Admixture for recycled aggregate concrete and preparation method thereof

A recycled aggregate and concrete technology, applied in the field of concrete admixtures, can solve the problems of rough recycled aggregate structure, large structural voids, insufficient density of recycled aggregate concrete, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

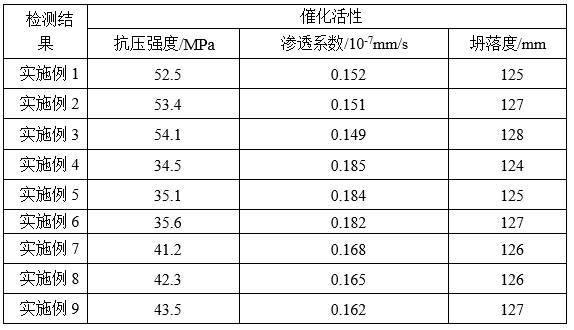

Embodiment 1

[0037] Mix 200mL of hydrophilic silica with a solid content of 15% and 2000mL of polyvinyl alcohol solution with a mass fraction of 5% and heat it in an oil bath at 100°C for 2 hours, then let it stand and cool to room temperature to obtain a mixed solution; use 5mL of 0.5mol / L sodium hydroxide solution was added dropwise to the mixed solution, and the dropping rate was controlled at 2mL / min. After the dropwise addition was completed, the suspension was collected; then 20mL of silane coupling agent was mixed with 200mL of the suspension to adjust the pH After reaching 10.0°C, heat-preserve and react at 40°C for 20 hours, collect the reaction liquid and place it in a rotary evaporation at 45°C, and when it evaporates to 1 / 3 of the volume of the reaction liquid, a hydrophilic porous silica sol is obtained;

[0038] Take 800mL of deionized water, 10g of polyvinylpyrrolidone, 6g of sodium erythorbate, 6g of sodium hexametaphosphate, 3g of D-sodium gluconate and 1g of zinc sulfate ...

Embodiment 2

[0043] Mix 225mL of hydrophilic silica with a solid content of 15% and 2500mL of polyvinyl alcohol solution with a mass fraction of 5% and heat it in an oil bath at 105°C for 2 hours, then let it stand and cool to room temperature to obtain a mixed solution; use 7mL of 0.5mol / L sodium hydroxide solution was added dropwise to the mixed solution, and the dropping rate was controlled at 2mL / min. After the dropwise addition was completed, the suspension was collected; then 27mL of silane coupling agent was mixed with 350mL of the suspension to adjust the pH After reaching 10.0°C, heat-preserve and react at 42°C for 22 hours, collect the reaction solution and place it in a rotary evaporation at 52°C, and when it evaporates to 1 / 3 of the volume of the reaction solution, a hydrophilic porous silica sol is obtained;

[0044] Take 900mL of deionized water, 12g of polyvinylpyrrolidone, 7g of sodium erythorbate, 7g of sodium hexametaphosphate, 4g of D-sodium gluconate and 2g of zinc sulf...

Embodiment 3

[0049] Take 250mL of hydrophilic silica with a solid content of 15% and mix 3000mL of 5% polyvinyl alcohol solution with a mass fraction of 3000mL, heat it in an oil bath at 110°C for 3 hours, and let it stand to cool to room temperature to obtain a mixed solution; use 8mL of 0.5mol / L sodium hydroxide solution was added dropwise to the mixed solution, and the dropping rate was controlled at 3mL / min. After the dropwise addition was completed, the suspension was collected; then 35mL silane coupling agent was mixed with 500mL suspension to adjust the pH After reaching 10.0°C, heat-preserve and react at 45°C for 24 hours, collect the reaction solution and place it in a rotary evaporation at 60°C, and when it evaporates to 1 / 3 of the volume of the reaction solution, a hydrophilic porous silica sol is obtained;

[0050] Take 1000mL of deionized water, 15g of polyvinylpyrrolidone, 8g of sodium erythorbate, 8g of sodium hexametaphosphate, 5g of D-sodium gluconate and 2g of zinc sulfat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com