Wet flue gas desulfurization wastewater treatment system

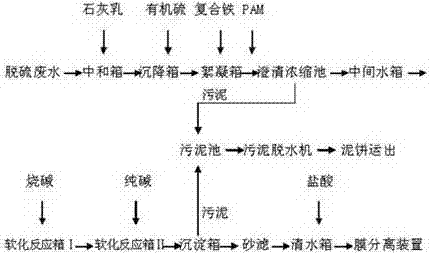

A wastewater treatment system and wet flue gas desulfurization technology, which are applied in the fields of dehydration/drying/concentrated sludge treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The problems of high investment cost and large amount of dosing can achieve the effect of reducing the load of suspended solids in the influent water, saving operating costs, and preventing re-dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

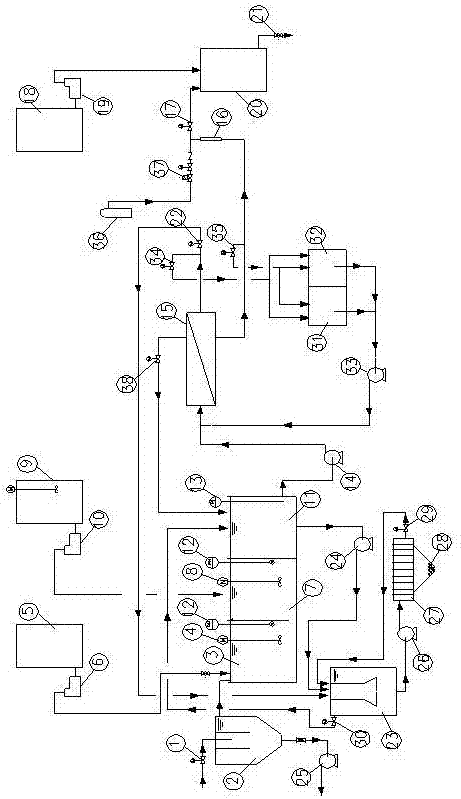

[0023] Such as figure 1 shown.

[0024] A new type of wet flue gas desulfurization wastewater treatment system, which includes water inlet electric valve 1, high-efficiency precipitator 2, pH adjustment box 3, pH adjustment box mixer 4, caustic soda metering box 5, caustic soda liquid metering pump 6, softening reaction box 7. Softening reaction box mixer 8, soda ash metering box 9, soda ash liquid metering pump 10, settling tank 11, PH meter 12, liquid level gauge 13, lift pump 14, tubular microfiltration membrane 15, backwash water column 16, clean water tank inlet Water electric valve 17, hydrochloric acid metering box 18, hydrochloric acid metering pump 19, clean water tank 20, clean water tank outlet valve 21, concentrated liquid discharge electric valve 22, sludge concentrator 23, settling tank sludge discharge pump 24, high-efficiency settler sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com