High-efficiency energy-saving thermal deaerator

A technology of thermal deaeration, high efficiency and energy saving, applied in the field of machinery, can solve the problems of thermal deaerators with poor deoxygenation effect, oxygen dissolution, and failure to meet industrial practical requirements, etc. Small, stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

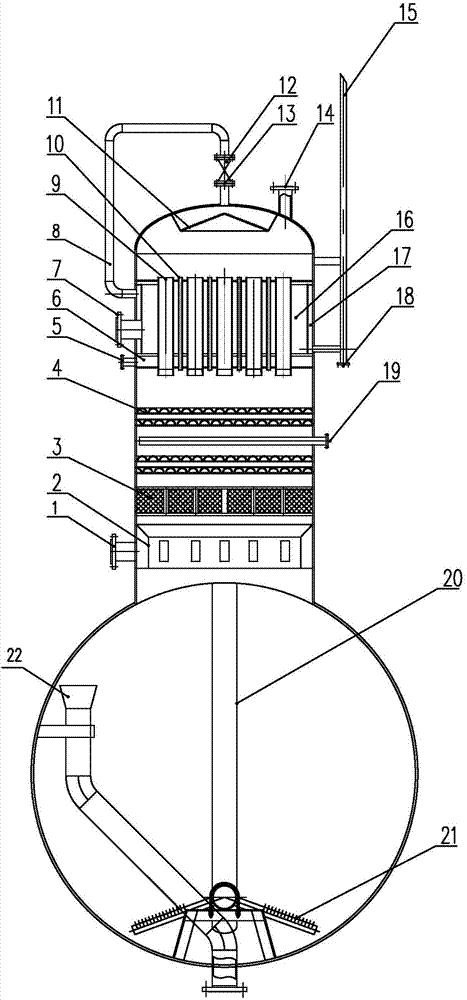

[0018] Such as figure 1 As shown, the high-efficiency energy-saving thermal deaerator according to the present invention includes a cylindrical shell, and the steam-water separator 11, the membrane spinner group, the water spray grate, the filling liquid vapor network, the steam The distribution plate and the water tank, and the film spinner group include a supply water chamber 16, a fixed steam chamber 6 under the supply water chamber 16, a water film tube 9 and a steam riser tube 10 are arranged on the supply water chamber 16 and the steam chamber 6, and exhaust pipes are arranged at the ends of the supply water chamber 16 and the steam chamber 6. The steam heating chamber 17, the upper end of the water film tube 9 is drilled with jet holes distributed along the helix, the lower part is provided with the jet hole for adjusting the shape of the water film commu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com