Novel method for utilizing hydrogen plasma electric arc melting technology to prepare high-purity rare earth gadolinium elementary substance

A plasma and arc smelting technology, which is applied in the field of high-purification preparation of new rare earth functional materials, can solve the problems of long cycle and low output, and achieve the effects of convenient operation, pollution avoidance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

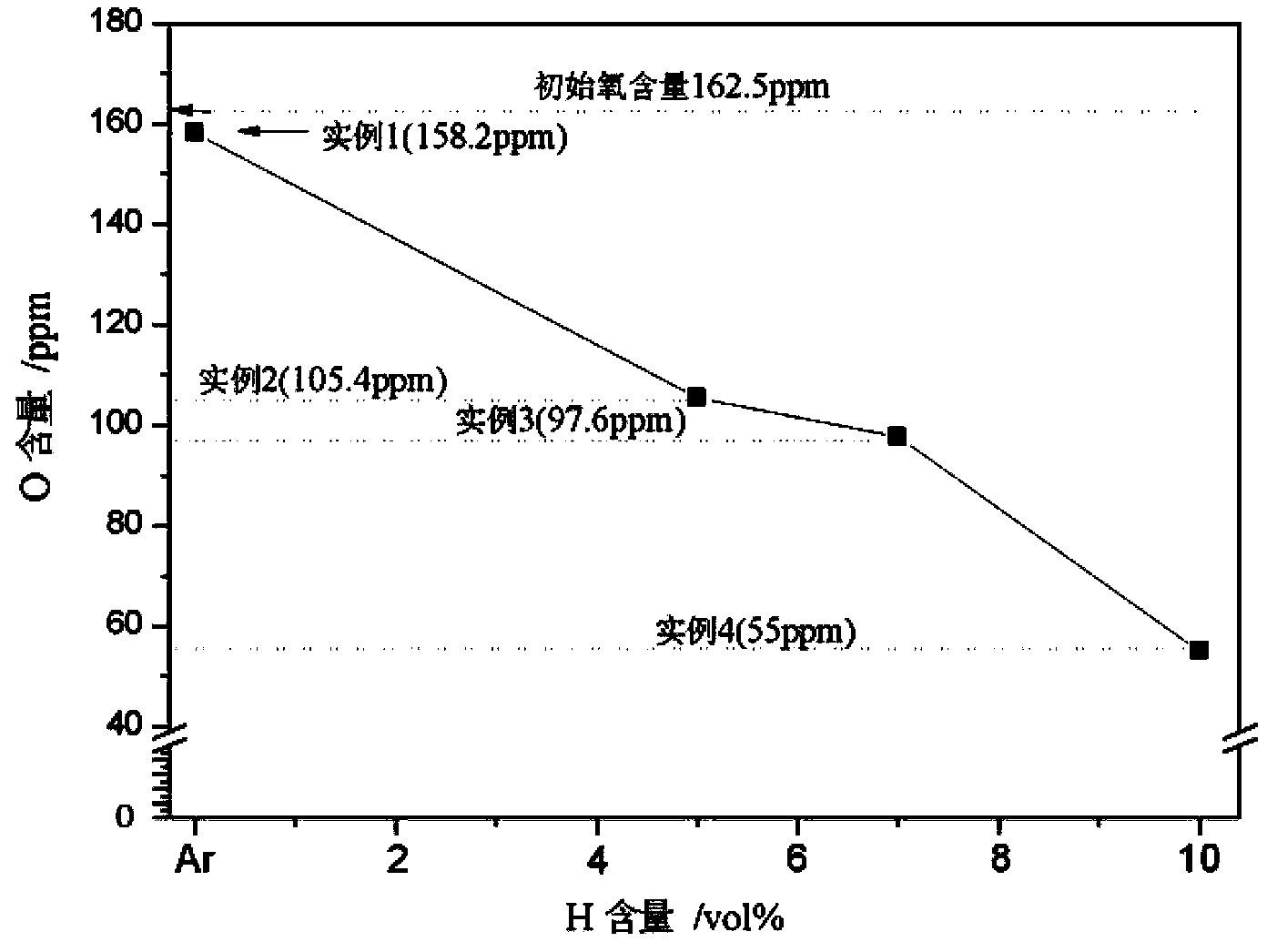

[0022] Example 1. Preparation of high-purity Gd elemental substance in high-purity argon (Ar) atmosphere

[0023] (1) Material preparation: Cut the raw material into metal blocks of about 20g on a cutting machine, wash with acetone, and then blow dry.

[0024] (2) Arc smelting: use a laboratory-type plasma arc smelting furnace, place the prepared sample raw materials in a water-cooled copper crucible with a diameter of 25 mm, and vacuumize to 4.6*10 -5 torr, quickly pass high-purity argon. The working current is set to 40A, turned over several times, smelted for 20 minutes, and released after the ingot is completely cooled (about 15 minutes).

[0025] (3) Composition test: The surface and sides of the sample after being released from the furnace were cut off with a cutter under an argon atmosphere, and the core sample was taken for oxygen content analysis. The detection adopts LECO-TCH600 oxygen, nitrogen and hydrogen analyzer, and the analysis results are as follows: figu...

Embodiment 2

[0026] Example 2, Ar+5%H 2 Preparation of high-purity Gd elemental substance in atmosphere

[0027] (1) Material preparation: Cut the raw material into metal blocks of about 20g on a cutting machine, wash with acetone, and then blow dry.

