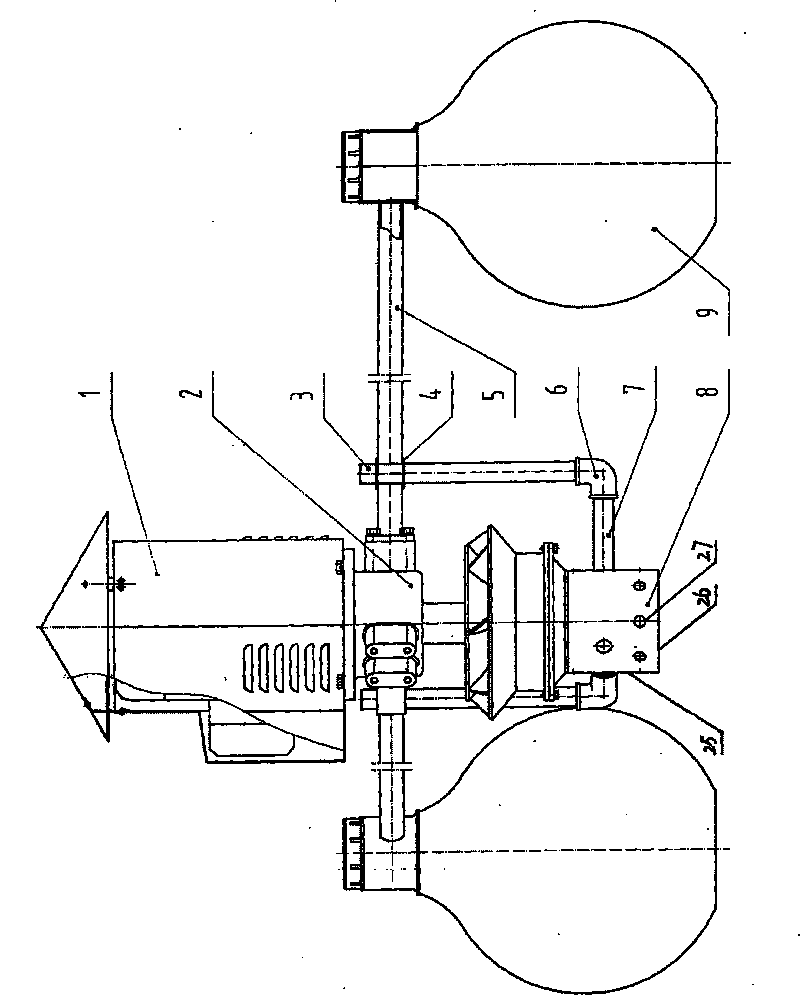

Membrane pollution vibration control device used in process of treating algae containing water through low-pressure spiral membrane and method for controlling membrane pollution through device

ActiveCN105692875AReduced Integrity ImpactAvoid damageSemi-permeable membranesTreatment using aerobic processesVibration controlHigh flux

The invention relates to a membrane pollution vibration control device used in the process of treating algae containing water through a low-pressure spiral membrane and a method for controlling membrane pollution through the device. The device and the method aim at solving the problem that at present, no vibration control technology provided for the low-pressure spiral membrane pollution phenomenon is available. A vibration driver is arranged in the device, a spiral membrane reactor is driven by a drive motor to rotate along the axis, rotate back to the original position, reverse and rotate back to the original position, and therefore the vibration effect of a membrane assembly is achieved. According to the vibration method, the time when the spiral membrane maintains high-flux operation is prolonged, and the quality of effluent is guaranteed.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

