Patents

Literature

154results about How to "Improve oxygen removal effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zero oxygen permeation plastic bottle for beer and other applications

InactiveUS6365247B1Increased molecular weightImprove intrinsic viscosityLayered product treatmentBottlesCopolyesterChemistry

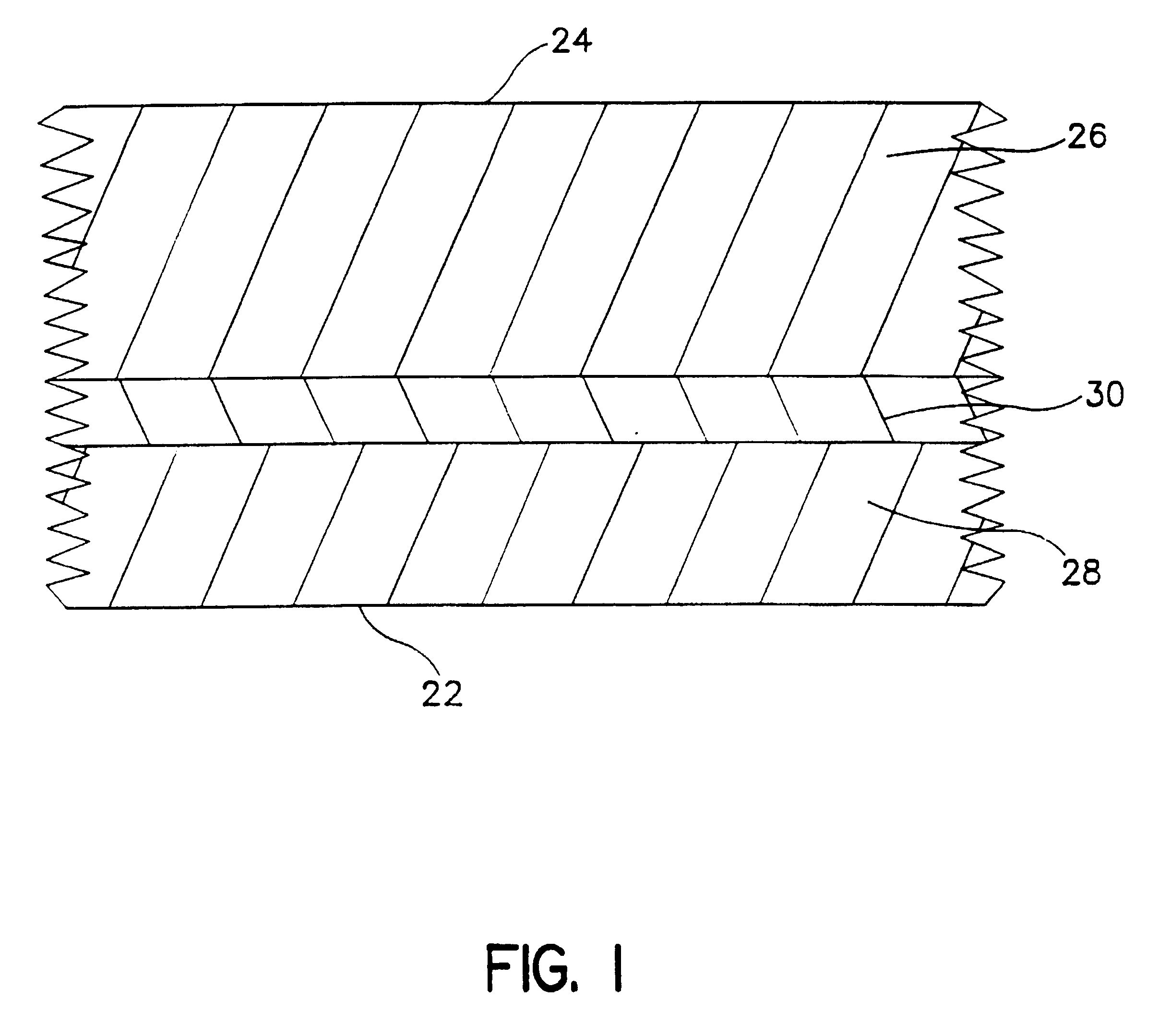

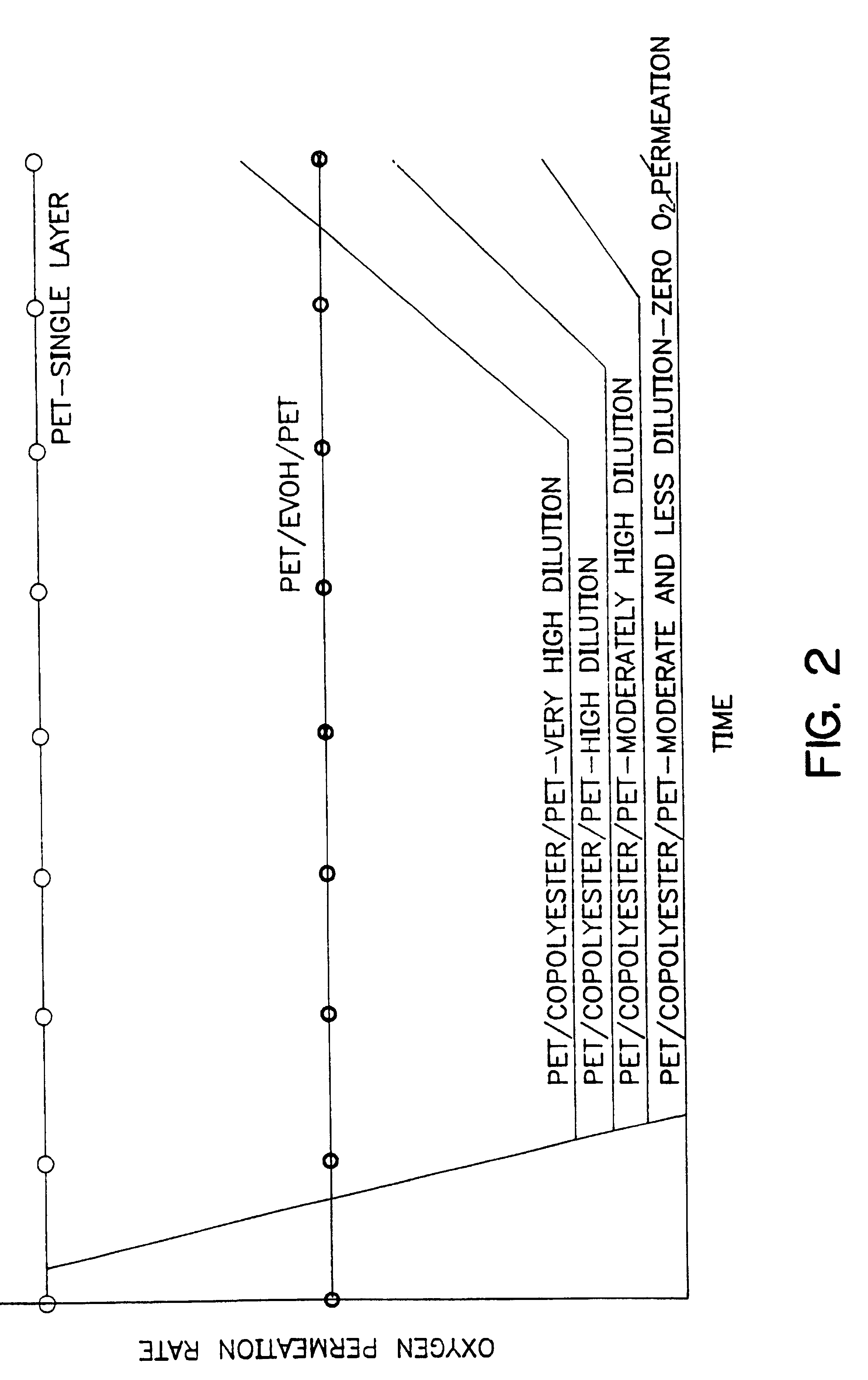

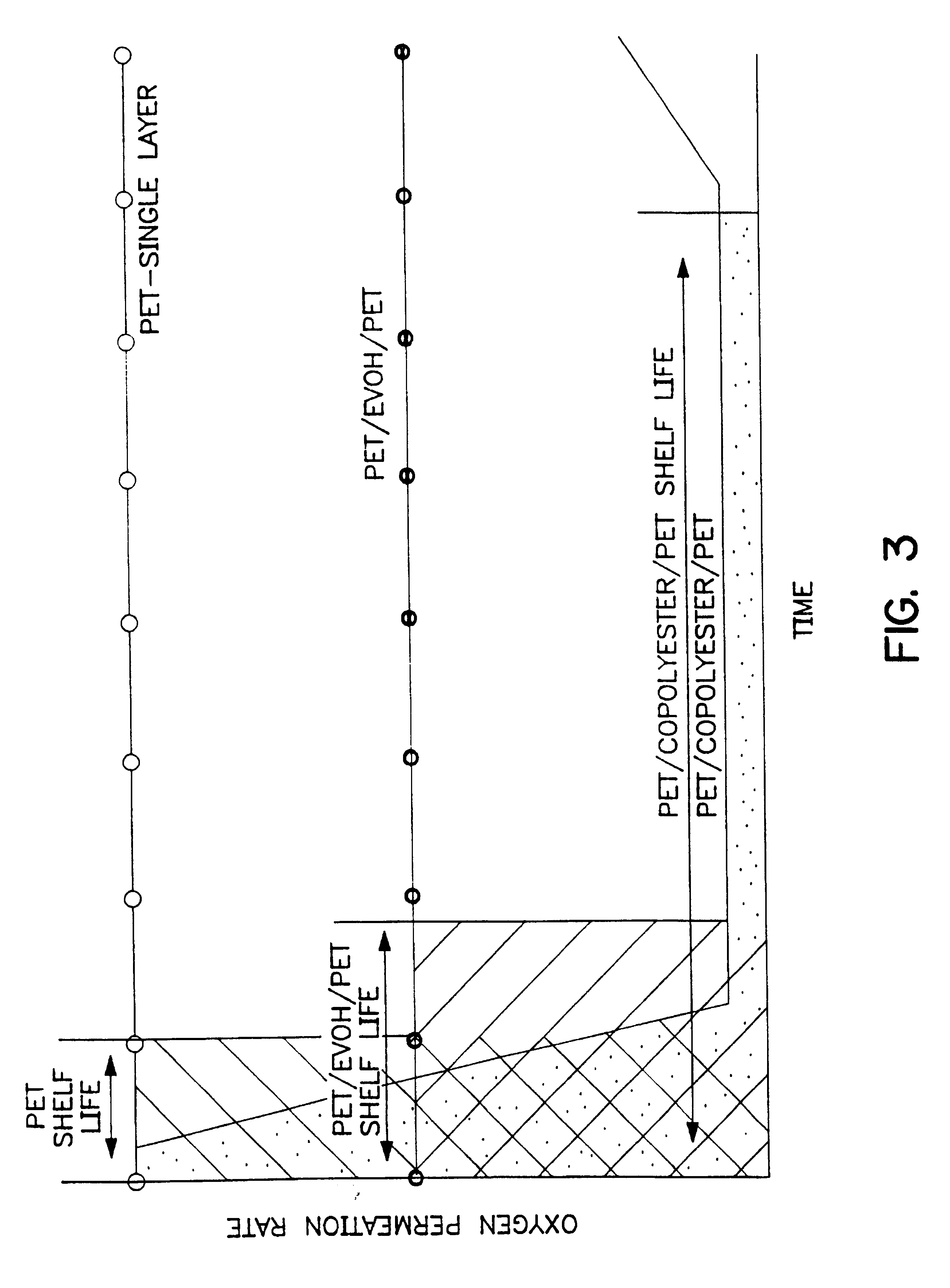

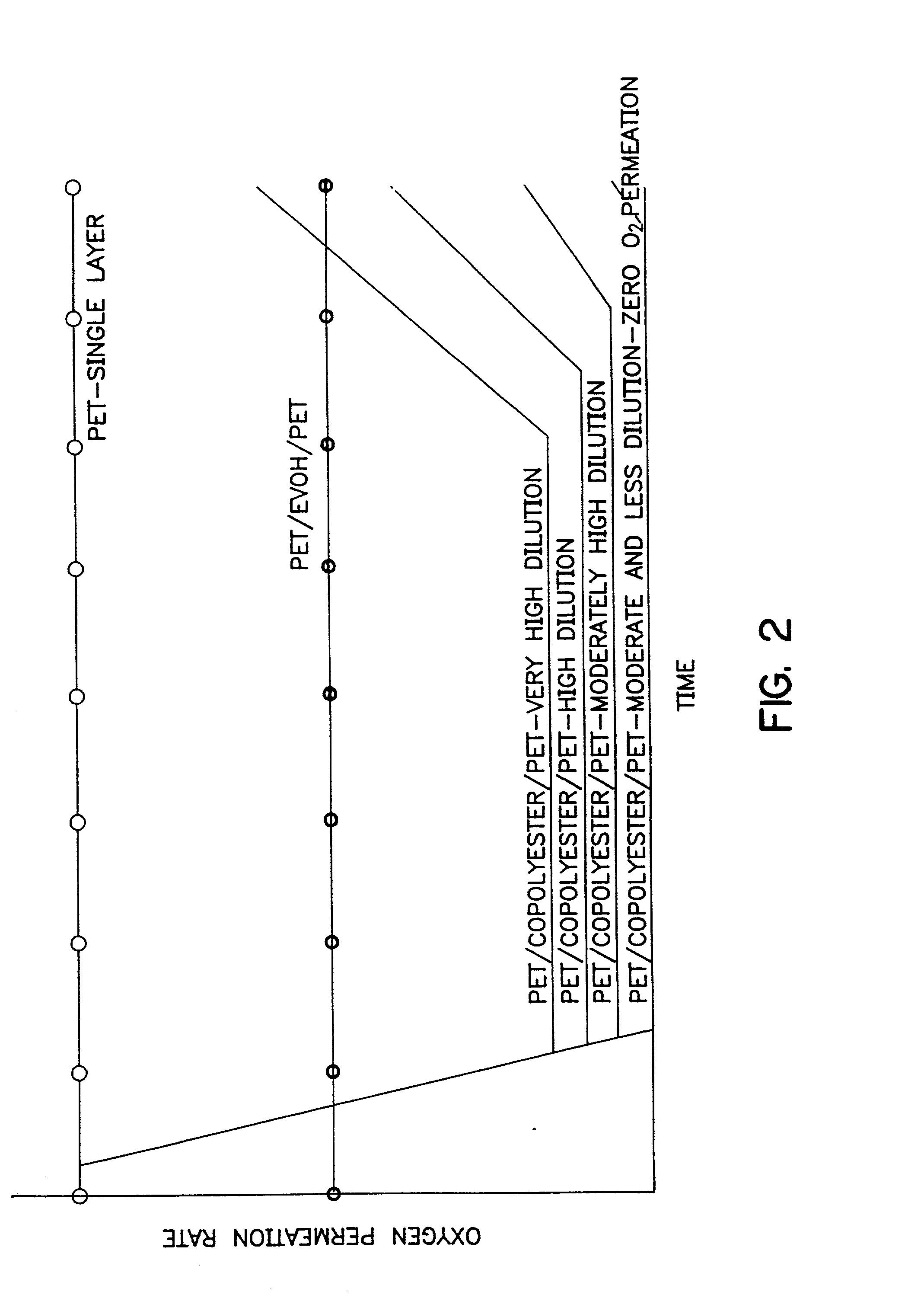

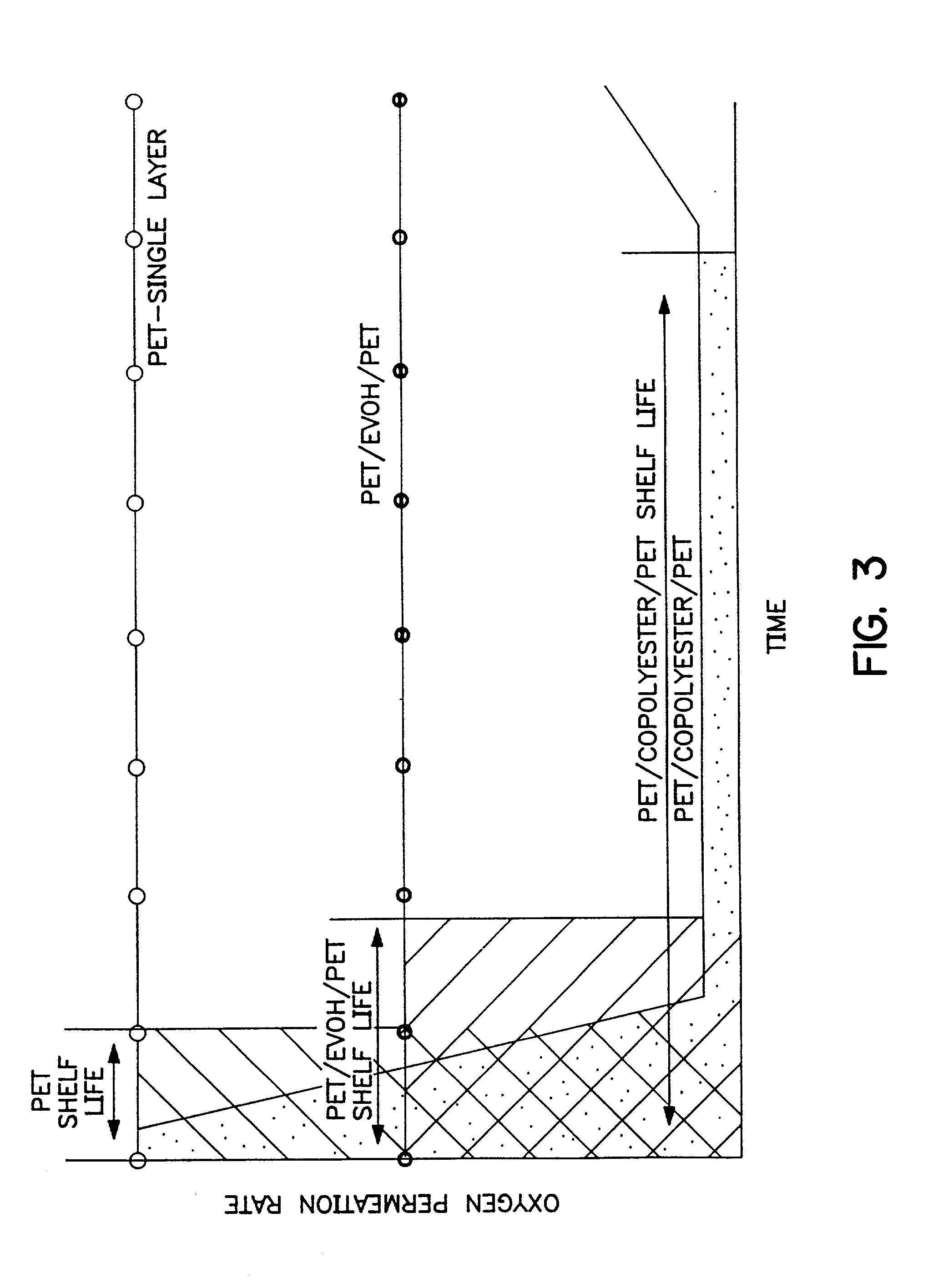

Multilayered plastic bottles are disclosed having oxygen scavenging capacity sufficient to maintain substantially zero or near zero (depending on product requirements) presence of oxygen in the bottle cavity for the planned shelf life of the bottled product under specified storage conditions. The bottles feature a layer comprised of oxygen scavenger copolyester and may be used for bottling beer and other products requiring nearly total absence of oxygen for the duration of the target product shelf life.

