Impermeable coating with heavy metal chelating function as well as composition and application thereof

An anti-seepage coating and heavy metal technology, applied in the coating and other directions, can solve the problems of heavy metal pollution in groundwater, the bulge of the anti-seepage membrane, and the brittleness, etc., and achieve the effects of increasing mechanical strength, high efficiency and lasting effect, and less dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

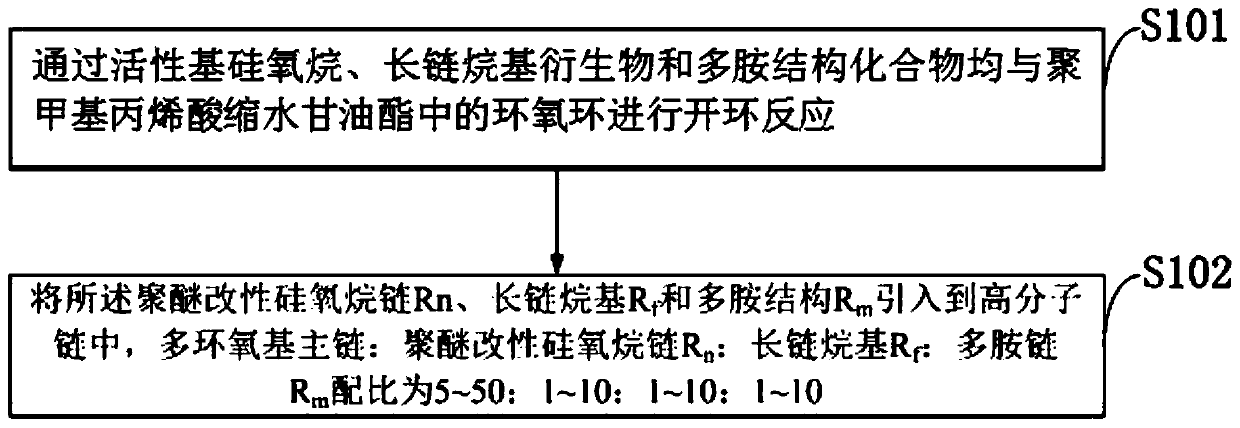

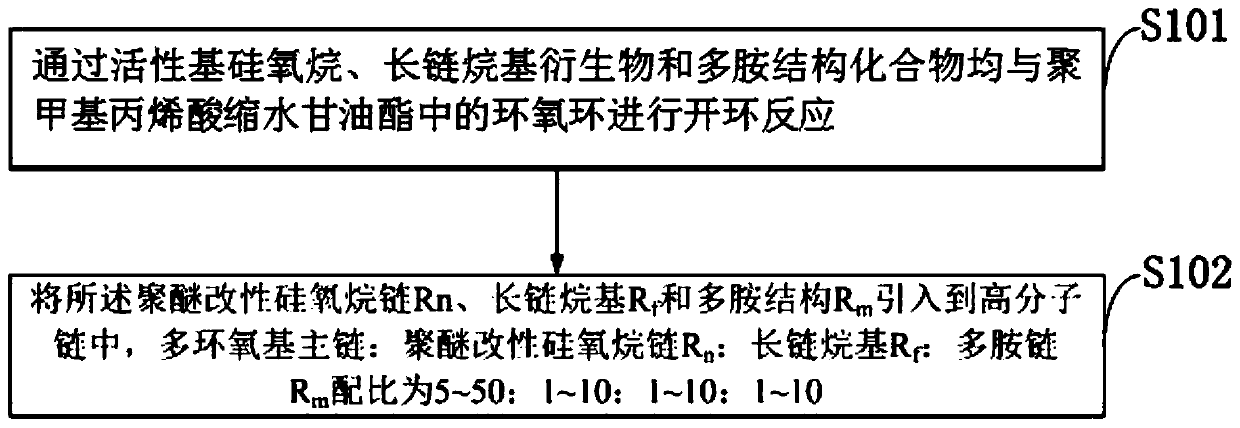

[0037] Such as figure 1 As shown, the preparation method of the anti-seepage coating with heavy metal chelating function provided by the embodiments of the present invention comprises the following steps:

[0038] S101: through active siloxane, long-chain alkyl derivatives and polyamine structure compounds, all undergo ring-opening reactions with polyepoxy main chain molecules or epoxy rings of polyepoxy polymers;

[0039] S102: The polyether-modified siloxane chain Rn, long-chain alkyl Rn f and the polyamine structure R m Introduced into the polymer chain, multi-epoxy main chain: polyether modified siloxane chain R n : long chain alkyl R f : polyamine chain R m The ratio is 5-50:1-10:1-10:1-10.