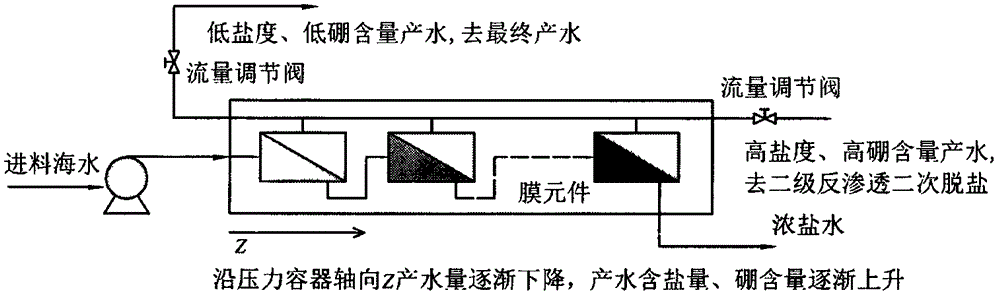

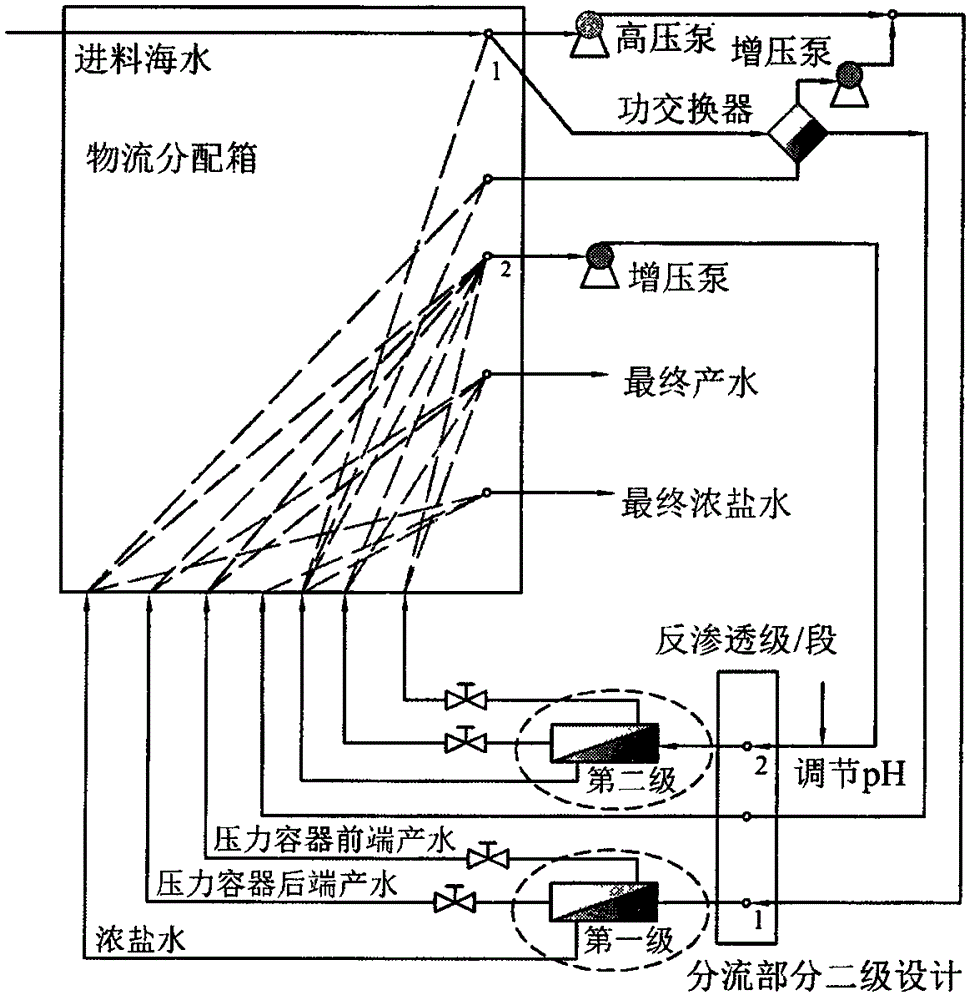

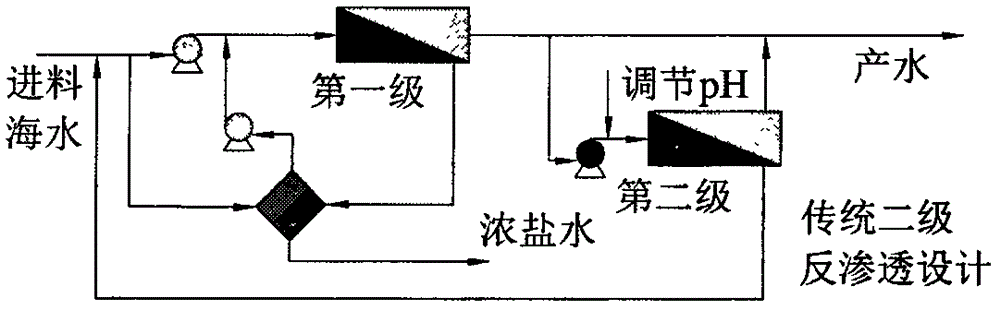

Method for optimizing flow distribution part two-stage type design spiral membrane element reverse osmosis seawater desalination system considering boron removal

InactiveCN105740509ALower water costsReduce energy consumptionGeneral water supply conservationSeawater treatmentWater qualityEngineering

The invention discloses a method for optimizing a flow distribution part two-stage type spiral membrane element reverse osmosis seawater desalination system considering boron removal. According to the method, an accurate model of a reverse osmosis seawater desalination transfer mechanism considering boron removal is established in a strict mechanism mode. The flow distribution part two-stage design is introduced; by utilizing a characteristic that the yield and quality of producing water at the front end of a pressure container are higher than those of producing water at the back end of the pressure container, the producing water at the front end of the pressure container is directly conveyed to final producing water and the producing water at the back end enters a next stage to be treated again; and a flow adjustment valve is added, so that the ratio of outlet water at the two ends can be flexibly adjusted according to an actual condition. A superstructure model of the reverse osmosis system is established, the changes of saline water pressure, concentration and flow in an axial direction of the pressure container as well as the salinity rise caused by saline water mixing in a worker exchange are considered, operation condition constraints are added for ensuring the system to run safely, and a simultaneous solution technology is adopted for solving optimization systems. The method comprehensively considers the influences of various factors on the seawater desalination system to further reduce the water producing cost and energy consumption of seawater desalination and enable the producing water of the system to meet the boron content standard of boron in drinking water. Not only can the reverse osmosis system be designed but also operation parameters can be optimized in a system operation process, so that the method has very good application prospects.

Owner:HEBEI UNIV OF TECH

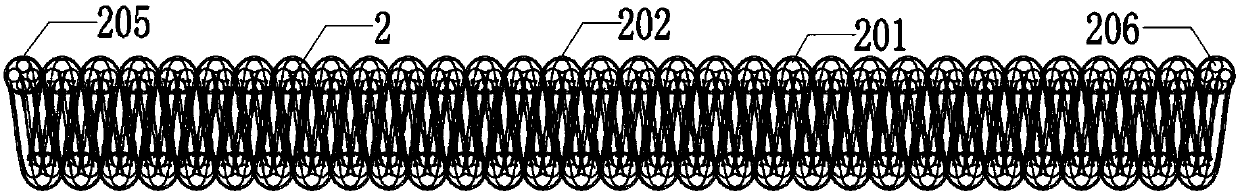

Spiral membrane element

ActiveUS20170304775A1Increase the effective membrane areaIncrease permeate flow rateMembranesSemi-permeable membranesSemipermeable membraneRejection rate