Owner:COLORMATRIX HLDG +1

Zero oxygen permeation plastic bottle for beer and other applications

InactiveUS20020155236A1Improve oxygen removal effectRapid responseLayered product treatmentBottlesCopolyesterPermeation

Multilayered plastic bottles are disclosed having oxygen scavenging capacity sufficient to maintain substantially zero or near zero (depending on product requirements) presence of oxygen in the bottle cavity for the planned shelf life of the bottled product under specified storage conditions. The bottles feature a layer comprised of oxygen scavenger copolyester and may be used for bottling beer and other products requiring nearly total absence of oxygen for the duration of the target product shelf life.

Owner:COLORMATRIX HLDG

Novel water treatment method for boiler feedwater

ActiveCN102344215AAvoid breedingDecreased water conductivityGeneral water supply conservationMultistage water/sewage treatmentChlorine dioxideUltrafiltration

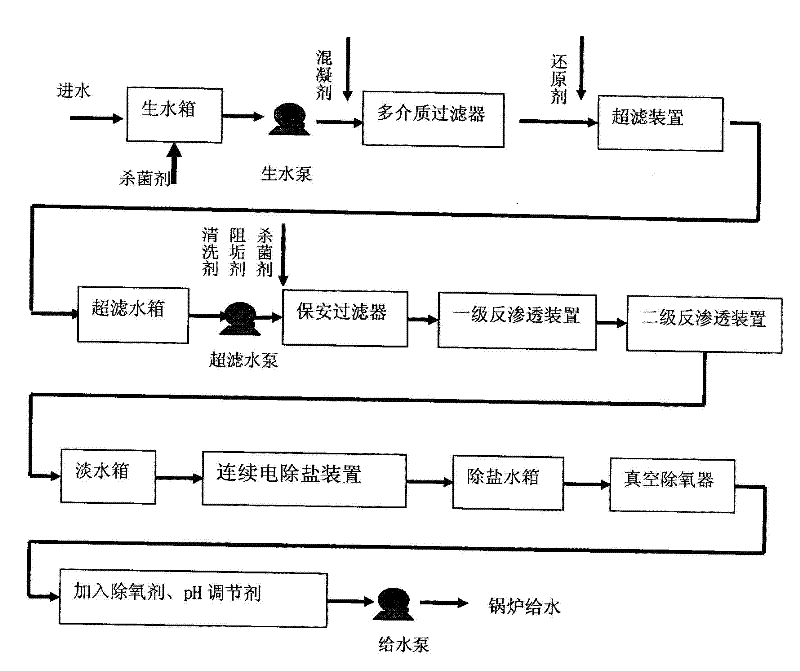

A novel water treatment method for boiler feedwater of the invention comprises the following steps: sterilization, that is adding liquid chlorine, sodium hypochlorite or stabilized chlorine dioxide into a raw water tank, controlling the residual chlorine amount in water to be 0.2-0.5 mg / L; filtration, that is adding a polyaluminium chloride coagulant before a multimedium filter with an amount of 10-20 mg / L, controlling the water turbidity of the ultrafiltration feedwater to be not more than 0.1 NTU and the SDI to be not more than 3; adding a reducing agent of sodium bisulfite before ultrafiltration with an adding amount of 3-5 mg / L; reverse osmosis, that is performing desalination treatment by a reverse osmosis membrane device, continuously adding a PTP-0100 scale inhibitor before a security filter with an adding amount of 3-5 mg / L; continuously adding a Micro Treat BIO bactericide with an adding amount of 3-5 mg / L; additionally adding cleaning agents of Dimamite and High Flux once a month with an amount of 3-5% of the water amount to be produced; desalination, that is performing desalination by an electrical desalination system (EDI); deoxygenation, that is performing deoxygenation by a vacuum deoxygenator, adding 10-20 microgram / L of deoxidants, controlling the agent residual amount to be 5-20 microgram / L, adding a corrosion-inhibiting pH regulator to control the pH value to be 8.8-9.3.

Owner:XINJIANG DELAND

Denitration catalyst regeneration solution and preparation method thereof as well as catalyst regeneration method

ActiveCN103949291AGood water solubilityImprove catalytic performanceCatalyst regeneration/reactivationIonCopper nitrate

The invention discloses a denitration catalyst regeneration solution and a preparation method thereof as well as a catalyst regeneration method. The denitration catalyst regeneration solution comprises the following raw material ingredients in parts by weight: 4-6 parts of vanadyl oxalate, 0.08-0.10 part of cerium nitrate, 0.11-0.13 part of lanthanum nitrate, 0.05-0.07 part of copper nitrate, 0.4-0.6 part of silica sol ST-O and 95 parts of deionized water. The catalyst regeneration method comprises the following steps of firstly, evenly mixing vanadyl oxalate and the deionized water; then, feeding cerium nitrate, lanthanum nitrate and copper nitrate into mixed solution, and fully stirring until the mixture is completely dissolved; finally, feeding silica sol ST-O, and continuing to stir until homogeneous phase is obtained; and sequentially carrying out strong scavenging and ultrasonic cleaning on an inactivated denitration catalyst module, soaking the module in cleaning solution for 18-25 minutes, continuing soaking the module in the regeneration solution for 25-40 minutes, taking out the denitration catalyst module and drying. After the denitration catalyst regeneration solution and the catalyst regeneration method are adopted, the activity of the inactivated denitration catalyst can be efficiently recovered, and the temperature range of the catalyst activity is widened.

Owner:江苏万德环保科技有限公司

Resin for Oxygen-absorbing Adhesive and Oxygen-absorbing Adhesive

InactiveUS20130143734A1Improve oxygen removal effectLow costNon-macromolecular adhesive additivesOther chemical processesPolyesterPolymer science

The purpose of the present invention is to provide a two-component curable oxygen-absorbing resin composition that has both oxygen-absorbing and adhesive properties and cohesive power. The resin for an oxygen-absorbing adhesive is a polyester comprising structural units derived from an acid component (A) and an acid component (B), wherein the ratio of the acid component (A) to total acid components is 70 to 95 mol %, the ratio of the acid component (B) to total acid components is 0 to 15 mol %, the polyester has a glass transition temperature of −20° C. to 2° C., the resin is cured using a hardening agent, the acid component (A) is tetrahydrophthalic acid or a derivative thereof, or tetrahydrophthalic acid anhydride or a derivative thereof, and the acid component (B) is phthalic acid.

Owner:TOYO SEIKAN GRP HLDG LTD

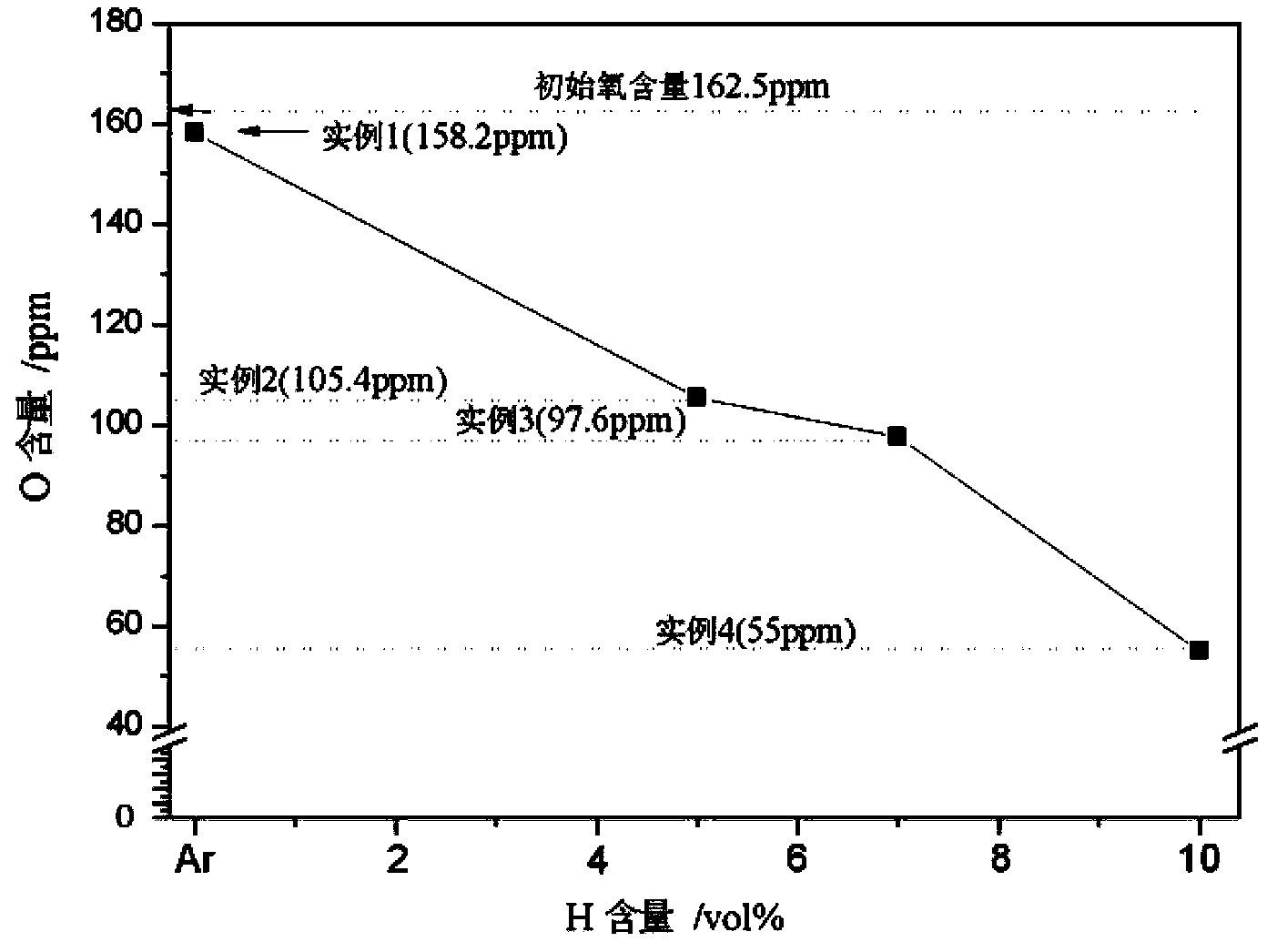

Novel method for utilizing hydrogen plasma electric arc melting technology to prepare high-purity rare earth gadolinium elementary substance

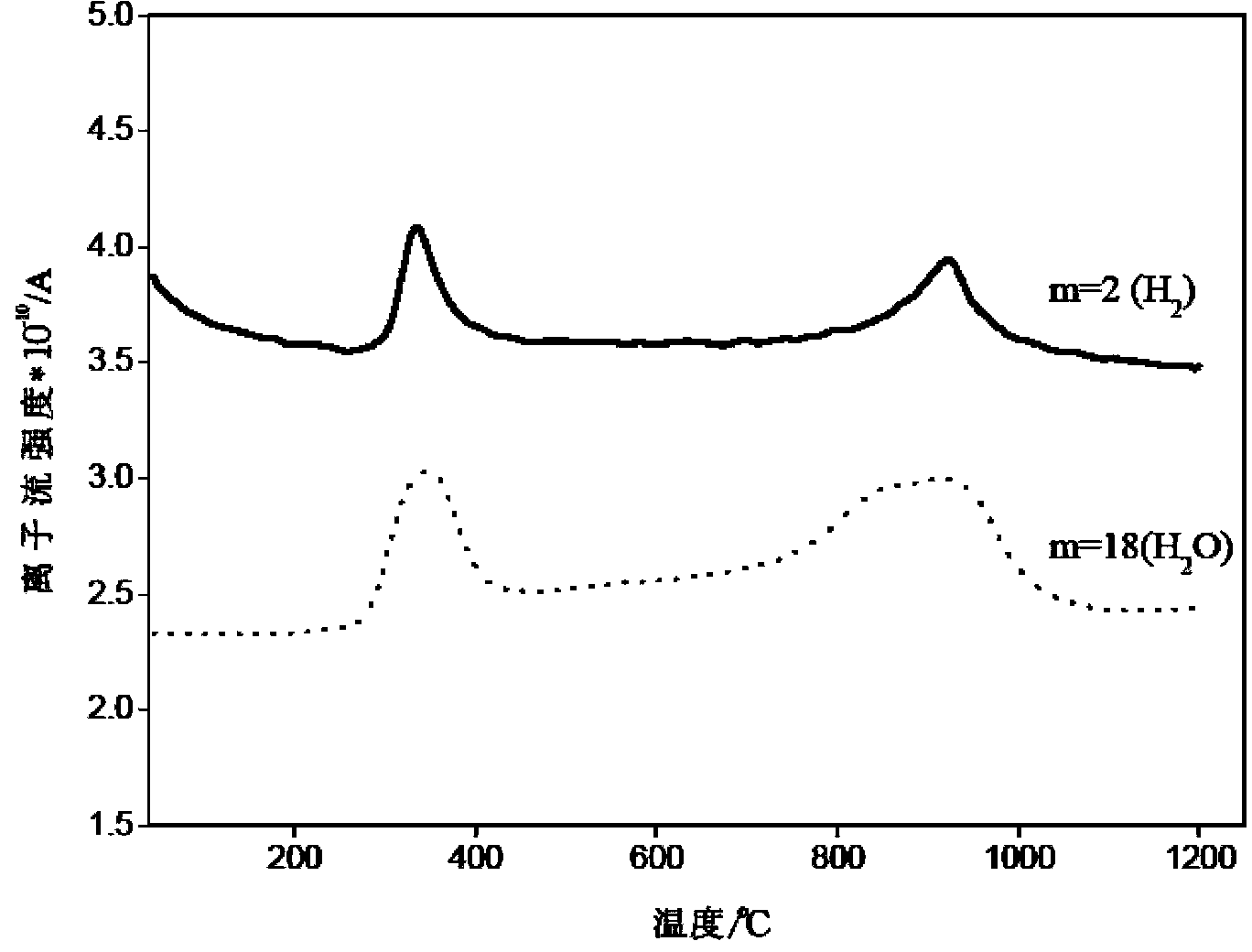

The invention discloses a novel method for utilizing hydrogen plasma electric arc melting technology to prepare a high-purity rare earth gadolinium elementary substance. The novel method comprises the following steps: firstly, taking high-purity argon gas as a plasma source, smelting a metal sample in a plasma electric arc melting furnace into a regular shape, and removing impurities adhered to the surface of the metal sample; secondly, replacing the argon gas atmosphere, injecting a proper amount of hydrogen into a cavity, generating electric arcs through argon gas and hydrogen both as plasma sources, repeatedly turning over and smelting, and effectively removing oxygen element in elemental gadolinium by utilizing the extremely-strong reducibility of hydrogen atoms at high temperature so as to obtain the high-purity oxygen-free gadolinium finally. The novel method is simple in process, high in preparation speed and remarkable in cleaning effect, can be widely used for preparing high-purity or superhigh-purity rare earth function materials and has a vital application value.

