Impeller water-spraying oxygen-increasing machine

An aerator and water spray technology, applied in fish farming, application, animal husbandry, etc., can solve the problems of easy water leakage and tripping, low aeration capacity, motor overload and burnout, etc., so as to avoid impeller damage and improve oxygenation. ability, the effect of increasing the oxygenation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

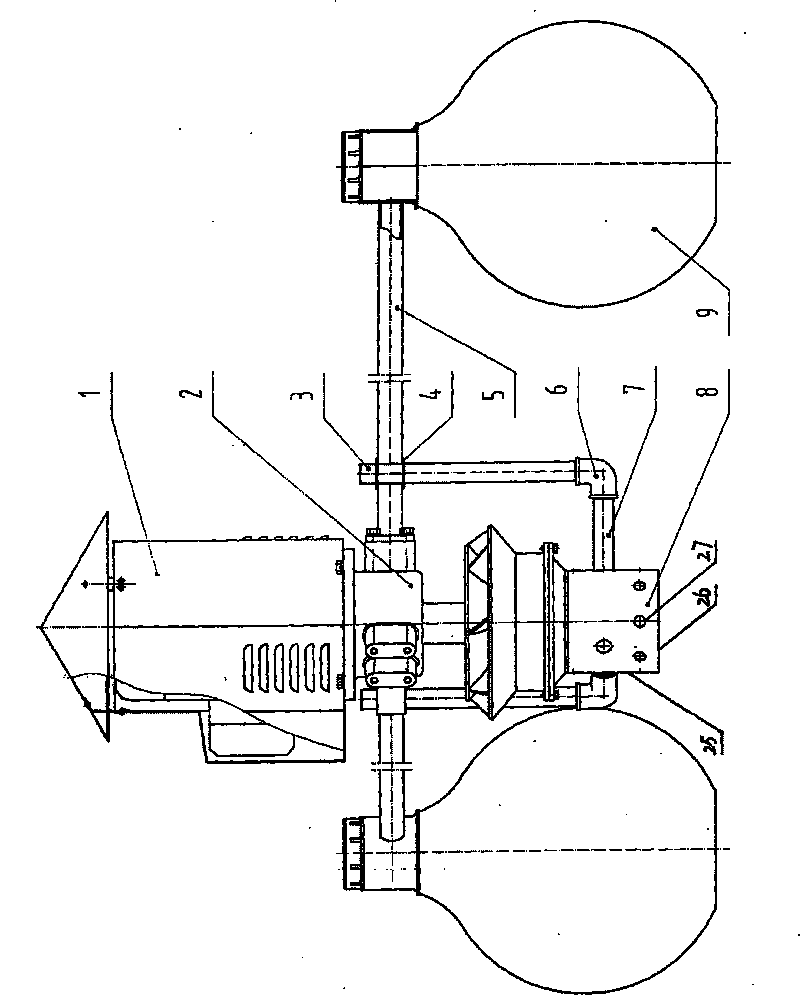

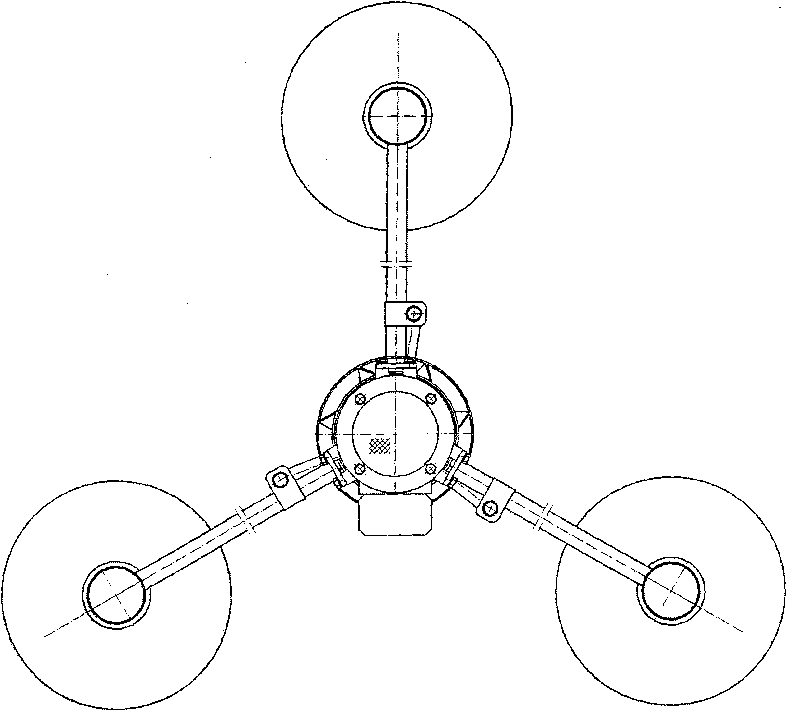

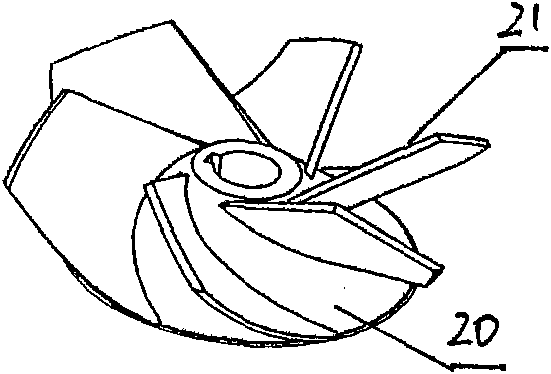

[0021] Such as Figure 1-6 As shown, the impeller water jet aerator comprises a motor 11, a support body 2, a support rod 5, a floating ball 9, an impeller shaft 14 and an impeller 18, and the motor 11 is installed above the support body 2, and three One end of the supporting rod 5 is connected in equal parts, a floating ball 9 is installed on the other end of the supporting rod 5, an impeller shaft 14 is installed on the shaft of the motor 11 through a coupling 13, and an impeller 18 is installed on the impeller shaft 14, and the characteristics are as follows: The water outlet body 16 is installed below the support body 2, the impeller shaft 14 passes through the center of the water outlet body 16, the water inlet cover 8 is installed under the water outlet body 16, and the impeller 18 is located in the cavity formed by the water outlet body 16 and the water inlet cover 8 .

[0022] In the impeller water jet aerator of the present invention, the impeller 18 is formed as a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com