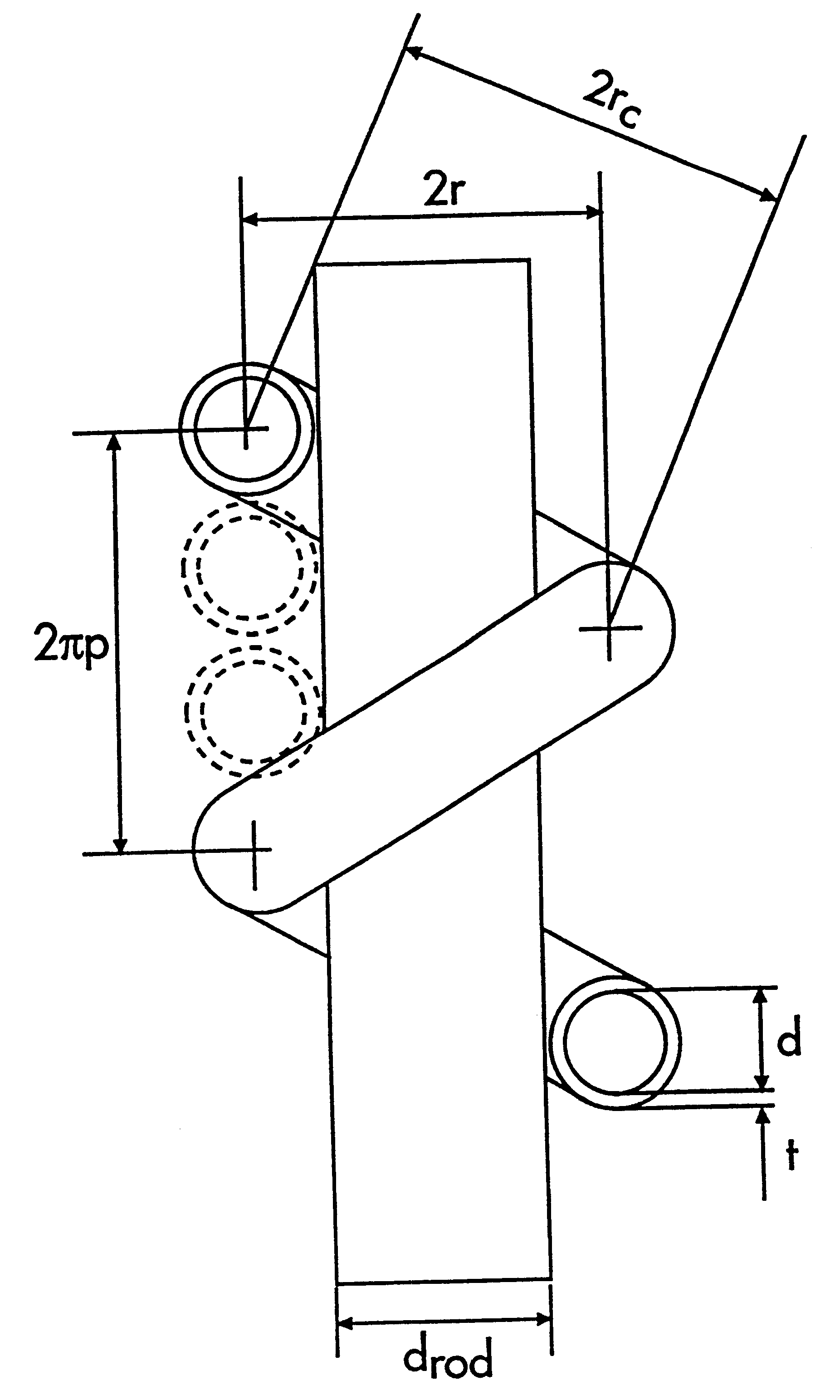

The present invention provides a spiral membrane element in which the effective membrane area of a composite semi-permeable membrane can be increased and any decrease in rejection rate is less likely to occur. The spiral membrane element includes: a laminate including a permeation-side flow path material, a supply-side flow path material, and a composite semi-permeable membrane having a separation function layer on a surface of a porous support; a perforated central tube around which the laminate is wound; and a sealing member for preventing mixing between the supply-side flow path and a permeation-side flow path, the spiral membrane element being characterized in that the thickness of the porous support of the composite semi-permeable membrane is 80 μm to 100 μm, the permeation-side flow path material is formed from a tricot knit fabric, and the width of a groove that continues in a straight line is 0.05 mm to 0.40 mm.

Owner:NITTO DENKO CORP

Membrane element sealing material holding member and membrane element

ActiveUS7867394B2Smooth deformationEasy to insertSemi-permeable membranesMembranesBiomedical engineeringSpiral membrane

A membrane element sealing material holding member comprising a central opening for insertion of a center tube of spiral membrane element, peripheral orifice for flowing of a raw liquid into a membrane end portion of membrane element and outer circumferential part for holding of circular sealing material, wherein the central opening has inner circumferential surface of cylindrical form with a diameter larger than the outer diameter of the inserted center tube, and wherein at three or more positions on the inner circumferential surface, there is provided projection that has sloping face on its side of center tube insertion and is deformable at the time of insertion of center tube with an outer diameter larger than that of incircle.

Owner:NITTO DENKO CORP

Method for separating high flux and low pollution membrane with biomimetic spiral membrane

InactiveCN101698136AImprove the perturbation effectReduce pollutionSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisFiberHollow fibre

The invention relates to a method for separating a high flux and low pollution membrane with a biomimetic spiral membrane, belonging to the technical field of membrane separation. The method aims to establish the efficient membrane separation components by using a biomimetic principle, lighten concentration difference polarization and membrane pollution, improve the membrane flux and reduce energy consumption. The invention is characterized in that flat membranes and hollow fibre parallel arrangement membrane components keep the characteristics of the biomimetic spiral membrane structure in space through the outside fixing method, the inside support structure and shape maintaining method or the combination of the two methods, and the distribution, the interaction and the change mode of membrane and the flow field in membrane separation are changed. The vibration and swing of the membranes are caused by the washing and the disturbing of the flow. The invention has the effect and advantages that under the premises that the material consumption and the energy consumption are not increased in the membrane separating process, mass transfer is strengthened, membrane pollution is lightened, and dynamic membrane operating effect is favorable. The method has obvious social and economic benefits and has wide application prospect in the fields of chemical industry separation, water treatment, medicine separation and the like.