Owner:PEKING UNIV

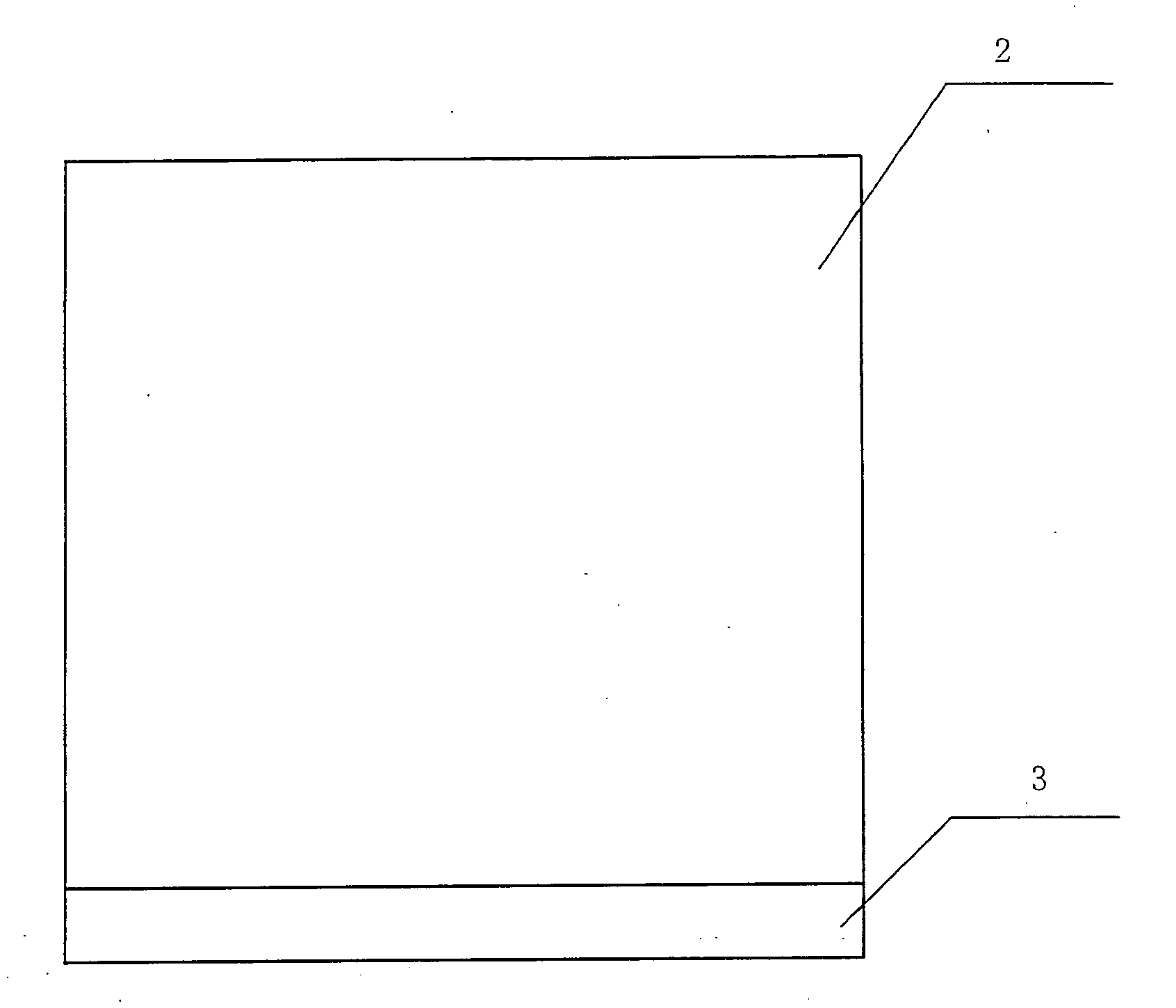

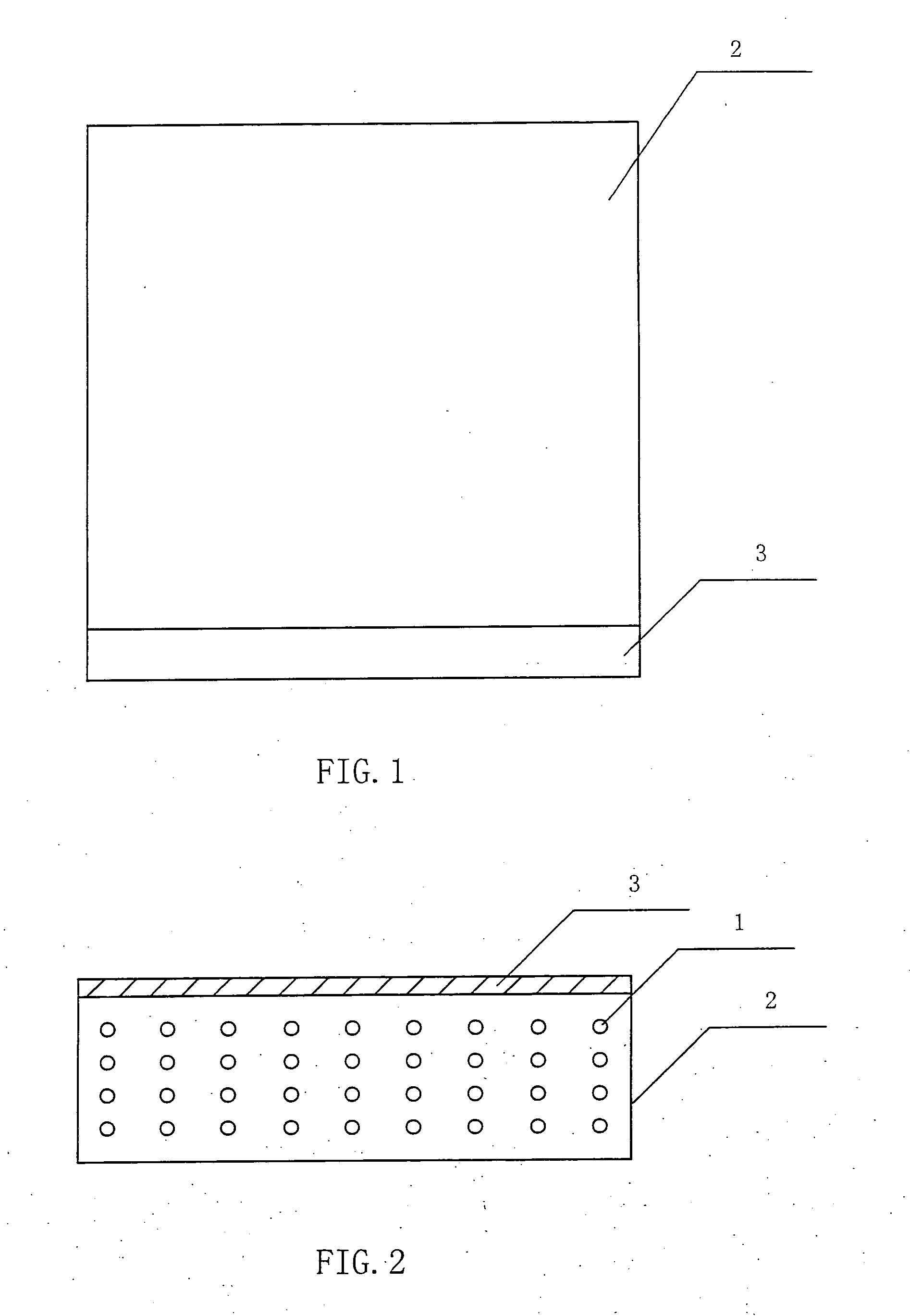

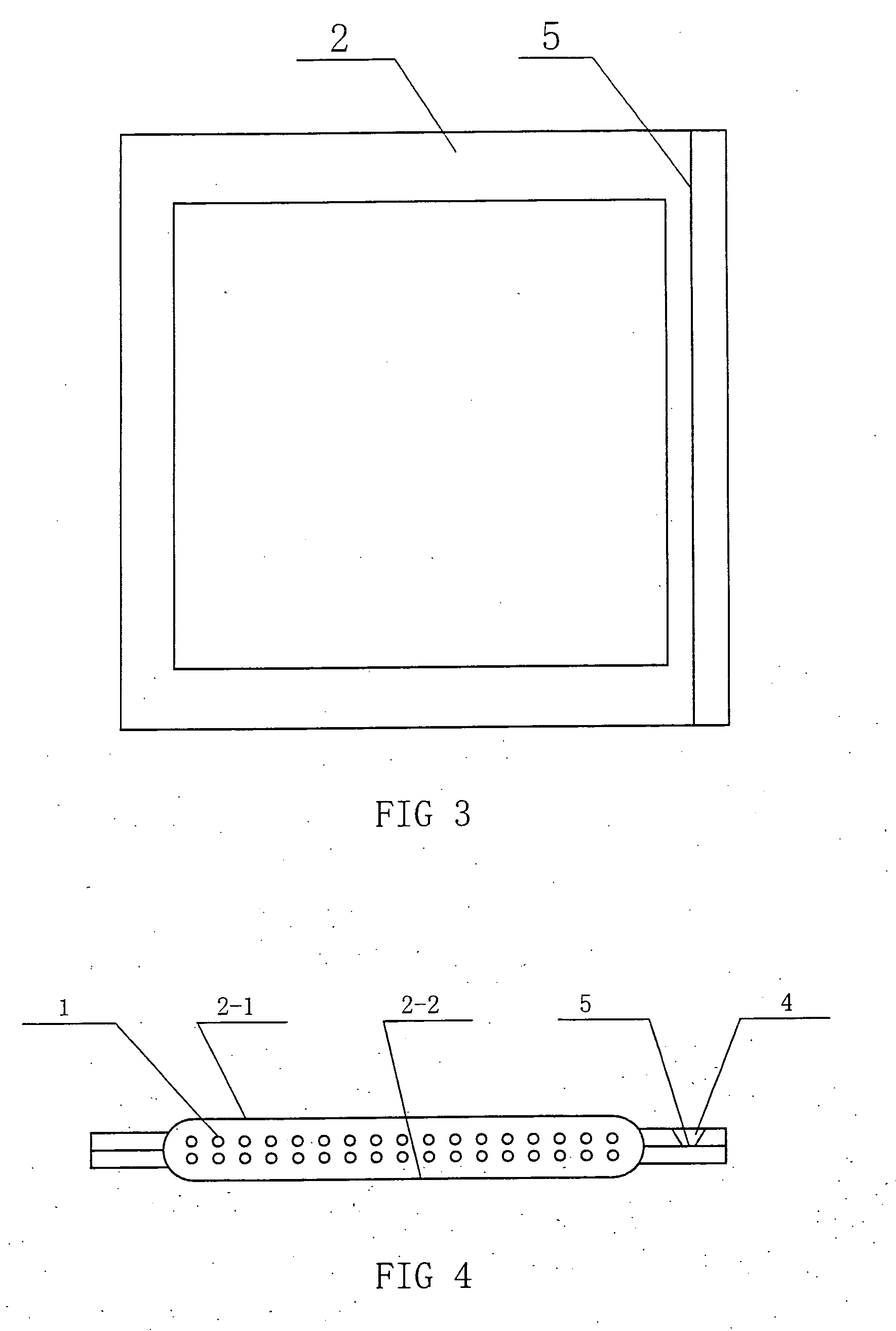

Intelligent oxygen scavenger with oxygen level indication

InactiveUS20060147340A1Quickly seeEasy to produceMicrobiological testing/measurementFood preservationBiologyOxygen level

An intelligent oxygen scavenger with oxygen level indication is provided, comprising an oxygen scavenger (1) and a packing bag (2). The oxygen scavenger (1) is contained in the packing bag (2), wherein the packing bag (2) is provided with a marker for color changing substance oxygen level indicator and an observation window (4) is provided in a position corresponding to the oxygen level indicator. The marker for the oxygen level indicator can be an oxygen level indicating layer or an oxygen level indicating line, etc. The packing bag (2) comprising inner packing film (6) and outer packing film (7) on both of which vent pores (61, 71) arranged in staggered manner are provided. Observation window (4) is transparent in a shape of continuous lines, dotted lines, round shape or strip like. Inner packing film (6) and outer packing film (7) are made of CPP of PE provided with vent pores, complex films of PET / CPP or PET / PE provided with vent pores. The object of the present invention is to provide an oxygen scavenger with oxygen level indication that will make a manufacture or a user to rapidly see the effects of the freshness keeping and oxygen removal of the oxygen scavenger directly. Further, the user is able to rapidly see the oxygen level directly after the oxygen scavenger is used at the same time such intelligent oxygen scavenger with oxygen level indication is easy to produce with low production cost. Further, the intelligent oxygen scavenger with oxygen level indication according to the present invention can prevent the oxygen scavenger from escaping the packing bag with excellent oxygen removal effect and simple manufacturing process.

Owner:YANG YUANMEI

Boiler oxygen scavenger

InactiveCN104108761AImprove oxygen removal effectSimple conditions of useWater/sewage treatment by neutralisationWater/sewage treatment by degassingEnvironmental engineeringBoiler feedwater

The invention provides a boiler oxygen scavenger and a preparation method of the boiler oxygen scavenger. The boiler oxygen scavenger comprises an organic reducing agent, a dispersing agent, a passivating agent, a pH adjusting agent and water, where the mass ratio of the organic reducing agent to the dispersing agent to the passivating agent to the pH adjusting agent to water is (10-40): (1-10): (5-20): (5-10): (20-40). The invention also provides a preparation method of the boiler oxygen scavenger. The method comprises the steps of sequentially adding the organic reducing agent, the dispersing agent, the passivating agent, the pH adjusting agent and water in parts by mass in a reactor in which a stirrer is arranged, stirring and dissolving to obtain the product disclosed by the invention, the boiler oxygen scavenger disclosed by the invention is non-toxic and harmless liquid chemical agent and can be used in the condition that boiler return water is used as drinking water or comes into contact with food. The boiler oxygen scavenger disclosed by the invention has an excellent effect of removing dissolved oxygen out of the boiler feed water and also can greatly reduce the contents of copper and iron in the feed water system; and therefore the boiler oxygen scavenger can be widely used in the fields of high-pressure and medium-pressure boiler water treatment.

Owner:WEIHAI XIANGYU TECH

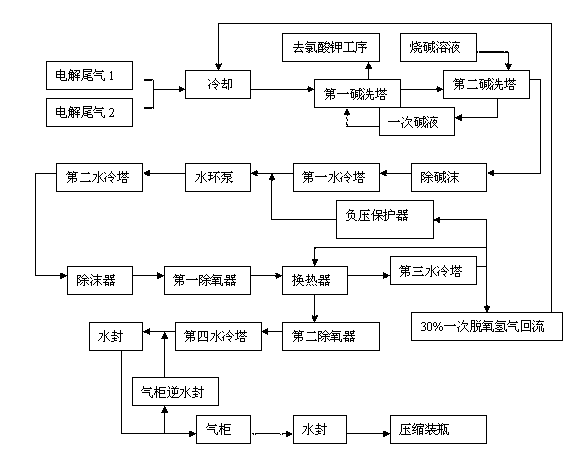

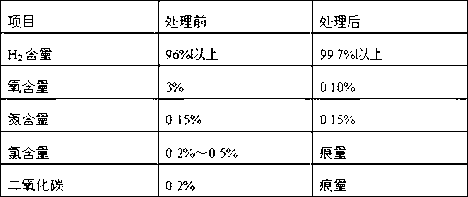

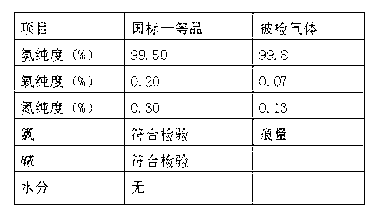

Method for recovering hydrogen from tail gas of chlorate electrolysis

The invention discloses a method for recovering hydrogen from tail gas of chlorate electrolysis. The method comprises the following steps of: removing chlorine and carbon dioxide; removing vapour; removing oxygen, namely, conveying the defoamed gas into a first oxygen remover, enabling hydrogen with oxygen to react to remove most of oxygen, conveying a high-temperature gas at 360-420 DEG C after oxygen removal into a heat exchanger to cool, conveying a cooled gas into a third water-cooling tower, conveying 70% (V / V) hydrogen into a heat exchanger tube to exchange heat with an inter-tube gas, increasing the temperature of the gas to a temperature of greater than 200 DEG C, conveying the gas into a second oxygen remover, reducing the content of oxygen in hydrogen to be less than 0.1%, and finally cooling to a temperature of lower than 30 DEG C via a fourth water-cooling tower and conveying hydrogen in a gas cabinet; and compressing and bottling the qualified hydrogen after being treated. The method disclosed by the invention is simple to operate during startup and shutdown, strong in adaptability, reasonable in process design, high in purity of the recovered hydrogen, higher in quality of hydrogen via secondary oxygen removal, and wider in the application of hydrogen and has an oxygen removal effect.

