Vacuum analysis deoxidizing device

A vacuum and vacuum pump technology, applied in the field of vacuum deaeration deaeration devices, can solve the problems of unsatisfactory deaeration effect and low purity of desorption gas, and achieve good deaeration effect, ensure deaeration effect, and ensure the effect of purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

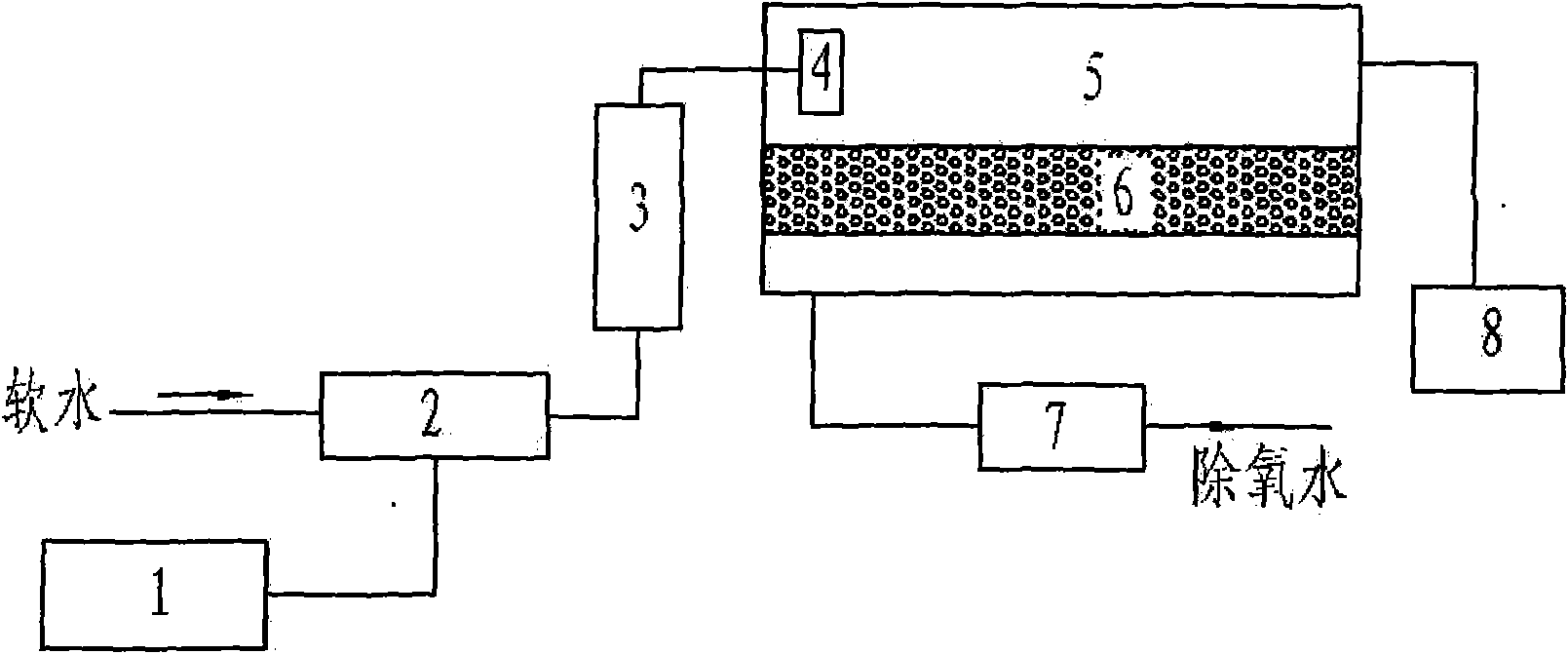

[0014] The vacuum analytical deaeration device includes a nitrogen generator 1, a mixer 2, a deaeration tank 5, an outlet water pump 7, a stainless steel filter 3, a deaeration nozzle 4, a filler 6, a vacuum pump system 8, an automatic control device and corresponding Process piping and control valves.

[0015] The demineralized water under pressure is sent to the mixer 2, and the nitrogen gas from the nitrogen device 1 is inhaled by the ejection of the mixer, and mixed with water to form an emulsion, and the fully mixed gas-water mixture is filtered through the stainless steel filter 3, and after filtration The water enters the deaeration tank 5 through the primary deaeration nozzle 4, forming a large area of mist in the tank. Due to the action of the vacuum pump 8, the tank is in a negative pressure state, which reduces the balance of oxygen in water and releases it. The evaporated water vapor and released oxygen and other gases (such as CO 2 , NH 3 ) is drawn out by a v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com