Owner:DALIAN UNIV OF TECH

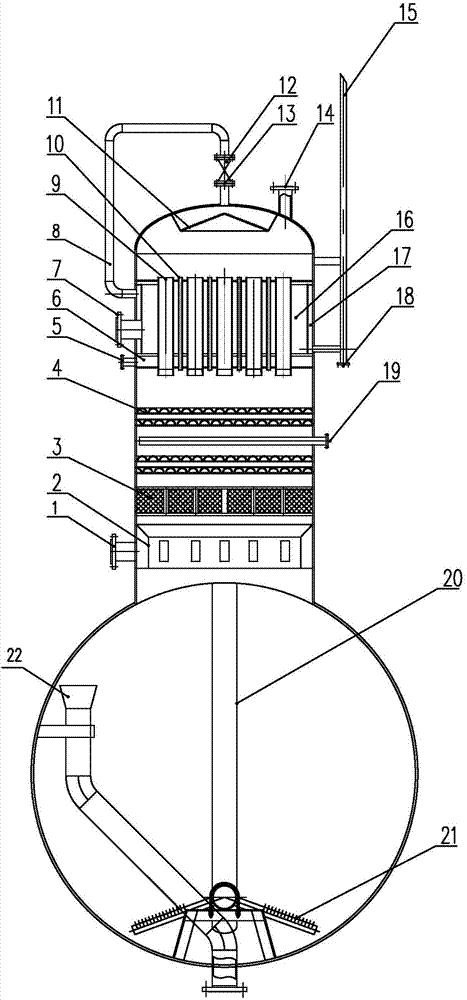

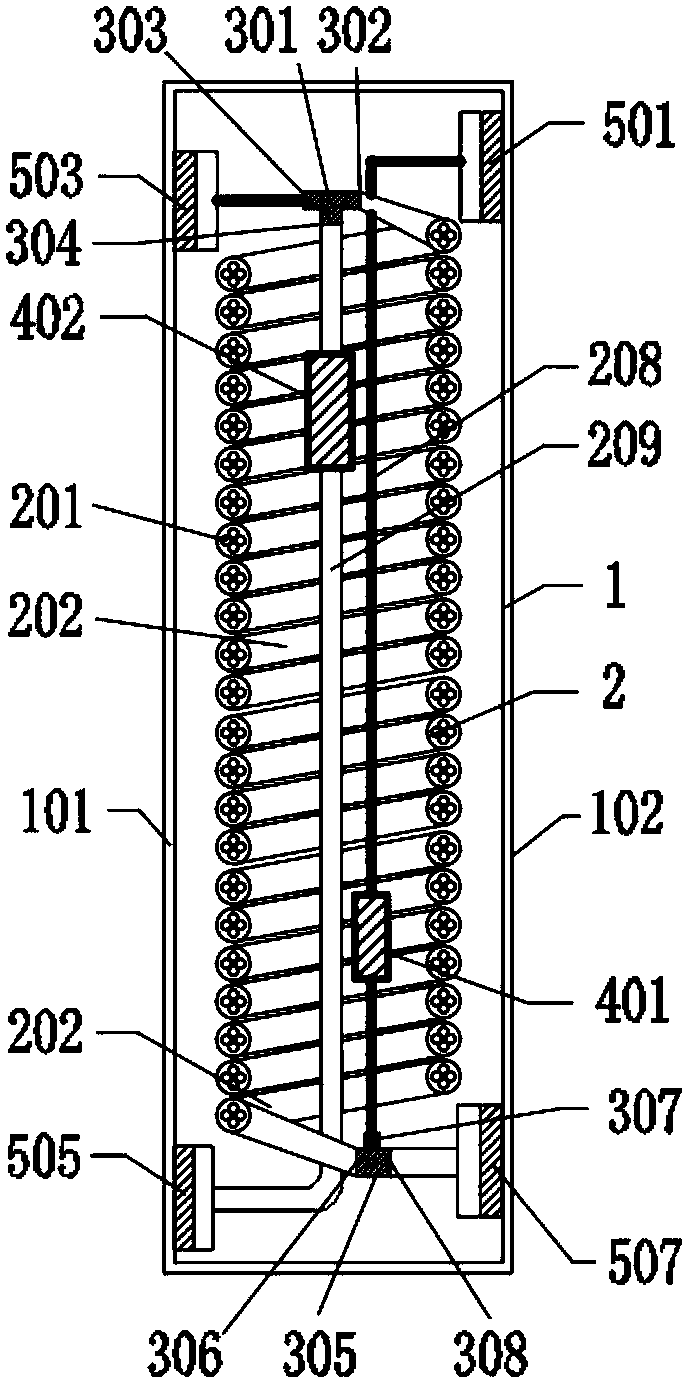

High-efficiency energy-saving thermal deaerator

ActiveCN103754971AImprove oxygen removal effectGuaranteed uptimeWater/sewage treatment bu osmosis/dialysisWater/sewage treatment by heatingDeaeratorEngineering

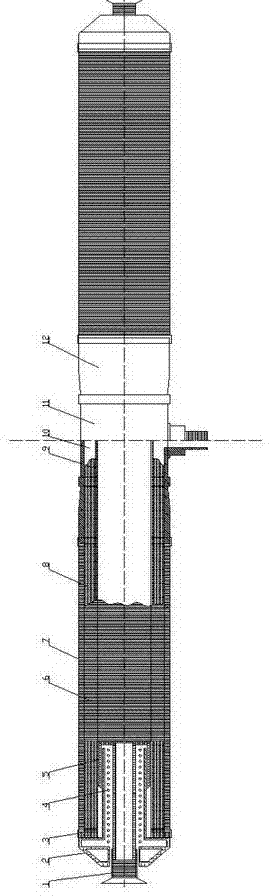

The invention relates to a high-efficiency energy-saving thermal deaerator, which belongs to the field of machinery. The deaerator comprises a cylindrical shell, wherein a gas-water separator, a spiral membrane device group, a watering grate, a filling liquid gas net, a gas distribution disc and a water tank which are arranged from top to bottom in sequence inside the cylindrical shell. The deaerator has a good deoxygenization effect.

Owner:山东佳能科技股份有限公司

Water-Treatment Membrane Module Unit

InactiveUS20150068970A1Simplify manifold structureReliable watertight connectionMembranesSemi-permeable membranesTreated waterMembrane configuration

A water-treatment membrane module with raw-water manifolds connected in common to both end portions of spiral membrane modules and allowing raw water to flow in or out of the spiral membrane modules, in which each of the manifolds comprises a box and cover which may be opened for inspection and access to a treated water manifold in fluid communication with the water collecting pipes.