Owner:HEBEI YUSN CHEM GROUP

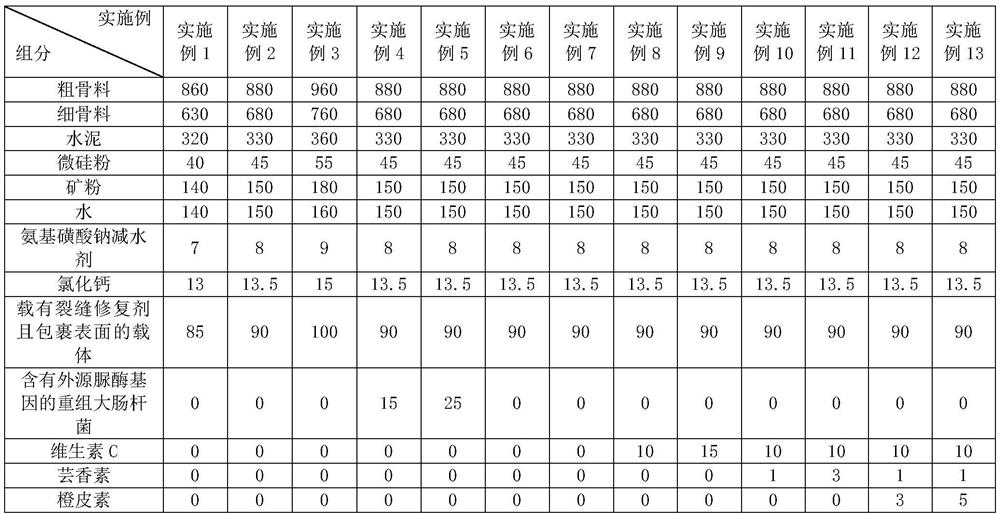

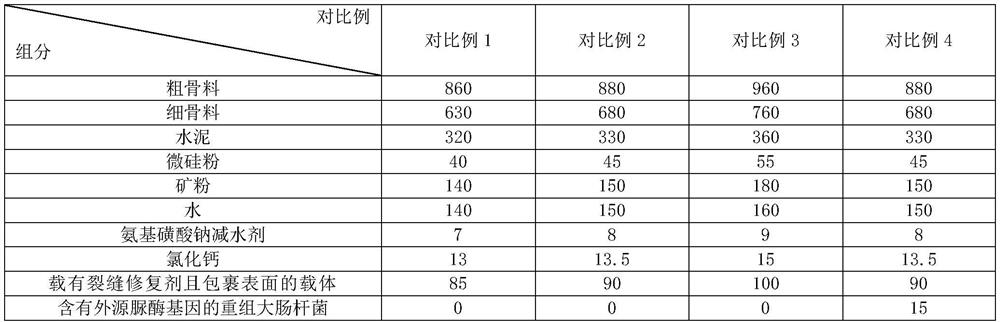

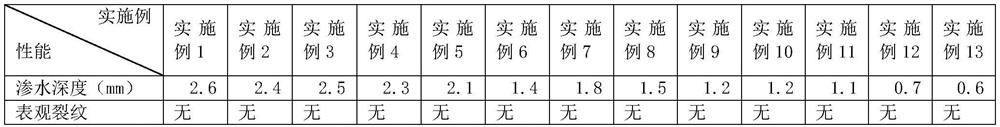

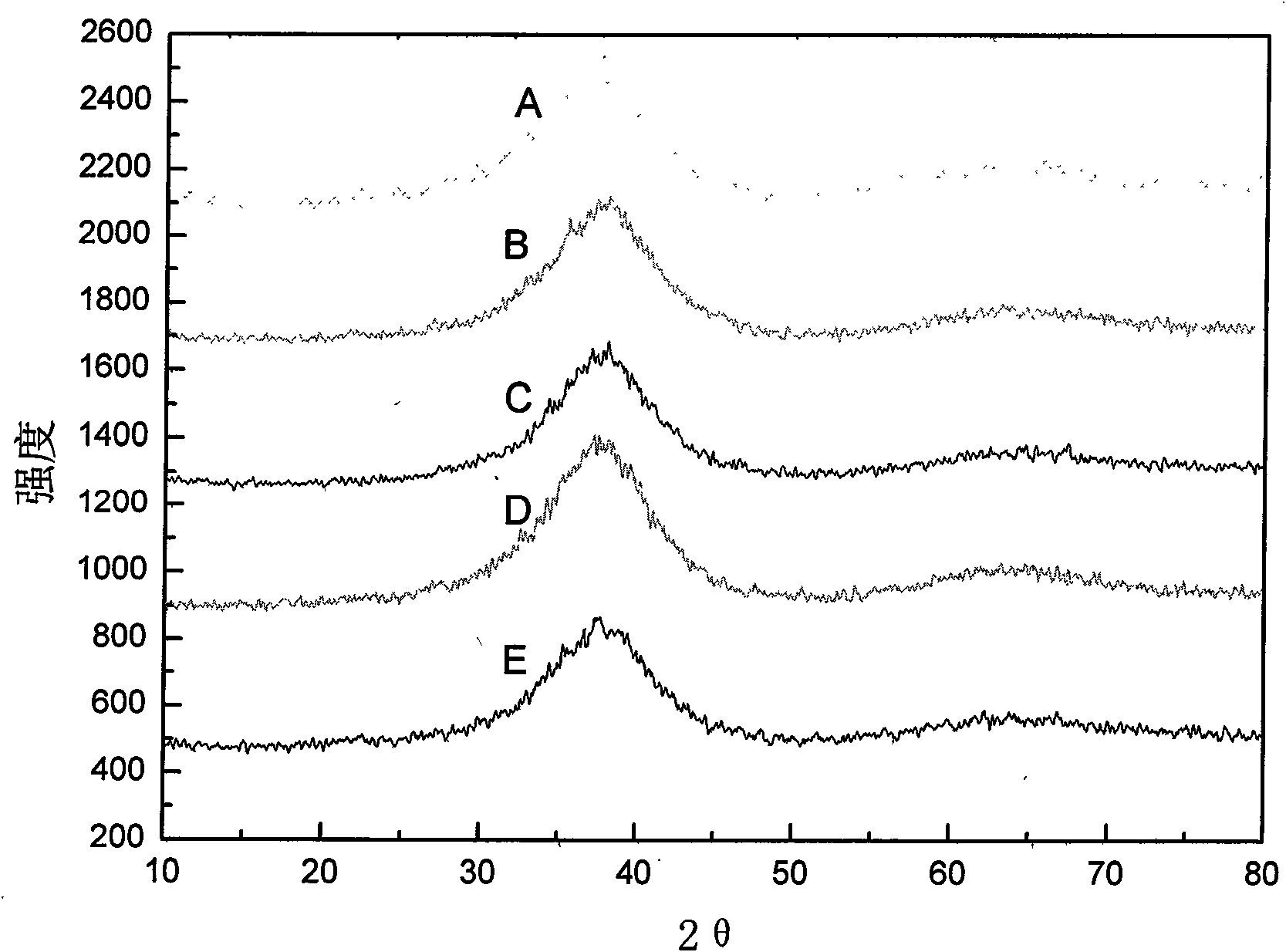

Microbial self-repairing concrete and preparation method thereof

The invention relates to the field of concrete, and particularly discloses microbial self-repairing concrete, which comprises the following components in parts by weight: 860-980 parts of coarse aggregate, 630-760 parts of fine aggregate, 320-360 parts of cement, 40-55 parts of silica fume, 140-180 parts of mineral powder, 140-160 parts of water, 7-9 parts of a sodium sulfamate water reducing agent, 11-13 parts of urea, 13-15 parts of calcium chloride, and 85-100 parts of a carrier, which is loaded with a crack repairing agent and has a coated surface, wherein the crack repairing agent is anaerobic bacillus pasteurii liquid. The microbial self-repairing concrete has the advantage that the concrete can be self-repaired after cracking in an anoxic environment.

Owner:陕西恒盛混凝土有限公司

Recovery method of zirconium based amorphous alloy

ActiveCN101684522AImprove flexural strengthReduce oxygen contentProcess efficiency improvementRare-earth elementRecovery method

The invention relates to a recovery method of zirconium based amorphous alloy, comprising the following steps: a. rust removal, oxide removal and degreasing treatment are carried out to a zirconium based amorphous alloy scrap; b. the processed scrap and additives containing rare earth elements are mixed according to proportion, and the mixture is vacuum-melted; c. the temperature of the melted mixture is reduced to 100-200DEG C above the melting point of the mixture, and then the temperature is insulated; d. the mixture is vacuum-melted again, the melted mixture is injected into a copper moldand is cooled under the protective gas, thereby obtaining the amorphous alloy ingot. The recovery method of zirconium based amorphous alloy can effectively reduce the oxygen content in the amorphous alloy scrap; meanwhile, the bending strength of an amorphous alloy sample can be effectively improved, so as to increase the critical size of the amorphous alloy sample.

Owner:CHANGSHU YISHENG COMMODITY

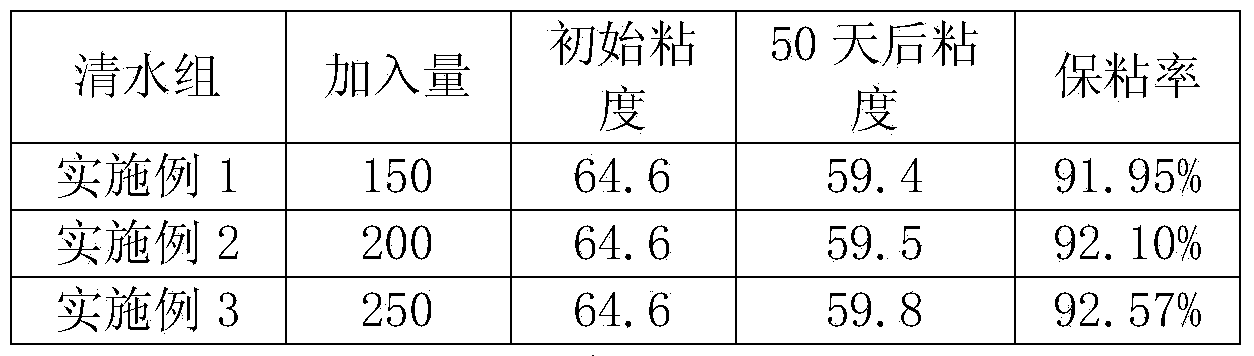

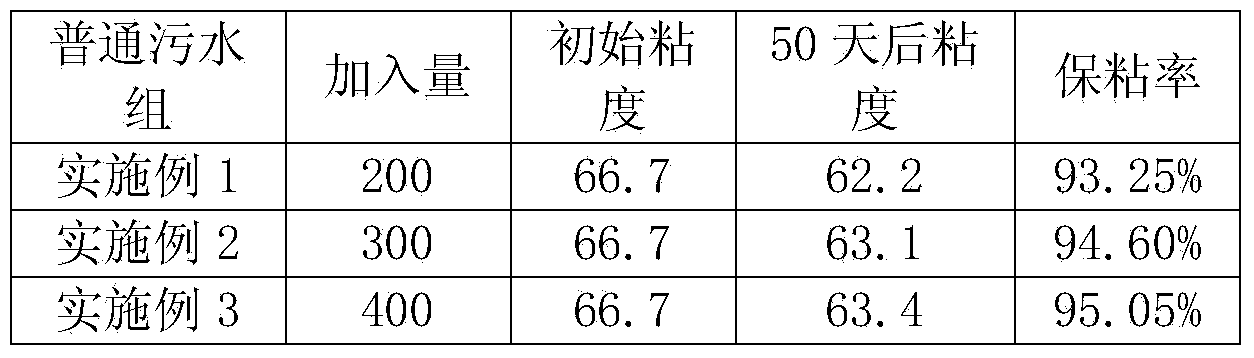

Viscosity stabilizing agent used for polymer flooding

ActiveCN103275679AImprove field application effectHigh viscosityDrilling compositionIsothiazolinoneEthylene diamine

A viscosity stabilizing agent used for polymer flooding is characterized by comprising components in percentage by mass as follows: 5%-8% of 2-mercapto benzimidazole, 2%-3% of hydroquinone, 10%-15% of sodium thiosulfate, 10%-15% of isothiazolinone, 5%-10% of glutaraldehyde, 6%-10% of isopropanol, 1%-2% of EDTA (ethylene diamine tetraacetic acid), and the balance of water. The viscosity stabilizing agent used for polymer flooding can improve viscosity stability of a polymer flooding system, the viscosity maintaining time is long, so that on the condition of oilfield wastewater preparation, the viscosity of the polymer flooding system maintains stable and is improved in a certain range, the field application effect of the polymer flooding is improved, the effect is remarkable, and the viscosity stabilizing agent is suitable for popularization and application.