[0040] The present invention also provides an anti-seepage coating composition with a heavy metal chelating function. The above-mentioned anti-seepage layer is used in conjunction with micro-nano particles, vinyl silicone oil, hydrogen-containing silicone oil and a catalyst to f...

Embodiment 1

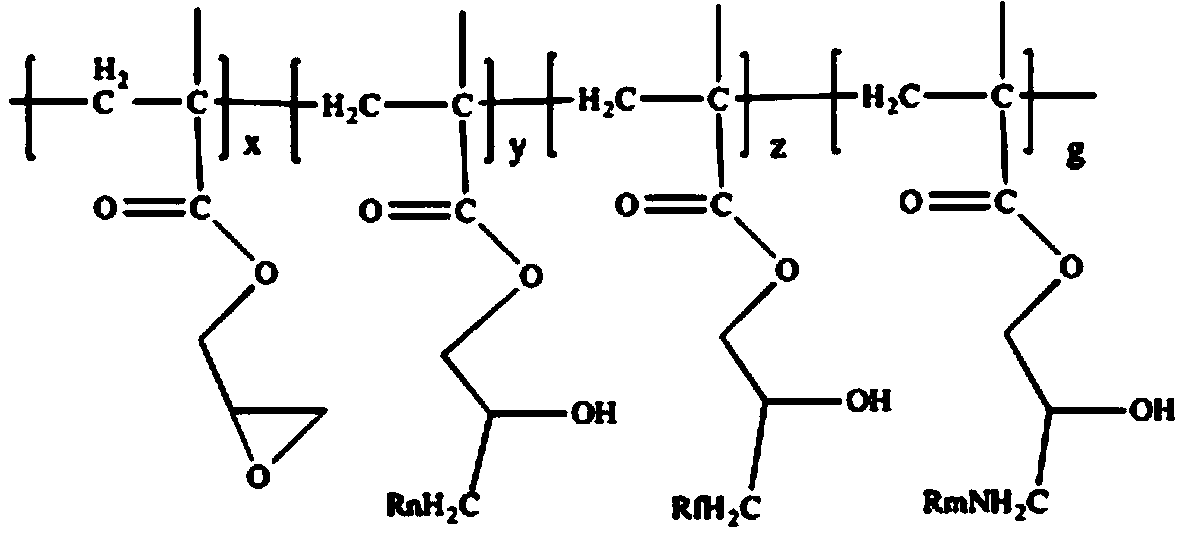

[0055] The anti-seepage coating with heavy metal chelating function provided by the embodiments of the present invention has the following structural features:

[0056]

[0057] Wherein, x, y, z, g are all integers of 10-500;

[0058] R n is aminosiloxane;

[0059] R f is hexyl hydroxyl alcohol;

[0060] R m is ethylenediamine;

[0061] The preparation method of the anti-seepage coating in the embodiment of the present invention is as follows: polyglycidyl methacrylate, aminosiloxane, hexyl hydroxyl alcohol, and ethylenediamine are stirred and mixed evenly in a molar ratio of 50:10:10:10, It is the anti-seepage layer with heavy metal chelating function.

[0062] The preparation method of the anti-seepage coating composition of the embodiment of the present invention is: anti-seepage coating, vinyl silicone oil, methyl silicone resin, diatomaceous earth, hydrogen-containing silicone oil, reaction inhibitor: chloroplatinic acid, in a molar ratio of 5: 10: 5: 5: 1: 0.05...

Embodiment 2

[0066] The anti-seepage coating with heavy metal chelating function provided by the embodiments of the present invention has the following structural features:

[0067]

[0068] Wherein, x, y, z, g are all integers of 10-500;

[0069] R n is hydroxysiloxane;

[0070] R f is dodecyl hydroxy alcohol;

[0071] R m is diethylenetriamine;

[0072] The preparation method of the anti-seepage coating in the embodiment of the present invention is as follows: polyglycidyl methacrylate, hydroxysiloxane, lauryl hydroxyl alcohol, and diethylenetriamine are mixed in a molar ratio of 5:2:3:1 and stir evenly to obtain the anti-seepage coating composition.

[0073] The preparation method of the anti-seepage coating composition of the embodiment of the present invention is: the anti-seepage coating, vinyl silicone oil, phenyl silicone resin, sepiolite, hydrogen-containing silicone oil, reaction inhibitor, and castor catalyst are mixed in a molar ratio Mix at 50:30:10:10:5:1:0.5 and gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com