Novel water treatment method for boiler feedwater

A technology for boiler water supply and water treatment, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, general water supply conservation, etc. It can solve problems such as lack of systematic research and achieve the effect of preventing breeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

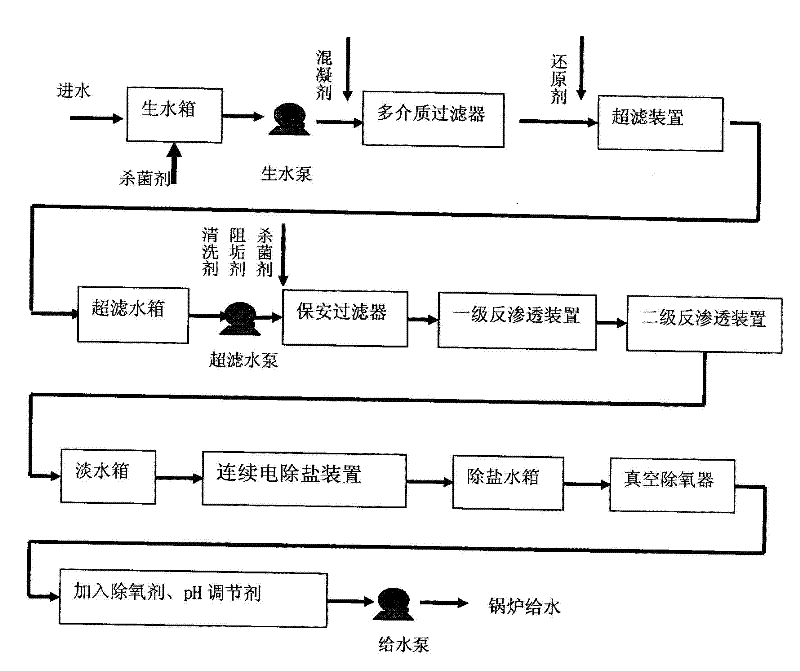

[0035] Operation according to the process: the steps of sterilization, filtration ultrafiltration, reverse osmosis, desalination, deoxygenation, and pH adjustment;

[0036] Dosing raw water fungicide: Dosing raw water fungicide before the raw water enters the raw water tank, using liquid chlorine, sodium hypochlorite or stable chlorine dioxide, and controlling the residual chlorine content in the water to 0.2-0.5mg / L;

[0037] Dosing coagulant: use coagulant before the multi-media filter, and the selected coagulant is polyaluminum chloride or polyaluminum ferric chloride or polyaluminum sulfate or polysilicon aluminum chloride. For surface water, use polyaluminum chloride to determine the dosage of the agent through the beaker coagulation test, and the general dosage is 10-20mg / L;

[0038] Dosing reducing agent: Dosing reducing agent sodium bisulfite before ultrafiltration, the amount is 2-5mg / L;

[0039] Dosing of reverse osmosis agent: use reverse osmosis membrane device fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com