Owner:DAQING HUAYING CHEM IND

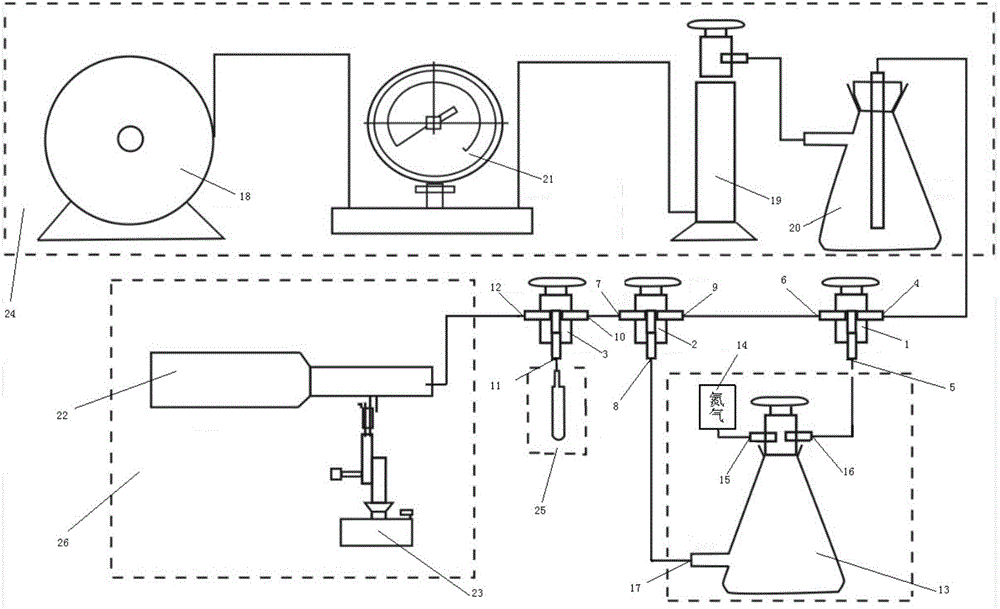

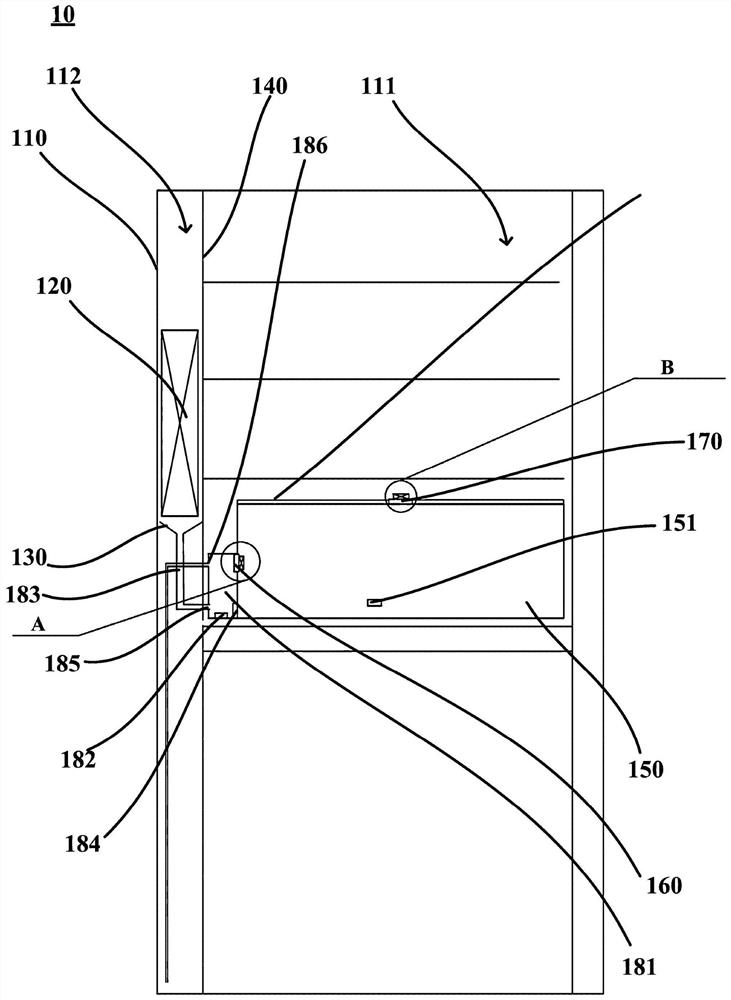

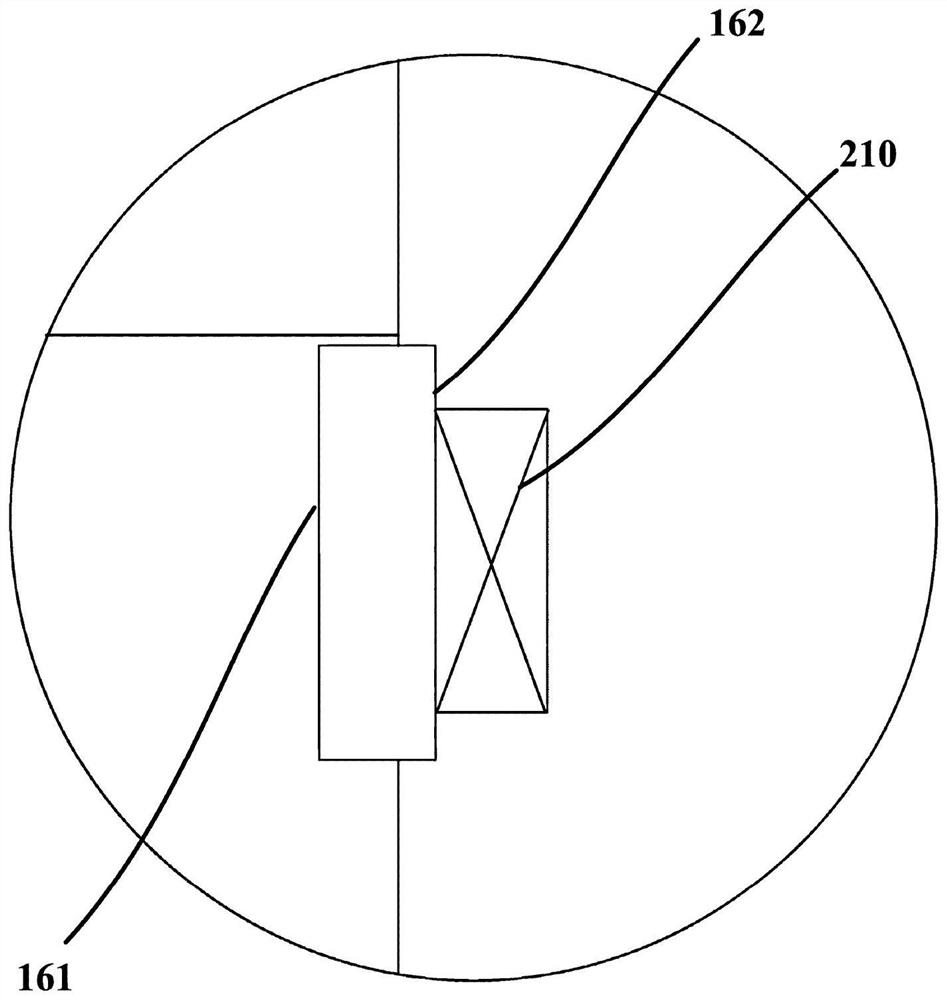

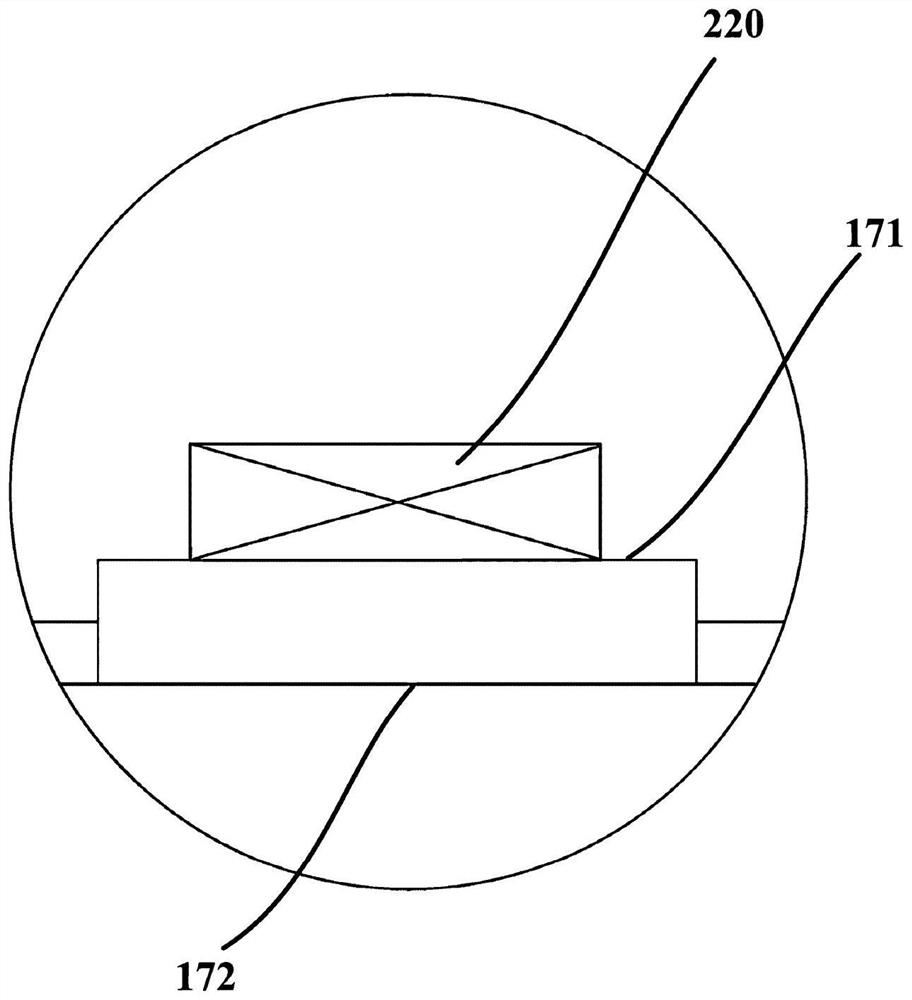

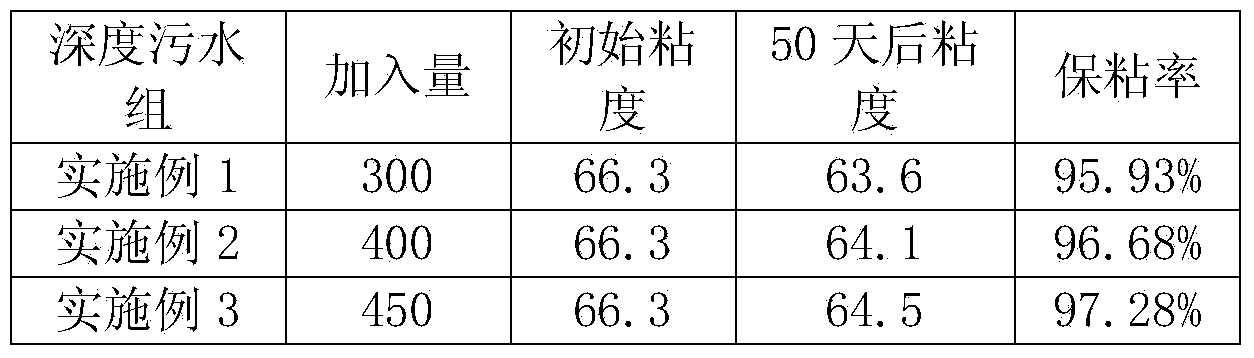

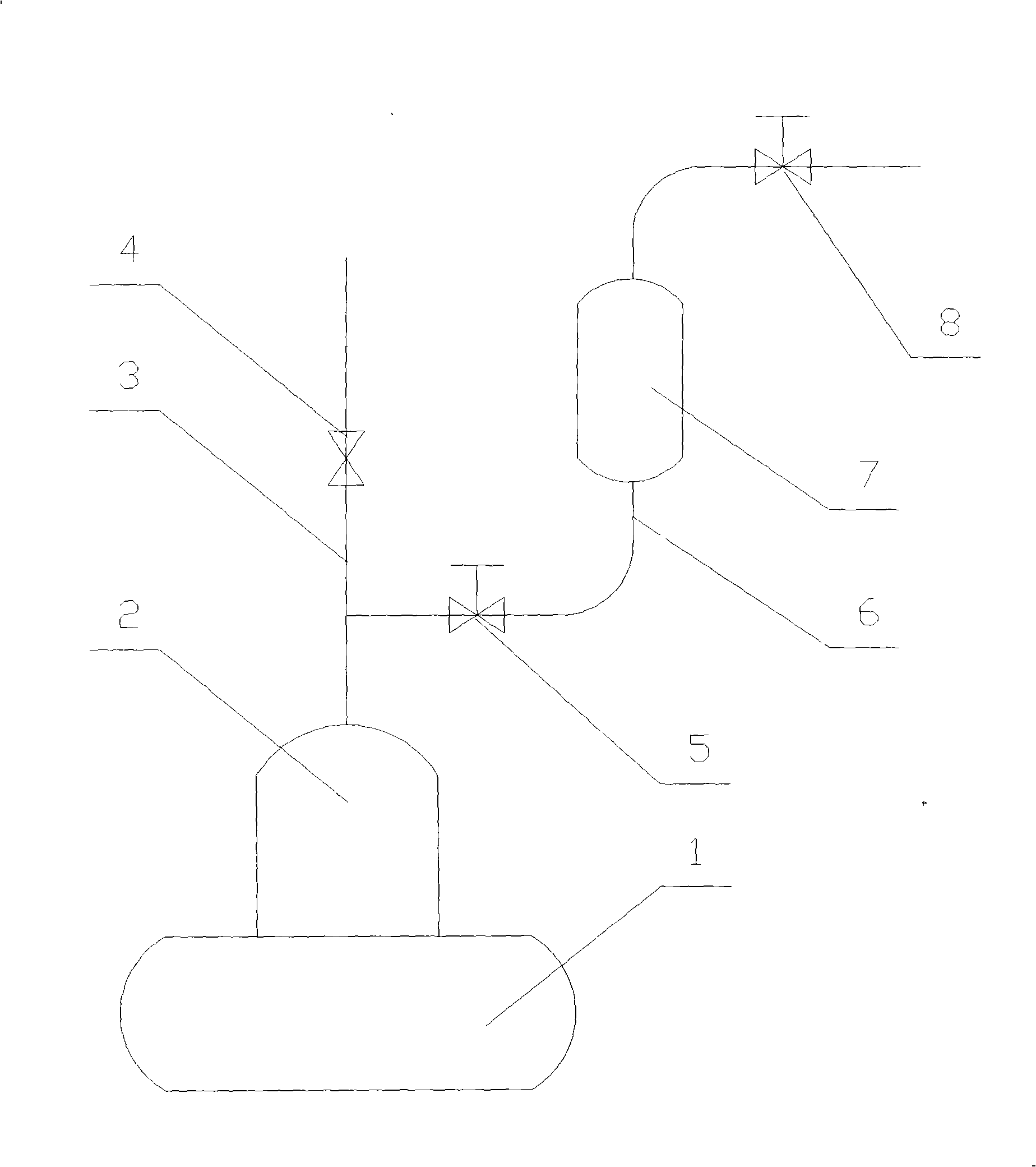

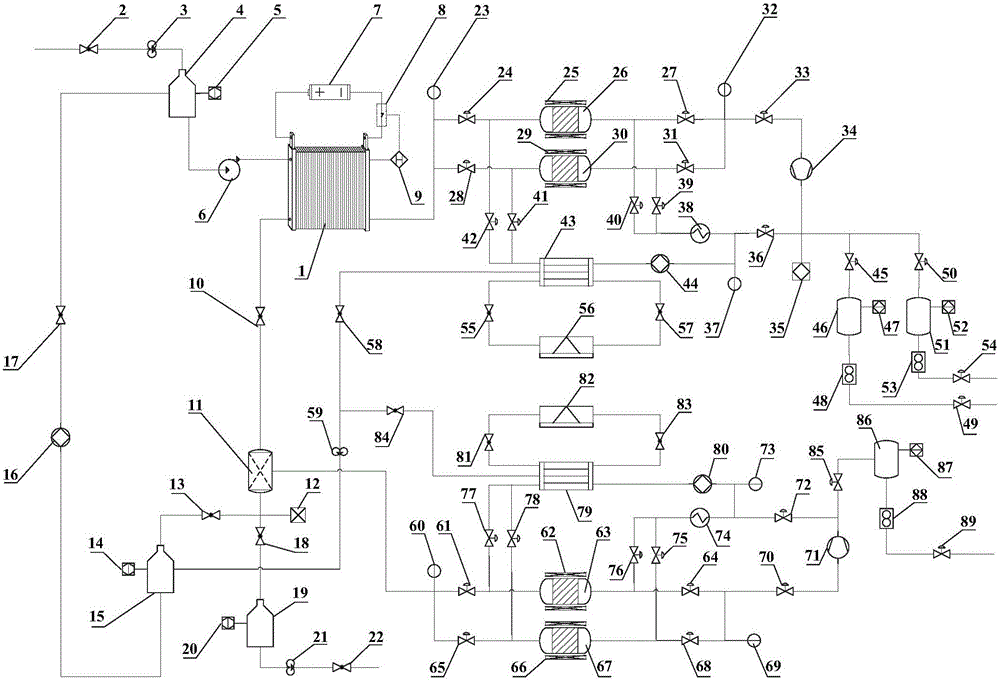

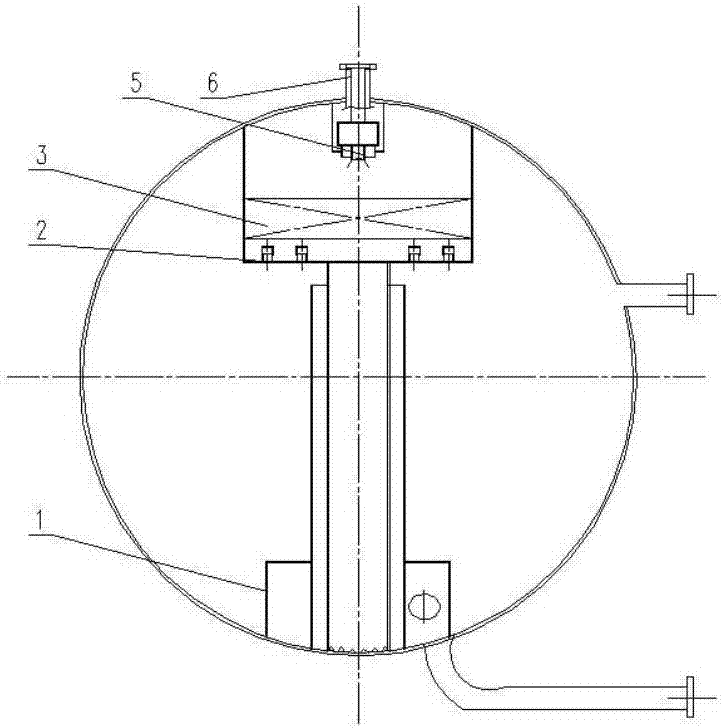

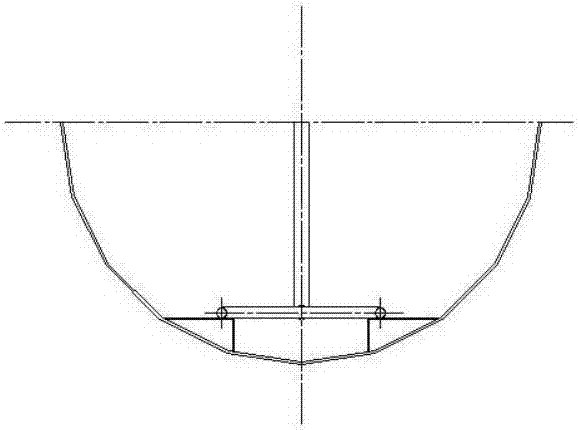

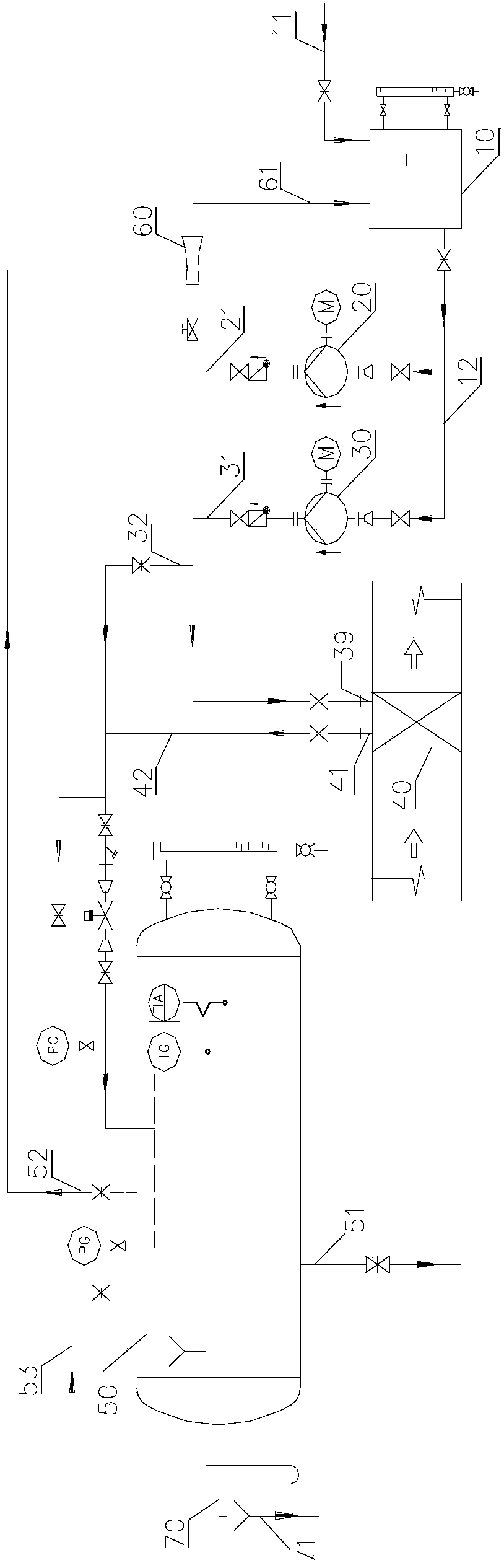

Polymer solution sealed deoxygenation device and method

ActiveCN104857743AImprove oxygen removal effectAccurate evaluationLiquid degasificationEngineeringPolymer solution

The invention discloses a polymer solution sealed deoxygenation device and a method. The polymer solution sealed deoxygenation device comprises a sealed container used for accommodating a polymer solution, wherein the upper part of the sealed container comprises at least two connecting ports including a first connection port and a second connecting port, the lower part is provided with a liquid outlet, and the first connection port is connected with an insert gas generator; a vacuumizing mechanism which is connected with the second connection port, and is used for vacuumizing and deoxidizing of the sealed container and the polymer solution in the sealed container; an oxygen measuring mechanism which is connected with the liquid outlet, and is used for detecting oxygen content of the polymer solution in the sealed container. The polymer solution sealed deoxygenation device can be used for removing oxygen in the polymer solution preferably, measuring oxygen content of the polymer solution accurately, and realizing accurate, convenient, and high efficiency evaluation on the long-term stability of the polymer solution.

Owner:CHINA PETROLEUM & CHEM CORP +1

Refrigerator

PendingCN112747525AImprove the electrochemical reaction rateSimple structureLighting and heating apparatusDomestic refrigeratorsElectrochemical responseElectrolysis

The invention provides a refrigerator, which comprises an inner container, and a storage compartment is formed inside; a storage container arranged in the storage compartment; a first oxygen removal assembly arranged on the storage container and provided with a first oxygen consumption part which faces the interior of the storage container and is used for consuming oxygen in the storage container through an electrochemical reaction, and a first electrolysis part which faces the exterior of the storage container and is used for electrolyzing water vapor outside the storage container; and a water supplementing device arranged close to the storage container and used for providing the water vapor required by the electrochemical reaction for the first electrolysis part. The water supplementing device is arranged on the rear side of the first oxygen removal assembly, so that the water supplementing device provides the water vapor required by the electrochemical reaction for the first electrolysis part, the electrochemical reaction rate of the first oxygen removal assembly can be increased, and the oxygen removal rate is increased; and the water supplementing device is arranged in the storage compartment, the structure is simple, and operation is easy.

Owner:QINGDAO HAIER REFRIGERATOR CO LTD +1

Preparation method of oxide dispersion strengthened (ODS) titanium and titanium alloy

The invention discloses a preparation method of oxide dispersion strengthened (ODS) titanium and titanium alloy, and belongs to the field of powder metallurgy titanium. Calcium-aluminum alloy (CaAl) powder and titanium powder are mixed in proportion, then cold isostatic pressing forming and vacuum pressureless sintering are conducted, and oxide dispersion strengthened titanium and titanium alloy are obtained. The preparation method has the advantages that Ca and Al elements are introduced into the titanium alloy by adding CaAl alloy powder, Ca is uniformly distributed in a matrix, and dispersedly distributed fine Ca-Ti-O oxide second-phase particles are generated in situ in the sintering process, and meanwhile, the Al element is subjected to solid solution in the titanium matrix to form aTiAl solid solution, so that the mechanical property of the titanium alloy is greatly improved. The method is a new thought for improving oxygen control and performance regulation and control of preparation of high-performance titanium and titanium alloy, the requirement for the oxygen content of titanium and titanium alloy powder raw materials is lowered, and the method has the advantages of being low in cost, simple in process, easy to operate, suitable for industrial production and the like.

Owner:UNIV OF SCI & TECH BEIJING

Polymer viscosity stabilizer

ActiveCN103666409AGood viscosity stabilityImproved rheology controlDrilling compositionPolymer scienceThiourea

Owner:TIANJIN DAGANG OILFIELD BINGANG GRP BOHONG PETROLEUM CHEM

Composite boiler water treatment agent composition

InactiveCN106277380AReduce dissolved oxygen contentImprove oxygen removal effectWater treatment parameter controlSpecific water treatment objectivesPressure systemCorrosion

The invention provides a composite boiler water treatment agent composition integrating corrosion inhibition, scale inhibition, deoxygenization and condensed water corrosion inhibition. The composite boiler water treatment agent composition is prepared from, by mass, an organic reductant 4-30%, polyphosphate 2-15%, amine 5-50%, a catalyst 0.01-2% and deionized water 50-80%. The composite boiler water treatment agent composition can be used for the boiler of any pressure system, has the effects of corrosion inhibition, scale inhibition, deoxygenization and condensed water corrosion inhibition and does not affect the quality of steam.

