Internal type headless higher-pressure deaerator and deaeration method

A built-in, deaerator technology, applied in the direction of chemical instruments and methods, separation methods, feed water heaters, etc., can solve the problems of high manufacturing and installation costs, complex structure of water tanks, poor operation stability, etc., to reduce equipment height, The effect of simple and compact structure and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

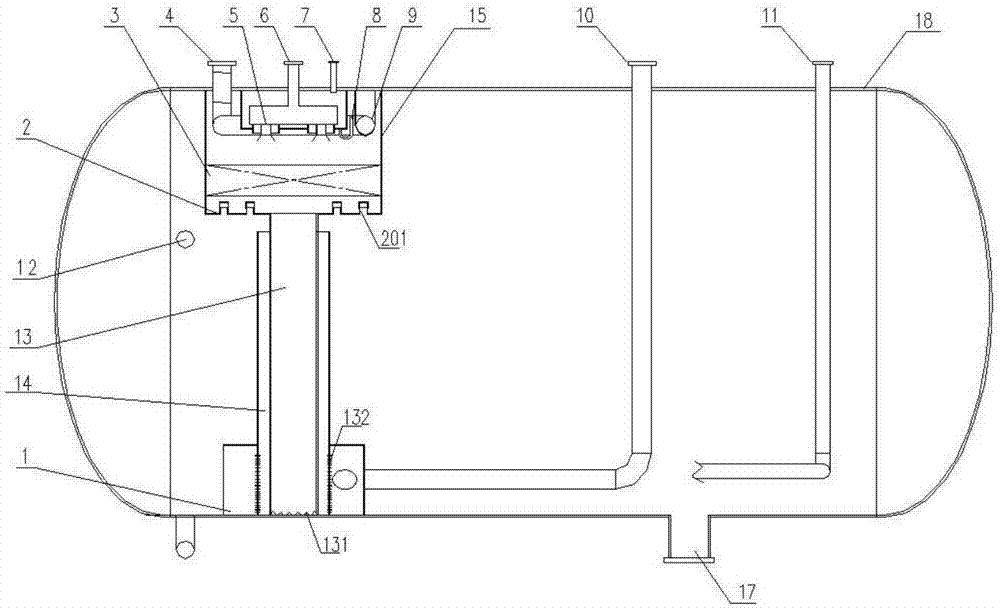

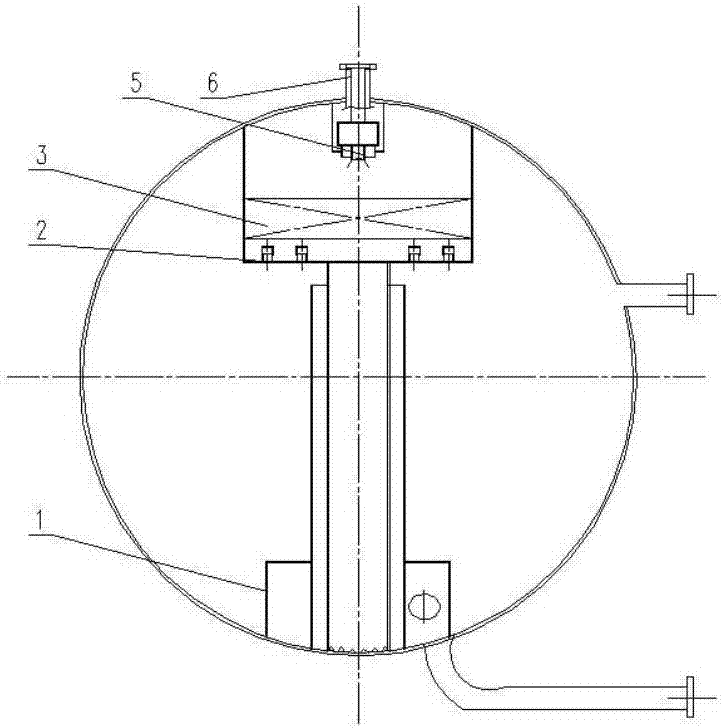

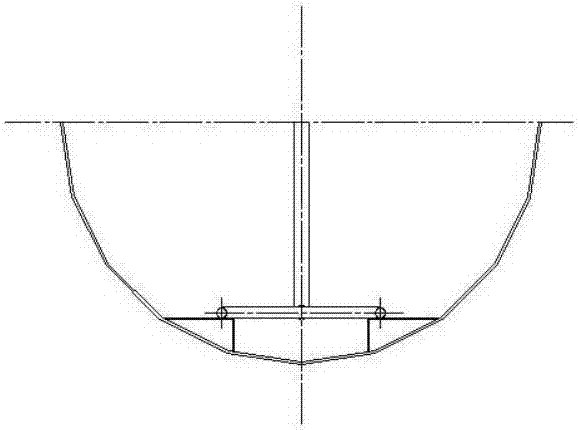

[0049] Built-in headless high-pressure deaerator, including a cylinder 18, characterized in that a built-in cylinder 15, a water spray inner cylinder 13, a reboiler 1, a steam mixing outer cylinder 14, and a heating steam pipe 10 are installed inside the cylinder , reboiling heating pipe 11 and deoxygenated water outlet 17;

[0050] The cylinder 18 surrounded by the built-in cylinder 15 is provided with a water supply pipe 6, a water return pipe 4 and an exhaust pipe 7, and the inside of the built-in cylinder 15 is also provided with a spray device and a wave net packing layer 3 from top to bottom; the built-in cylinder 15 The bottom is connected to the flange of the steam tray 2, and the steam tray 2 is provided with a vent hole 201;

[0051]The spraying device comprises a constant velocity nozzle 5 and a spraying device casing, the constant velocity nozzle 5 is at the bottom of the spraying device casing, and the constant velocity nozzle 5 is connected to the water supply pi...

Embodiment 2

[0061] A method for deoxygenating by using a built-in headless high-pressure deaerator to remove oxygen from water through a three-stage device, the method includes the following steps:

[0062] Step 1, first-level oxygen removal: the softened water with a temperature of 20°C enters the spray device through the water supply pipe 6, and the constant-speed nozzle 5 atomizes the demineralized water in a constant-speed conical shape, and the atomized water is rich in free oxygen The demineralized water in cylinder body 18 and the hot steam at 104°C rising up through steam tray 2 and wave net packing layer 3 are separated after completing the first heat and mass exchange in the space between packing layer and spraying device; free state Oxygen in the spraying device enters the shell of the spray device through the non-condensable gas collection pipe 8, and is discharged into the outdoor atmosphere through the exhaust pipe 7 to complete the first deoxygenation.

[0063] Step 2, two-...

Embodiment 3

[0066] A method for deoxygenating by using a built-in headless high-pressure deaerator to remove oxygen from water through a three-stage device, the method includes the following steps:

[0067] Step 1, first-level oxygen removal: the softened water with a temperature of 20°C enters the spray device through the water supply pipe 6, and the constant-speed nozzle 5 atomizes the demineralized water in a constant-speed conical shape, and the atomized water is rich in free oxygen The demineralized water in cylinder body 18 and the 180°C hot steam rising up through the steam tray 2 and wave net packing layer 3 are separated after the first heat and mass exchange is completed in the space between the packing layer and the spraying device; the free state Oxygen in the spraying device enters the shell of the spray device through the non-condensable gas collection pipe 8, and is discharged into the outdoor atmosphere through the exhaust pipe 7 to complete the first deoxygenation.

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com