High performance water reducing agent in new type comb shaped molecular structure

A technology of molecular structure and water reducing agent, applied in the field of building materials, can solve problems such as high cost and complex process, and achieve the effects of easy control, good production reproducibility and easy structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

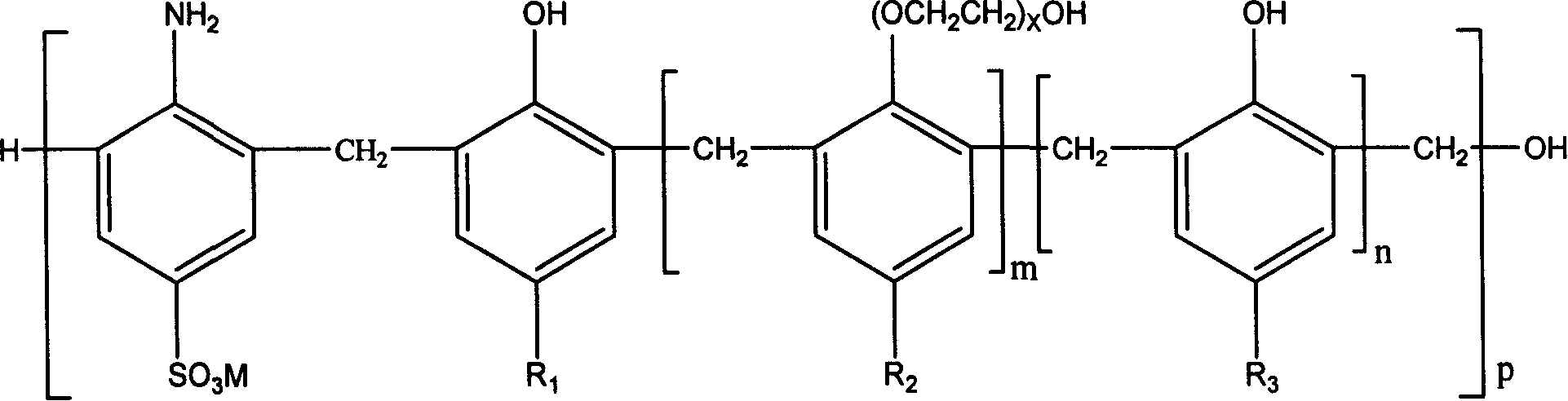

[0037] Example 1: 11.00mol of water was added to the reactor, 0.44mol of phenol, 0.75mol of sodium p-aminobenzenesulfonate, modified polyether [HO-C 6 h 4 -(OCH 2 CH 2 )10-OH] 0.56mol, the temperature was raised to 80°C, and 0.80mol of 37% formaldehyde was slowly added dropwise in 2 hours. Then the temperature was raised to 95 degrees, and the reaction was carried out for 6 hours. Cool down, adjust the pH value of the solution, adjust the solid content to 27%, filter and pack to obtain the liquid water reducing agent.

[0038] test:

[0039] Concrete test: Refer to GBJ8076-97 "Test Method for Ordinary Concrete Mixture". After adding a certain water reducing agent, reduce the corresponding water consumption, and keep the slump of the concrete mixed with the water reducing agent and the blank concrete the same (80±10mm), calculate the corresponding water reducing rate and test the workability of the concrete; Refer to GBJ107-87 "Concrete Strength Inspection and Evaluation ...

Embodiment 2

[0042] Example 2: Add 11.00mol of water, 0.32mol of phenol, 1.43mol of sodium p-aminobenzenesulfonate, modified polyether [HN-C 6 h 4 -(OCH 2 CH 2 )15-OH] 0.86mol, warming up to 95 degrees, slowly dripping 37% formaldehyde 0.86mol in 1.5 hours, and then keeping warm for 5 hours, cooling to normal temperature, adjusting the pH value, adjusting the solid content to 27%, and filtering and packaging. Can. Test: same as embodiment one

[0043]

Embodiment 3

[0044] Example 3: Add 44.44mol of water and 1.00mol of p-aminobenzenesulfonic acid into the reaction kettle, then add sodium hydroxide to adjust the pH value to 7-8, add 1.04mol of phenol, modify the polyether [HN-C 6 h 4 -(OCH 2 CH 2 ) 20 -OH] 0.88mol, heat up to 75°C, slowly add 37% formaldehyde 4.94mol dropwise within 2 hours, and keep warm for 8 hours. Cool, adjust the solid content to 27%, filter and pack.

[0045] Test: same as embodiment one

[0046] make up

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com