Owner:WEIHAI XIANGYU TECH

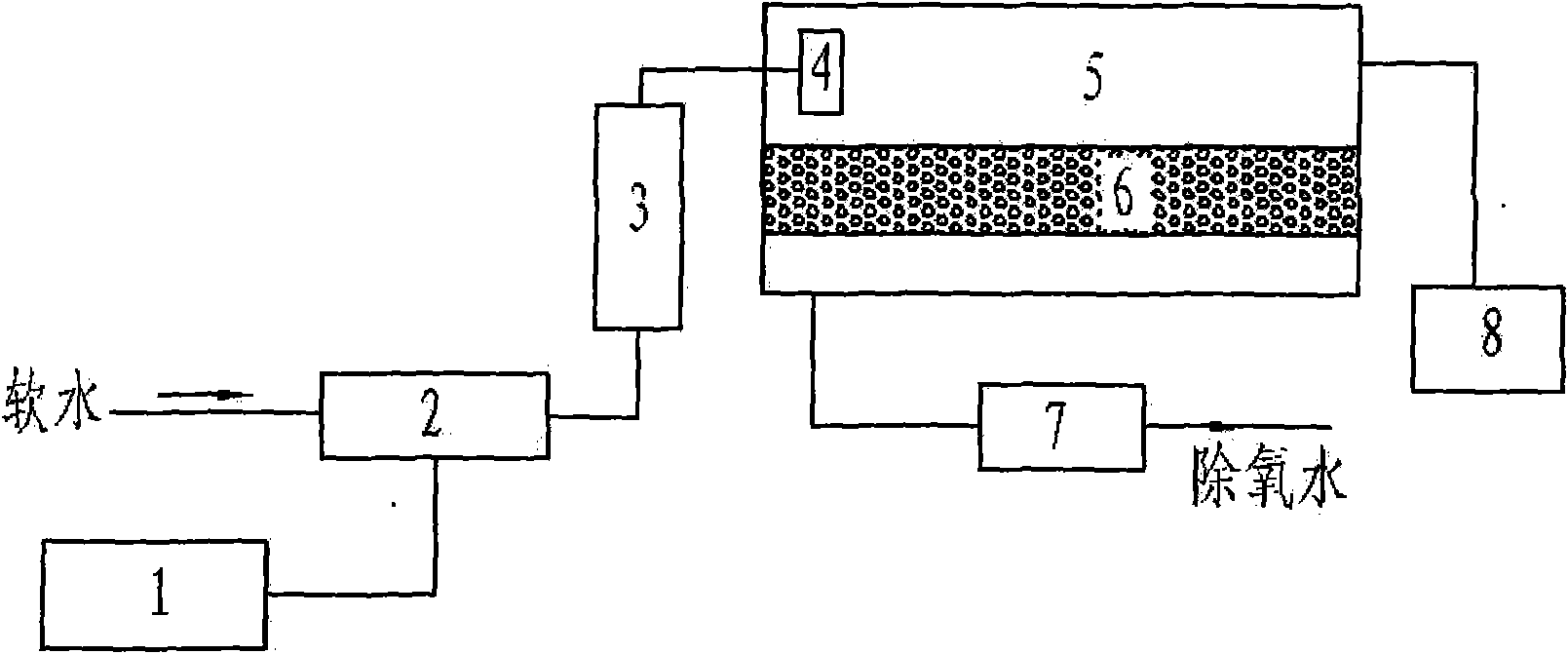

Vacuum analysis deoxidizing device

InactiveCN101549219ANo increase in self-consumption steamSmall footprintLiquid degasificationSoftened waterSoft water

The invention discloses a vacuum analysis deoxidizing device, mainly comprises a mixer, a deoxidizing horizontal tank, a pump, a filter, a deoxidizing nozzle and a vacuum pump system; the device is characterized that: a nitrogen producing device is placed before the mixer; the deoxidizing horizontal tank is built with fillers; the softened water is sent to the mixer; the nitrogen from the nitrogen producing device is absorbed by using the ejector action of the mixer and is mixed with water; the gas-water mixture is filtered by the filter, and the filtered water enters into the deoxidizing horizontal tank after first deoxygenization by the deoxidizing nozzle; the evaporated vapor, released oxygen and other gas are removed by the vacuum pump; the water is deoxidized twice after first deoxygenization by the filler; the processed deaerated water is supplied to the users. The invention has the advantages of improving the original deaerator by the nitrogen producing device, and executing twice deoxygenization to the softened water by the filler. The invention conquers the shortcomings of the original vacuum deoxidizing device and analysis deoxidizing device and reduces the operating vacuum degree of the vacuum deoxidizing device and improves the purity of the analysis gas.

Owner:SHANGHAI SHENGYU TECH CO LTD

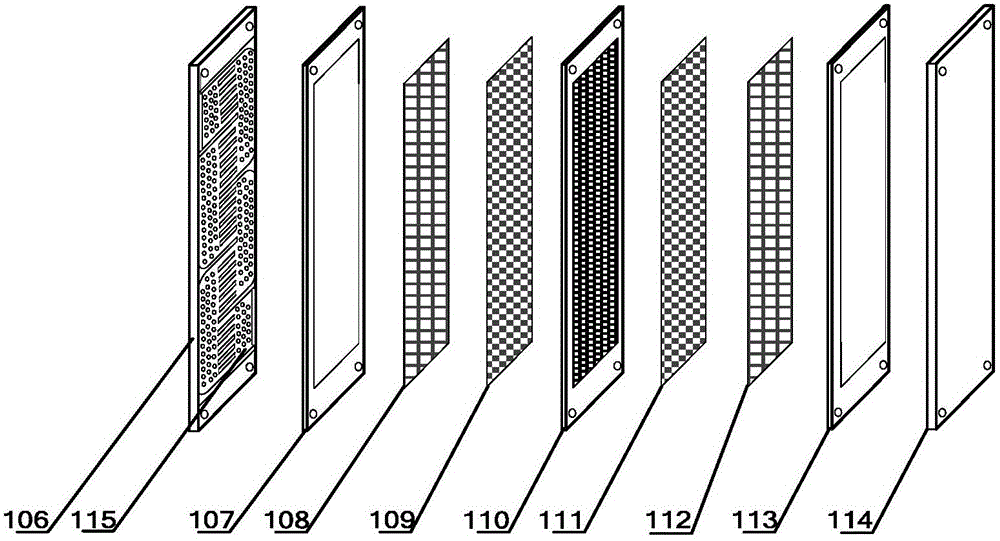

Air cooled steam exhaustor with built-in oxygen remover

ActiveCN1752418AReasonable structureSimple structureMachines/enginesEngine componentsDeaeratorEngineering

The invention includes a exhaust device, a sparge pipeline, a deflector and a deaerator set in the exhaust device. The deaerator comprises a heating steam passage, a upper sprinkling screen, a lower sprinkling screen, a stuffing layer disposed between the upper sprinkling screen and the lower sprinkling screen and a condensation water pipeline. The water jet of the condensation water pipeline is set above the upper sprinkling screen. The air jet of the heating steam passage is set below the lower sprinkling screen.

Owner:HARBIN TURBINE

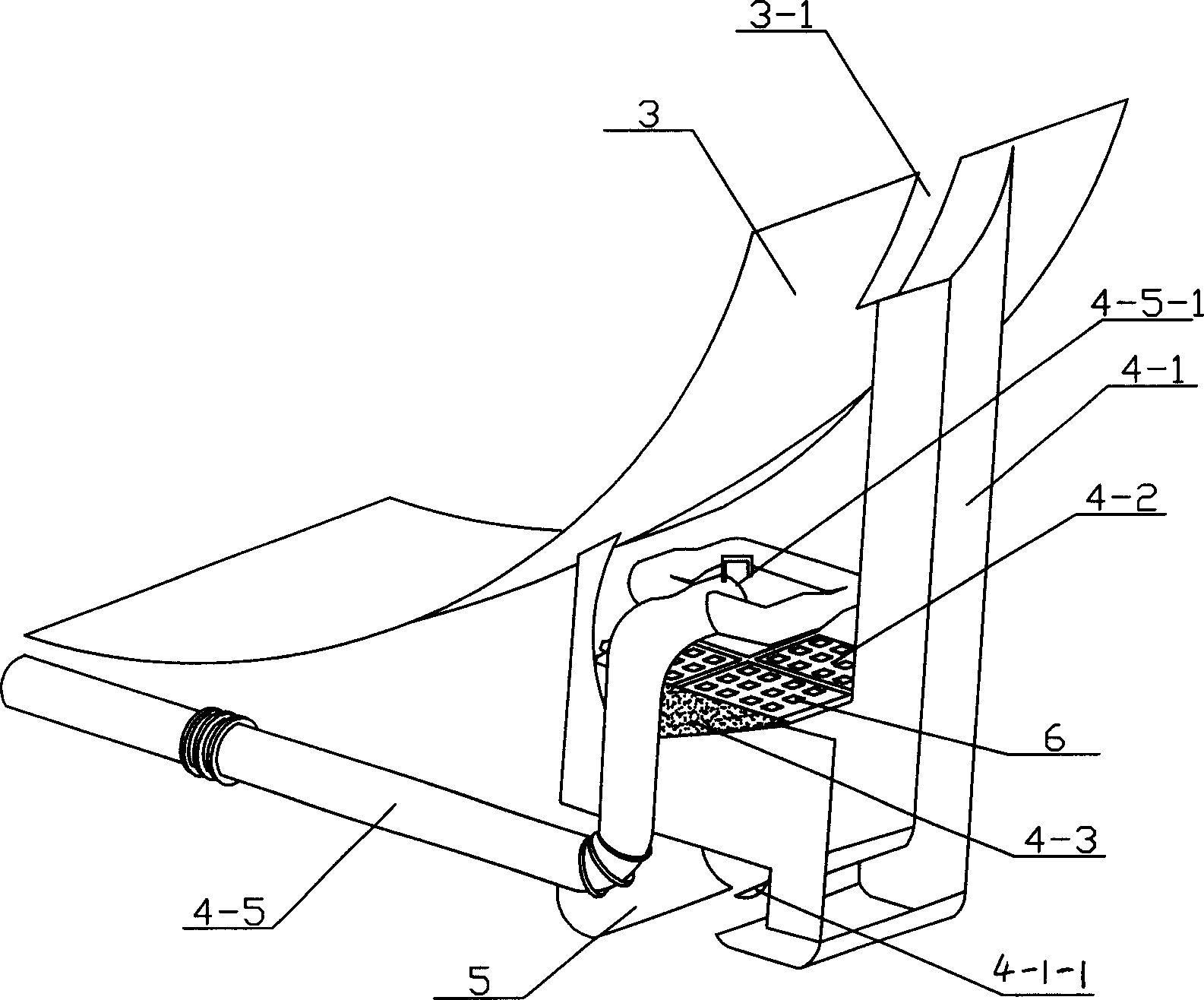

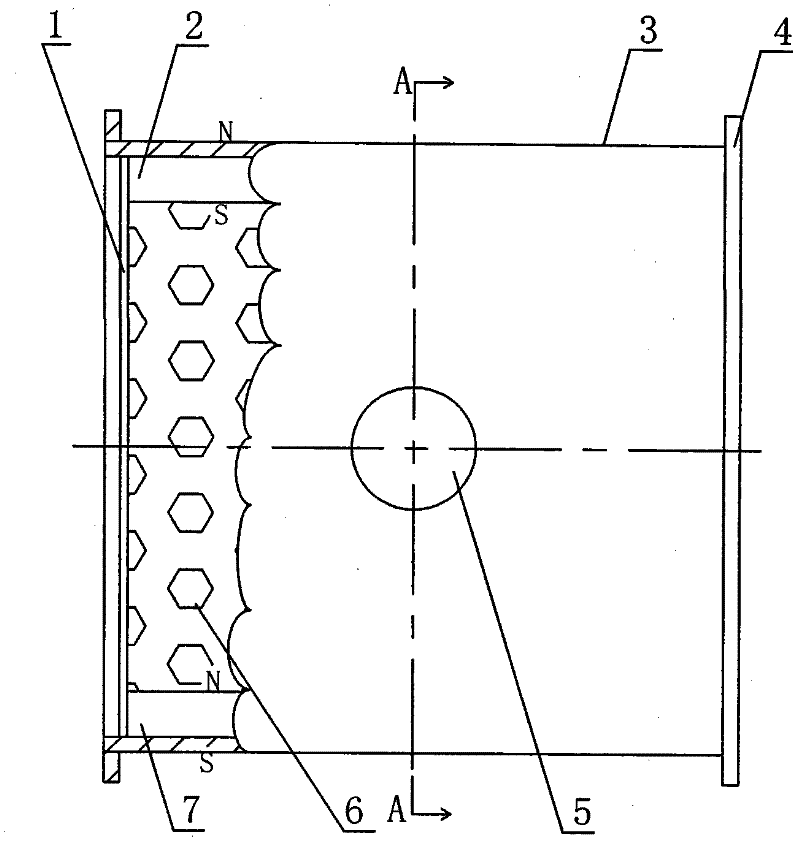

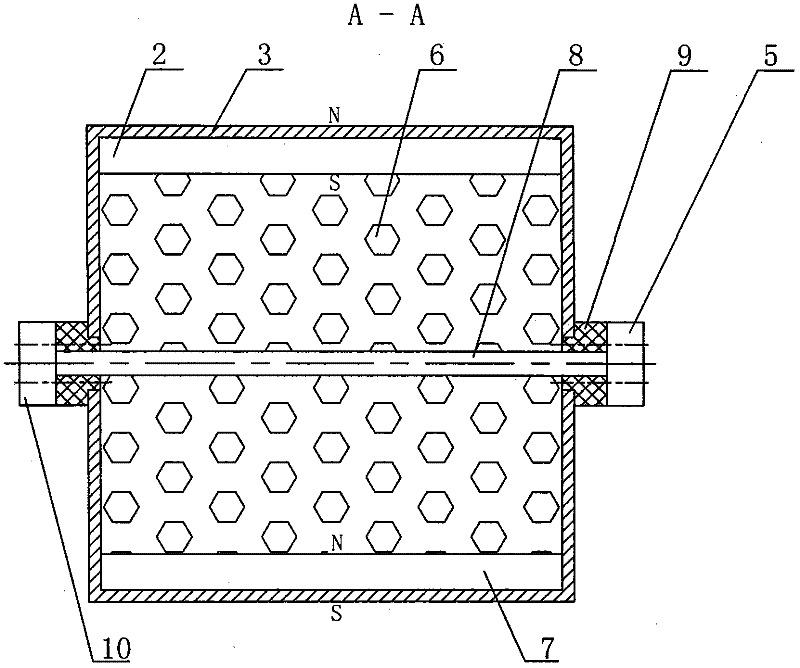

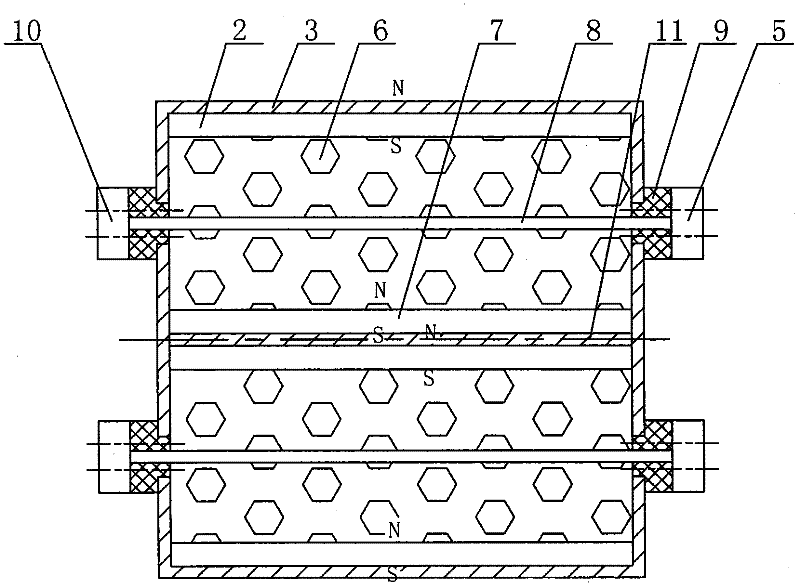

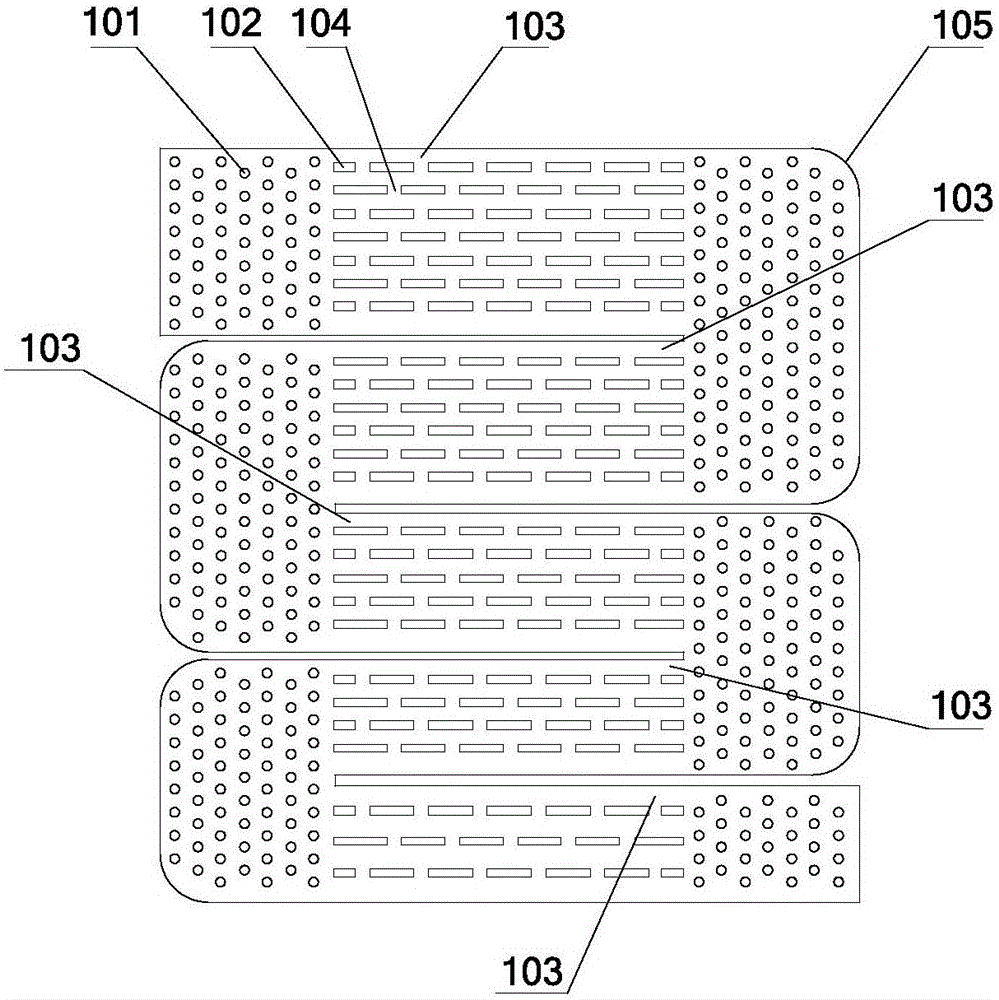

Magnetic-acoustic field synergistically enhanced sponge iron water deoxygenizing component

InactiveCN102225788AImprove oxygen removal effectEfficient removalWater/sewage treatment with mechanical oscillationsWater/sewage treatment by magnetic/electric fieldsUltrasonic sensorElectrical polarity

The invention relates to a magnetic-acoustic field synergistically enhanced sponge iron water deoxygenizing component, which comprises flanges arranged at left and right ends of a shell, at least one deoxygenizing unit located on the shell and a partition arranged between two adjacent deoxygenizing units, wherein the deoxygenizing unit is characterized in that filter nets are arranged at the left and right ends inside the shell, radial ultrasound radiation pipes are arranged at the center positions of the front and rear inner walls of the shell, a front power ultrasonic transducer is arranged on the front outer wall of the shell, a rear power ultrasonic transducer is arranged on the rear outer wall of the shell, the radiation end of the front power ultrasonic transducer is connected with the front ends of the radial ultrasound radiation pipes inside the shell, the radiation end of the rear power ultrasonic transducer is connected with the rear ends of the radial ultrasound radiation pipes inside the shell, an upper permanent magnet is located at the inner top of the shell, a lower permanent magnet is located at the inner bottom of the shell, the lower end surface of the upper permanent magnet and the upper end surface of the lower permanent magnet have opposite polarities, and sponge iron particles are filled between the upper permanent magnet and the lower permanent magnet and between the two filter nets.