Owner:MITSUI ENG & SHIPBUILD CO LTD

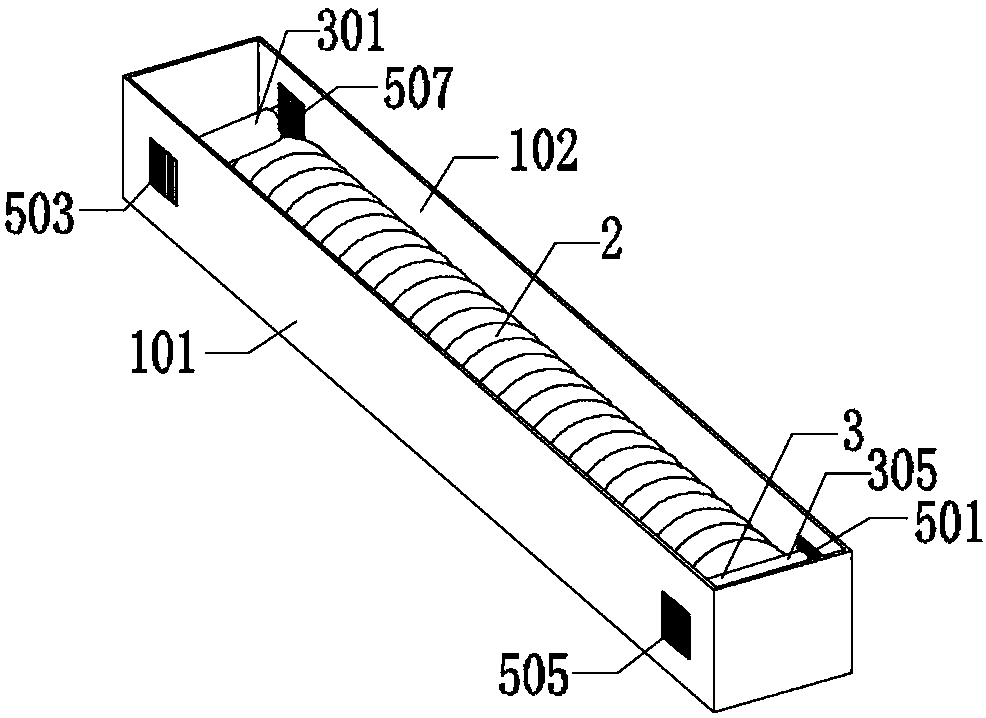

Micro-pore aerator

InactiveCN103755014AOvercoming the ills that cannot be openedGood automatic cleaning effectWater aerationSustainable biological treatmentEngineeringSpiral membrane

The invention discloses a micro-pore aerator which comprises aeration components, a pressure adjusting system, a support component and a connecting component, wherein the aeration components are arranged on the support component; the aeration components are spiral membrane sheets; the spiral membrane sheets are uniformly wound on the support component; grooves are formed in the spiral membrane sheets. The micro pore aerator is simple in structure, good in automatic washing effect, convenient to mount, efficient and energy-saving, and the production cost is effectively lowered.

Owner:普民环保科技有限公司

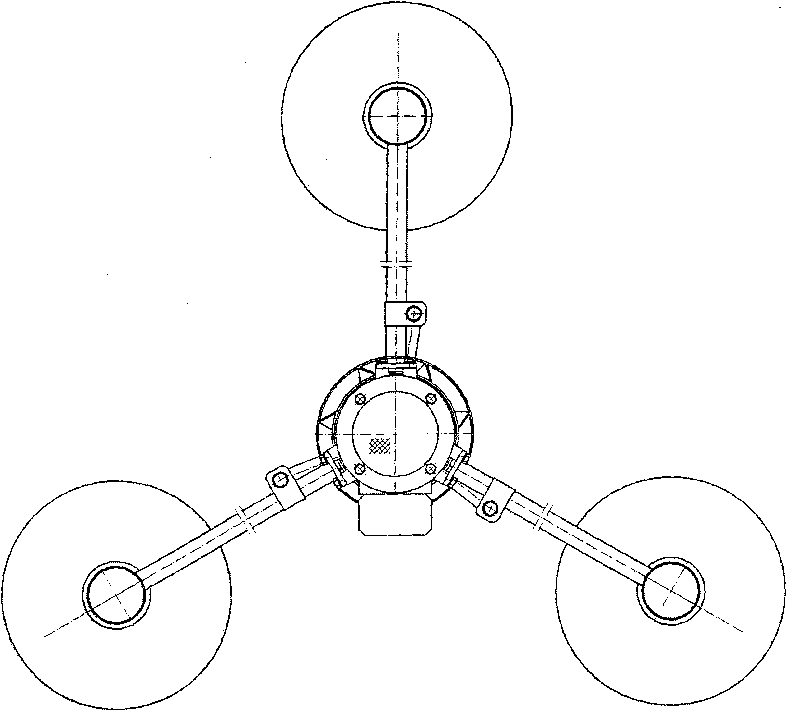

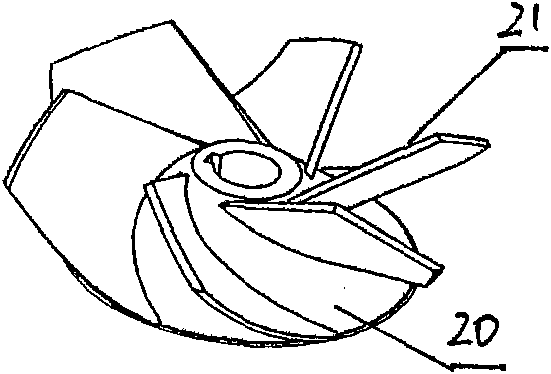

Impeller water-spraying oxygen-increasing machine

The invention discloses an impeller water-spraying oxygen-increasing machine, wherein a motor (11) is arranged above a support body (2), the support body (2) is connected to one end of a support rod (5) in a trisection mode, the other end of the support rod (5) is provided with a floating ball (9), a shaft of the motor (11) is provided with an impeller shaft (14) through a coupler (13), and the impeller shaft (14) is provided with an impeller (18). The impeller water-spraying oxygen-increasing machine is characterized in that a water outlet body (16) is arranged below the support body (2), the impeller shaft (14) penetrates through the centre of the water body (16), a water inlet cover (8) is arranged below the water outlet body (16), and the impeller (18) is positioned in a cavity formed by the water outlet body (16) and the water inlet cover (8). A spiral membrane on the water-outlet body enables the spraying water to be in a rotation state so that the water can contact with the air for a longer time, the water and the air are further mixed, convection and exchange of a bottom-layer water body and an upper-layer water body are realized, and the oxygen-increasing capability is improved.