[0028] (2) Arc melting: use a laboratory-type plasma arc melting furnace, place the prepared sample raw materials in a water-cooled copper crucible with a diameter of 25mm, set the working current to 40A, and vacuumize to 4.4*10 -5 torr. Introduce high-purity argon, turn over and melt for 2 minutes in an argon plasma atmosphere, and remove surface impurities; secondly replace the argon atmosphere, pass 5% hydrogen into the chamber, turn over several times, and melt for 20 minutes; finally replace with argon again Atmosphere, turn and smelt for 5 minutes, and release the ingot after it is completely cooled (about 15 minutes).

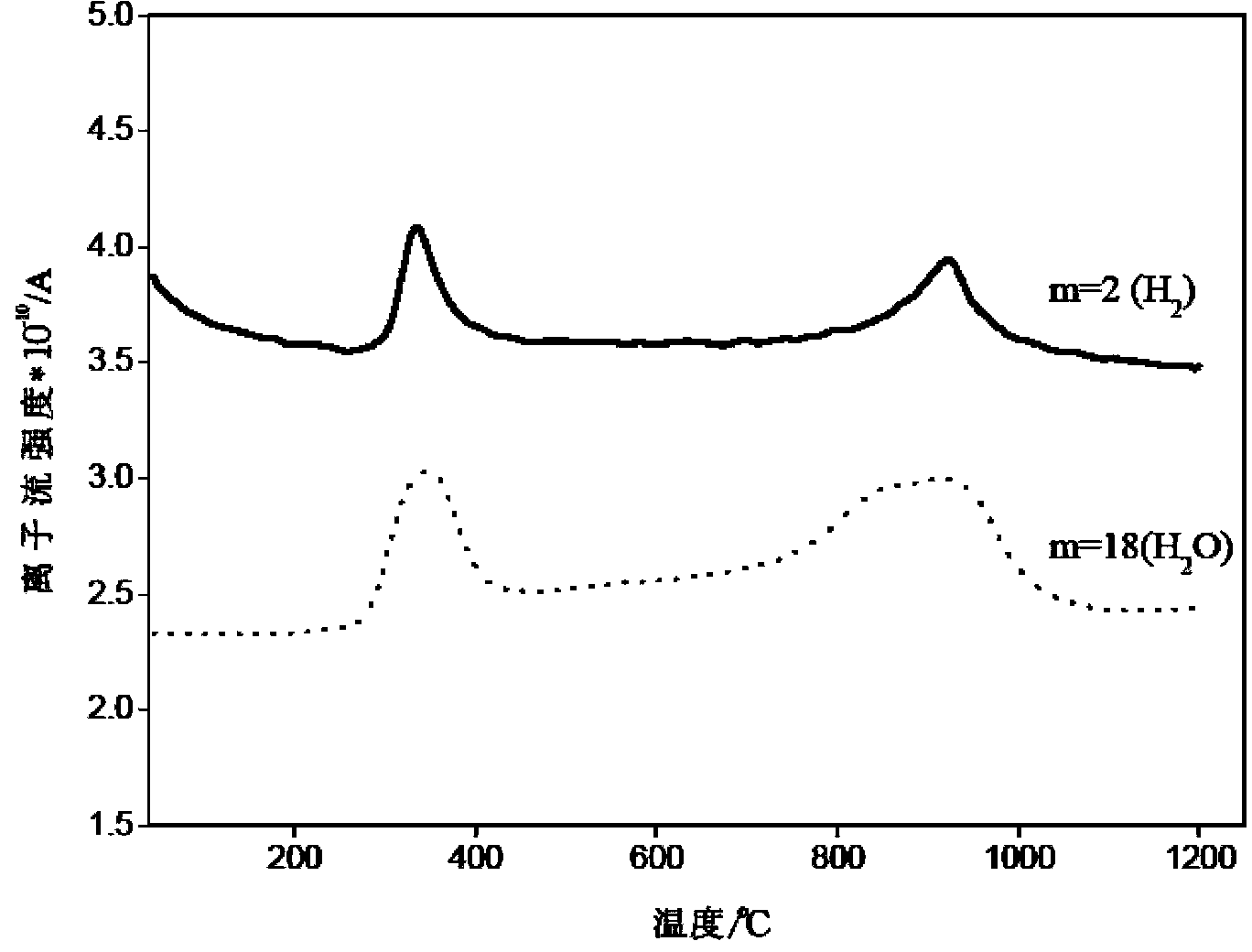

[0029] Gadolinium metal hydride as GdH 3 , decomposes to generate Gd elemental substance and hydrogen molecules ...

Embodiment 3

[0031] Example 3, Ar+7%H 2 Preparation of high-purity Gd elemental substance in atmosphere

[0032] (1) Material preparation: Cut the raw material into metal blocks of about 20g on a cutting machine, wash with acetone, and then blow dry.

[0033] (2) Arc melting: use a laboratory-type plasma arc melting furnace, place the prepared sample raw materials in a water-cooled copper crucible with a diameter of 25mm, set the working current to 40A, and vacuumize to 4.5*10 -5 torr. Introduce high-purity argon, turn over and melt for 2 minutes in an argon plasma atmosphere, and remove surface impurities; secondly replace the argon atmosphere, pass 7% hydrogen into the chamber, turn over several times, and melt for 20 minutes; finally replace with argon again Atmosphere, turn and smelt for 5 minutes, and release the ingot after it is completely cooled (about 15 minutes).

[0034] (3) Composition test: The surface and sides of the sample after being released from the furnace were cut o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com