Owner:SHAANXI NORMAL UNIV

Admixture for recycled aggregate concrete and preparation method thereof

The invention relates to the field of concrete admixtures, and particularly discloses an admixture for recycled aggregate concrete and a preparation method of the admixture, and the admixture for recycled aggregate concrete comprises the following substances in parts by weight: 30-50 parts of a sulfamate water reducing agent, 20-30 parts of a polycarboxylic acid water reducing agent, 10-15 parts of nano silicon dioxide sol and 20-45 parts of water, wherein the nano silicon dioxide sol comprises hydrophilic solid silicon dioxide sol and hydrophilic porous silicon dioxide sol which are mixed at equal molar mass. The water reducing agent and the nano silicon dioxide are added into the admixture, the slump retaining effect of the concrete is improved by adding the water reducing agent firstly, and then the solid nano silicon dioxide sol and the porous nano silicon dioxide sol are compounded to serve as a filler of an internal pore structure of the recycled aggregate concrete, so that the compact strength of a concrete structure is improved; the hydration degree of the cement is reduced, and the workability, flowability and compactness of the recycled aggregate concrete are improved.

Owner:中建西部建设北方有限公司 +1

Deoxidation energy conservation method by heating energy conservation technological improved apparatus of deoxidation device by heating

InactiveCN101343092AEasy dischargeIncrease working temperatureWater/sewage treatment by degassingExhaust valveDeaerator

The invention relates to an energy-saving method of thermal deaerating and a transformed device of a thermal deaerator, wherein the top of the thermal deaerator body is connected to a deaerating buffer tank, or called a gas holder, by a connecting pipe; the top of the gas holder is equipped with an exhaust pipe; the deaerator body comprises a deaerating tower and a water tank which is mounted at the bottom of the deaerator body, adopts the mode of steam heating to achieve continuous deaerating, while the gas holder adopts the mode of intermittent exhaust to exhaust gases, otherwise, a connecting valve on the connecting pipe is opened, and an exhaust valve on the exhaust pipe is closed; the matter distribution mode that the lower part is hot water, the middle is predominated by steam and the upper part is predominated by oxygen and other gases is formed inside the integral space comprising the water tank, the deaerating tower and the gas holder; and the valve is controlled to exhaust when part of the space inside the gas holder is predominated by oxygen and other gases. The method and the transformed device are conducive to saving water resources and heat energy, and essentially can be used in the transformation of thermal deaerating of boiler feed water.

Owner:李树生

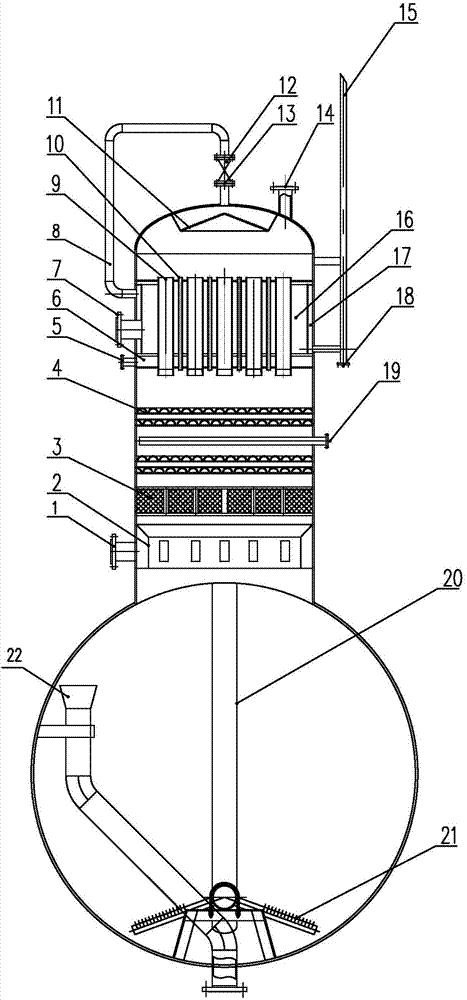

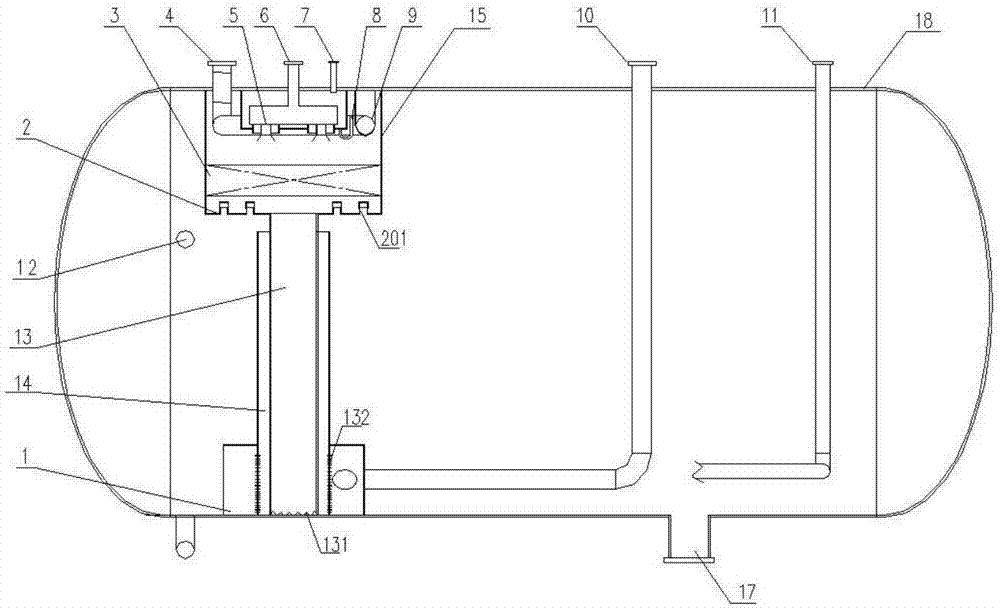

High-efficiency energy-saving thermal deaerator

ActiveCN103754971AImprove oxygen removal effectGuaranteed uptimeWater/sewage treatment bu osmosis/dialysisWater/sewage treatment by heatingDeaeratorEngineering

The invention relates to a high-efficiency energy-saving thermal deaerator, which belongs to the field of machinery. The deaerator comprises a cylindrical shell, wherein a gas-water separator, a spiral membrane device group, a watering grate, a filling liquid gas net, a gas distribution disc and a water tank which are arranged from top to bottom in sequence inside the cylindrical shell. The deaerator has a good deoxygenization effect.

Owner:山东佳能科技股份有限公司

SPE (Solid Polymer Electrolyte) electrolysis system used for tritium concentration and realization method for electrolysis system

The invention discloses an SPE (Solid Polymer Electrolyte) electrolysis system used for tritium concentration. The electrolysis system comprises an electrolytic tank system, a tritiated water supply system, a gas-liquid separator, a tritiated water collection system, a hydrogen drying system, an oxygen drying system, a hydrogen collection system, a product oxygen collection and storage tank, a condensation system and a detection and control system. The invention further provides a realization method for the SPE electrolysis system used for tritium concentration. The electrolysis system can meet all process demands of aqueous phase tritium concentration, wherein the processes include a tritiated water circulating concentration process, a hydrogen leakage emergency power-off process, a molecular sieve drying bed continuous treatment process and the like. Meanwhile, due to the tritiated water circulating concentration, the tritiated water concentration can be quantitatively controlled, so that the tritium concentration efficiency is greatly improved and a large amount of tritium-poor hydrogen is obtained.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Internal type headless higher-pressure deaerator and deaeration method

PendingCN106996556AAvoid redissolutionHeating fastLiquid degasificationWater/sewage treatment by degassingDeaeratorEngineering

The invention discloses an internal type headless high-pressure deaerator. The internal type headless high-pressure deaerator comprises a barrel body, wherein an internal barrel body, a water-spraying inner barrel, a re-boiler, a steam mixing outer barrel, a heating steam tube, a re-boiling heating tube and a deaerated water outlet are mounted inside the barrel body; a water feeding tube, a water return tube and a gas exhaust tube are arranged on a barrel body surrounded by the internal barrel body; and a spraying device and a filler layer are further arranged inside the internal barrel body from top to bottom. The invention further provides a deaeration method which separates oxygen in water through a tertiary device. Compared with a conventional system with a deaeration head, the internal type headless high-pressure deaerator has the beneficial effects of reducing equipment height, greatly reducing civil engineering cost, reducing lift of a water inlet pump, achieving the energy-saving effect, being more complete in deaeration, and being capable of achieving effect of 0.05 ppm, and being applicable when a steam temperature ranges from 104 DEG C to 190 DEG C. The internal type headless high-pressure deaerator is simple and compact in structure, and is convenient to mount and maintain.

Owner:山东岱星金属设备有限公司

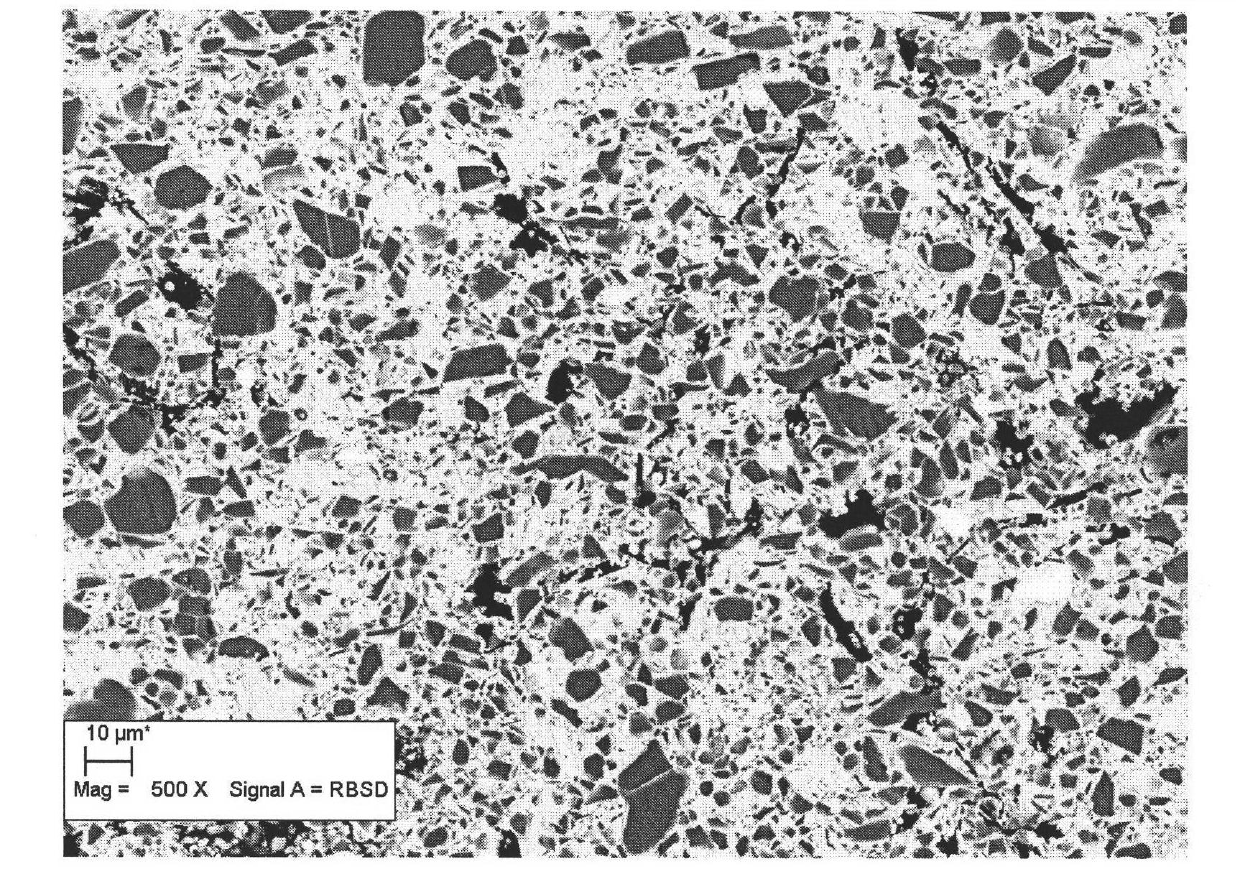

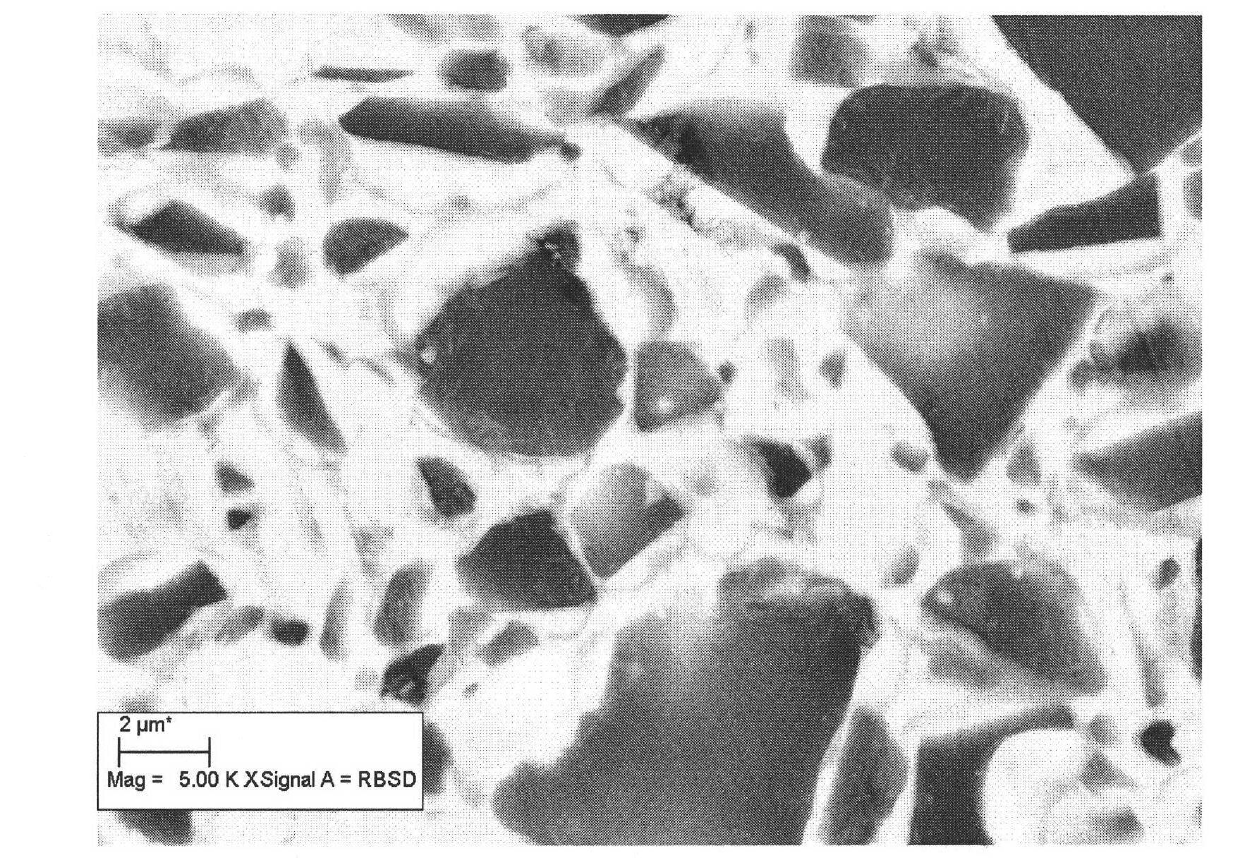

Method for lowering oxygen content of titanium carbide and titanium nitride powder