Owner:JIANGSU HENGSHENYANG MACHINERY

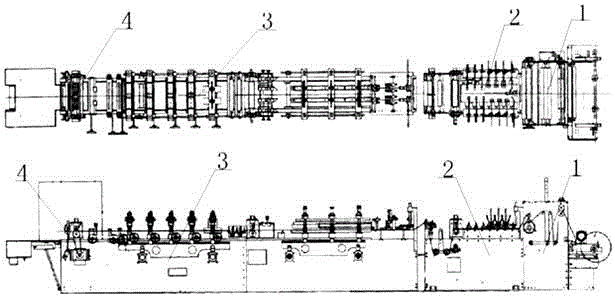

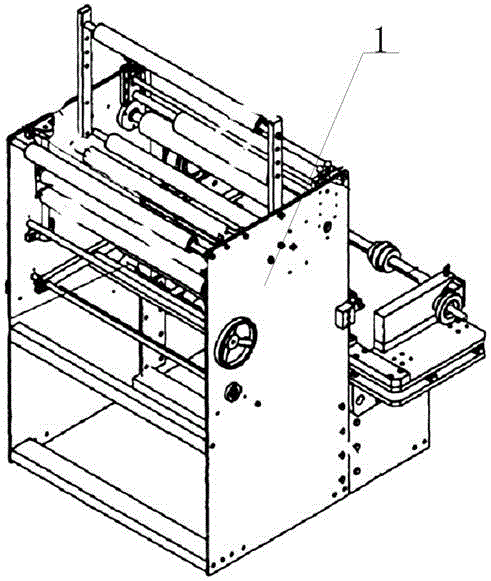

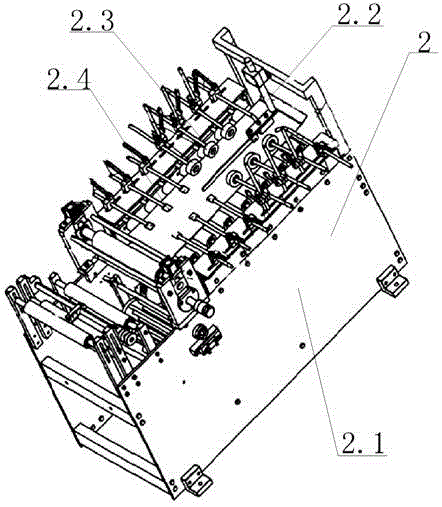

Double-output middle sealing full-automatic bag-making apparatus and bag-making method thereof

ActiveCN105522755AIncrease production capacityLow costEnvelopes/bags making machineryEngineeringMechanical engineering

The invention relates to a double-output middle sealing full-automatic bag-making apparatus that is capable of utilizing a doubly-printed spiral membrane as a raw material, simultaneously producing two membrane bags every time, effectively improving the production efficiency and saving energy sources. The double-output middle sealing full-automatic bag-making apparatus comprises a feeding device 1, a folding device 2, a hot sealing device 3 and a discharging device 4, all of which are connected orderly from front to back; the double-output middle sealing full-automatic bag-making apparatus is characterized in that the feeding device 1 comprises a back folding device 1.1 that includes a first baffle plate 1.1.1, a second baffle plate 1.1.2, a third baffle plate 1.1.3, a fourth baffle plate 1.1.4 and a fifth baffle plate 1.1.5, and the first baffle plate 1.1.1, the second baffle plate 1.1.2, the third baffle plate 1.1.3, the fourth baffle plate 1.1.4 and the fifth baffle plate 1.1.5 are arranged up and down alternately; the folding device 2 comprises a folding device body 2.1, a cutter 2.2, a clamping roller 2.3 and a plurality of folding plates 2.4, and the cutter 2.2, the clamping roller 2.3 and the plurality of folding plates 2.4 are mounted on the folding device body 2.1.