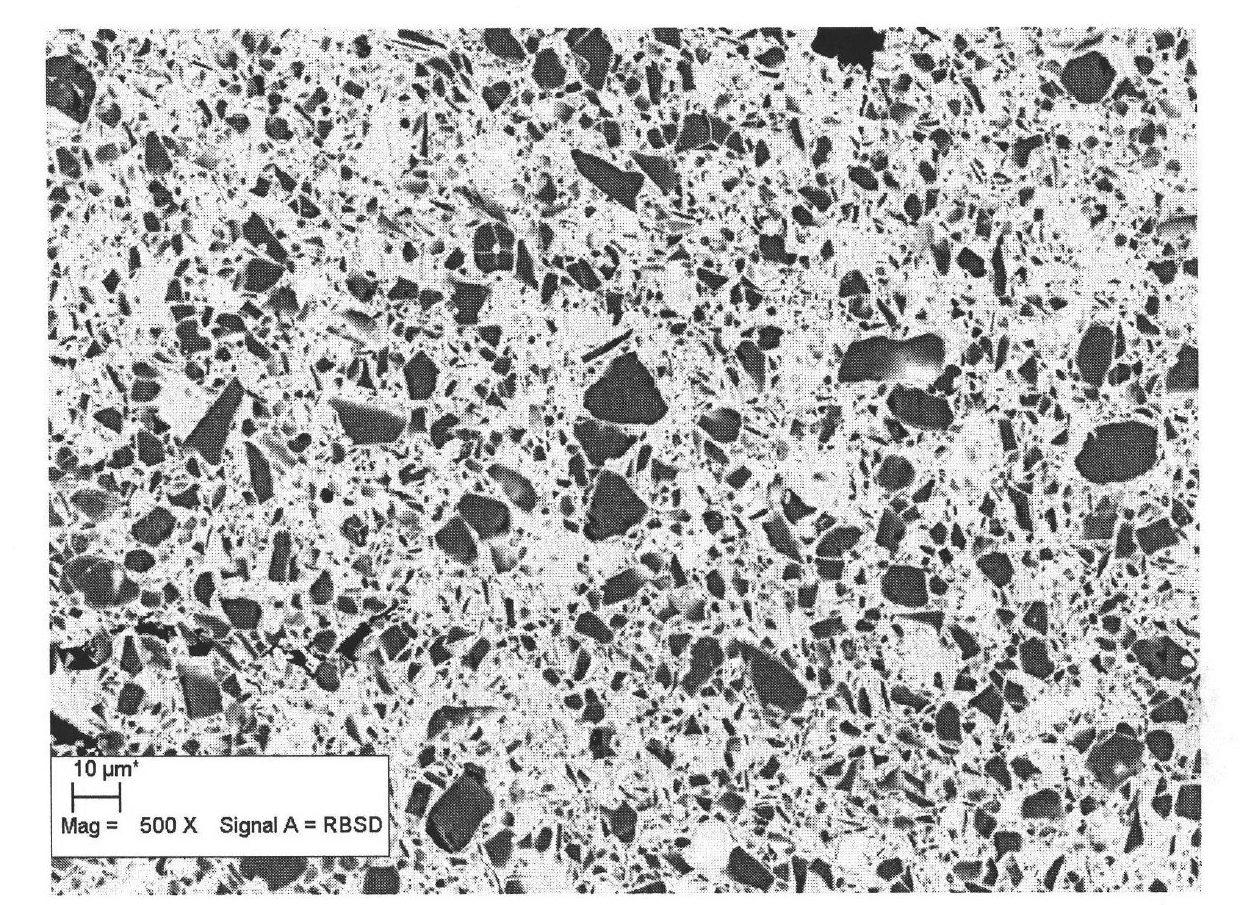

The invention discloses a method for lowering oxygen content of titanium carbide and titanium nitride powder. Solid titanium carbide powder and solid titanium nitride powder are respectively put in chloroform liquid; the volume ratio of two kinds of solid powder to chloroform liquid is 1:1-10; titanium carbide processing temperature is 35-61.7 DEG C, and titanium nitride processing temperature is 40-60 DEG C; the processing process ends when no bubbles are generated. The invention uses a chloroform chemical method to remove a TiO2 oxidation film on the surface of titanium carbide powder and titanium nitride powder particles so as to lower oxygen content of the powder, thus solving the problems of high porosity and low mechanical property of prepared titanium diboride base metal ceramic due to oxidization in the storage and transportation process of powder. TiC and TiN powder processed with the method of the invention are used for preparing titanium diboride base metal ceramics to eliminate sintering flaws, obviously decrease hard phase size, brings obviously even microscopic structure and obviously improves bending strength.

Owner:CHINA THREE GORGES UNIV

Two-part curable Oxygen-absorbable Resin Composition, and Oxygen-absorbable Adhesive Agent

ActiveUS20130280537A1Improve oxygen removal effectLow costOther chemical processesPolyureas/polyurethane adhesivesIsocyanatePolyester

The purpose of the present invention is to provide a two-part curable oxygen-absorbable resin composition which has all of oxygen absorbability, adhesion properties and a cohesive force. The present invention provides a two-part curable oxygen-absorbable resin composition comprising: a main component which comprises a polyester polyol containing tetrahydrophthalic acid or a derivative thereof or tetrahydrophthalic acid anhydride or a derivative thereof as a raw material; and an aliphatic and / or alicyclic isocyanate curing agent component.

Owner:TOYO SEIKAN GRP HLDG LTD

Phloroglucinol injection and preparation method thereof

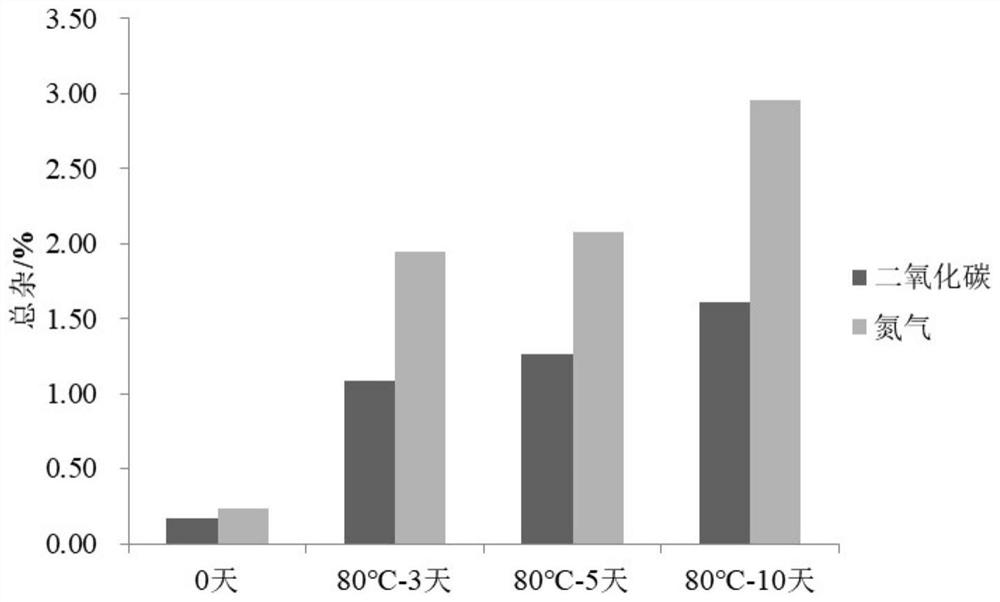

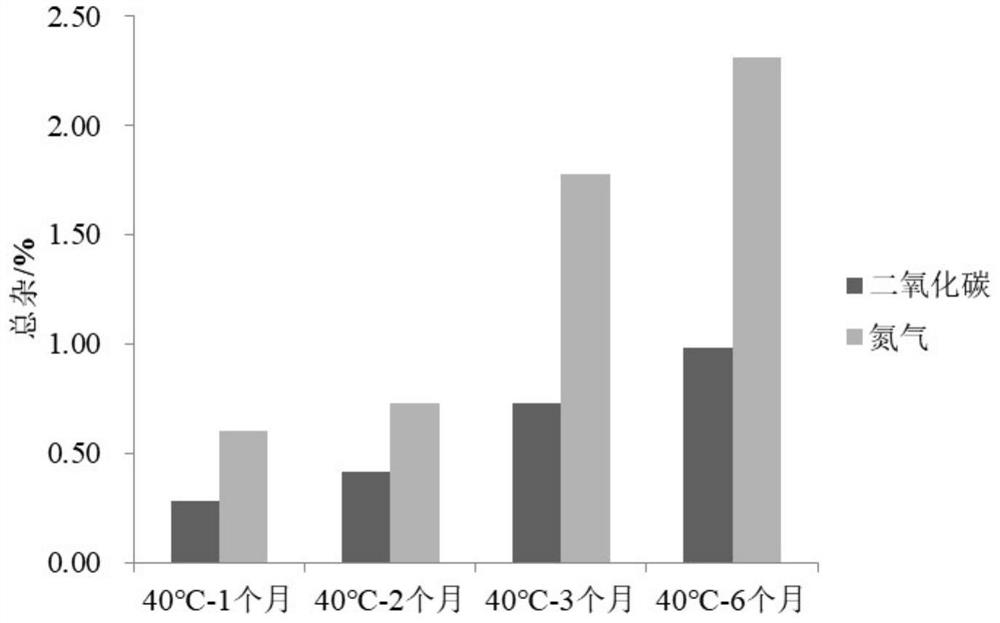

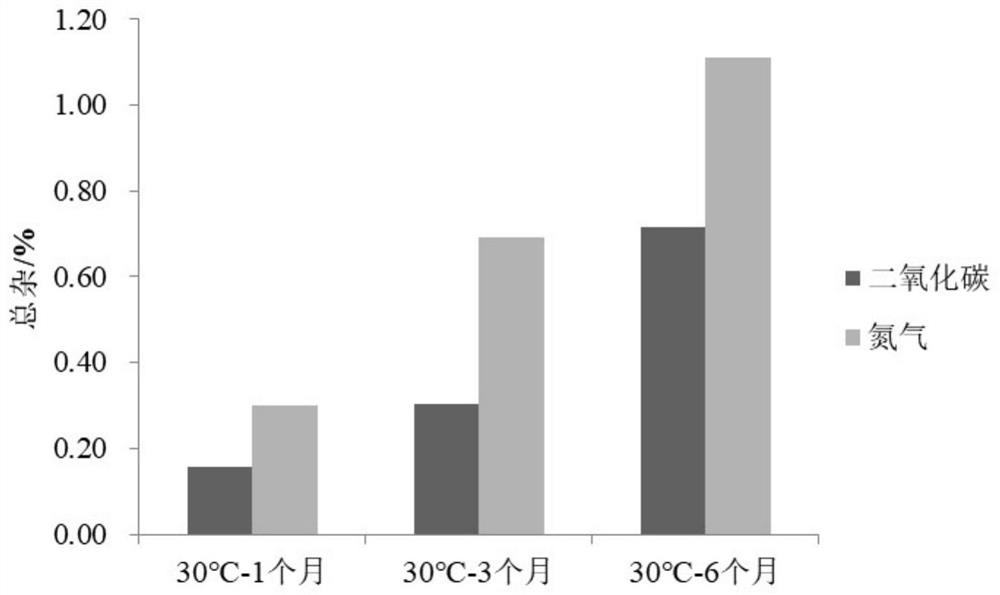

ActiveCN112516077AImprove oxygen removal effectAvoid raw material compatibility issuesHydroxy compound active ingredientsDigestive systemDrugs preparationsAnoxomer

The invention belongs to the field of pharmaceutical preparations, and relates to a phloroglucinol injection and a preparation method thereof. The phloroglucinol injection comprises the following mainactive pharmaceutical ingredients: phloroglucinol, trimethylphloroglucinol, an osmotic pressure regulator sodium chloride and water for injection. The preparation method is mainly characterized in that carbon dioxide is used as a stabilizer, so that the use of an antioxidant is avoided, the pH value of the solution is reduced, the stability of the solution is improved, the prescription process issimplified, and the phloroglucinol injection with stable content, slow impurity growth and long validity period is obtained.

Owner:ZHEJIANG WANBANG PHARMA

Novel thermodynamic vacuum deaeration system

PendingCN107940440AGood oxygen removal effectGood energy saving effectLiquid degasificationFeed-water heatersSoftened waterEngineering

The invention provides a novel thermodynamic vacuum deaeration system. The novel thermodynamic vacuum deaeration system comprises a softened water tank (10), a softened water pump (20), a coal economizer (40), a deaerator water feeding pump (30), a deaerator (50) and a vacuum ejector (60); a vacuum ejection pipeline for carrying out pressure reduction on the deaerator is connected to the softenedwater tank (10), the softened water pump (20), the vacuum ejector (60) and the deaerator (50); and a water injection pipeline for injecting water into the deaerator is connected to the softened watertank (10), the deaerator water feeding pump (30), the coal economizer (40) and the deaerator (50). The thermodynamic vacuum deaeration system has the advantages of being good in energy saving performance, high in working efficiency, good in waste heat recovery function and the like.

Owner:CERI PHOENIX INDAL FURNACE CO TD +1

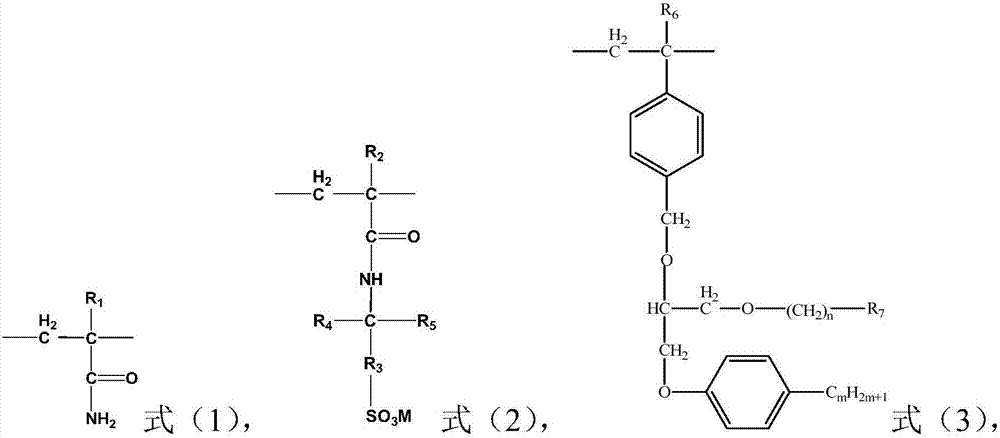

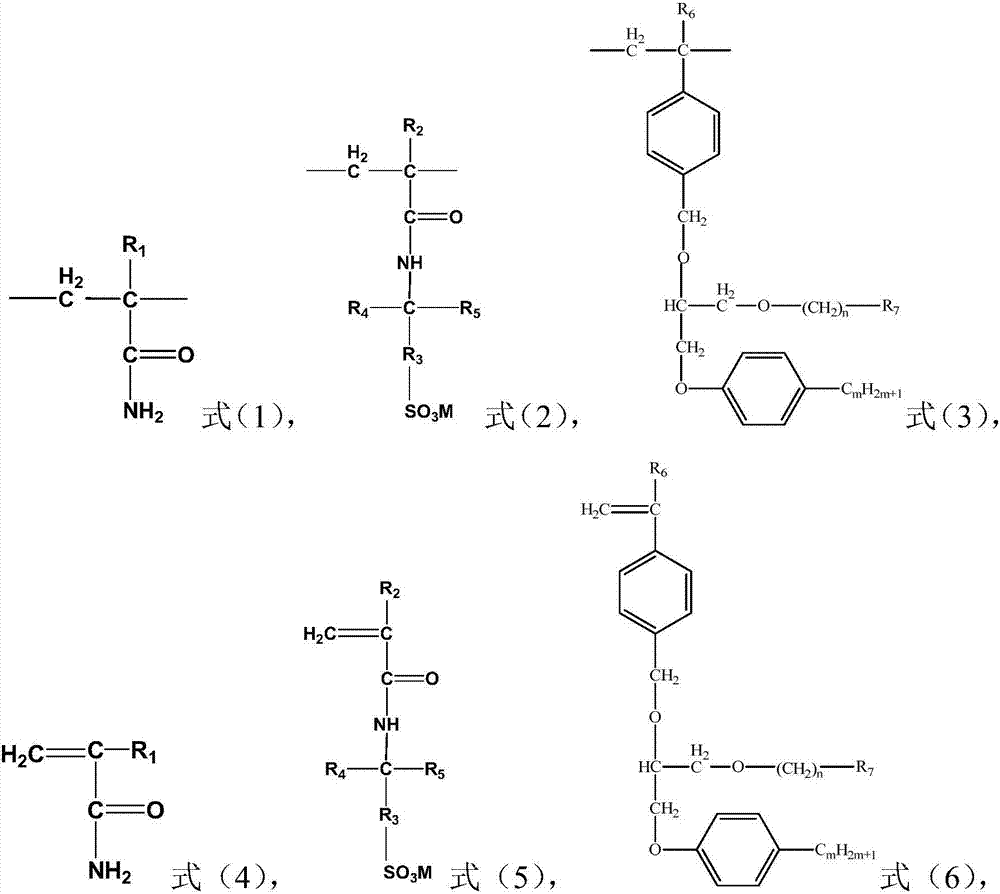

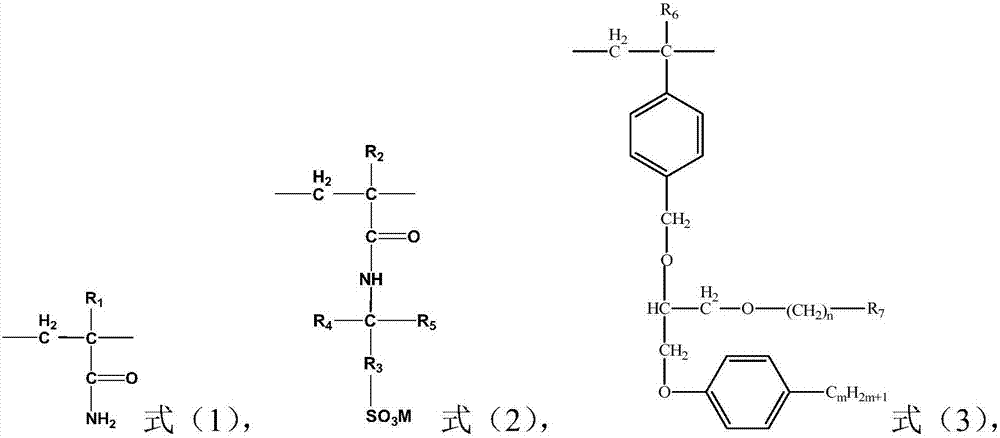

Polymer having surface activity function, and preparation method and application thereof

ActiveCN107226884AWith surface active functionGood water solubilityDrilling compositionPolymer sciencePolymer solution

The invention relates to the field of crude oil recovery, and discloses a polymer having a surface activity function, and a preparation method and application thereof. The polymer contains a structural unit A, a structural unit B and a structural unit C, wherein the structural unit A is a structural unit having a structure shown in Formula (1); the structural unit B is a structural unit having a structure shown in Formula (2); and the structural unit C is a structural unit having a structure shown in Formula (3). According to the invention, a polymerizable monomer having surface activity is introduced onto a macromolecular chain, and the ether chain structure determines that the synthesized copolymer has high hydrolysis resistance and thermal stability, thereby improving the aging resistance of the polymer; and meanwhile, the surface tension and interfacial tension of the polymer solution are greatly reduced, so that the polymer has favorable surface activity and fine compatibilization, emulsification and oil washing capabilities, thereby improving the crude oil recovery factor. The Formula (1), the Formula (2) and the Formula (3) are shown in the specification.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com