Owner:WUXI TIEMIN PRINTING MACHINERY

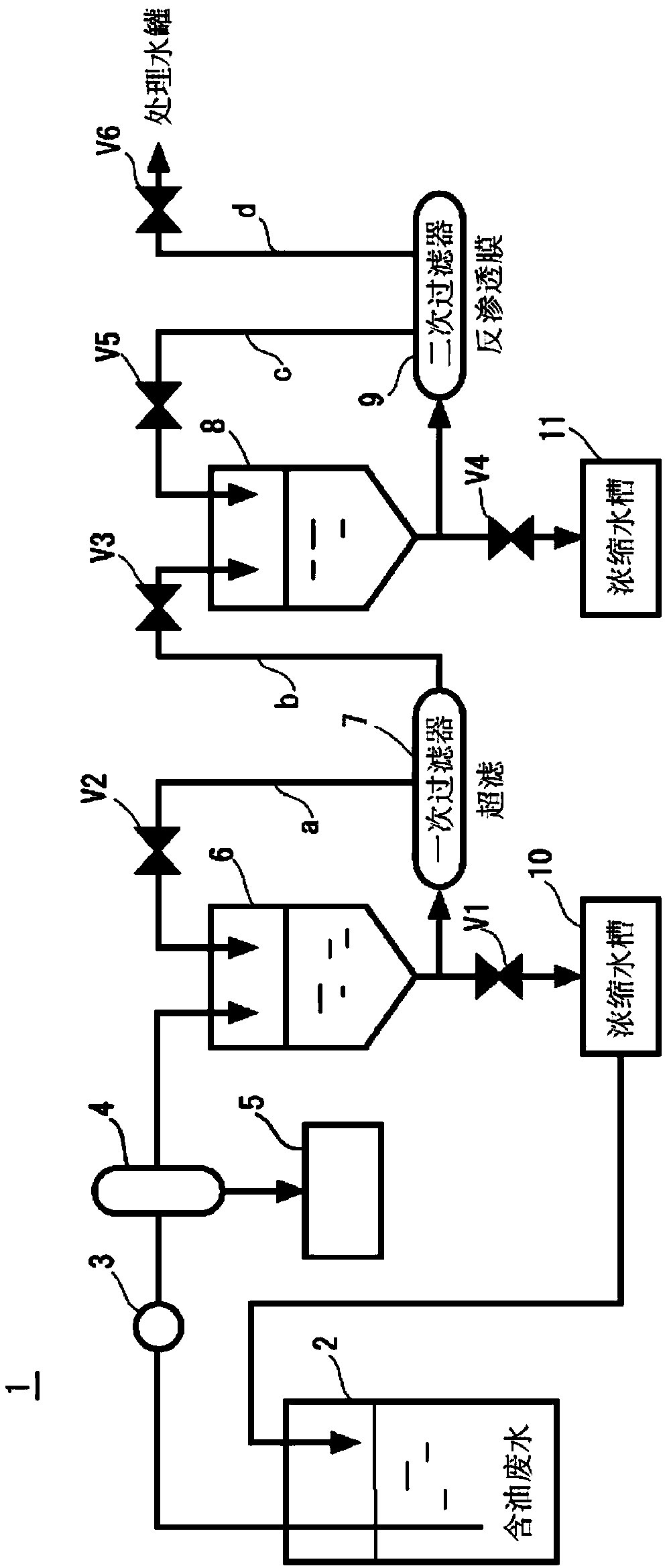

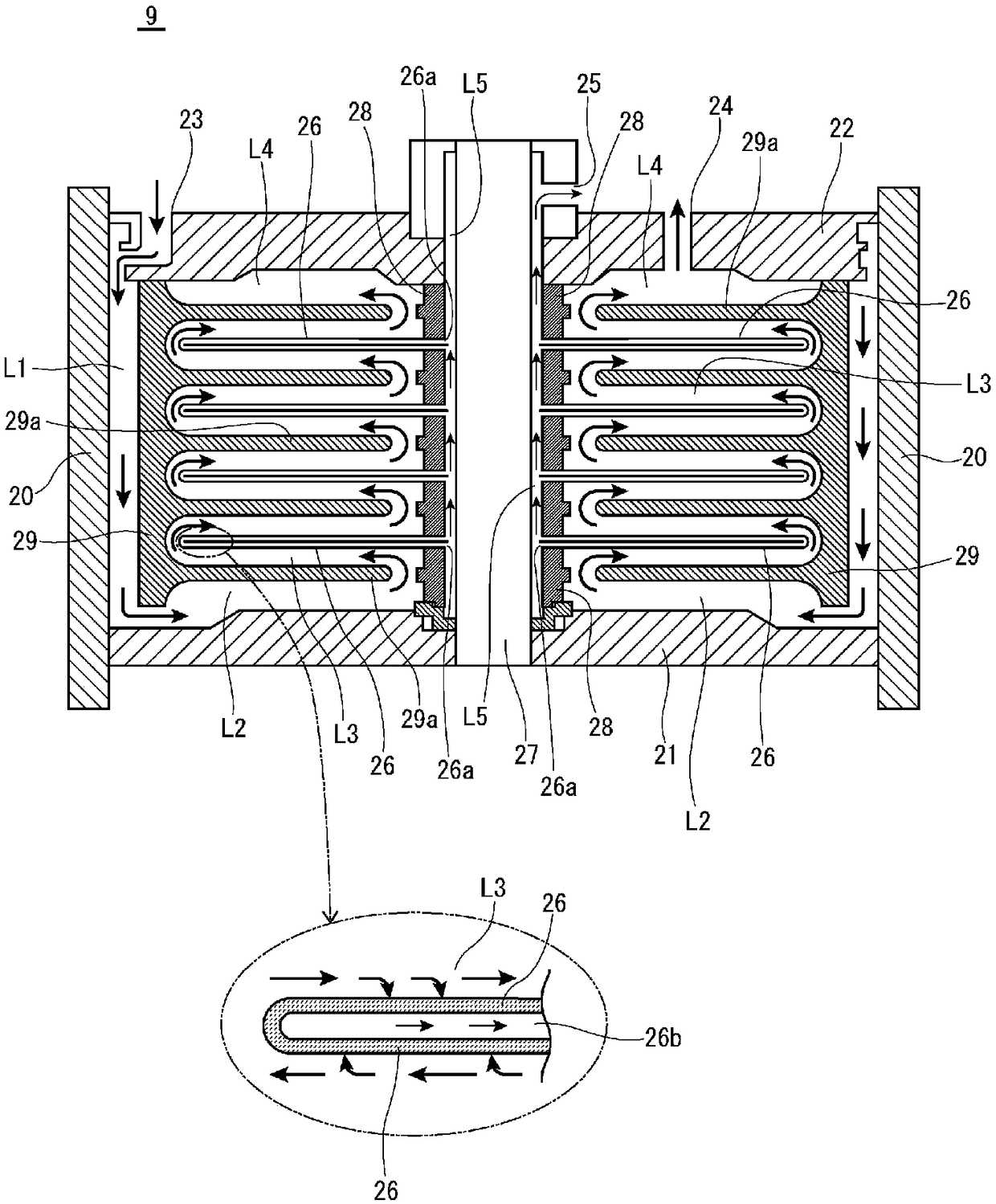

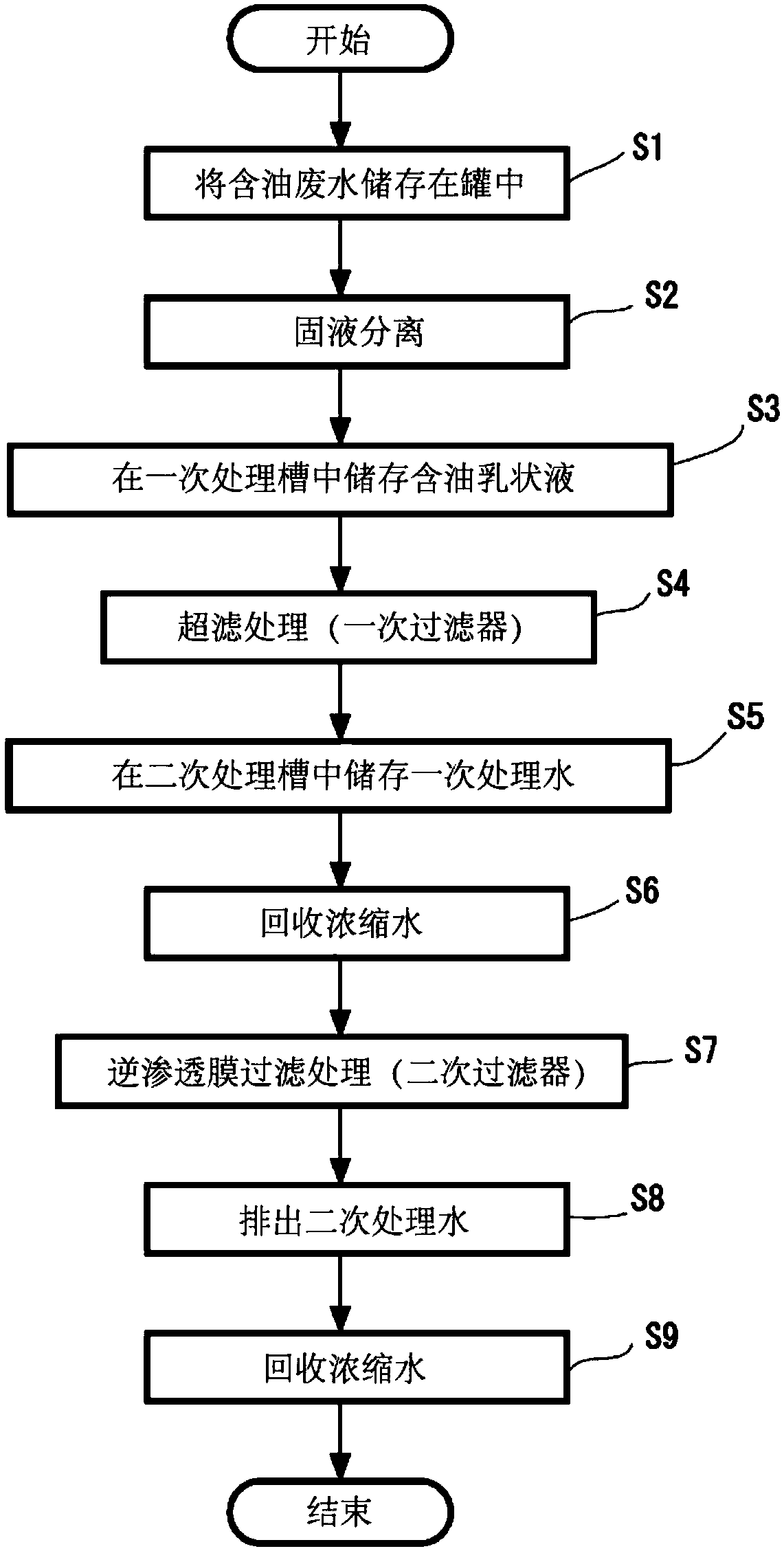

Oily wastewater treatment device and oily wastewater treatment method using same

InactiveCN109311705AAvoid cloggingInhibition of attachmentUltrafiltrationReverse osmosisEmulsionFiltration

Provided are an oily wastewater treatment device that can process smoothly, can reduce costs for processing, and can perform wastewater treatment capable of purifying water to a level below the release standard value for public waters with little impact on the environment and an oily wastewater treatment method using same. An oily wastewater treatment device 1 comprises: a primary filter unit 7 that performs ultrafiltration on an oil-containing emulsion contained in oil-containing wastewater and that separates the oil-containing emulsion into an oil component and primary treated water; and a secondary filter unit 8 that performs a filtration treatment using a reverse osmosis membrane on the primary treated water separated by the first filter unit and that separates the primary treated water into low-molecular-weight impurities that were not removed by the primary filter unit and secondary treated water. The primary filter unit 7 is a filter having an ultrafiltration membrane filter structure of a tubular membrane type or a spiral membrane type, and the secondary filter unit 8 is a filter having a filter structure in which a plurality of disk-shaped reverse osmosis membranes is stacked.

Owner:AZTECH CORP

Novel window frame with heat and humidity treatment function

PendingCN110500003AGuaranteed qualityFull heat and moisture exchangeLighting and heating apparatusVentilation arrangementAir blowerSpiral membrane

The invention discloses a novel window frame with a heat and humidity treatment function. The novel window frame mainly structurally comprises a spiral membrane pipe, an exhaust sleeve pipe, a windowframe, a gas distribution pipe assembly, a fan assembly, a shutter assembly and the like. According to the sleeve type novel window frame, a fresh air pipe is of a spiral structure design, is made ofa high-molecular heat-humidity exchange membrane in a combined hemp rope form and is combined with the window exhaust sleeve pipe to constitute a spiral sleeve pipe type structure, and high-efficiencyheat-humidity exchange between indoor fresh air and outdoor exhausted air is realized under the action of an air blower and an exhaust fan; the investment cost of equipment is effectively reduced dueto the combination of heat-humidity equipment which is simple and easy and a window frame structure; and due to the combination of an internal structure of the window frame and a building structure,the equipment operation efficiency is improved, the heat exchange volume is saved, and meanwhile, the quality of indoor air is ensured.

Owner:北京世纪天创智业系统集成技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com